A car has roughly 30,000 parts if you count every nut and bolt. Each is manufactured separately by various makers around the world and shipped to one location for assembly. It’s a time-consuming and laborious process that hasn’t changed much since automobiles were invented.

Then there’s the 3D printed electric Czinger 21C hypercar that’s designed and manufactured by Divergent 3D. By consolidating thousands of parts into hundreds of parts, including the front and rear impact structures, the entire front structural assembly, and exhaust components, the Czinger 21C not only reduces the part count but speeds up production, lowers the weight, and improves the functionality — 0 to 65 mph in 1.8 seconds.

This level of part consolidation is only possible with 3D printing.

From cars and rockets to hydraulics and heat exchangers, engineers are using 3D printing to create higher-functioning, more efficient, lighter, and smaller parts that replace multi-piece components. Let’s take a look at why and how.

What Is Part Consolidation

Consolidation of parts in manufacturing is the redesign — and reimagining — of an assembled component into fewer but more complex parts that are fabricated as a single unit with no assembly required.

Because 3D printing, also called additive manufacturing (AM), builds layer by layer, it can create nearly any shape — and shapes within shapes, such as internal channels and lattice-filled walls. The technology provides engineers the freedom to design internal structures and external contours of a component into the build process instead of the extra steps of drilling and machining.

By leveraging the benefits of metal and polymer AM technologies and applying design specifically for 3D printing techniques, new consolidated products are produced.

