Even if you aren’t running a high-output 3D print farm, you might be familiar with 3DQue. The small Canadian company, headquartered in Vancouver, British Columbia, has attached itself to a niche in 3D printing that gets surprisingly little fair: 3D printer automation.

3DQue, with its Quinly product, automates G-code queues and print removal. With it, parts are printed on a specialized print bed, called the VAAPR bed, and are simply pushed off with the print head for removal — a routine made reliable by the specialized build surface. Prints are made in this manner in sequence and without user intervention, at least until the filament runs out.

The company often emphasizes that large enough print farms operating traditionally face production bottlenecks caused by limited operator time. In facilities with enough operators to keep up with demand, they become the business’s biggest expense. So, to solve this, 3DQue created its Quinly system, which it refers to as a “virtual operator”, that is able to handle the most frequent and tedious tasks of operating a 3D print farm.

With Quinly installed, operators need only queue print jobs and come back when they’re all finished, freeing time for maintenance and other work. Where previous attempts to automate cells of 3D printers have relied on robot arms and conveyor belts, both removing build plates entirely, or at least on belt 3D printers with often troublesome beds, 3DQue’s solution is appealing in its simplicity. But as a third-party offering made to run on popular 3D printers, we’ve wondered how well it really works.

If you’ve ever come across the Quinly, its price and required proprietary VAAPR print bed might have given you pause when similar open-source solutions do exist for precisely this problem. So, we decided to test 3DQue’s product to see how it stacks up against the open-source solutions for automated (or continuous) 3D printing available today.

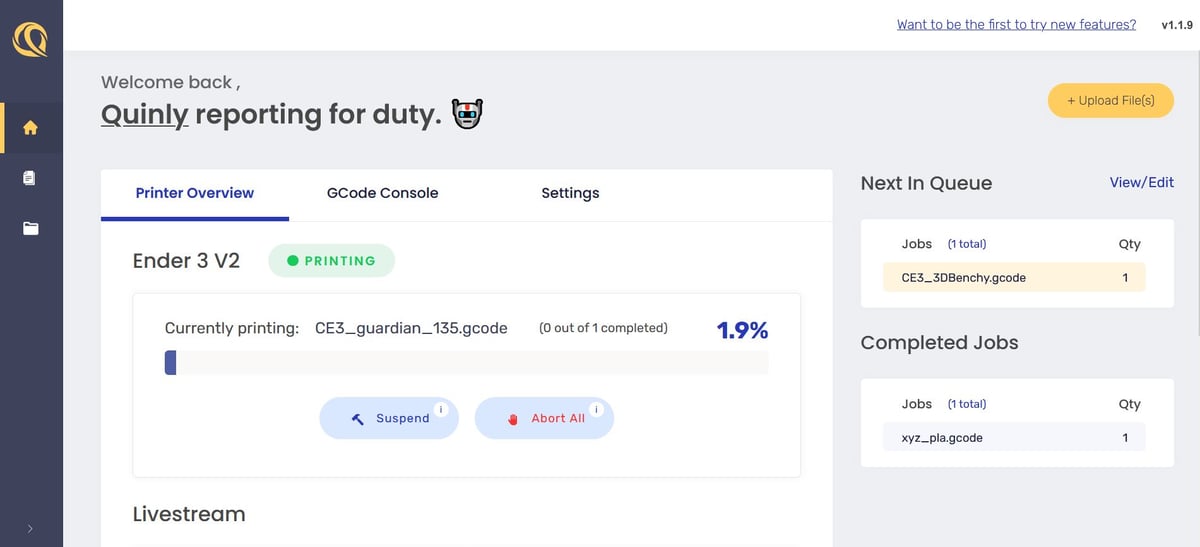

Update — May 31, 2022: 3DQue reached out to All3DP to inform us that the power loss behavior experienced in this Quinly review was unexpected — the system is meant to suspend on power loss. We experienced this issue on Quinly 1.1.6 and 1.1.9 but, after upgrading to 1.1.10, Quinly now starts in a suspended state following power loss as the manufacturer intends.

