Manufacturers have been stamping, cutting, molding, and welding stainless steel for well over 100 years. 3D printing the metal dates back only decades, but it already rivals traditional methods for speed and cost. Plus, 3D printing enables complex designs not possible with any other manufacturing method, which drives product innovation.

Today, 3D printed stainless steel is used for a multitude of industrial parts, as well as for design, architectural, and artistic applications. Why? Because it’s often faster, cheaper, and more efficient than traditional manufacturing methods. If you’re looking for stainless steel spare parts, prototypes, or tools, there’s a wide services available if you don’t want to invest in your own 3D printers.

We’ve found eight reputable 3D printing service providers offering stainless steel 316L and put them to the test requesting a quote on a common stainless steel part.

The sample part* we selected is a golf club designed by a Thingiverse user named Pozzituwp and is a reverse engineered model of one of their golf clubs. Were you to modify this file, you’d likely want a metal prototype to test it.

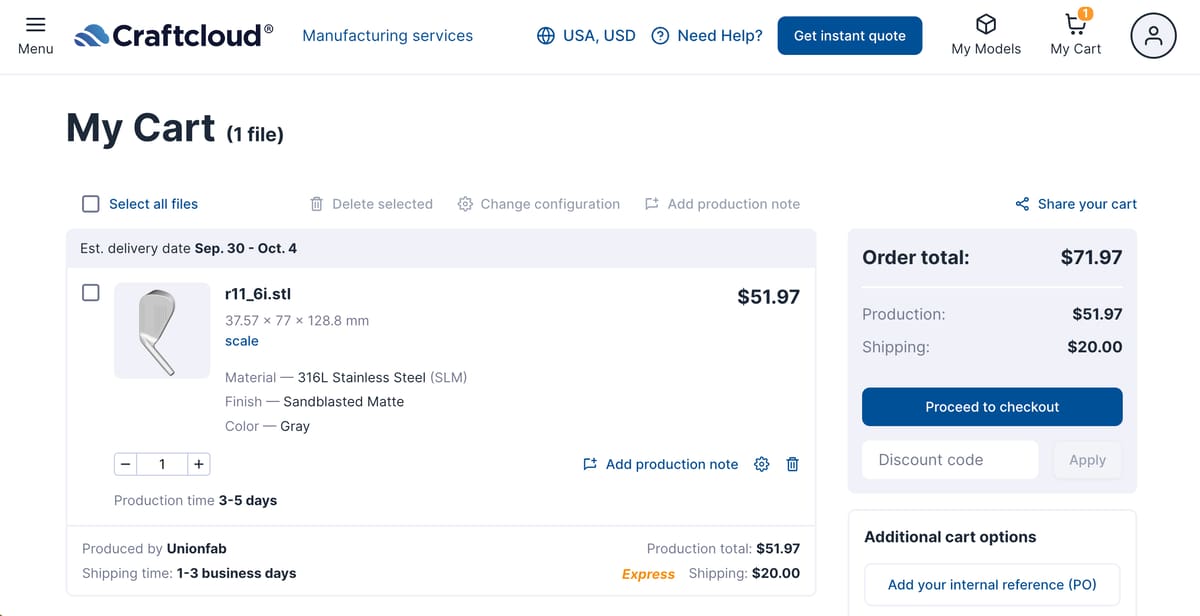

At most services you can upload your part’s digital file and get a quote right away, yet some will get back to you via email. Below you’ll find a wide range of prices for arguably the exact same part. Some of the higher price tags are the result, we believe, of a reluctance of some providers to print a single part. They prefer clients who want higher volume orders, so you’ll see their prices become more competitive as volume increases.

| Company | Technologies for Stainless Steel 316L | Sample Part Price* | Delivery |

