You probably don’t give much thought to opening a PDF document on your laptop or smartphone. Today, you can fill out a PDF form and interact with a PDF brochure on any device, browser, or operating system. But it wasn’t always like that.

Before PDFs, you had to have the same software the document was created in to view it, and, if you didn’t, you’d encounter missing fonts, scrambled layouts, and interacting was pretty much impossible.

Then Adobe established the PDF format in the ’90s to present documents independent of application software, hardware, and OS. Every PDF file encapsulates a complete description of a document design, including the text, fonts, graphics, security, form fields, and other information needed to display and interact with it.

Not a single 2D printing company ignored PDF when it came out — in fact, they unanimously welcomed it. PDFs changed the way 2D printed material was produced and disseminated.

The 3MF format is doing the same for 3D models. 3MF brings 3D printing file formats a leap forward because it carries more information (materials, colors, units, multiple objects), leading to fewer errors and better print reliability.

Within the past year, new features have expanded the benefits of the 3MF file. Now, it can communicate complex lattice structures with the Beam Lattice extension and manufacturing data at the voxel level with the Volumetric Extension, along with slice and security information.

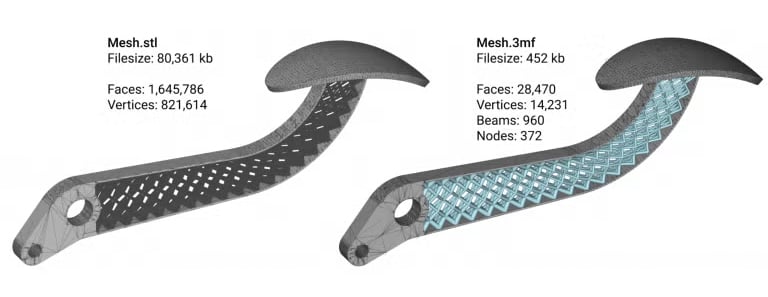

3MF is more efficient than some older formats. 3MF files are typically smaller in size than STL files, which means that they can be transferred and processed more quickly. This can be important in applications where speed is a concern, such as when printing large or complex 3D models.

The STL file format is still usable — after all, there’s a reason why it has stuck around for more than three decades. If you scroll through 3D printing model repository sites like Thingiverse and Printables, you’ll mostly find STLs, but professional 3D printing has moved on.

3MF has been shown to deliver more reliable and repeatable results, it’s open-source, and it saves a lot of time and work preparing models for printing. Today, more than 100 software programs from Autodesk Fusion to Bambu Lab Studio are compatible with the 3MF. This is opening up more opportunities for you to convert your old STLs to 3MFs for better 3D prints.

3MF also give you the ability to save authorship information and copyright license type natively in the file format.

Here, we’ll explore the 3MF file format, what it does, and why designers, engineers, and additive manufacturers need it. We’ll also take a look at how you can start using 3MFs with your 3D printers and convert your STLs to 3MFs.

What is a 3MF?

The 3D Manufacturing Format, or 3MF, is gradually dethroning STL as the standard file format for additive manufacturing because it provides answers to many problems STL faces, such as limited model data storage and, frankly, low-quality files.

In fact, 3MF is in the process of being certified as an ISO standard.