The Verdict

Pros

- VAAPR print bed is very impressive

- Straightforward and intuitive UI

- Customer support available

Cons

- Expensive

- Power loss poses machine hazard

- Limited software features

3DQue’s Quinly 3D printing automation system does what it’s supposed to without much fuss: files are queued for printing and automated removal. The printer runs sans operator until maintenance, like changing spools, is needed. It’s a simple yet effective solution that saves users overburdened with print jobs ample time. The system eliminates some concerns over manual calibration and user error when setting bed clearing routines compared to similar open-source solutions that are more onerous on end-users — the availability of customer support assuaged further concerns over the unforeseen.

While Quinly’s software is efficient, even detecting the printer it’s plugged into automatically, it doesn’t offer much in terms of supporting features. So much so that oversights can be, on occasion, severely detrimental to the product and even hazardous to machines. However, since Quinly is designed for users to interact with as little as possible, this is usually understandable and poses little problem. That said, we all know it’s when things go wrong with 3D printers that we want the most from its features. Though open-source solutions like OctoPrint with its Continuous Print plugin are more involved to get up and running, and lack the customer support businesses might prefer, they do present users with useful options Quinly does not for tweaking processes and carrying out maintenance.

In terms of hardware, Quinly’s key component, the VAAPR print bed, is an impressive surface that cinches any doubt about the product’s value. We found the proprietary surface to meet the manufacturer’s claims, bonding to materials with incredible strength when heated and reliably releasing them once cool. It’s pleasantly effective, even with materials like PETG that are often stubborn to remove from textured glass.

Though Quinly could stand for some additional quality-of-life features, it does serve its purpose well and makes large print queues a breeze. While the ~$230 asking price for the Ender 3 Quinly may be steep for a consumer running one or two systems, the value of reliable systems with full support increases exponentially in busy print farms.

The Tech

3DQue’s Quinly comes as a curated package for supported printers, with prices that vary by model on the extreme side. We tested Quinly with an Ender 3 V2 kit that 3DQue charges ~$230 for, but the Prusa Mk3 kit will cost users ~$450. 3DQue attributes this dramatic price difference to software features, saying the added development effort to make use of all a given 3D printer’s features — and therefore achieve the expected print quality and reliability — adds to its value. That said, aside from a VAAPR print bed made for another build volume, customers appear to be getting the same product regardless of which printer they run it on.

We opted for the Ender 3 V2 system, which came with a tilt system, comprised of two aluminum extrusions and 3D printed parts to prop the printer on an angle and direct prints down its front; the VAAPR print bed, a proprietary print surface by 3DQue and one of the most interesting aspects of Quinly; and a permanent license for the Quinly software, which installs onto a single-board computer (SBC) like a Raspberry Pi or Rock64 (the two supported SBCs).