|---|---|---|---|

| Craftcloud | LPBF, FDM, Metal Binder Jetting, LMM | $71.97 (LPBF) | 1-3 days |

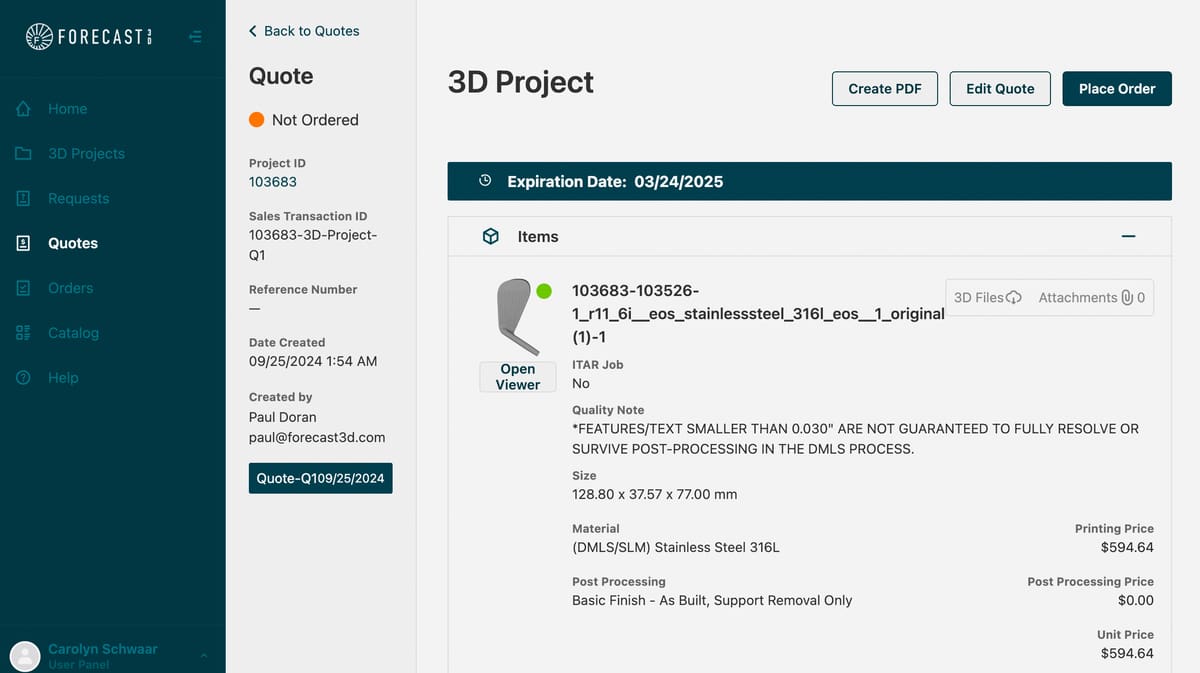

| Forecast 3D | LPBF, Metal Binder Jetting | $594.54 (LPBF) | 6-10 days |

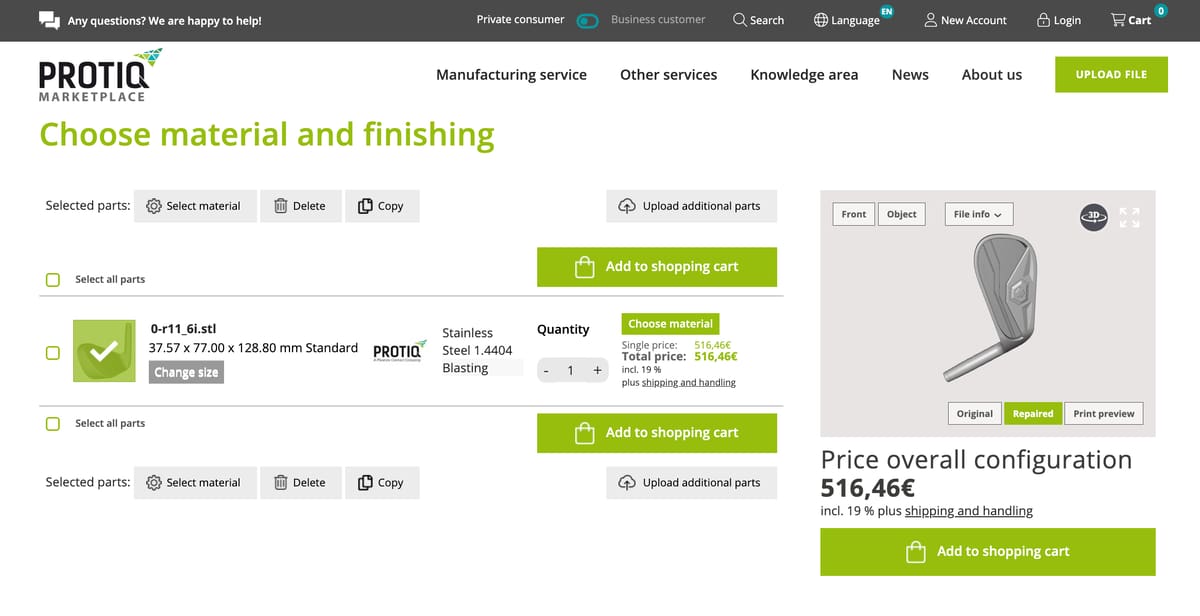

| Protiq | LPBF, LMM | $516.46 + shipping (LPBF) | 3-12 days |

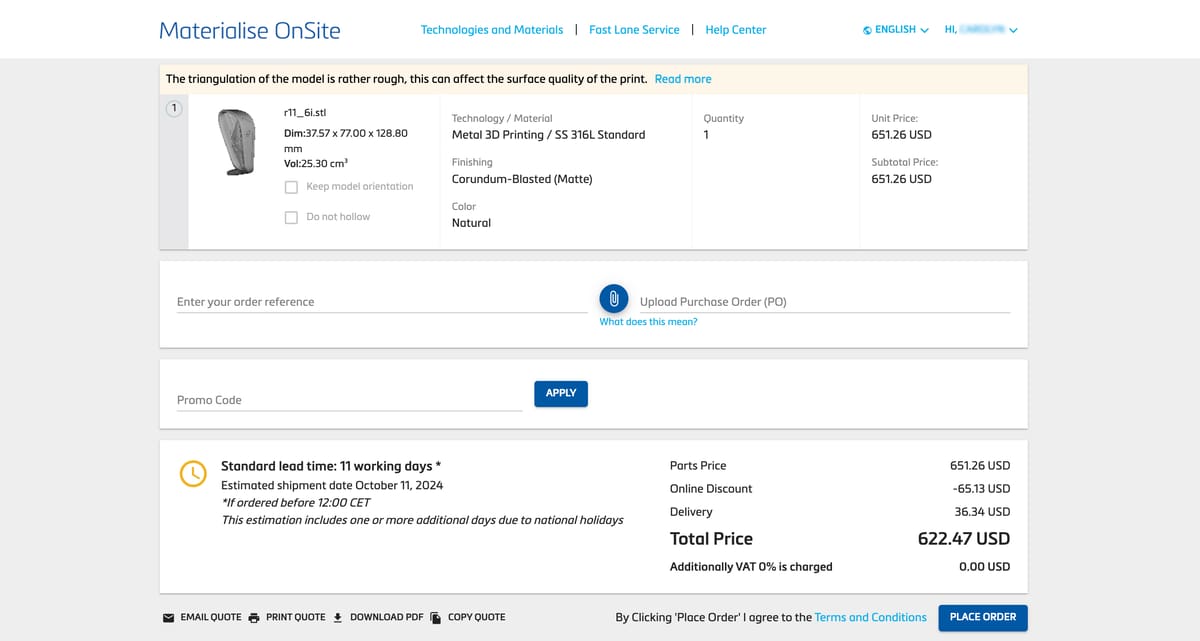

| Materialise OnSite | LPBF | $622.47 (LPBF) | from 11 days |

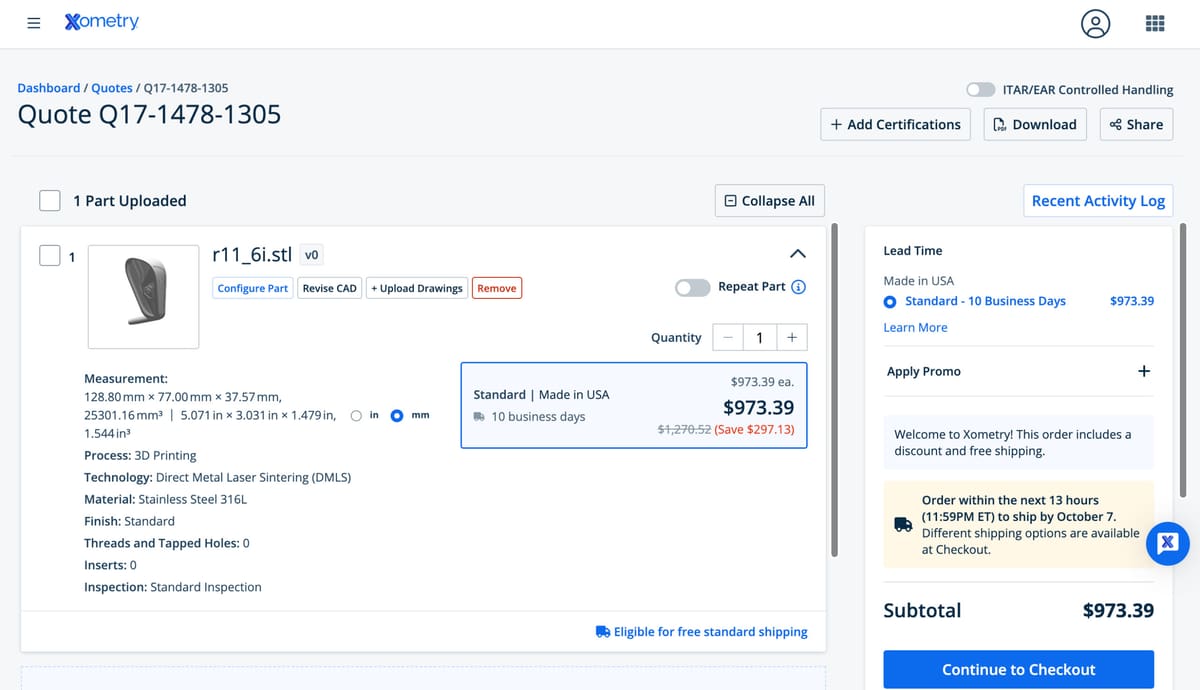

| Xometry | LPBF, Metal Binder Jetting | $973.39 (LPBF) | from 12 days |

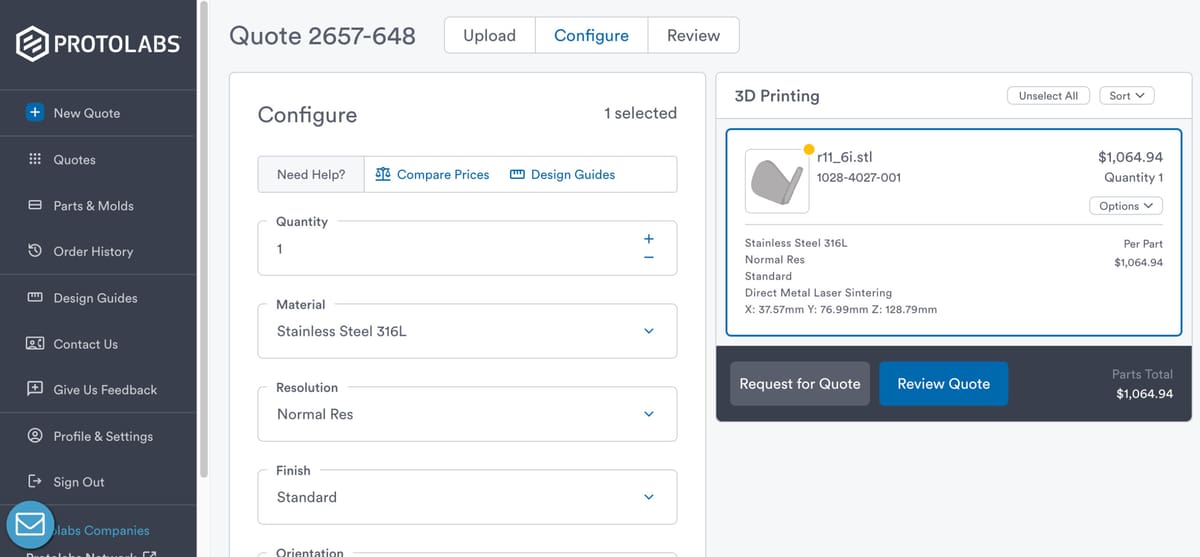

| Protolabs | LPBF | $1,064.94 (LPBF) | 30 days |

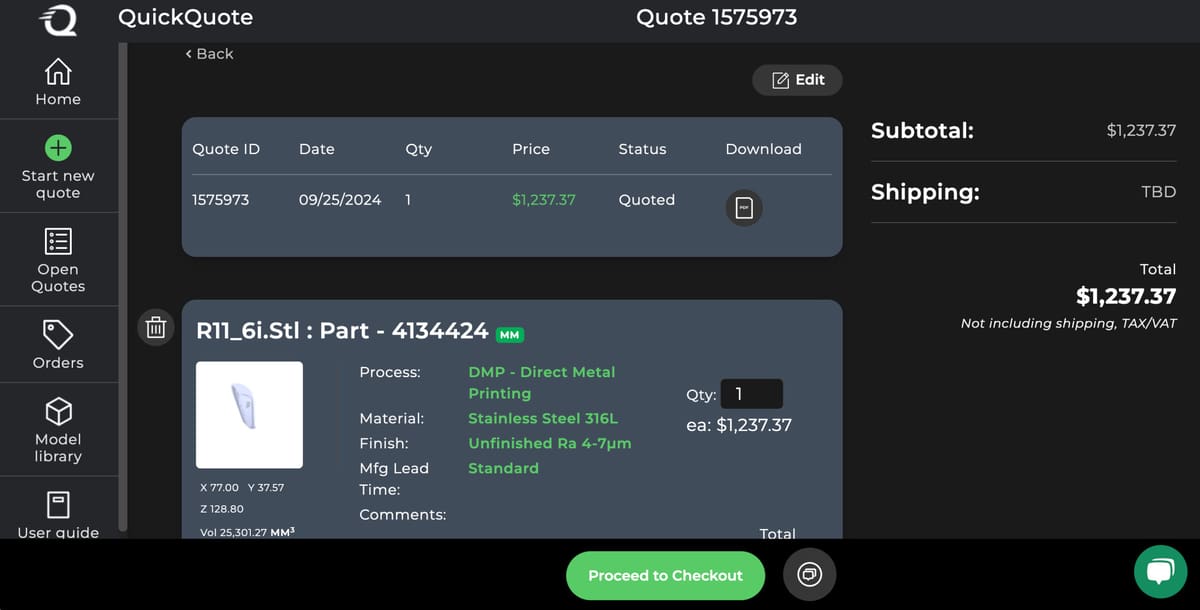