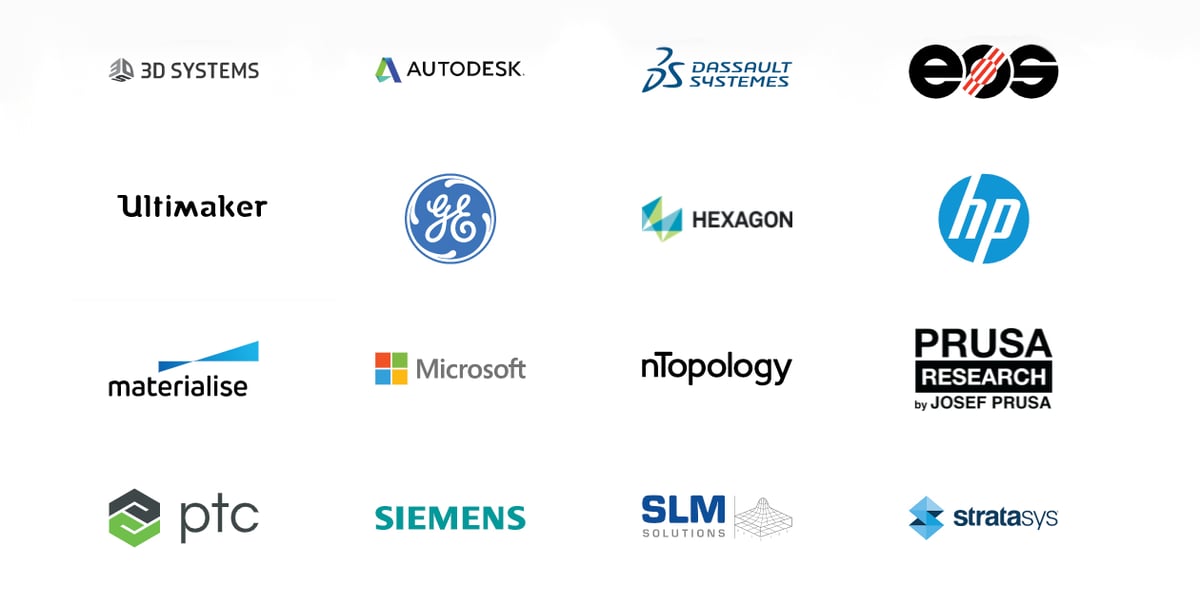

3MF is was introduced in 2015 by the 3MF Consortium, a group of computer software, hardware, and additive manufacturing developers that includes — among others — Autodesk, Dassault Systemes, HP, Microsoft, and UltiMaker. It’s part of the Linux Foundation, which means that software makers can incorporate it into their products.

The aim was to create a file format for industrial 3D printing that could not only encapsulate more data about a model than the existing SLT format, but also solve the compatibility and inoperability issues that plagued the industry.

Designed with additive manufacturing in mind, 3MF is a handy tool that stores large amounts of model data in one small file

3MF Files Can Contain:

- Full color and texture data

- Material data

- Designer’s name, part description, copyright & licensing data

- Thumbnail images

- More than one object per scene

- Support structures attached to part data

- Beam lattices

- Scene scale and measurements

- Full tray support for direct machine preparation

- Printer configuration information

- Data encryption

- Volumetric Design

- Tool paths (in development)

All of this seems like it would produce massive files, but 3MF files use the same compression method as the popular ZIP format, which makes 3MF files lightweight and small in file size (typically half to a third the size of an STL file of the same model). This also means that you can easily decompress the file to work on the contained data, just like a ZIP.

