Even though a growing number of 3D printers will now print with pure copper, buying a metal 3D printer is a significant investment compared to ordering copper parts from a 3D printing service provider.

However, copper is not yet a common material among service providers. In fact, copper is not on the menu at Materialise, Xometry, Protolabs, QuickParts, or Oerlikon. Fortunately we found five reputable service providers offering copper (and its cousins: brass and bronze), so we put them to the test requesting a quote on a common copper part.

The sample part* we selected was a heatsink designed by a Printables user named InternalError33 and is a model of Creality’s Modified E3D V6 heatsink intended to be used as an aid for designing modifications. Were you to modify this file, you’d likely want a metal prototype to test it.

At most services you can upload your part’s digital file and get a quote right away, yet some will get back to you via email.

| Company | Materials | Technology | Sample Part Price* | Delivery |

|---|---|---|---|---|

| Craftcloud | Cu, (also brass & bronze) | LPBF, FDM, Lost Wax Casting | $126.14 | 10-14 days |

| Uptive | Cu | FDM | $250 | 12 days |

| Forecast 3D | CuCr12r, (also bronze) | LPBF | na | na |

| Protiq | Cu, CuNi2SiCr, CuCr1Zr, (also brass) | LPBF | $267 + shipping from Germany | 22 - 27 days |

| Beamler | CuCrZr, CuNi2SiCR, Cu | LPBF | $595.96 | 10 business days |

3D Printing Copper Overview

Copper is one of the fastest-growing and sought after materials in metal 3D printing and plays a huge role in global sustainability objectives as a key part of e-mobility, charging infrastructure, solar power, and batteries.

Today, 3D printed copper propulsion systems send rockets into space, 3D printed copper heatsinks keep CPUs cool, and 3D printed copper coils boost electric motor performance. Of course, it’s also a perfect material for statues, trophies, personalized coins, and jewelry.

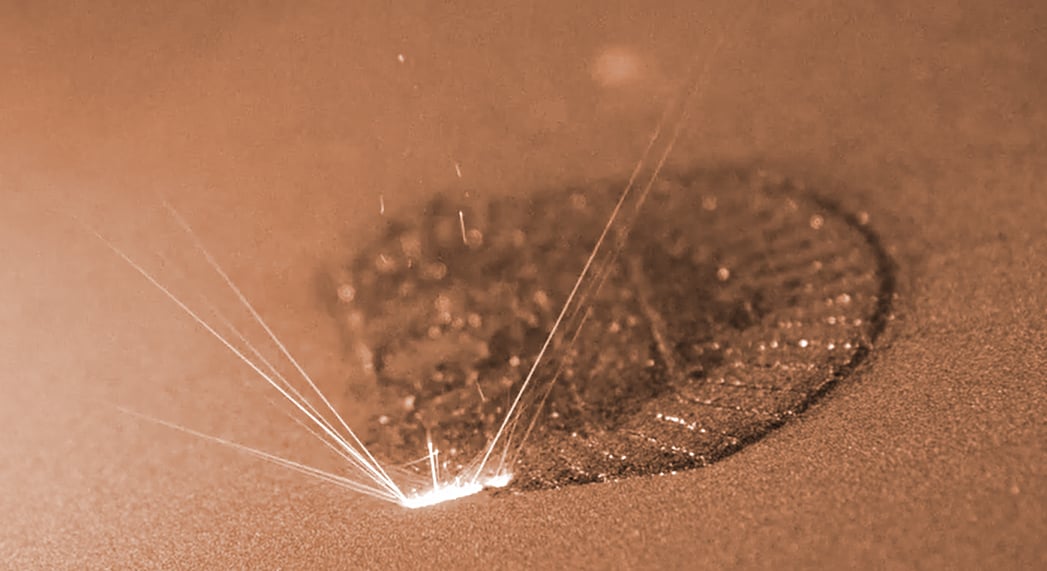

Previously, it was a challenge to 3D print with copper because of the metal’s reflectivity and high heat conductivity. But advances in printers and materials have largely met these early challenges.