| Quickparts | LPBF | $1,237.37 (LPBF) | NA |

| Beamler | LPBF, Metal Binder Jetting | (pending) | 10 business days |

3D Printing Stainless Steel Overview

From cutlery and surgical tools to auto parts and turbine blades, stainless steel is all around us, and for a good reason. It’s highly resistant to corrosion and heat, and it’s a lightweight and affordable metal, making it ideal for 3D printing. 3D printing uses the same 316L type of stainless steel as other traditional processes.

The mechanical properties of your 3D printed part, however, will vary from a CNC milled part or an injection molded part. The most common question when it comes to 3D printed steel is: “Is it as strong as forged or cast steel.” The short answer is yes … and no.

3D printed steel parts can be as strong or stronger than steel parts made with traditional manufacturing. This depends on a number of variables including your choice of 3D printing method (there are 10), your end use, the type of steel, post-processing, and part shape. In addition, comparisons depend on which aspect of strength you focus on: tensile strength, strength at static load, high cycle fatigue, etc.

3D printed steel is used for aerospace components, military applications, medical tools, and in a wide range of construction projects, so its strength is not in doubt, but let’s look closer.

3D printed steel using one technology in particular, laser powder bed fusion (LPBF), has smaller microstructures compared to cast metal components. This gives them higher tensile properties, but cast parts are currently still stronger overall. LPBF steel is most often used to replace cast components, but in unique cases, 3D printed components can replace forgings.

One study showed that under certain conditions stainless steel parts made on LPBF 3D printers were up to three times stronger than stainless steel parts made by conventional techniques. Another recent study showed that stainless steel 3D printed parts exhibited a yield strength (of 1157 MPa) comparable to its wrought counterpart after precipitation-hardening heat-treatment.