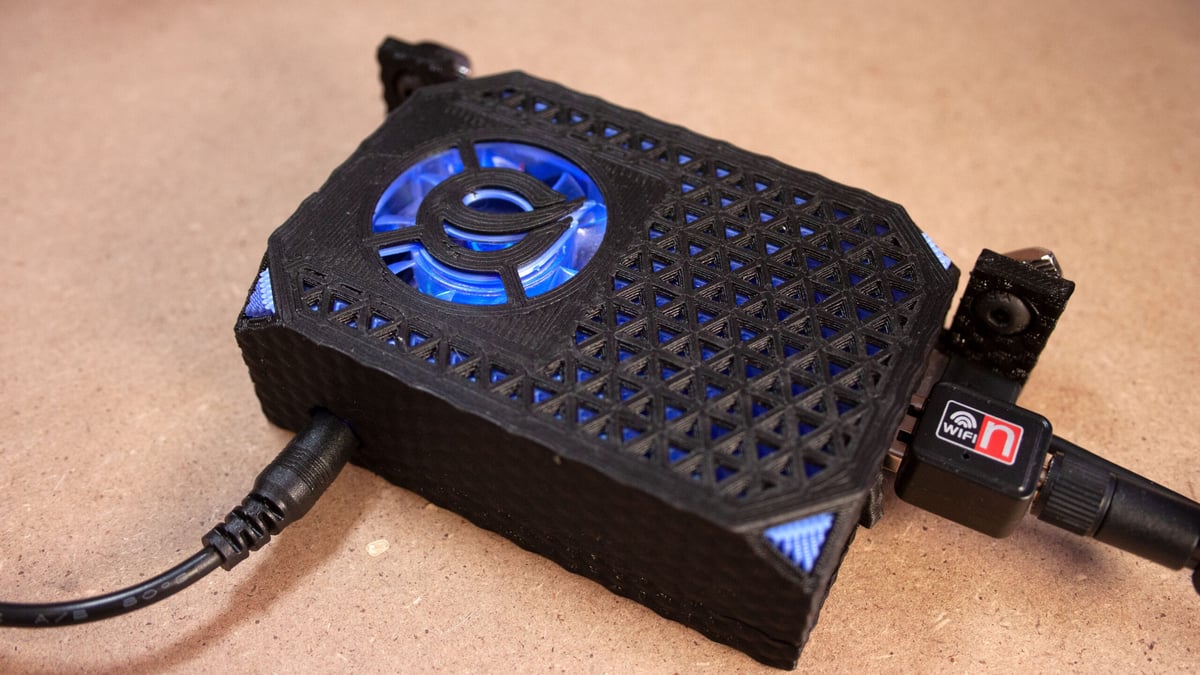

Customers can additionally purchase a “Quinly Hub”, a Rock64 SBC with a 3D printed case, a fan, and the most recent version of Quinly pre-installed on a suitable microSD card for ~$120 more with the printer kit or ~$170 on its own. 3DQue calls its Quinly Hub a “plug-and-play” system, but you will need to make some simple edits to files on the SD card for use over Wi-Fi. Updates were also required to be manual in the version we tested, 1.1.6, but 3DQue says Quinly will introduce over-the-air software updates in an upcoming version.

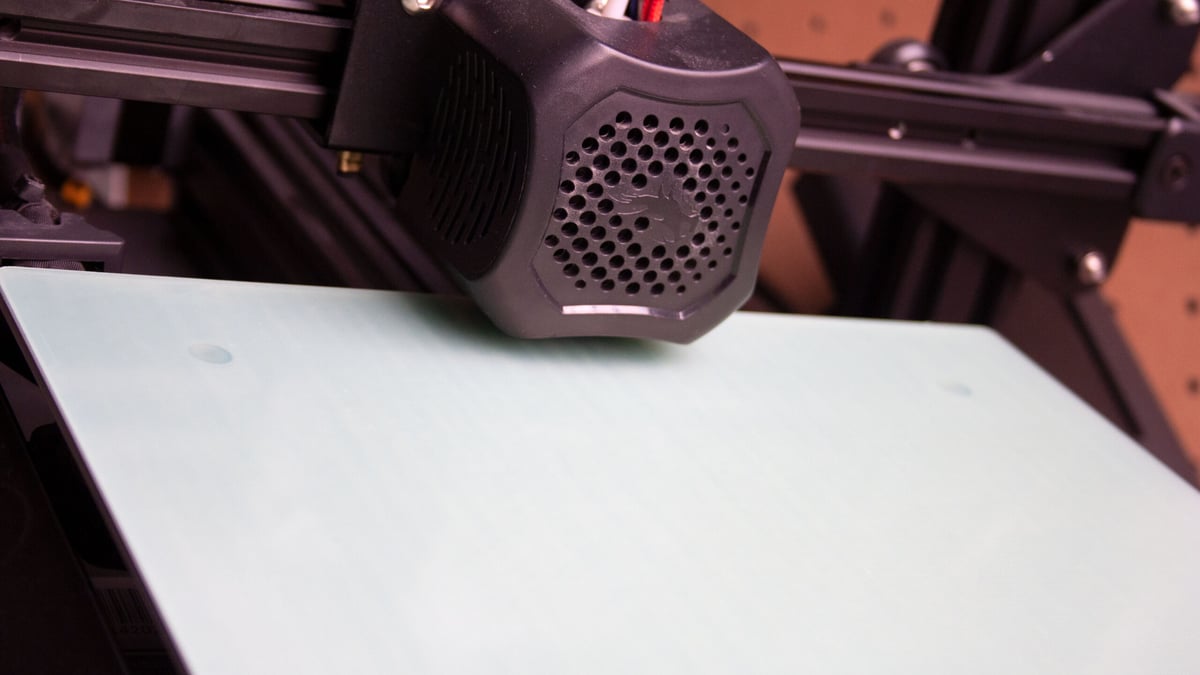

VAAPR Print Bed

The VAAPR print bed is quite simply the best part of the Quinly package and the key to making automated 3D printing reliable with a variety of materials. We found it to bond with incredible strength at high temperatures and release materials almost entirely at low temperatures.

