ABS (acrylonitrile butadiene styrene) is one of the most commonly used 3D printing plastics; in fact, it’s one of the most common plastics, period. This material is used in all types of things you may have around you now, such as LEGO bricks or your Logitech computer mouse.

ABS is strong, tough, and durable, but not as easy to print as PLA. So, if you’re struggling with printing your ABS parts at home, consider a 3D printing service. ABS is chosen above PLA for a range of reasons: it will distort and bend before breaking, making it well-suited for items that get used often in day-to-day life; it has great mechanical properties and is resistant to high temperatures; it’s also easy to post-process (smooth, paint, etc.), giving you the option to customize your project even further.

This material generally has superior mechanical properties compared to the 3D printing standard PLA and even PETG, particularly when it comes to stiffness and impact resistance. That’s why it’s often used in prototypes and parts that have functional requirements.

Thanks to its low cost and versatility, ABS is a popular choice with 3D printing services when the job requires something economical but durable — plus, it often comes in a wide range of colors.

If you’ve used a 3D printing service before and selected the cheapest material — usually PLA — and weren’t satisfied with the results, here’s why you should consider paying a bit more for ABS next time.

Types of ABS & Finishes

There are many kinds of ABS, including varieties fortified with carbon fibers or Kevlar fibers to make them stronger, as well as blends of ABS with other plastics, such as polycarbonate, that give them extra properties.

There are recycled ABS materials (rABS) and biocompatible ABS that can withstand sterilization and even gamma radiation. Some medical-grade ABS is certified as a medical device. There is also food-grade ABS for food packaging.

In addition to standard ABS, many companies offer ABS-M30, a high-strength formulation that makes it up to 70% stronger than standard ABS filament. Some services only offer this formulation of ABS.

ABS-ESD7, another common choice, is electrostatic-dissipative, making it ideal to be used alongside sensitive electronics without the risk of static discharges damaging delicate components.

Vapor Smoothing ABS

Although FDM is popular for its accessibility and affordability, there can be some downsides, such as visible layer lines that distract from the design itself. This is where post-processing comes in and the ability to sand, smooth, and even paint your ABS parts. In fact, one particular benefit of ABS is that it is highly reactive to acetone, making a process called “vapor smoothing” a popular finishing option.

When ABS material is exposed to acetone in vapor form, the outer surface of the parts will swell. The swelling and subsequent evaporation of acetone causes a rearrangement of the surface structure, completely eliminating any visible layer lines and leaving a clean and smooth surface finish.

Because acetone is a highly flammable and hazardous chemical, it’s a good idea to let a 3D printing service vapor smooth the parts for you.

Comparison Summary

We at All3DP put the top 3D printing companies to the test for their ABS options, including price, delivery time, customer service, and post-processing options. Although the actual parts were not printed and delivered — that would have been wasteful — we took both the instant quote and manual review process for a spin.

Although the term “top” is subject to interpretation, we used the following evaluations to select the companies included in this guide:

- Services and customization: Offering additional services for ABS parts, especially post-processing, finishing, and design is a huge plus.

- Range of materials:The more materials a company offers, the more it can guide you toward the best options.

- Range of technologies: Although there is generally only one way to print ABS (FDM), companies that offer a range of technologies can often give you better price, speed, and quality options.

- Lead and quote response time: You can’t rush quality, but faster response and lead times are imperative if you’re dealing with an urgent project or replacement part.

Comparison Results in a Nutshell

Best for Material Selection

Craftcloud offers ABS in 56 colors, plus carbon fiber ABS, ESD-safe ABS for electronics, ABS Kevlar, and PC-ABS.

Best for Price

For our two projects uploaded to all six sites, Craftcloud had the lowest prices followed by PCBway and Protolabs Networks.

Best for Fast Delivery

Both Xometry and Materialise OnSite has either guaranteed 24 or 48 hour delivery, usually for an extra fee.