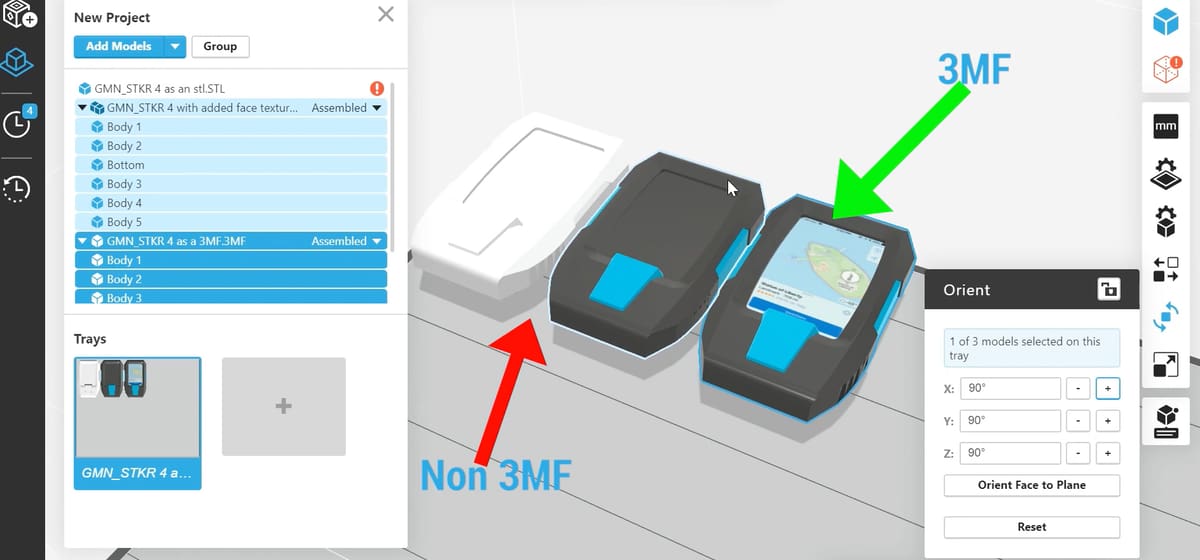

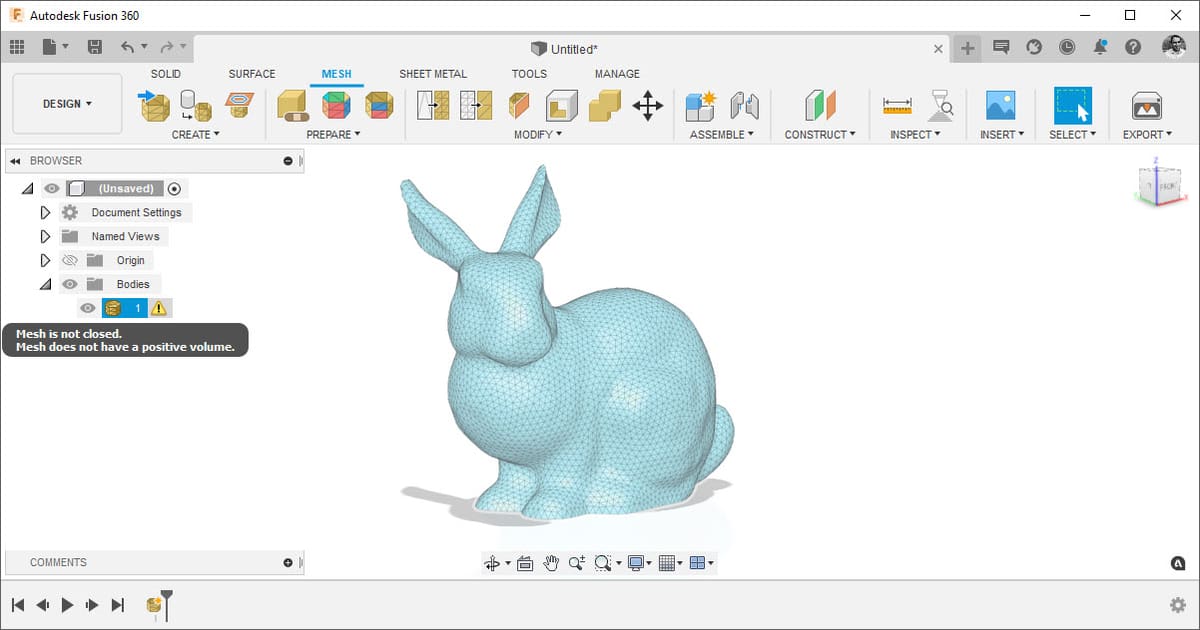

In addition to its small but mighty size, 3MF also provides clear definitions of printable mesh requirements (or manifoldness). Because of this feature, unprintable files are impossible because you can’t even save a file as 3MF if it has non-manifold edges, helping prevent print errors. Compared to STL files cycled routinely through printability checks and uploaded to programs that can fix them, 3MF saves time and money because you can do away with printability checks.

