If you’ve been 3D printing for a while, you may have come across the term “glass-filled” or “GF” when shopping for materials and thought to yourself: why put glass in plastic? It turns out that adding glass powder or glass fiber gives polymers, such as nylon or PET, a tremendous boost in specific areas that could be just what your 3D printing application needs.

Here, we look at the transformative nature of glass in a range of polymers, what it is ideal for, and some printing tips to help you get the most out of this often misunderstood material.

If you’ve 3D printed with carbon-fiber filled materials, you’ll find that glass-filled materials share a lot of the same print parameters and attributes, but typically at a lower cost.

What Are Glass-Filled 3D Printing Materials?

The term glass-filled refers to the addition of glass powder, glass beads, or glass fibers into a base polymer in filament, pellet, or powder form. The glass fill could be from 5% to 40% and the the “base” material into which the glass is infused can be nylon (PA11, PA12), PET, PEEK, or a wide range of other polymers.

It makes a difference if your polymer is filled with glass “fibers” or glass “powder” or glass “beads”, so pay attention to the type of glass additive.

Glass fibers are thin strands of fiberglass, typically a few microns in diameter, that are extremely strong and rigid. They come from fiberglass, the composite material commonly used for home insulation and boat hulls, which is very strong and durable.

When you think of fiberglass, the company Owens Corning may come to mind since it is the world’s largest manufacturer of fiberglass products, such as insulation and roofing materials. It used to make 3D printing filament reinforced with its fiberglass until 2020 when an offer came from BASF’s 3D printing wing Forward AM to buy its GF filament business and the IP that went with it. The Owens Corning XStrand materials are now BASF Ultrafuse.

Glass beads are what you’ll find in polymer powder used in technologies including selective laser sintering, Multi Jet Fusion, and others. The glass beads, which often come from recycled glass, function in the base polymer much like the glass fibers do in filament; adding stiffness and structural integrity to final parts like tooling, housings, jigs and fixtures.

Glass powder consists of small, finely ground glass particles. This glass is “regular” silica-based glass, not fiberglass, so it doesn’t elevate the strength or mechanical properties like the fiberglass does but provides a matt finish to filament 3D prints that helps hide layer lines. It’s the least common option of the three.

Not every polymer can be infused with glass, but certain ones are idea. The most commonly glass-filled polymers for 3D printing include nylon, polypropylene, ABS, PLA, and polycarbonate. These glass-filled materials offer enhanced mechanical properties like strength, stiffness, heat resistance, and wear resistance to the base material.

For example, if your application requires all of the water and chemical resistance of polypropylene (PP) but you find your parts tend to warp during printing, switching to glass-filled polypropylene would add more dimensional stability during printing since it is less flexible. There are always drawbacks to consider, such as the fact that the glass-filled PP part would be more dense and heavy than the pure PP part and you’d be trading a smooth surface finish for a rougher one with the addition of glass.

Before we look at the top glass-filled polymers individually, detailing their unique properties and usages, the chart below provides a snapshot of the general effect that adding glass fibers has on most polymers.

Glass-Filled Nylon (PA)

Nylon is the most popular materials choice used as a base for glass, usually fibers. Adding glass fibers to nylon increases its tensile strength, stiffness, and thermal stability, while reducing its tendency to warp during the printing process.

When comparing the mechanical characteristics of parts made from glass-fiber nylon to carbon-fiber nylon you’ll notice that the glass-fiber parts may be heavier and have better stiffness, but aren’t typically as strong or heat-resistant as carbon fiber parts. The trade-off we already mentioned in often cost.

It’s used in automotive parts, functional prototypes, gears, and mechanical components where high strength and durability are required.

In the chart above we compare three nylons from 3DXTech: AmideX Nylon 6-66 copolymer, CarbonX PA6+CF Gen 3, and FibreX PA6+GF30 glass fiber. Unfortunately 3DXTech doesn’t have figures on impact strength, one of the stand-out feature of glass-filled nylon, so we also took a look at the difference in impact strength from a few other brands below.