Consolidated Parts at Work

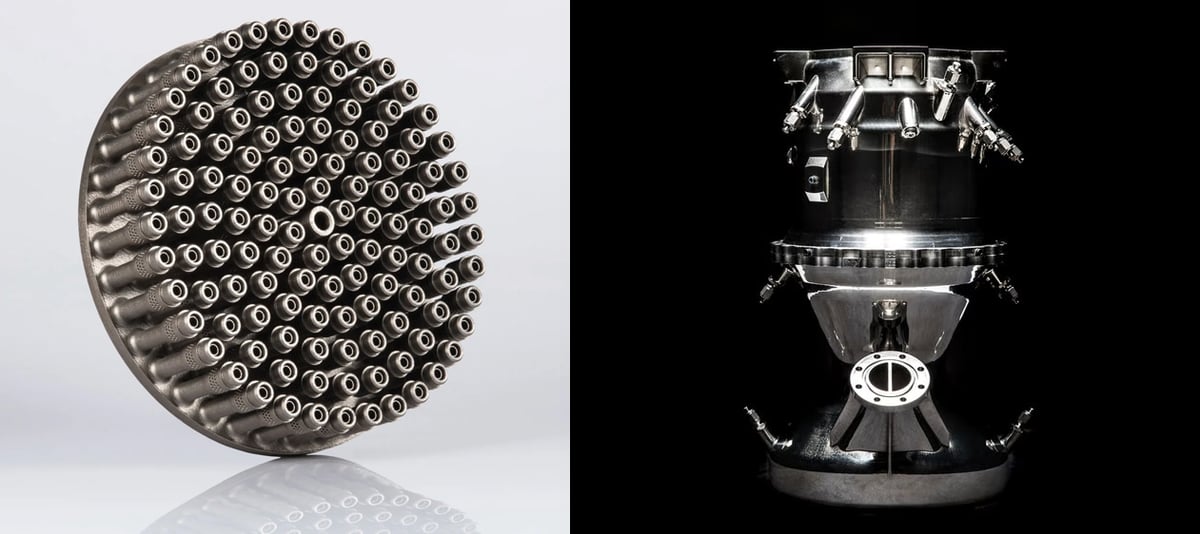

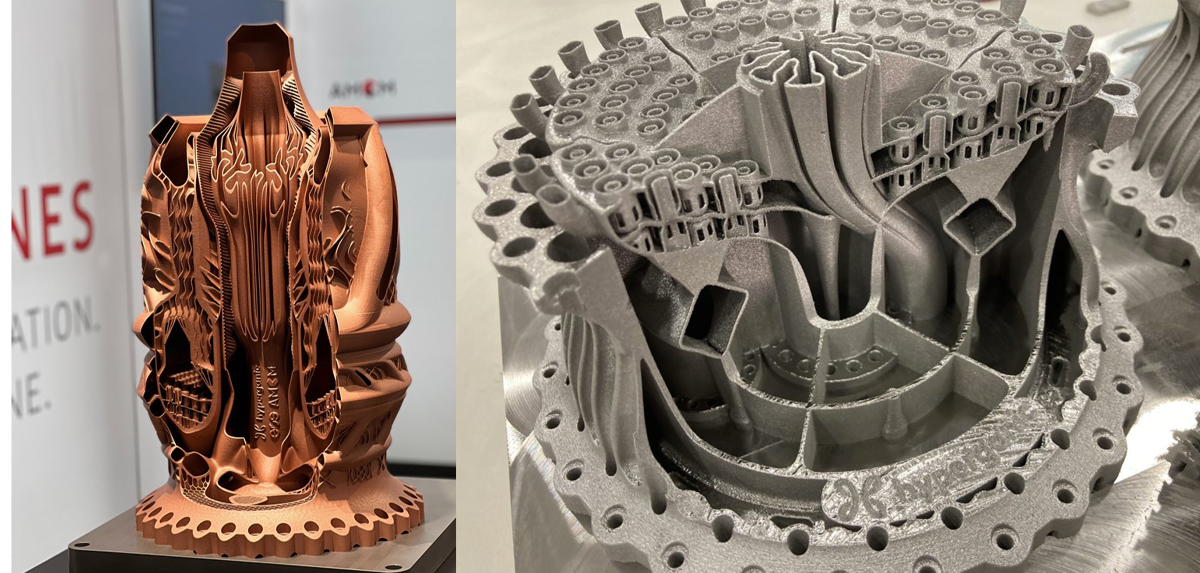

Rocket company Relativity Space uses part consolidation and additive manufacturing for its engines and other components to make rockets with 100 times fewer parts than conventionally manufactured rockets and build them in just 60 days. The company says it is “enhancing mission reliability by reducing part count in engine combustion chambers, igniters, turbopumps, reaction control thrusters, and vehicle pressurization systems.”

The company designs rocket components with 3D printing in mind from the start, using mechanical, thermal, and other optimization approaches to make complex parts that were previously impossible to manufacture. Relativity Space incorporates internal features into its monolithic parts, such as conformal cooling channels within combustion chambers.

The additive manufacturing processes used on EOS 3D printers also meant that innovation cycles were sped up. Engineers could make structural improvements, design modifications, and 3D test components without making new molds or tools, as is the case when casting parts.

There are dozens of examples of part consolidation in the aerospace sector because the manufacturing of these high-value components is so specialized, low volume, and requires expensive materials, such as titanium alloys. But everyday manufacturers also take advantage of the part consolidation that 3D printing enables.