“STL files are notoriously bad,” says Sualp Ozel, senior product manager at Autodesk, “and we see a lot of our (Fusion) users immediately going over to mesh repair mode and spending time and effort repairing those bad STLs.”

As a cherry on top of it all, 3MF is a relatively widely supported file format despite its newness. Due to the high number of large-scale additive manufacturing players in the 3MF Consortium, 3MF has been adopted by nearly all major CAD tools, 3D printer manufacturers, and others suppliers across the ecosystems, ensuring interoperability across products. This high adoption rate helps manufacturers more easily implement 3MF.

The amount of software between design and part is only getting larger; there’s simulation software, DfAM software, specialized nesting software, AM workflow software, manufacturing execution systems (MES), and more. And 3MF is a data package that can work with all of them.

Why Is 3MF Needed?

The current standard 3D printing file format is the good old STL, but its quickly becoming antiquated — in fact, for additive manufacturing, it’s that already. The STL format was introduced in 1987, an eternity ago in terms of information technology.

Its age introduces several issues to STLs. First of all, we already mentioned the data that STLs don’t include, such as color, textures, or material properties. If you’re printing with a full-color 3D printer, like a Stratasys J55 or a 3D Systems ProJet CJP, the embedded color information in a 3MF will save you a lot of time.

More importantly, STLs don’t store an accurate mathematical representation of your model in a three-coordinate environment. At best, you get a close mesh reproduction of what the model is supposed to be.

This reproduction can cause significant issues during printing. Using STLs can result in faceted prints and other print errors because the STL misinterprets the model data or introduces rounding errors when converting it to a mesh. Additionally, this method of storing model data makes STL files huge, often several times larger than the original 3D model file.