It is unfortunate that, in the case of Quinly for the Ender 3 V2, the VAAPR print bed must be adhered directly to the heat plate, but this isn’t the case for every version of Quinly. The Prusa i3 version, for example, instructs users to adhere the VAAPR bed to an easily replaceable magnetic bed. In the case of the Ender 3 V2, however, the bed would be frustrating to remove. In fact, 3DQue doesn’t even offer removal instructions. The company simply prompts users who would like to remove the bed to get in touch with them for instructions. If there’s a trick to it, that should really be included with the other customer resources.

Quinly Wireless Hub & Software

The Quinly wireless hub is an optional addon that hosts Quinly’s software component. Without it, Quinly must be user installed on a customer’s Raspberry Pi or Rock64. Originally, Quinly was only available for user installation on a Raspberry Pi but 3DQue began offering Rock64s when the supply chain crisis made Pis difficult and expensive to obtain. Still, the Raspberry Pi is fully supported. The Quinly Hub offering does also serve to bridge a gap for a certain user base who would prefer not to install the software themselves, as the Quinly wireless hub is now marketed as “plug and play.” We tested Quinly on version 1.1.6 which necessitates an SBC per printer, but an upcoming “Quinly Pro” variant can manage multiple 3D printers (and will see the current Quinly renamed “Quinly Basic”).

Quinly’s software has an appealing user interface and does its basic job well. It includes file systems to organize G-code, target temperature settings for bed clearing by file, print bed and hot end temperature controls, and a terminal.

Unfortunately, that’s about it.

3DQue has missed ample opportunities to add software value to its product, some of which can impact user experience. That said, Quinly users are likely more concerned with having to touch the software as little as possible than with the extra features available when they do. Still, the software lacks features that would make the day-to-day operating of 3D printers via a host easier – and serve to match features that open-source alternatives already have. Simple things like motion and bed-leveling commands outside the terminal would be nice, but we’ll delve into the more impactful features that are missing further on.

The Experience

Setting Up

Installing Quinly was, on the Ender 3 V2, a straightforward affair. The tilt system installs quickly with the simple T-nuts, and the part ramps snap into place on existing extrusions without much thought. The VAAPR print bed was only slightly more involved. It required removing the textured glass build plate and its clips before wiping down the aluminum heat plate with a provided alcohol wipe. After cleaning the heat plate, the VAAPR print bed can be adhered directly to it, pressing any air from below as you go. The instructions for this are comfortingly detailed, but it’s already a simple process akin to installing a screen protector – just apply the hinge method.

The Quinly wireless hub is, as advertised, plug-and-play but only if it’s connected to the network via ethernet. Not likely, since it requires a direct connection to its printer – the case even comes with T-nuts to connect it to the printer extrusions directly. To set up a wireless connection, users will need to open the microSD card’s file system and update the “wifi.txt” file with their network details. Still more or less plug and play. The most recent version, Quinly 1.1.9, has placed that text file very obviously when you open the SD card’s file system, so even the technologically challenged among us won’t have much trouble getting things up and running.

From here you can access Quinly’s interface to upload and queue print jobs. You may want to test your materials to determine which temperatures they release from the VAAPR bed before starting long queues, but we found 3DQue’s default 29 °C to work for every material we tested. If you’d like some tips on which materials work in advance, 3DQue offers a list.

The Experience

Quinly is straightforward and appealing to use. Its bed clearing routine works great out of the gate with no need for user input of any kind. Rather than rely on users to input bed dimensions and enable extra features like auto bed-leveling, Quinly detects the printer and the commands at its disposal. In fact, the only G-code we needed for Quinly was our sliced files. Nothing special in the start or end code from users, it handled everything.

The standout feature of 3DQue’s offering is the VAAPR print bed. Other beds like textured glass are also known for bonding at high temperatures and releasing when cool — that’s the goal after all –but the VAAPR bed manages to work its magic consistently, to better effect, and with a wider variety of materials. It’s a shame you can’t get your hands on one without the full Quinly purchase.