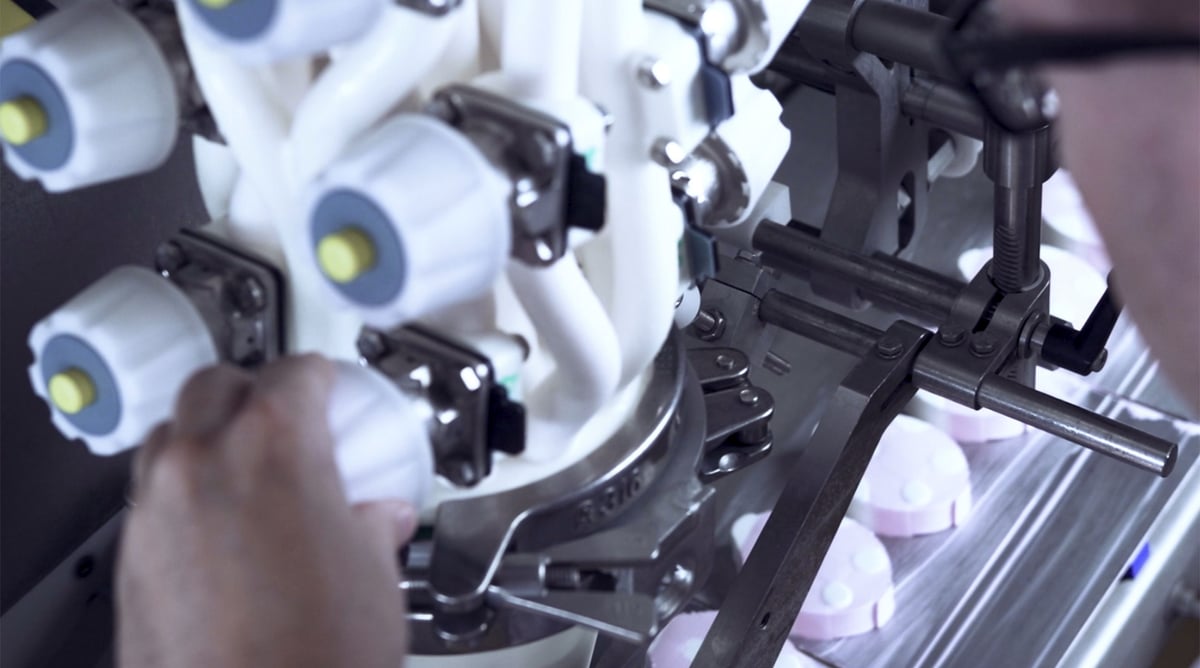

Tetra Pak Ice Cream, one of the world’s largest processors and packagers of ice cream, used part consolidation through 3D printing to reimagine its nozzles for extruding ice cream. Previously, it welded together many small stainless steel parts to make new nozzle designs, which were very expensive and time-consuming. Now the nozzles are 3D printed in nylon, which is much cheaper and faster. Overall, the nozzle went from 30 parts to three, and the manufacturing time went from eight weeks to just four while cost shrank 60%.

“A component like this one, which is 3D printed, gives us a competitive advantage,” says Elsebeth Baungaard, portfolio manager at Tetra Pak Ice Cream, “because the price is significantly lower and we have a high level of hygiene, and our customers can make new products in a very short time.”

According to Conflux Technology, an additive manufacturing company specializing in heat exchangers and manifolds, part consolidation in 3D printing enables the company to produce monolithic structures with significant weight and size reduction so they can fit the space available. This innovation has been put to use in electric vehicles and electronics.