3D printing (also known as additive manufacturing) enables the production of exceptionally complex shapes, fine detail, internal structures, and lattice infills not possible with any other type of metal manufacturing. These features reduce weight, increase efficiency, and reduce manufacturing and assembly time. 3D printing requires less raw material — and wastes less — than other manufacturing methods, plus multi-part assemblies can be 3D printed as a single unit, which also reduces the amount of raw material while boosting efficiency.

If you already manufacture custom copper parts, you may be able to dramatically lower production costs while optimizing part performance with 3D printing. There’s also the major benefit of producing prototype copper parts for testing without the time and expense of mold making and tooling required for other metal manufacturing methods.

Top Copper 3D Printing Services

Craftcloud

Craftcloud has you covered for your copper needs with three technologies to produce your parts: laser powder bed fusion (LPBF), fused deposition modeling (FDM), and lost wax casting, which is the preferred method for jewelry making where the mold for the jewelry is 3D printed, not the jewelry itself.

For the FDM option, Craftcloud offers the ADAM technology from 3D printer maker Markforged on its Metal X™ System. ADAM (or Atomic Diffusion Additive Manufacturing) uses plastic-bound metal powder rods fed into an extrusion 3D printer which forms the parts layer by layer. After printing, the parts are washed in a debinding solution and sintered in a furnace. The sintering step burns off the plastic binder and causes the metal powder to diffuse together into dense metal parts.

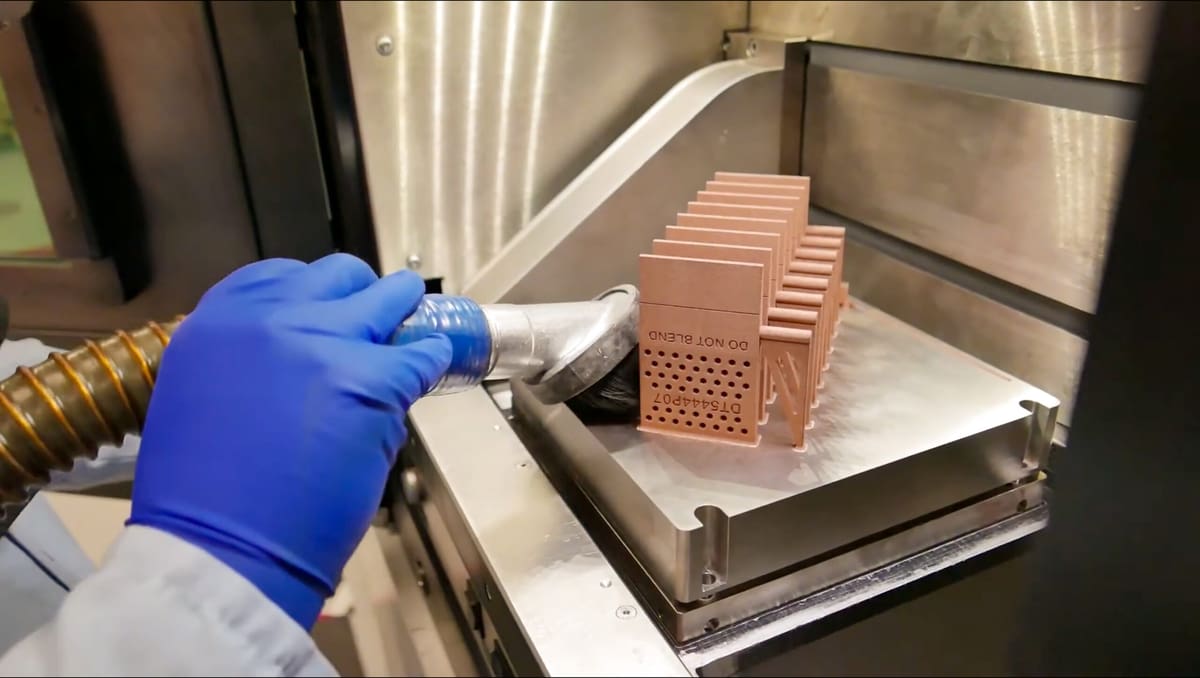

The LPBF solution uses pure copper powder as the base material. It’s then sintered with a laser fine layer by fine layer to create the final part. If you’re interested in jewelry or figurines, you can find out more about lost wax casting in the article linked below.

