As an aircraft mechanic on B-52 Bombers for the United States Air Force many years ago, I would have laughed at the notion of replacing a failed or end-of-life metal part with one that was 3D printed. Had a fellow Airman suggested this, I would have sarcastically accused them of watching too many Star Trek episodes.

Fast forward to 2020, the Oklahoma City Air Logistics Complex at Tinker Air Force Base produces and installs the first certified 3D printed metal jet engine part for the B-52 Stratofortress, and my job today is to educate people about metal 3D printers.

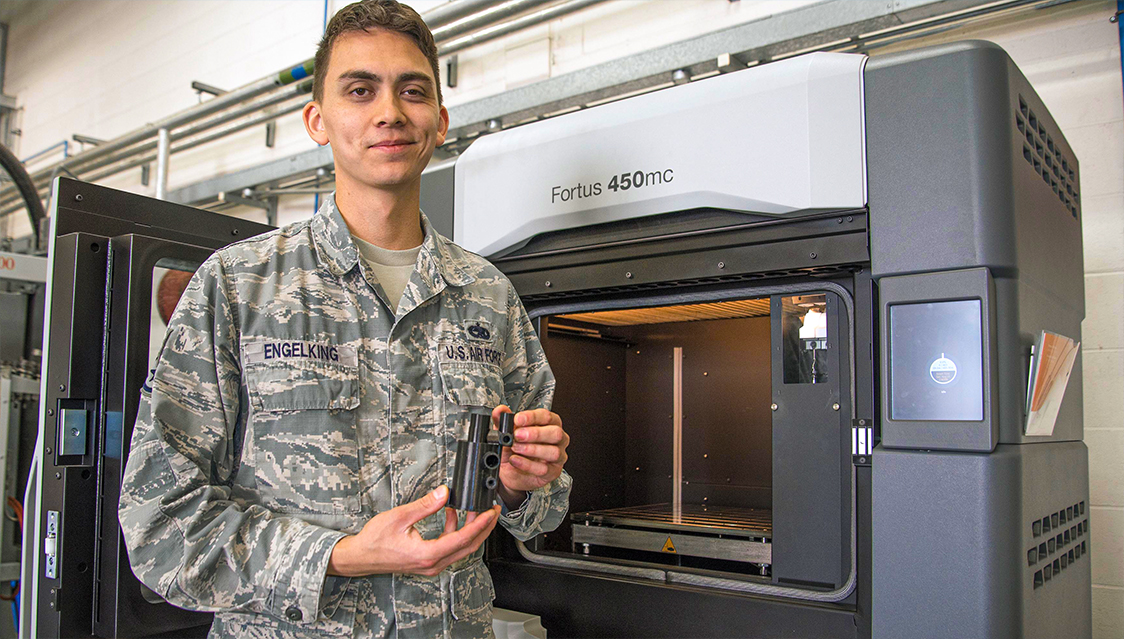

Last year, I visited Tinker AFB for the eighth time in as many years. More than 10,000 military and civilian professionals run this impressive facility that’s part of the Air Force Materiel Command, performing maintenance and modifications on various aircraft for the Air Force, Navy, and Marine Corps. These skilled professionals and artisans are also responsible for the development, sustainment, and battle damage repair of vehicles using various tools, including a fleet of 3D printers.

The world’s top militaries have poured hundreds of millions into 3D printing research and development, and it’s easy to see why. Nowhere is control over your supply chain more critical than in the military. The ability to bring manufacturing to the front lines significantly reduces the costs and time of shipping replacement parts from machine tooling hubs overseas.

Armed forces – from the US to Australia – have recognized additive manufacturing’s potential for decades and have already put 3D printers to use in the field. 3D printed parts are in critical aircraft engines, on tanks and submarines, and on the soldiers themselves. From 3D printed Humvee door handles and rifle grips to fighter jet engine parts and custom prosthetics, the uses of 3D printing within the military are vast.

US Military Goes All-In on Additive Manufacturing

The Pentagon’s 2021 additive manufacturing strategy called for 3D printing to be integrated into the defense industrial base and promoted for use within all branches. Today, 3D printers are used worldwide throughout the entire military-industrial complex and are changing how and where equipment is repaired and maintained on land, at sea, and in the air. As a result, the role that additive manufacturing now plays in national defense capabilities is becoming increasingly critical, giving AM a prominent seat at the sustainment and readiness table.