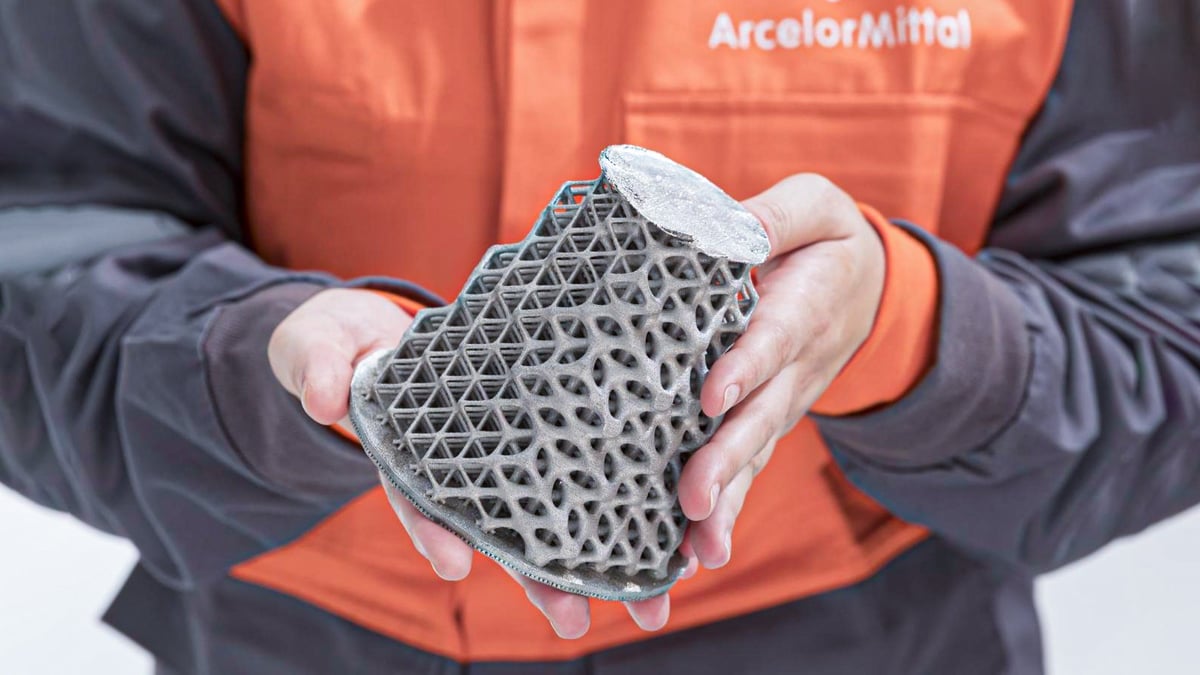

Although 3D printing can be the faster and cheaper way to get the parts you’re used to producing via more traditional manufacturing, the main reason to 3D print parts, however, is so that you can introduce design features that make your part better and aren’t possible (or are very difficult) to achieve with traditional manufacturing methods. These include exceptionally complex shapes, fine detail, internal structures, and lattice infills that reduce weight, increase efficiency, and reduce manufacturing and assembly time.

Stainless Steel 3D Printing Service Providers

Craftcloud

Craftcloud is more than just a metal 3D printing service. It enables you to compare prices and services from different custom manufacturers and find the right one at the right price. With over 150 partners around the world, Craftcloud presents you with the best services in terms of price and lead time, with no additional fees.

Craftcloud has you covered for your stainless steel needs with three technologies to produce your parts: laser powder bed fusion (LPBF); fused deposition modeling (FDM), which is the most affordable option; and lithography-based metal manufacturing, which is for micro-size 3D printed parts.

For the FDM option, Craftcloud offers stainless steel useing the Ultrafuse stainless steel 316L filament. This plastic-bound metal powder filament is fed into an extrusion 3D printer which forms the parts layer by layer. After printing, the parts are washed in a debinding solution and sintered in a furnace. The sintering step burns off the plastic binder and causes the metal powder to diffuse together into dense metal parts. This method is ideal for prototypes.

The LPBF solution at Craftcloud (called either SLM, SMLS, or DMP) uses pure stainless steel powder as the base material. It’s then sintered with a laser fine layer by fine layer to create the final part. If you’re interested in jewelry or figurines, you can find out more about lost wax casting in the article linked below.

Forecast 3D

Founded in 1994, Forecast 3D grew from a single-car garage to occupy more than 49,000-square-feet of a Carlsbad, Calif., manufacturing space featuring more than 30 pieces of additive and subtractive manufacturing equipment.

Forecast 3D specializes in metal part production, as well as design and manufacturing services and it always makes our list of top metal 3D printing services. When it comes to copper, however we were a little lost with the quoting platform since it didn’t offer copper as an option. We were able to write it in the notes.

There’s no instant quote option for stainless steel parts, but if your register on the site you can upload a digital file and begin a dialog with their customer care folks.