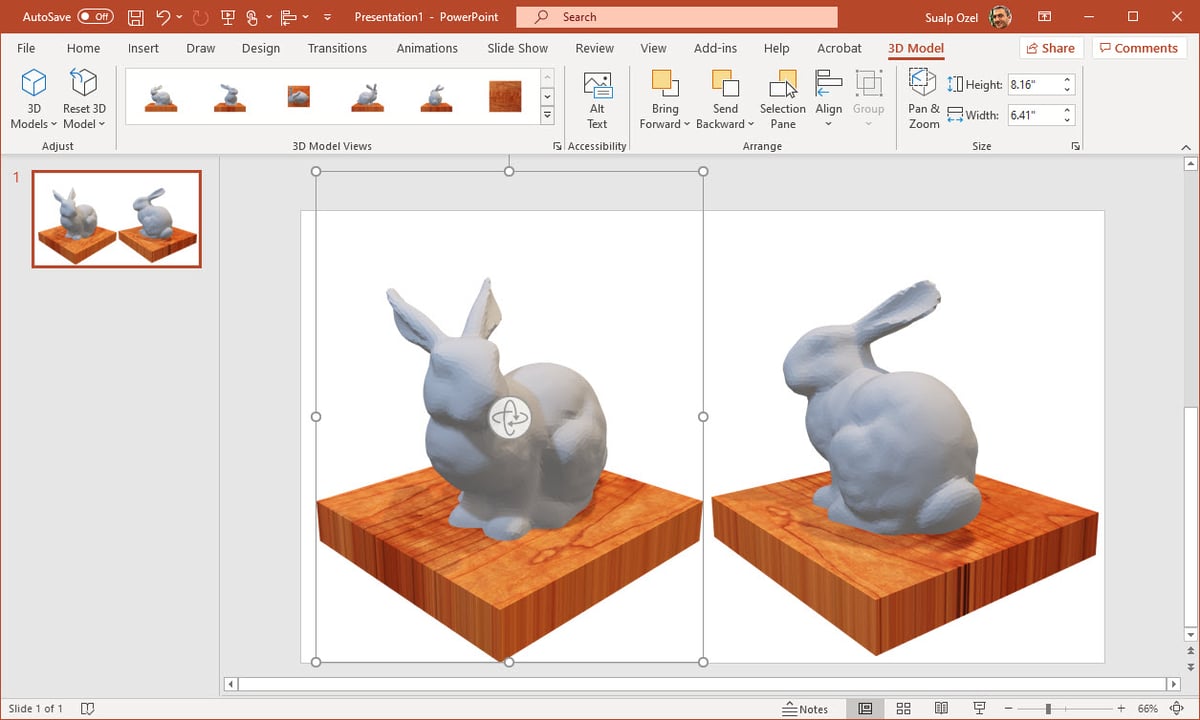

3MF doesn’t suffer from mesh inaccuracies that are endemic to STLs since it contains mathematically accurate geometry data. This data, stored in a human-readable XML format, means you can view the code and modify it directly if necessary.

Finally, STL files include no printer configuration data, unit measurements, or any other information that would be helpful in printing the file. As a result, you may need to do a lot of print preparation work in your slicer or print prep software to get your STL to print correctly.

3MFs, on the other hand, have all of that data embedded, giving you more confidence that your model will print as intended every time. The 3MF Consortium sums it up this way: 3MF communicates to the 3D printer what the product designer intends their product to look and behave like.

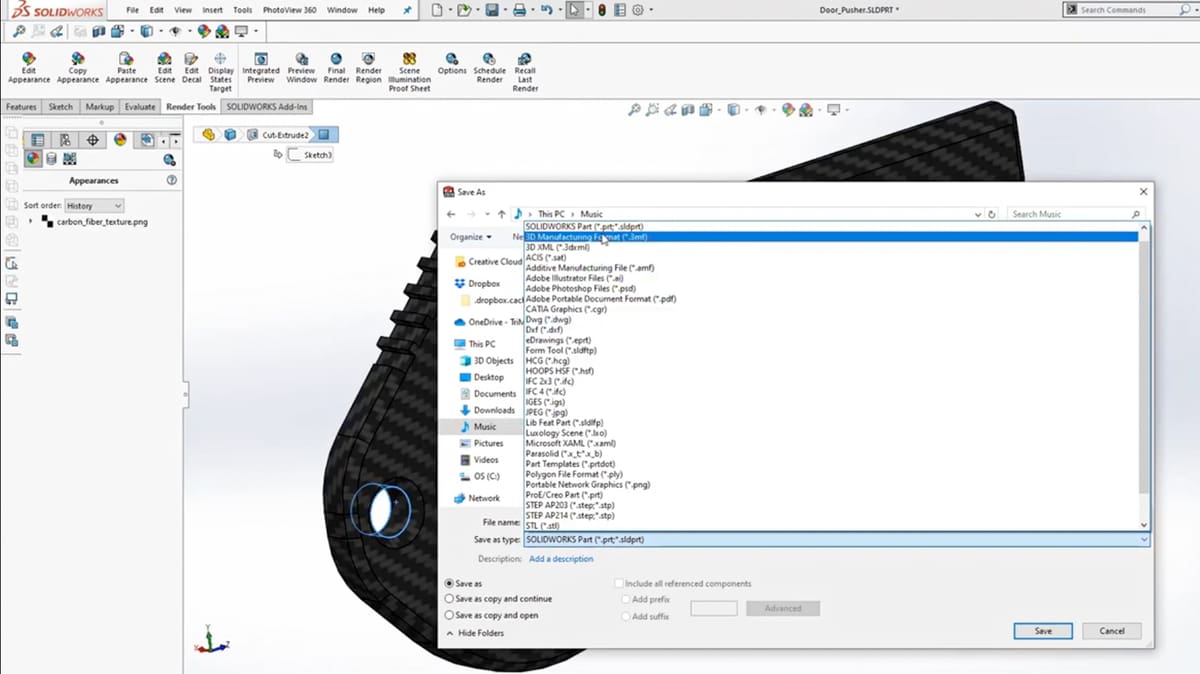

Of course, there are other alternatives to STLs, such as OBJ, VRML, and FBX. However, none of these formats are designed for additive manufacturing. They include a lot of information 3D printers don’t need while also missing data they require. The level of support different software and hardware manufacturers give to these formats also varies wildly.