And, as a microcosm of the wider society, we can look to the military’s development, application, innovation, and even failures using 3D printing as a bellwether.

How Militaries Use 3D Printing

Beyond the obvious repair and maintenance advantages gained by expeditionary additive manufacturing are countless other uses, including 3D printed concrete bunkers, ammunition, shaped charges, drone repair, and medical applications, to name just a few.

The demand for all types of military 3D printing solutions is expected to grow more than 20% over the next five years, according to new research by Market Reports.

Top AM Pillars for Military & Defense

- Expeditionary Point of Need Repair

- Digital Inventory

- Tooling & Fixturing

- Research & Development

- Depot Maintenance & Repair

Within these broad categories are these noteworthy AM initiatives already underway.

- Air Forces – Certify/qualify airworthy parts for flight-critical applications

- Land Forces – Expeditionary point of need repair for warfighters in theater

- Naval Forces – Certify/qualify SUBSAFE parts, 3D printers on vessels

- Space Forces – Specialized materials for hypersonics, 3D printers in orbit

These projects may seem ambitious for those new to this industry. However, I can assure you that they are all within the realm of possibility. In fact, last month, I was at the Phillips Additive Innovation Center inside the US Army’s Rock Island Center of Excellence (CoE) in Illinois. Those in attendance collectively possessed an impressive knowledge of 3D printing, further reconfirming that AM is no longer a thing of the future and that even the most significant goals are within reach. Today’s warfighters are not only fully entrenched in the future trajectory of the 3D printing industry, but in many regards, they are leading the way.

Expeditionary Point of Need Repair

Last year, I participated in Project Convergence 2022 (PC22) with metal 3D printer maker Spee3D, which took place in the Mohave Desert at Fort Irwin National Training Center in Southern California. The US Army hosted an all-service event with hundreds of British and Australian military troops to exercise interoperability with its allied partners. One of the primary objectives of PC22 was to practice sustainment capabilities in a contested environment while working collaboratively.

During this event, failed or broken parts were removed from armored vehicles, measured and modeled in CAD software, and 3D printed—on the spot. Heat treatment and machining were sometimes required for metal parts to achieve the desired dimensional accuracy and strength. The British Army was up for the task with a fully functioning mobile machine shop nestled inside a 20-foot metal connex container. Even more impressive is that it was within walking distance from the point of need. This event validated 3D printing’s near-term ability to offer global military units from around the world unprecedented supply chain agility, allowing them to stay in the fight if the need ever arises.

One recent example of 3D printing in the US Army was a seemingly innocuous vehicle hatch plug. This essential component is mounted on combat vehicles for missions carried out in low-light conditions, allowing the drivers to see clearly at night. The original manufacturer discontinued the part, meaning that replacements would cost upwards of $10,000 and take months to produce.

With a metal 3D printer from Markforged, the Army was able to fabricate hatch plugs that were not only significantly cheaper but sleeker and more efficiently designed. Army engineers simplified the design of the hatch plug down to four parts from ten. Additive manufacturing saved the Army more than $244,000 in costs for low-volume production, as well as streamlined the design of crucial equipment.

In what’s being called a world first, French manufacturers called the Naval Group, developed the largest 3D printed metal ship propeller installed on a service military ship.

Launched in 2021 after nearly three years of R&D, the propeller printed using wire arc additive manufacturing (WAAM) technology, boats a 2.5-meter span supported by five 200-kg blades. 3D printed propellers provide ships with greater efficacy at sea, including increased thrust efficiency, stealth and lightweighting, says Naval Group.

“The assembly of this 3D printed propeller shows great promise for the future,” says Eric Balufin, director of the Naval Group. “This new technology will enable us to considerably reduce technical constraints and therefore allow for new manufacturing solutions for complex geometrical shapes which cannot be produced through conventional processes. It will also enable us to greatly reduce production time and consequently in-service support.”

The Australian Navy is studying 3D printing in a submarine environment. Having a 3D printer that can fit within the tight space of a submarine and carry out necessary repairs at sea will allow the subs to deploy for longer periods of time.

Testing, Certification & Readiness

A decade ago, there were no qualifications, procedures, or specifications approved by the U.S. military to apply 3D printing processes to engineer components of its assets. That’s all changed now. Years of research, investing heavily in qualifications of additive manufacturing, and comprehensive non-destructive testing have laid the groundwork for the production and installation of parts.