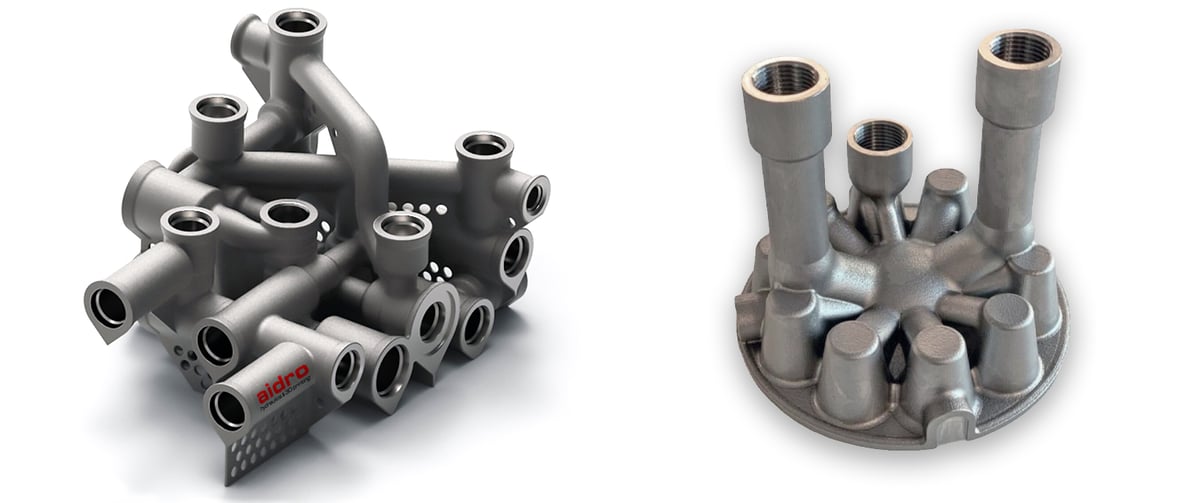

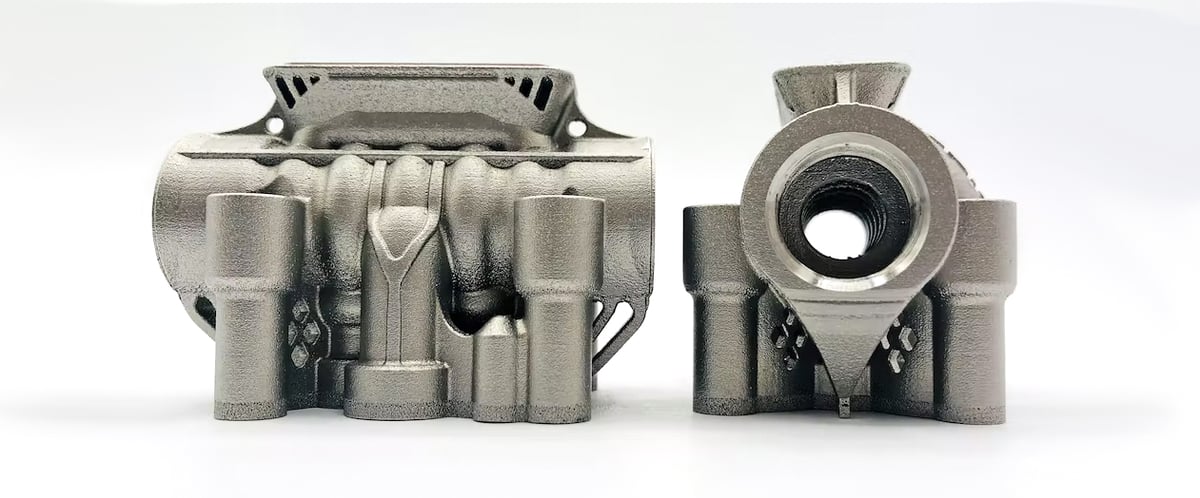

Another specialty additive manufacturer in hydraulics creates components to overcome the limits of traditionally manufactured parts. 3D printed valves and manifolds from Aidro, a Desktop Metal company, integrate multiple parts into one for faster production and better performance.

Aidro re-designed the rotary valves bonnet pictured here, for additive manufacturing that resulted in improved internal paths and flow optimization leading to higher performance with reduced weight. The weight saving, in this case, is particularly important for sub-sea applications in order to reduce the costs of transport and handling. In the 3D printed hydraulic valve body below, the internal design is improved for a better flow path.

Pros & Cons of Part Consolidation

Creating a part as one piece has some obvious and some hidden benefits, plus potential drawbacks.

Consolidated assemblies remove the time, labor, and potential human error of assembly. They eliminate bolting, screwing, welding, or other joining methods that may introduce weaknesses to the overall structure and removes the potential for alignment issues or inconsistent tolerances among parts.

Part consolidation through additive manufacturing provides an opportunity to centralize your manufacturing and eliminate part supply chains and the number of manufacturing partners a business is trying to juggle.

The overall result of consolidating components in additive manufacturing can be improved safety and performance, quicker manufacturing, reduced waste, and lower costs.

Pros

- Less material use

- Eliminate joints and joint failure risk

- Lower labor and energy to manufacturer

- Reduced need for skilled labor for welding, etc.

- Simplified manufacturing processes since one machine can manufacture many parts

- Faster product to market because iterations can be quickly produced without retooling

- Reduction in inventory since parts can be printed on demand

- Localized manufacturing on-site or at a skilled service bureau

- Reduced supply chain risk since parts are on-site or at a skilled service bureau

Cons

- Significant time and investment to redesign for additive manufacturing

- Complex shapes can take longer to manufacture

- Some AM technologies have lengthy post-processing steps

- Some parts may require lengthy support removal steps

- Parts are limited to the dimensions of the building chamber of the 3D printer

- New part inspection processes are required

- Your consolidated part may still require some machining

When to Combine Parts?