Protiq

Protiq has a robust service offering in Europe with shipping worldwide. It also cover everything from the design and engineering of your part, simulation of the digital model, through to the 3D printing and even CT scanning to ensure quality. They’ll check your digital file to ensure printability and even reverse engineer a part if you don’t have a digital file of it.

When it comes to stainless, we were offered 316L for laser powder bed fusion and lithography-based metal manufacturing (LMM) for micro-parts.

Protiq operates manufacturing facilities in Germany, the US, and India in addition to its manufacturing partners.

Protiq is as complicated or simple as you want to make it. They offer both a quick web portal where you upload and configure your 3D digital files and receive quotes on your project from a number of suppliers, and it offers a full contract manufacturing relationship.

If the products you’re looking to print are gears, conductors, or other popular parts, the company offers a quick part configurator. With just a few clicks, you can pick your design, material, size, and volume.

Each of the manufacturing partners on the Protiq Marketplace is listed with its materials, technologies, and certifications.

Materialise OnSite

Based in Belgium with a manufacturing facility in Michigan, Materialise is known for its 3D printing software, yet also offers both a rapid prototyping and on-demand additive manufacturing for volume production. Both options offer metal.

The Materialise portal features an automated check for the 3D printing suitability of your part and optional consultation with engineers. Their services are structured by industry, having set up a department for each major client group, including healthcare, optics, and jewelry.

There are also several business integration solutions, like manufacturing partnerships and white-label integration. This makes it easy for your firm to partner with Materialise to provide parts and services for your customers under your own name. If you sell your own digital 3D models, there is even an integration partnership that enables you to offer your customers a way to order a print of your models from Materialise, and you get a cut.

The company also provides full service consulting, so you can bring them your basic questions or your complex problems and they’ll let you know if metal 3D printing even makes sense for your part or your business.

Xometry

Xometry has become one of the world’s largest online 3D printing service, using a nationwide network of manufacturing partners. It provides instant quotes for many projects filtered by production method, material, and lead time. Beyond 3D printing, Xometry offers a wide range of pro-manufacturing services like CNC machining, sheet metal parts, injection molding, supply-chain solutions, and services you need for high-volume production.

When it comes to 3D printing metal parts, Xometry has the most common technologies in store, namely metal binder jetting and direct metal laser sintering. Material-wise, you get a broad choice of materials like stainless steel, aluminum, titanium, Inconel, or copper, with a variety of finishes.

Using the service is straightforward, but registration is mandatory to get a quote from Xometry.

Protolabs

Minnesota-headquartered Protolabs makes their claim to fame with speed. The company promises very short lead times. They also have a digital quoting platform, which provides not only instant quotes but also design analysis — to make sure what you want to print is printable. Back in 2021, Protolabs joined forces with the online manufacturing platform Hubs, which has greatly enhanced its production capabilities. The Hubs division changed its name to Protolabs Network in 2024, but its services stayed the same.

In Nov. 2023. Protolabs opened a new 120,000-square-foot facility in North Carolina primarily dedicated to metal 3D printing.

Protolabs offers a suite of services around the certification of your part so you feel confident that it will perform as intended, including material traceability, which can be very important in regulated industries. When you receive your metal part you can also get a detailed analysis of the metal powder used and an inspection of the part’s mechanical properties.

Quickparts

Quickparts is a full-service additive manufacturer that grew from printer maker giant 3D Systems. Based in South Carolina, with a global presence, they offer printing and consultation services and can also provide additional services like CNC machining and casting patterns.

Because of its 3D Systems pedigree, Quickparts only offers metal 3D printing on 3D Systems’ laser powder bed systems machines, which isn’t necessarily a drawback considering that 3D Systems are some of the most popular machines on the market.

They have experienced engineers, dedicated project managers, and five well-equipped facilities to handle your low-volume production, although for mass-production, it relies on its casting and injection molding services.

Although we haven’t tested it out for ourselves, we like the idea behind Quickpart’s “Lifecycle Support.” The offering promises to provide you with a dedicated program manager to oversee your part from design to prototype and through to the final parts and evening scaling up to full production.