Before a 3D printed part is installed on an aircraft, for example, it must pass a rigorous qualification and certification process. Although several important data points are measured, material properties remain at the top of the list and are evaluated with great scrutiny. As the US Air Force continues refining its airworthiness process, we can expect more 3D printed parts flying fast and high across clear blue skies.

A hurdle, however, is that each branch has its own methods and certifications. In an effort to share data and increase readiness while saving money, the Defense Logistics Agency announced in Feb. 2023, that it is working to develop common technology, standards, and processes for additive manufacturing across the military services. DLA is also working toward remote inspection for additively manufactured parts. Conventional inspections can take over 100 steps, but remote inspections typically take about 10.

3D Prints Certified to Fly

Despite the challenges, there are plenty of 3D printed parts in action. The F-22 Raptor, the US Airforce’s most expensive fighter jet, flew with 3D printed parts starting in 2019. The 3D printed component is a small part used in the cockpit that was made originally of aluminum and was replaced 80% of the time during maintenance. Unlike the aluminum part, the 3D printed titanium part will not corrode and could last the remaining lifetime of the stealth fighter.

“One of the things we found … is that we could potentially solve the supply shortage by reengineering and printing something and prove it was safe to fly,” said Richard Banks, 76th PMXG delegated engineering authority engineer. “This type of engineering makes it easier to source materials, greatly reduces lead time and ultimately helps to reduce logistical and supply issues.”

The Air Force said it has at least five more metallic 3D printed parts it plans to test on the F-22.

Five-Step Buying Process For Military 3D Printers

Not all 3D printers are created equal

Having sold more than 100 professional and production AM solutions, many of which were to the military and some exceeding $1,000,000, I have learned firsthand that not all 3D printers are created equal. I would liken buying the wrong 3D printer for a specific application to purchasing a small car to pull a large boat or driving a large truck for daily inner-city commuting. You may be surprised to learn that the decision-making logic for selecting the right vehicle is similar to choosing the most suitable AM solution.

If you work in the military or defense sector and are considering purchasing AM technology for the first time—or looking to add additional printers, your primary objective is to get the right product from a good company at a fair price. To purchase the best product for your 3D printing needs, consider following this tested five-step buying process outlined below.

Step One: Select Primary Application

The first question that must be answered is how will the 3D printer be used. Remember that it is common practice to validate the purchase of a 3D printer for one primary application but strengthen the ROI by adding secondary applications. These primary and secondary applications may relate to one or several of the following categories:

- End-Use Parts

- Rapid Prototyping

- Patterns & Tooling

- Conceptual Models

- Mass Customization

- Repair & Maintenance

- Research & Development

If you are an engineer by education, training, or profession, you know it’s significantly easier to solve a single-body problem than a two-body one. For this reason, consider making it a best practice to select a primary application representing at least 70% of the proposed business case you are trying to justify and request that the seller focus their efforts on this area. Otherwise, asking a sales professional to validate a single AM solution capable of equally producing multiple application types can prove challenging and frustrating for all parties involved, so stay focused—especially in the beginning.

Step Two: Establish Desired Requirements

Now that a primary application has been determined, you can begin to establish your minimum desired requirements and capabilities by addressing the following ten questions:

- How many parts will be printed monthly?

- What will be the largest part size printed?

- What will be the smallest part size printed?

- What will be the average part size printed?

- How much can be spent on consumables?

- What are the desired materials/properties?

- What are the post-processing requirements?

- What is the desired part accuracy (x/y/z)?

- What is the desired part strength (x/y/z)?

- What is the desired part heat deflection?

The bottom line is this; What is the problem you are trying to solve or the benefit you will gain by purchasing a 3D printer, and how will this be measured?

Important note: Besides hardware capabilities, it’s essential to create a list of requirements related to delivery time, payment terms, warranty, training, waste disposal, and, most importantly—site preparation.

Step Three: Determine Timeline & Budget

Once a primary application has been selected and the desired requirements of the AM solution have been established, determine budgetary parameters and an estimated buying timeline. Then, when you contact a manufacturer or reseller for the first time, ask them to informally disclose the price range of their products for your budgetary considerations.

This professional courtesy considers everyone’s time and should be developed into a best practice. Inversely, be cautious of moving forward with sellers who refuse to provide approximate, estimated, or ballpark pricing for their published offerings—unless they can offer a legitimate and justifiable reason.