There are plenty of examples where print automation like Quinly via open-source solutions has worked well with a textured glass print surface, but we’d be nervous to remove PETG models from a textured glass bed with a print head. PETG parts with wider bases can have strong adhesion to glass even once cooled, and ramming the print head into that could easily burn out your stepper motors if the part doesn’t give. Not so with the VAAPR bed. In testing with PETG prints we’ve had, at times part-ruining, difficulty removing from textured glass the VAAPR surface easily and reliably released at about 35 °C – 6 °C higher 3DQue’s default recommendation and in line with PLA release temperatures. We ended up using PETG for most of our time with Quinly when we’d usually use PLA as standard.

The VAAPR bed really does bring Quinly to the next level. When we let the bed reach room temperatures closer to 25 °C, prints detached with the slightest nudge. It’s very impressive.

While its hardware was impressive, Quinly’s software left something to be desired.

Quinly is clearly intended as a “set it and forget it” system — something operators rarely need to interact with. This is probably, of course, how most operators want to use Quinly. If an operator’s fleet is well maintained and prints without a hitch, Quinly’s software is perfectly adequate at carrying out long queues. Its UI is laid out well, its options are all intuitive, and its G-code folder system is greatly appreciated. However, Quinly lacks almost any features beyond getting things queued and setting a temperature for the bed clearing routine to run; missing quite a few opportunities to make typical operations and maintenance routines easier for its users.

The clearest example of 3DQue’s software oversights is the inflexibility of Quinly’s bed clearing routine. Though a crucial aspect of the product, Quinly has only one removal routine that covers the whole print bed – first moving the print head straight down the print bed’s middle from top to bottom, then similarly clearing the whole bed left to right. This routine doesn’t take an excessive amount of time, but it does take more time than is necessary. This seems to us an exceedingly simple thing to provide users a few more options for. All of our prints were cleared on the first middle pass, but we had to wait out the whole routine. A simple option for a single bed-clearing motion (or better yet custom routines) would have saved us ample time — and only more the longer your queue.

The bed clearing routine also can’t be run manually. It is, admittedly, a niche circumstance in which this would be required, but remote operation is always nice when it’s needed.

Even the software features that do exist are often limited in odd ways. Prints can be queued in quantities, so if you need more than one of a file it’s easy to queue up multiple. Unfortunately, these quantities can’t be changed later — which would be a convenience for any users who realize they need more or less of a part mid-queue. Prints queued with quantities can also only be aborted all at once. So, if you do realize you need one less part than you scheduled, you’ll need to abort all the parts you queued – possibly including one that is mid-print. This is a problem even barring user errors. If one print fails and you need to end it early, you’ll need to manually re-queue the remaining prints. Why not add the option to skip one of a quantity? The only workaround right now seems to be manually queueing a file multiple times; one-by-one until the desired quantity is reached with two confirmations between each. Worse yet, the bed clearing routine doesn’t run for aborted prints, making manual operator intervention required lest the print head ram a half-finished part.

These oversights are far from experience ruining but do make the software feel too limited given its premium. Adjusting quantities mid-queue and remotely aborting and clearing failed prints seem like obvious features for this kind of software.

In the worst of circumstances, these sorts of oversights become hazardous. When faced with temporary power loss, Quinly will restart and abort the ongoing print but pick the queue back up with the next print in line. Again, without clearing the bed. This time when no operator intervention has occurred. In our case, this resulted in a coupler ripped from the stepper motor’s shaft when the print head ran over the still very well adhered print to start the next one.

3DQue needs some precautions here urgently, at the very least a queue suspension, because right now we wouldn’t want to use the Quinly system without an uninterruptable power supply (UPS).

Is It Worth It?

3DQue’s Quinly does its job well and is generally a pleasant system to use, even if there’s plenty of room for quality-of-life features within the somewhat lacking software. Though we found one oversight in power loss response that needs immediate addressing, we found nothing else so concerning and don’t believe there’s much room for destructive errors in this curated system.

At ~$230 Quinly may seem steep to consumers, but the value increases exponentially per printer. Those running a busy print farm will almost certainly find Quinly to take a load off their shoulders and be well worth its value.