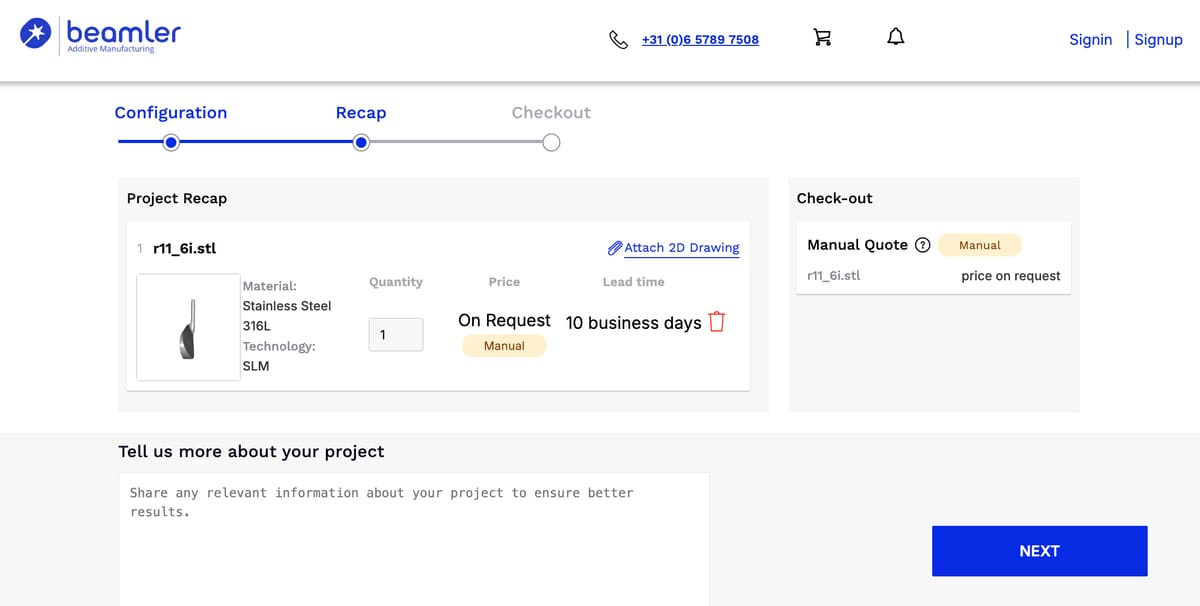

Beamler

Beamler is a Netherlands-based on-demand additive manufacturing platform specializing in high-performance materials like silicone, tungsten, and copper, but it also offers stainless steel in LPBF and metal binder jetting.

The online quoting system provided a clear way to upload digital files and select materials although no instant quote was available for this part, so we’re waiting for Beamler customer service to get back to us with a figure.

How is Stainless Steel 3D Printed?

Most services will offer you laser powder bed fusion (LPBF) — also known as selective laser melting (SLM), laser sintering, direct laser metal sintering (DMLS) — which is the most widely used method of metal 3D printing.

LPBF 3D printers use high-powered lasers to selectively melt a metal powder. The melted parts fuse together layer-by-layer on a molecular basis until the homogenous model is complete. The packed powder on the printing bed provides support to the model during the printing process so supports are rarely required. The surface finish of the final melted part is rough and, depending on your requirements, it may need post-processing to achieve a smooth and shiny result.

When assessing your stainless steel 3D printing options, consider the final part density (90% – 99%), porosity (which could be a drawback or a benefit depending on your application), and the set of mechanical properties required, such as tensile strength.

It is also possible to get stainless steel parts from a technology called fused deposition modeling (FDM) and Bound Metal Deposition (BDM), which are forms of metal extrusion printing. These use filaments or bound metal rods infused with high percentages of stainless steel powder to print. These methods tend to be the most economical and often used for printing small replacement parts or prototypes.

On part with LPBF is metal binder jetting, which is the fastest method of 3D printing stainless steel and used especially for large-volumes of products. Stainless steel powder is deposited at the bottom of a build box, where a print head moves across the box and selectively sprays a binder solution. The 3D model is built layer by layer until completion before it is dried in an oven to strengthen the binder. Because of its speed, binder jetting is most often selected for large-volume consumer products.

There are other methods for 3D printing stainless steel, including cold spray, wire Arc Additive Manufacturing. and lithography-based metal manufacturing (LLM), which is a type of micro 3D printing but they are not widely available from 3D printing services.

You May Also Like:

License: The text of "8 Stainless Steel 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.