Durable Household Appliance

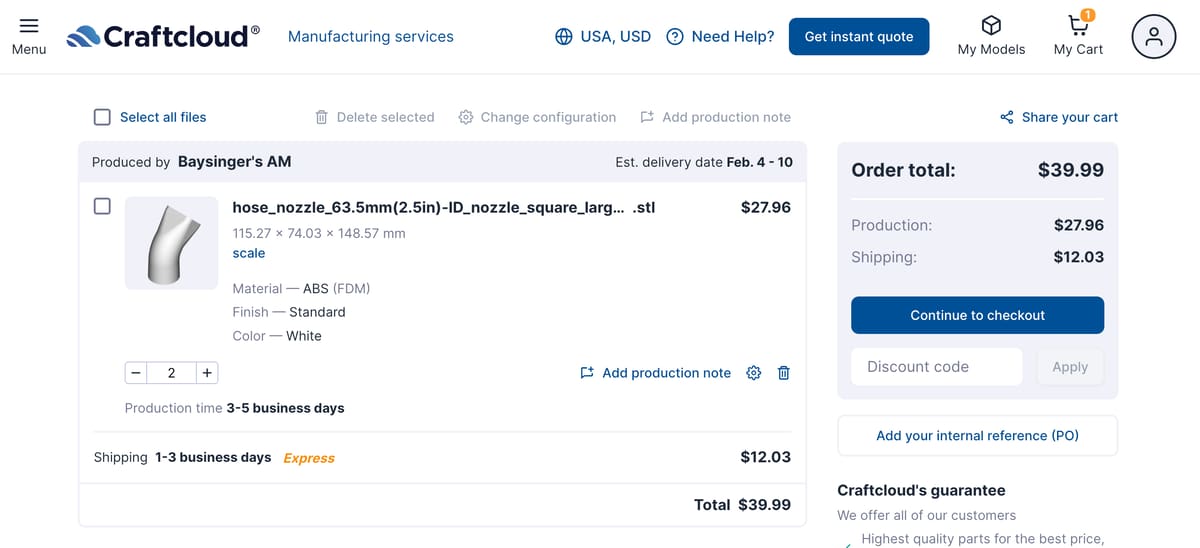

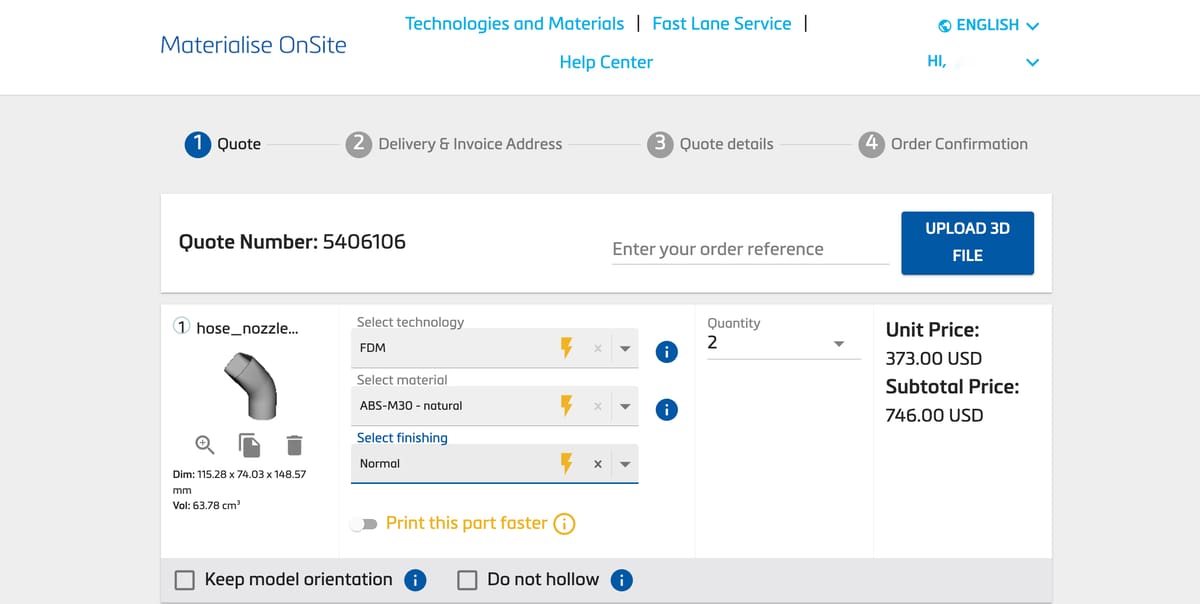

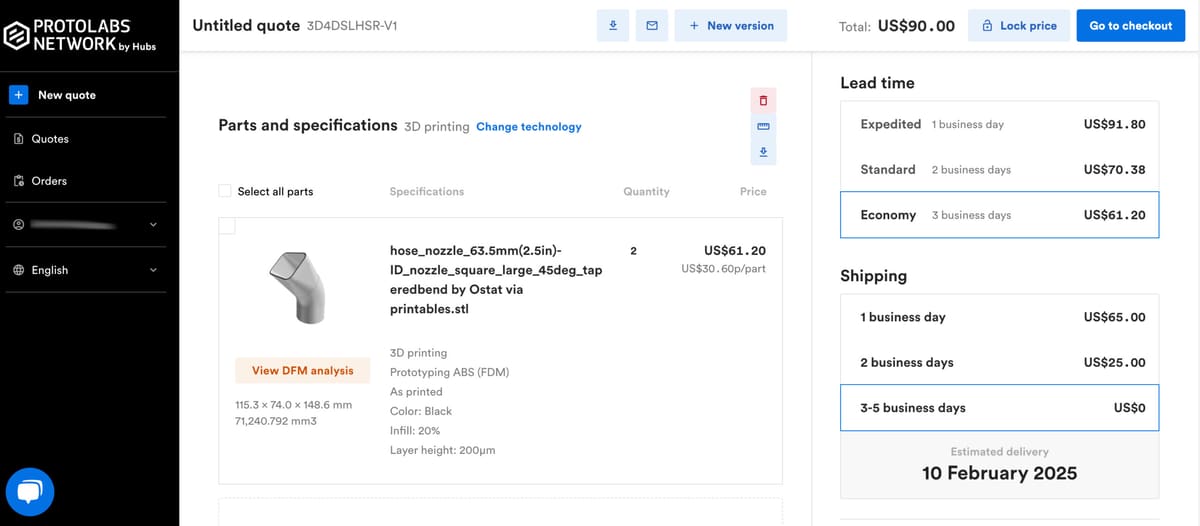

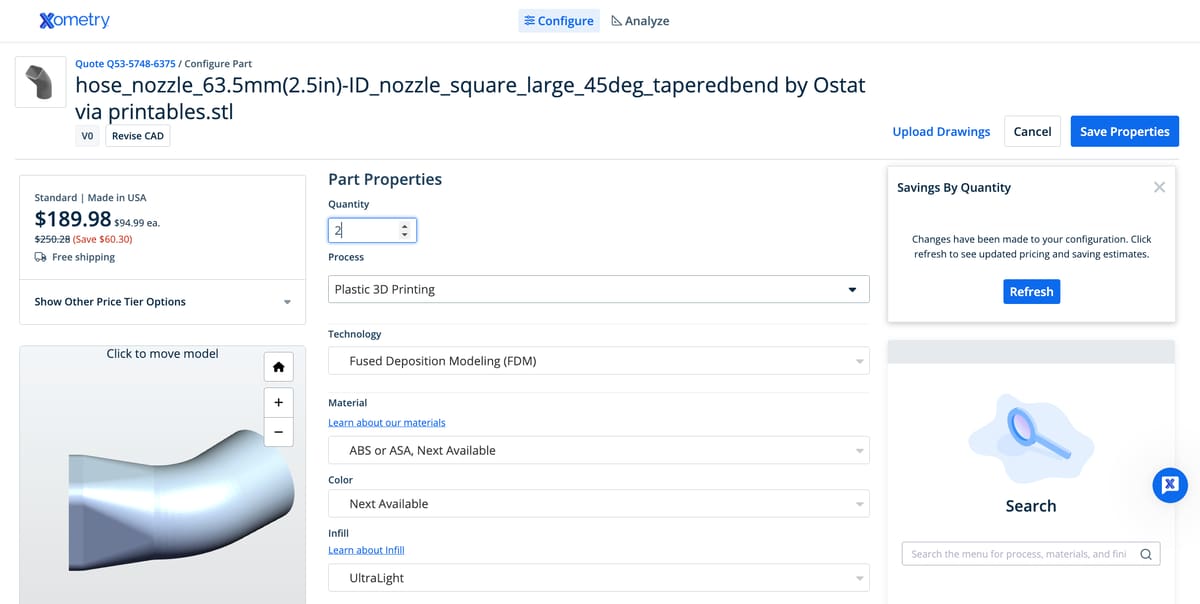

The quotes below represent a total quantity of two parts printed in ABS using FDM, with no post-processing used. It’s important to note the various ABS material on offer at these services. Some are inherently more expensive than others. Services like Craftcloud and Xometry offer both standard ABS and industrial grades of ABS, while Materialise and Stratasys only offered industrial grades. This, naturally, led to a difference in pricing. Standard or prototyping ABS is great for durable end-use parts. The industrial grades are, in our view, only necessary if you’re selling this ABS part and want to go the extra mile for durability, or if you also need the extra qualities that carbon fiber or kevlar filling bring, or if you need the part to be biocompatible or ESD safe.

Prices include shipping except where indicated.

In terms of pricing, Craftcloud beat out all other competitors, with PCBWay in a close second with a much shorter lead time (however, we were not able to factor in shipping times and costs from PCBWay, which is located in China).

Because Protolabs itself does not offer 3D printing in FDM, we turned to its offshoot, Protolabs Network. It’s important to note that Protolabs Network has a minimum order requirement of $90, so while the parts themselves were quoted at $76.50 each, an automatic surcharge is added. Although we selected the “economy” lead time of three days, the “standard” lead time option of two days ends up being a better deal when the minimum order surcharge is factored in. Likewise, Fathom Mfg had a $150 minimum order.

Because Materialise OnSite provides larger discounts for bigger projects, this small run of two parts was the most expensive option available.