It’s often difficult to compare technical data across brands because they often use different measures and often don’t disclose which part orientation the test sample was in (e.g. XY, YZ, Z)

Glass-Filled Nylon Powder

Nylon is the most common powdered polymer used in technologies including selective laser sintering (SLS) and Multi Jet Fusion (MJF).

The glass type typically added to nylon powder is glass beads in various percentages. HP features a recycled glass in its Nylon PA12 GB. Other companies offering a glass-filled nylon include Formlabs and EOS.

Glass-Filled Polypropylene (PP)

Glass-reinforced polypropylene offers enhanced mechanical properties while maintaining some of the lightweight nature of the polymer.

Glass-filled polypropylene has improved stiffness, impact resistance, and temperature stability compared to pure PP, making it more suitable for demanding applications, such as automotive parts, appliances, and chemical-resistant components. The glass fibers help it withstand higher temperatures without losing strength or deforming, making it more suitable for high-temperature applications.

You might choose glass-filled polypropylene over pure PP when higher strength, stiffness, and dimensional stability are required, especially in load-bearing applications. However, if flexibility, impact resistance, and lightweight properties are more important, pure polypropylene would be a better option.

Ultrafuse offers a PP GF30 it says is fully printable without need for drying. BCN3D’s also offers a PP GF30 (polypropylene 30% glass fiber) it says is ideal for chemically resistant, lightweight and dimensionally stable parts.

Glass-Filled ABS (Acrylonitrile Butadiene Styrene)

Adding glass fibers to ABS greatly improves its tensile strength, and load-bearing capabilities, making it stronger than pure ABS. It’s much stiffer and more rigid, which can make it better suited for parts that need to withstand higher mechanical stresses, such as hooks and brackets.

On the flip-side, the addition of glass fibers makes ABS more brittle and more likely to crack or break under sudden impacts compared to pure ABS. Glass-filled ABS is frequently used in automotive parts, consumer electronics, toys, and functional prototypes.

Glass-Filled PC (Polycarbonate)

Glass-filled polycarbonate is known for its exceptional strength and heat resistance. Glass fibers make polycarbonate even stronger and more resistant to heat, while also improving its rigidity and impact strength. It’s widely used in lighting fixtures (although it does not come in clear, like pure PC) and electrical housings.

Forward AM makes Ultrafuse PC GF30, a PC with 30% glass fibers. Its UL94 V0 rating makes PC GF30 the solution for applications in transportation industry that require flame retardancy. The resistance to UV light exposure and its low moisture uptake makes it suitable for exterior applications.

Glass-Filled PLA (Polylactic Acid)

When it comes to glass-filled PLA you may be thinking: Why reinforce PLA when you could just use a material with a higher impact strength, like ABS?

The fact that there are only a few makers of glass-filled PLA may answer that question, but the full answer would depend on your application and the exact balance of strength, flexibility, stiffness, impact resistance, and other factors you’re looking for.

Glass-filled PLA is stiffer and more durable than standard PLA but, if you’re simply looking for a higher impact strength, and other factors aren’t relevant, you’d select ABS. For example, eSUN’s ePLA-GF has an impact strength just a bit higher than its regular PLA (10.16 kJ/m2 vs. 9 kJ/m2) while the company’s ABS+ has an impact strength more than four time higher (42 kJ/m2).

PLA is an easy-to-print material and adding the glass-fiber typically doesn’t make it harder to print (if you follow the print profile). Glass-filled PLA is low-odor and doesn’t need a heated bed.

There are only a few makers of glass-filled PLA, including eSun.

Glass-Filled PET / PETG (Polyethylene Terephthalate Glycol)

PETG is a popular 3D printing material known for its durability and chemical resistance, and when infused with glass fibers, it becomes even stronger. It’s used in functional prototypes, food containers, electronic housings, and mechanical components.