Uptive

Uptive is an Illinois-based additive manufacturing service that was born from the 2023 merger of competing services Re3DTech and GoProto. It offers traditional manufacturing options alongside 3D printing.

When it comes to copper the offering is a bit murky, which we’ll chalk up to the recent merger of equipment and facilities. In its material menu, Uptive lists four technologies capable of printing copper (LPBF, FDM, DED, and binder jet), but if you drill down, copper doesn’t appear on the individual pages of those technologies.

When we uploaded our part for a quote (no instant quote, only a form to fill out every time you want a quote), we had to first select a technology, but binder jetting or DED were not listed. Uptive calles LPBF “direct metal laser sintering” or DMLS, which is the EOS brand name of the technology.

Forecast 3D

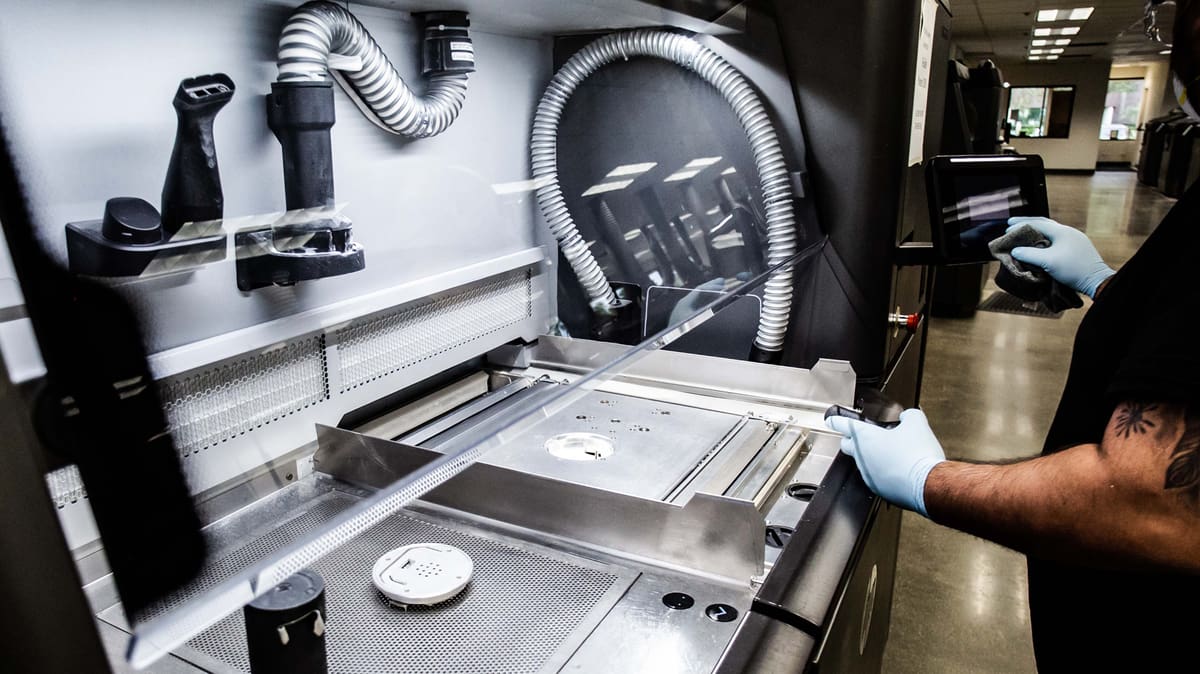

Founded in 1994, Forecast 3D grew from a single-car garage to occupy more than 49,000-square-feet of a Carlsbad, Calif., manufacturing space featuring more than 30 pieces of additive and subtractive manufacturing equipment.