How Does 3MF Help Industrial Additive Manufacturers?

From the beginning, the 3MF format has been designed for additive manufacturing to make 3D printing operation as fast and efficient as possible.

The print-ready format stores all the support and slicing information in its data archive, making printer-specific slicers obsolete since all information is in the 3MF file. This format makes sharing 3D printing files much easier than ever before and it’s ideal for today’s distributed production. For example, an industrial designer can create a model in a CAD program, such as Fusion, that offers extensions for additive manufacturing to set print parameters, part orientation, and support structures, then send it to any printer anywhere that supports 3MFs.

3MF also supports several security features, such as data encryption. This support is particularly useful in medical additive manufacturing, where unsecured files could violate patient confidentiality regulations, or with military applications where 3D printing is used on the battlefield.

Some people and organizations active in additive manufacturing have expressed concerns that the 3MF format could become proprietary in the future. At the moment, we see no reason to be concerned. 3MF is open-source and available to any company without becoming a member of the 3MF Consortium. The consortium says all its members have agreed to make all necessary patent claims regarding 3MF available on a royalty-free basis.

How to Turn Your STLs into 3MFs

Perhaps this article has inspired you to start using 3MF. If your operation is currently based on STLs, you might be wondering how to switch over to 3MF.

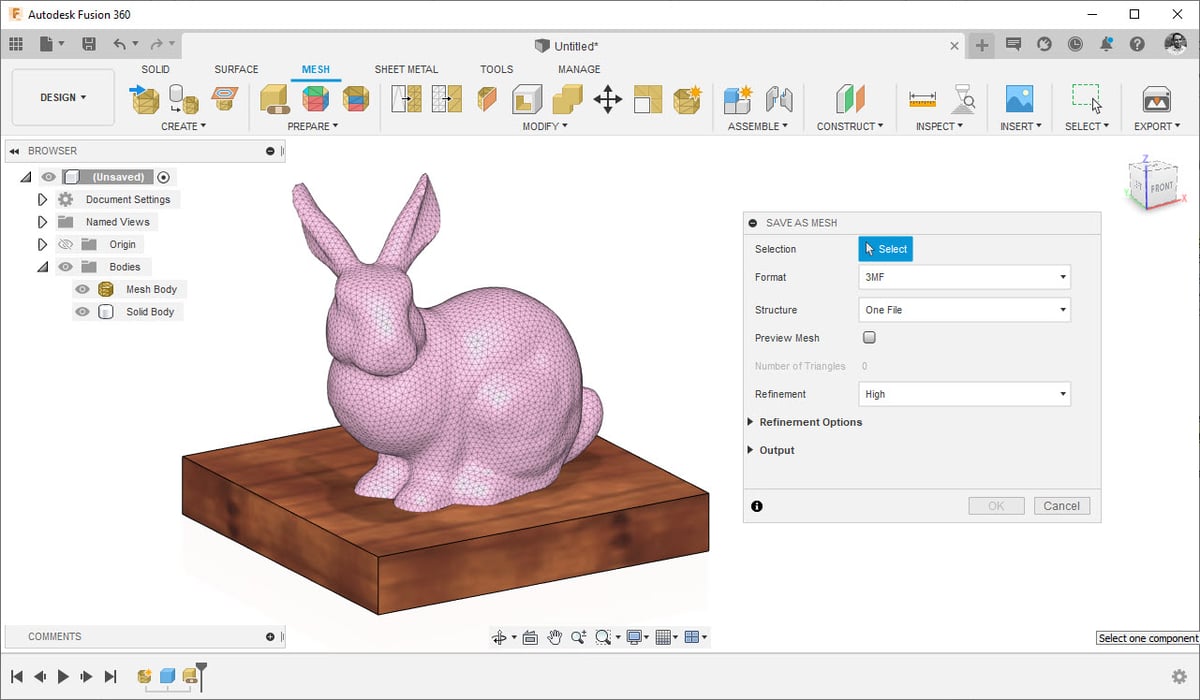

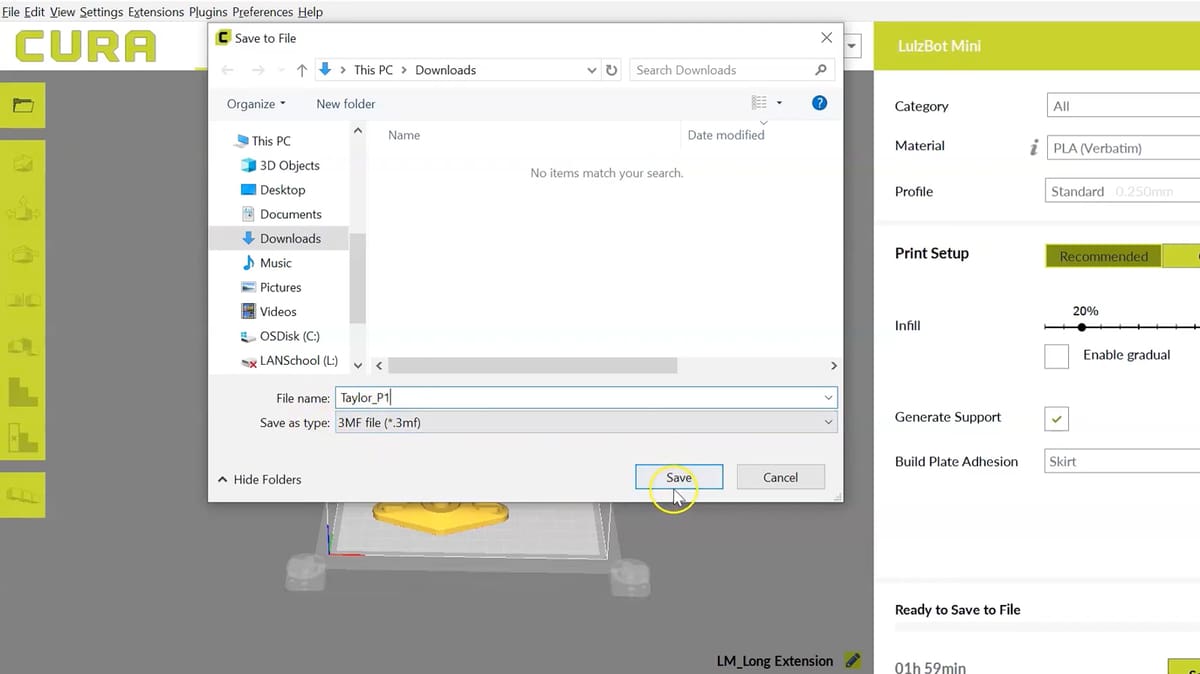

The answer is simple: Just use any of these mainstream software packages below (some free, some paid) as they’re all capable of opening STLs and exporting them to 3MFs. In fact, there are more than 50 software programs that can export as 3MF and you probably already have one.

STL to 3MF Converters

- Autodesk Fusion (free and paid)

- Blender (Free)

- PrusaSlicer (Free)

- UltiMaker Cura (Free)

- Microsoft 3D Builder (Free on Windows)

- Materialise Magics (paid)

Most of these programs see active use in professional additive manufacturing applications, from aerospace to consumer goods. As such, it’s easy for professional 3D printer operators to make the leap to 3MF.