Nanovia makes a PETG GF it says is water and temperature resistant up to 80 °C and also enriched with UV resistant additives.

PET (Polyethylene Terephthalate) is know to be harder to print than PETG and has higher heat resistance. Prints made with Raise3D’s Industrial PET GF can be annealed after printing to achieve a heat resistance of around 120 ℃, the company says.

Glass-Filled PEI (Ultem) & Glass-Filled PEEK (Polyether Ether Ketone)

PEEK is one of the strongest and most heat-resistant materials available for 3D printing so infusing it with glass-fibers improves its already excellent mechanical properties, providing superior chemical resistance, heat resistance, and dimensional stability.

It’s not widely available since it retails for about $700 per kg, but it is used in high-performance aerospace, medical devices, oil and gas components, and industrial applications where extreme heat and mechanical stress are present. The FibreX PEEK+GF20 has 20% glass fiber and requires an all-metal extruder capable of reaching (and holding) temps upwards of 400°C or more depending on your specific printer.

PEI, also known as Ultem, is another high-performance material known for its heat resistance and mechanical strength. With the addition of glass fibers, PEI becomes even more rigid and heat-resistant, making it ideal for demanding industrial applications in aerospace, automotive, and medical devices where high thermal and mechanical loads are common.

Glass-Filled TPU (Thermoplastic Polyurethane)

It may seem counterintuitive to make TPU stiffer, but there are specific applications for glass-filled TPU.

Glass-filled TPU offers improved rigidity and dimensional stability while maintaining some flexibility. Yet, the glass fibers greatly reduce the flexibility and elasticity of TPU so it becomes more suitable when you’re using TPU for its natural resistant to abrasion and wear, which are enhanced by the glass fiber.

Instead of gaskets or seals, glass-filled TPU is suited for wear-resistant components.

The 3DXFlex TPU+GF30 ($135/kg), however, boasts a hardness of 60D for tough, impact resistant, and flexible prints.