That said, there are times when the open-source solutions via freely available hosts like Octoprint or Repetier may be preferable. In particular, when a user wants more interface options than Quinly’s limited software offers. Octoprint’s Continuous Print plugin, for example, allows for custom bed clearing G-code while Quinly’s bed clearing routine is starved of options.

Where freely available open-source options may be preferable to users undaunted by additional setup time and a lack of support, Quinly’s most unique features may close the gap. Its ability to detect the 3D printer it’s connected to and carry out system-specific routines removes small burdens from operators, the VAAPR print bed dramatically increases reliability for those interested in printing with sometimes troublesome materials, and 3DQue’s customer support is responsive and enthusiastic with multiple channels to connect through — including an active Discord with regular employee presence for less pressing issues or queries that aren’t Quinly-specific.

Ultimately, we can recommend Quinly to print farm operators (with a UPS) as a reliable solution for 3D printer automation. But the size of the print farm in question, and the amount of business it receives, will likely determine if the cost of entry is worth it.

Alternatives

If you’re willing to put in some work and forgo support should the need arise (and aren’t enticed by the VAAPR print bed), there are some open-source options to automate your 3D printing. Here are some of the best around right now:

OctoPrint with the Continuous Print Plugin

If you’re scouting options for a 3D printer host for any purpose, OctoPrint is bound to be the first thing you see. The excellent open-source software has been developed by Gina Häußge since 2012 and has maintained its popularity all that time. For good reason, too. OctoPrint is a consistently impressive and hardware-agnostic option for 3D printer hosting.

In terms of 3D printer automation, though, we’re after an OctoPrint plugin called Continuous Print. Much like Quinly, Continuous Print simply queues up G-code and runs a bed clearing routine. It’s been used to great effect by members of the community. This plugin’s bed clearing routine is notably customizable, but when we tried the default routine we found it sunk the print head too low and rammed against the print bed — so make sure you check it on your printer before starting a queue.

Learn More From: OctoPrint

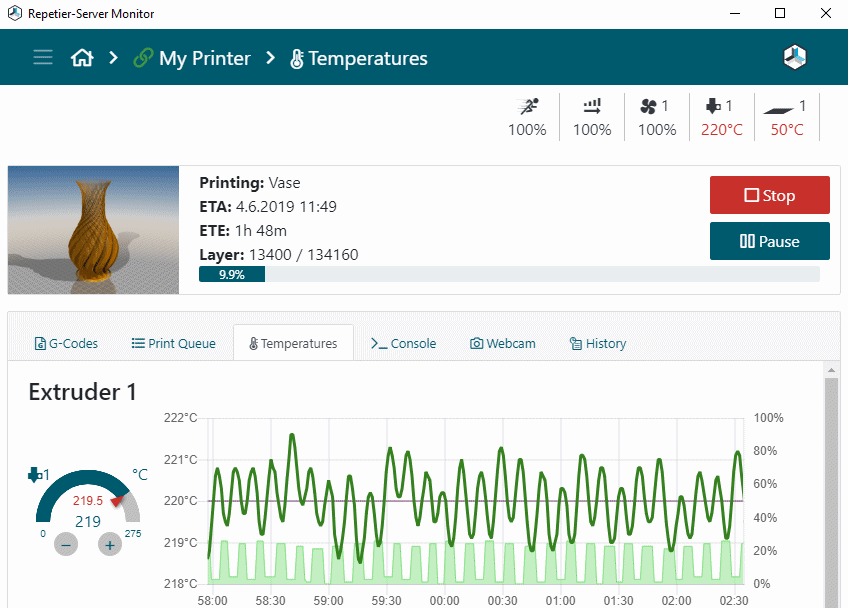

Repetier Server

When asked if Repetier had continuous printing capabilities, the company responded that the command “@autostart_next_job” is available with Repetier Server. Users need only add the command to the end of their G-code and Repetier will print the next job in its “todo list”.

This means that users will be responsible for any bed clearing routines, and must tack it to their slicer’s end G-code. It’s a pleasantly simple solution to use an established and feature-rich 3D printer host for your 3D printer automation. Do mind that you’re using Repetier Server as opposed to Repetier Host, which doesn’t have all the same commands.

Learn More From: Repetier

License: The text of "3DQue Quinly Review: Automated 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.