You can also convert your files online without installing any software. Multiple online services, like 3D-Convert.com and SwiftConverter, let you convert STLs to 3MFs with only your browser. Note, however, that the results of these free converters may vary wildly and may not be suitable for professional purposes.

Microsoft, one of the founding members of the 3MF Consortium, aimed to make the format natively compatible with its Windows operating system from the start. As such, you can preview and edit 3MF files directly in Windows with tools such as Paint 3D. Microsoft also has a free STL to 3MF conversion web service that you can access here.

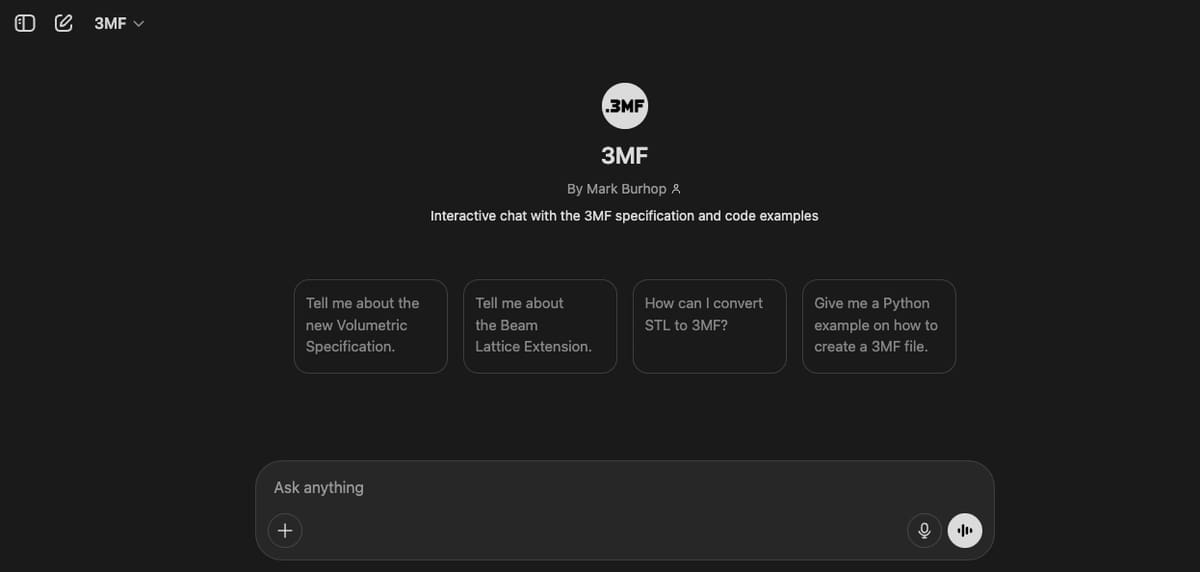

Want More? Ask the ChatGPT 3MF

The 3MF Consortium has launched the ChatGPT 3MF, a version of ChatGPT to answer any of your 3MF questions. “It is designed to serve as an accessible, interactive learning tool for software, hardware, and mechanical engineers seeking to deepen their understanding of the 3MF format,” the Consortium says. “It aims to demystify the complexities associated with 3D printing file formats, providing users with instant access to expert-level knowledge on how to best use 3MF for their projects.”

You can use this ChatGPT 3MF to understand how to optimize a design for manufacturing and explore the benefits of 3MF in creating more accurate, reliable, and functional parts. For software engineers, it provides a deep dive into the technical underpinnings of the 3MF specification, including how to implement and support 3MF in software solutions, ensuring compatibility and efficiency across the additive manufacturing ecosystem.

You May Also Like:

Lead image source: The blue 3MF consortium triangle logo.

License: The text of "3MF File Format – All You Need to Know" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.