Forecast 3D specializes in metal part production, as well as design and manufacturing services and it always makes our list of top metal 3D printing services. When it comes to copper, however we were a little lost with the quoting platform since it didn’t offer copper as an option. We were able to write it in the notes.

There’s no instant quote option, but if your register on the site you can begin a dialog with their customer care folks to narrow down your needs.

Protiq

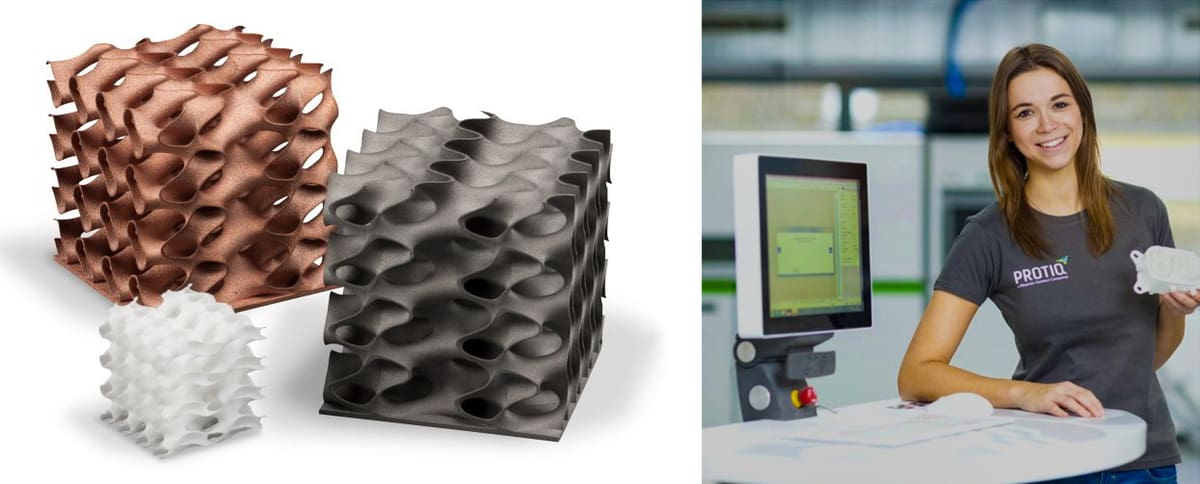

Protiq has a robust service offering in Europe with shipping worldwide. It also cover everything from the design and engineering of your part, simulation of the digital model, through to the 3D printing and even CT scanning to ensure quality. They’ll check your digital file to ensure printability and even reverse engineer a part if you don’t have a digital file of it.

When it comes to copper, we were offered three types and the option to choose the technology.

Protiq operates manufacturing facilities in Germany, the US, and India in addition to its manufacturing partners.

Protiq is as complicated or simple as you want to make it. They offer both a quick web portal where you upload and configure your 3D digital files and receive quotes on your project from a number of suppliers, and it offers a full contract manufacturing relationship.

If the products you’re looking to print are gears, conductors, or other popular parts, the company offers a quick part configurator. With just a few clicks, you can pick your design, material, size, and volume.

Each of the manufacturing partners on the Protiq Marketplace is listed with its materials, technologies, and certifications.

Beamler

Beamler is a Netherlands-based on-demand additive manufacturing platform specializing in high-performance materials like silicone, tungsten, and copper.

Through its newtwork of service providers, Beamler offers copper laser powder bed fusion parts. The company names its specific 3D printers, such as the Trumpf TruPrint 5000 and the Nikon SML 300, but you’ll need to ask which machine will be printing copper parts.

The online quoting system provided a clear way to upload digital files and select materials. There was no instant quote, so we’re waiting for Beamler customer service to get back to us with a figure.

3D Tech for Copper

When you turn to a 3D printing service for your copper parts you’ll may be presented with several technologies to select from: metal laser powder bed fusion, fused deposition modeling, lost wax casting, binder jetting, direct energy deposition. How do you know which one to select?

Our complete guide to Copper 3D Printing linked below covers each of these methods and more to help you make the right selection.

License: The text of "5 Copper 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.