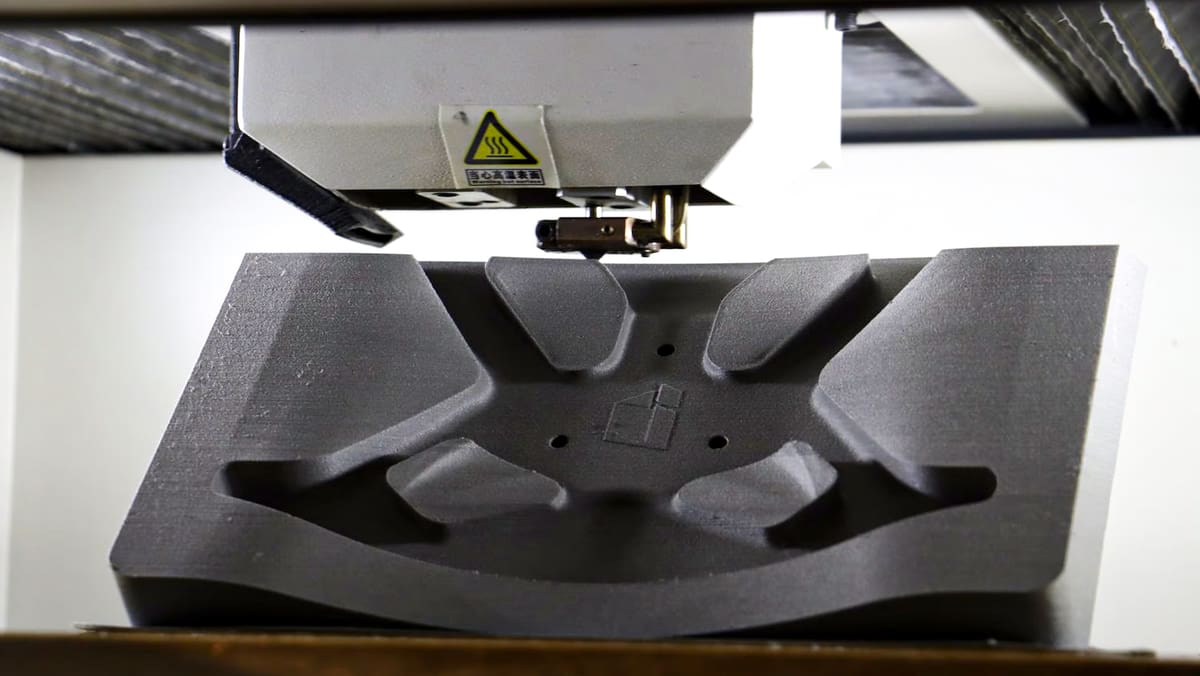

How to Print Glass-Filled Polymer Parts

The main 3D printing technologies with glass-filled materials are fused deposition modeling (FDM) and polymer powder bed fusion technology, including selective laser sintering (SLS) and Multi Jet Fusion (MJF).

Tips for FDM Printing with Glass-Filled Filament

FDM 3D printing is the most accessible and versatile method for making glass-filled parts. Glass-filled filament can be used on a wide range of FDM 3D printers as long as you use a hardened steel nozzle and can reach the required temperature for the base material.

Filaments containing glass fiber particles work the same way as carbon fiber and often have the same print profile. The heat from the extruder makes the filament pliable and also aligns the embedded glass fibers in the print direction, which gives the final print its strength and stiffness.

- Hardened steel nozzle: Glass fiber is a very abrasive material that will quickly wear down a traditional brass nozzle. Make sure your printer is equipped with a suitable hardened steel nozzle or equivalent before attempting to print with GF blends.

- Nozzle temperature: Glass fiber often requires a much higher nozzle temperature than PLA or PETG, with most brands recommending between 260 °C and 300 °C. Check your filament manufacturer’s recommended settings for best results. 3D printing glass-filled PEEK, will require a very high temperature, heated bed, and heated-chamber.

- Extrusion speed: The glass fibers give the material a higher melt flow so you’ll want to pay attention to your extrusion speed.

- Clogging: Glass fiber, much like any filament blend with additives, is known to clog as the glass fiber particles don’t melt like the rest of the material. These particles can potentially build up at the tip of the nozzle and form a clog. A larger nozzle size, such as one with a 0.6-mm diameter, is recommended to reduce the chances of clogging.

- Bed temperature: While some Glass fiber filaments will print fine on standard 60 °C print beds, many brands require a bed temperature closer to 100 °C. Make sure your printer can reach the temperatures needed for any filament you choose.

- Print bed material: After looking at the printing recommendations from several glass-filled brands it clear that the printing bed or sheet is very polymer-specific. Some recommend glass while others a PEI sheet with glue stick.

A final note to remember is that glass fiber increases the base material’s brittleness, so it can also adversely impact layer adhesion in some cases.

Glass Fiber SLS

SLS 3D printing uses high-powered lasers to fuse powdered plastic material together into 3D shapes one layer at a time. It can create parts that are finely detailed, strong, durable, and heat resistant all at once. Glass fiber filled nylon (GF-PA) is one of the most popular materials for SLS 3D printing and SLS is often chosen over FDM for the smooth surface finish it creates and ability to fabricate more complex shapes.

Glass fiber-filled nylon tends to be highly anisotropic, which means that the material properties will vary depending on part orientation during printing because the small fibers will align with how the powder is spread across the build platform. For example, tensile strength will be much higher in one direction than the other two, so part orientation is important and something your build preparation software should alert you to.

Glass Bead MJF

One of the lesser used Multi Jet Fusion materials is the company’s glass-filled nylon. HP’s PA12 GB is ideal for producing complex parts with a high level of detail. The material is suitable for the production of short and medium series and boasts a high level of reusability.