As we’ve shown, part consolidation in additive manufacturing simplifies an object and improves features like performance and safety. However, it isn’t the right choice for all assemblies. How do you know when it’s right for you?

There are general rules around part consolidation. For example, moving parts are not candidates for part consolidation. This includes components, such as axles or gears, which must be separate from other components to function properly.

Similarly, objects made of multiple materials are not often candidates for part consolidation. Most 3D printers can only work with one substance at a time, limiting the amount of consolidation possible with several materials.

Think: If something does not need to be disassembled, consolidation may be the way to go.

At this point, perhaps you’re convinced your business can save on manufacturing and speed up production by consolidating parts. Where do you start?

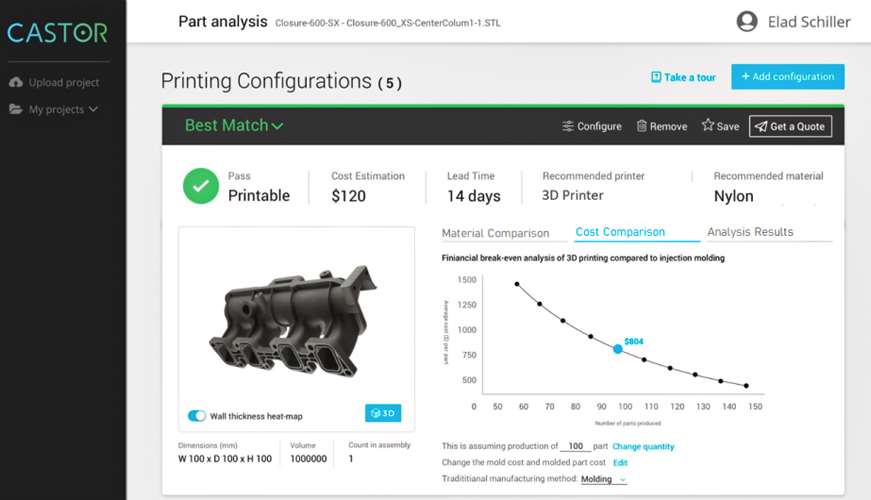

Fortunately, there’s a growing category of software designed to analyze entire part inventories and recommend parts for consolidation.

Additive manufacturing services companies, such as Materialise and Protolabs, offer design consultants that can evaluate and redesign your current multi-part assembly into a single part that can then be produced at an on-demand 3D printing company removing the need for you to hire in-house skill. These consultants will also tell you when traditional manufacturing would make more sense for your part.

If you’re keen to redesign your parts yourself, part consolidation tools can be found in your existing CAD software.

Part Consolidation in CAD Software

Engineers and product designers who have decided to implement part consolidation for an existing component start with the digital file of the component at hand. Part consolidation itself is done in the design phase with computer-aided design (CAD) programs, such as Fusion 360, SolidWorks, or nTopology.

Although Fusion 360 and others feature some basic buttons to enable part consolidation and optimize parts for additive manufacturing, a design process called generative design is most often used to develop consolidated, 3D printable parts. Fusion 360 also includes generative design functionality.

Generative design enables you to select and prioritize attributes you want in your part, such as light weighting or part consolidation, to find more relevant design options.

Software For Part Consolidation:

- Fusion 360

- NetFabb

- nTopology

- Stratasys ParaMatters CogniCAD

- Creo Generative Design Extension from PTC

- Ansys Discovery

- Dassault Systèmes CATIA Generative Design Engineering

- Inspire by Altair

- NX by Siemens

- APEX Generative Design (MSC)

- Elise

Consolidation Gallery

Do you have a part that you’ve redesigned to be consolidated and 3D printed? Post it in the comments below.

License: The text of "3D Printing for Part Consolidation – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.