Step Four: Prioritize Buying Criteria

Collaborating with your team and known stakeholders, document the following five buying criteria in the order of most important to least important:

- ROI

- Price

- Quality

- Capability

- Service & Support

It is understood that each criterion on this list will likely be heavily considered when making a critical buying decision for a new 3D printer. However, these attributes must be ranked and weighted before vetting potential sellers. Adding this critical step to your buying process can streamline your purchasing experience while increasing your chances of selecting the right product from the right company. After all, if you don’t know what is most important to you, nobody will.

Step Five: Validate Capabilities & ITAR Compliance

The fifth and final step of the AM buying process is to validate the capabilities of the solution(s) you are most interested in procuring. The most effective way to accomplish this is to provide a CAD or STL file to the seller that offers a fair representation of your primary application.

Important note: Avoid distributing files or information about any application under ITAR unless or until you verify that the seller’s organization is ITAR registered and compliant. If you would like to work with a seller who does not meet these requirements, only share dumbed-down or non-sensitive information that protects all parties involved.

Once the sales professional or applications engineer has confirmed the feasibility of your application, they should provide you with a time and cost study, which can be as elaborate as a multi-page PDF or as simple as a few sentences in the body of an email. Regardless, the study should include, at minimum, 1) How long does it take to print your part? 2) How much does it cost to print your part (if you own the printer)? This would be the equivalent of looking at the window sticker of a new car to determine gas mileage, engine size, etc.

Suppose the time and cost study reveals data that you consider acceptable. In that case, the final step toward validating a solution’s capabilities toward meeting your desired outcomes is to request a physical benchmark part of the file you provided. Or, as a substitute, a sample part that offers a fair and acceptable substitution based on your stated criteria. The benchmark provides a physical proof of concept that helps you and your team effectively determine whether or not a 3D printer can produce a part that meets or exceeds the manufacturer’s published specifications.

As a final point to remember, people who purchase a ¼” drill bit are buying a ¼” hole, so don’t place too much emphasis on the 3D printer—focus on the parts it can produce.

Consider the Give and Take

The last point I want to leave you is regarding give and take. When a 3D printer sales professional touts differentiators that make their solution stand out from the crowd, ask them, “What is the tradeoff?” For example, if a salesperson says their product can print in an ultrafine resolution unrivaled by the competition, ask how this exceptional characteristic affects the printer’s speed. Specifically, ask if their published throughput rates referenced in their marketing materials can be achieved while maintaining the superior surface finish they are highlighting.

In my professional experience, finding a solution that can produce “really fast” and “super smooth” parts simultaneously is challenging and, if available, is typically accompanied by a significant increase in price. With AM technology, features that go above and beyond the industry norm often simultaneously reduce a capability in another area. When weighing benefits and features, look at it as if you’re trying to solve one side of a Rubik’s Cube puzzle without messing up another. Get in the habit of asking questions that uncover any hidden exchange of “give and take” anytime outlier attributes are boasted, and you’ll be glad you did!

Top 3D Printers for Military Use

Now, let’s talk printers.

As you’ve already read, there is a wide range of 3D printers spanning seven major technologies and hundreds of materials. Here at All3DP, you’ll find guides to the top makers in each method, along with specialty guides to materials such as titanium, aluminum, and high-performance polymers.

To see 3D printers up-close and speak to the vendors with military applications, join the thousands of military personnel who crowd the aisles of an expo and conference specifically for 3D printing in the military. The Military Additive Manufacturing Summit takes place every February in Tampa, Fla.

Key players in the Global Military 3D Printing Market

- Optomec

- Markforged

- ExOne/Desktop Metal

- Stratasys

- EOS

- 3D Systems

- Xact Metal

- Velo3D

- Spee3D

- SLM Solutions

- Formlabs

- GE Additive

- Meltio

- Essentium

- DMG Mori

- BigRep

About The Author

Chris Harris serves as the Vice President of Defense for a global manufacturer specializing in point-of-need additive manufacturing technology for military readiness and warfighters. He is the author of Phase Selling for Additive Manufacturing and has provided his proprietary sales training and consulting services to more than 200 AM companies from over 60 countries. Connect with Chris Harris via LinkedIn.

License: The text of "Militaries Worldwide Leverage 3D Printing to Enhance Readiness, Enable Repairs" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.