Are Glass-Filled Materials Recyclable?

Although glass-filled 3D printing materials are technically recyclable like their base material, the process is more complex and less efficient compared to pure polymers due to the presence of glass fibers. The resulting recycled material typically has reduced mechanical properties, making it more suited for lower-performance applications.

Overall glass-filled materials are not a sustainable choice due to their lack of recyclability. There’s potential for using glass fibers to reinforce recycled polymers, but research hasn’t translated into any commercial products yet.

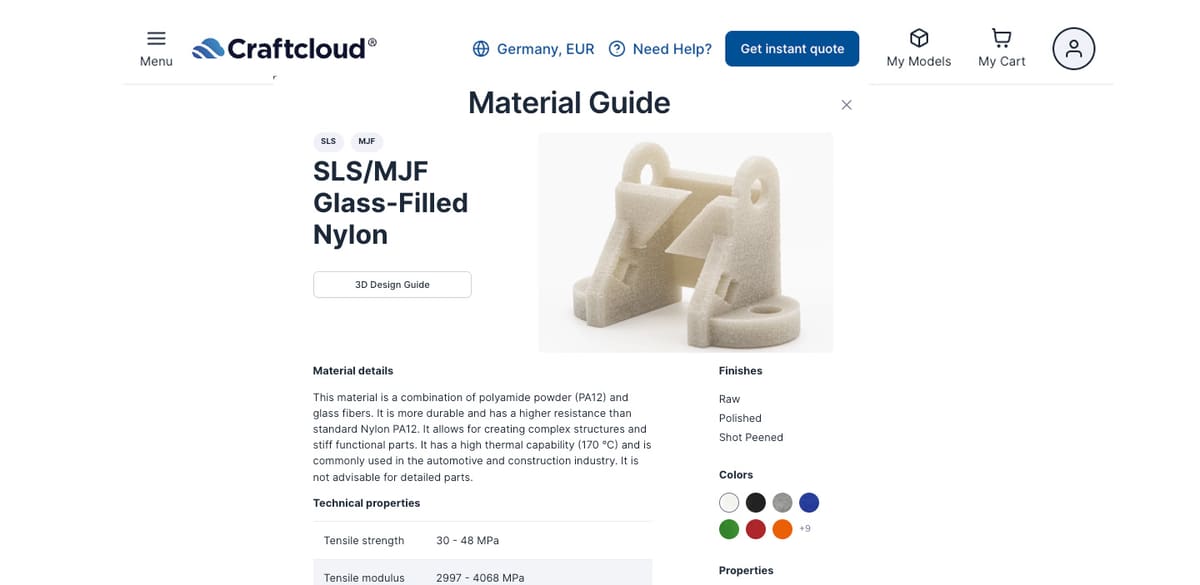

Order Glass Filled 3D Printed Parts

If you want to see what the addition of glass does for your 3D printing and don’t want to do all of the experimenting with print profiles that are often necessary, turn to a service and order parts.

3D printing service providers are also a great option when the number of required parts doesn’t warrant the initial investment into glass-filled materials or you simply want to try out the many options. There are many 3D printing services available that offer glass fiber printing, all with their own strengths and specialties.

Craftcloud, allows you to compare and choose from more than 150 manufacturers across the globe. There is no minimum order requirement and all you need to do is upload your CAD model, pick your material and finish, and find a quote that works best for you. The quotes are generated instantaneously in real-time and don’t include any hidden fees.

For glass-filled parts, Craftcloud offers:

- Glass-Filled Nylon for SLS & MJF

- Glass-Filled Polypropylene for SLS

- Glass-Filled Nylon for FDM (9 colors)

- Glass-Filled PEEK for FDM

- Glass-Filled Ultem for FDM

Lead image source: All3DP

License: The text of "3D Printing With Glass-Filled Materials – A Quick Start Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.