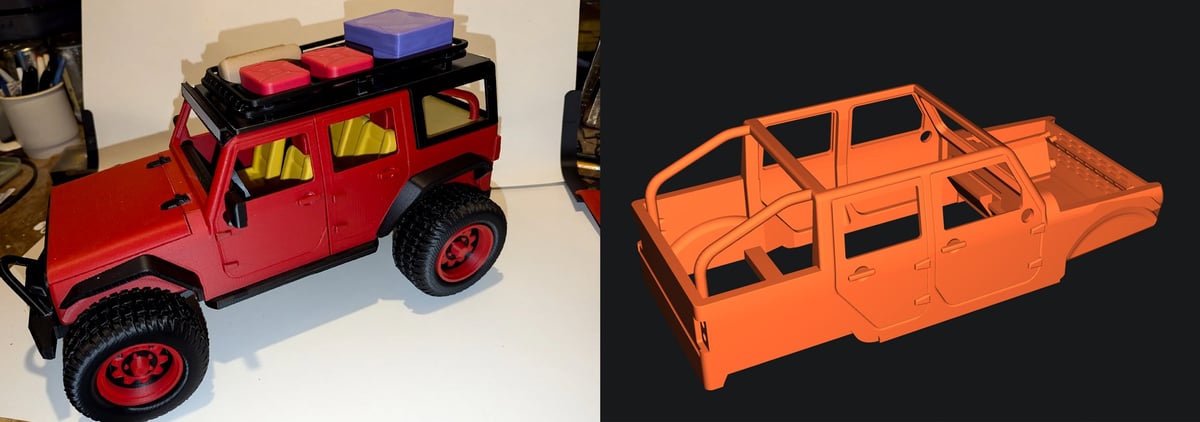

Smoothed Model Parts

The second project we tested is the body of a remote control Jeep. ABS is a great material to use for model kits like these, as they need to be relatively durable to withstand everyday use.

Because model kits are typically painted, we wanted this part vapor smoothed or sanded to give it a smooth surface. The quotes below represent a proposed cost for a total quantity of five parts in a light gray ABS.

Once again, although Craftcloud does not offer vapor smoothing at this time, it is by far the cheapest option for this project — we opted for a sanded finish instead.

Other services, such as Xometry generally offer post-processing, but the options for vapor smoothing or sanding on this particular project was not available at the time of the request. The price reflects the parts made with ABS M30.

With Fathom, vapor smoothing added an additional $143 and 2 days of processing time. While their price tag is slightly high, their customer service was fast, and we received a customized quote within a few hours of our initial request — even suggesting cheaper and more efficient alternatives along the way.

Craftcloud

Craftcloud is more than just a 3D printing service. It enables you to compare prices and services from different service providers and find the right custom manufacturer at the right price.

With partners around the world, Craftcloud presents you with the best services in terms of price and lead time, with no additional fees. Quotes are generated in real-time based on your uploaded models and location. Using the platform is as simple as any other 3D printing service but with many more options available.

Craftcloud offers ABS in 56 colors, plus carbon fiber ABS, ESD-safe ABS for electronics, ABS Kevlar, and PC-ABS.

Materialise OnSite

Materialise OnSite is the 3D printing service that belongs to the Belgian Materialise group, the developers of the popular software suite Materialise Magic. Materialise offers a wide range of 3D printing technologies aimed at the industrial and healthcare sectors.

Materialise actually offers different online 3D printing service portals; there’s i.Materialise, which is aimed at hobbyists and offers one type of ABS (ABS-M30), among other materials. For this article, we used Materialise OnSite, a service geared towards prototyping and professional use, as they offer ABS, PC-ABS, ABS ESD7, ABS-M30, and PC-ABS.

Protolabs

Although Protolabs does not offer FDM printing in their in-house facilities, their offshoot Protolabs Network (formerly Hubs) offers FDM printed parts with prototyping ABS and ABS M30 using Stratasys printers. You can opt to print in 7 colors, with custom requests available.

A huge plus for using Protolabs services is their consistent precision and fast lead time. For the purposes of our test prototypes, we chose the cheapest option — “economy” lead time of three days — but they also offer standard and expedited lead times as short as one day for a higher price. They are an industry leader, serving companies like NASA, Audi, HP, and Intel.

Xometry

US-based Xometry operates a global network of more than 5,000 suppliers for both additive and traditional manufacturing, offering a wide range of ABS materials: ABS-M30, ESD7, M39i, and ABSi. The company’s ABS-M30i is specially formulated to be biocompatible, although it is important to note even though the material is certified as biocompatible, that does not mean the end product will automatically be compliant. Lastly, there’s ABSi, which is translucent.

All 3D printed parts produced in the U.S. through Xometry are eligible for free two-day shipping or ground shipping, and expedited next-day delivery is also available. The company can also ship parts internationally and has production partners in multiple countries. The Xometry website offers instant quotes based on an uploaded CAD model and selected options.

Xometry also offers rapid prototyping, high-volume production, and custom assembly services.

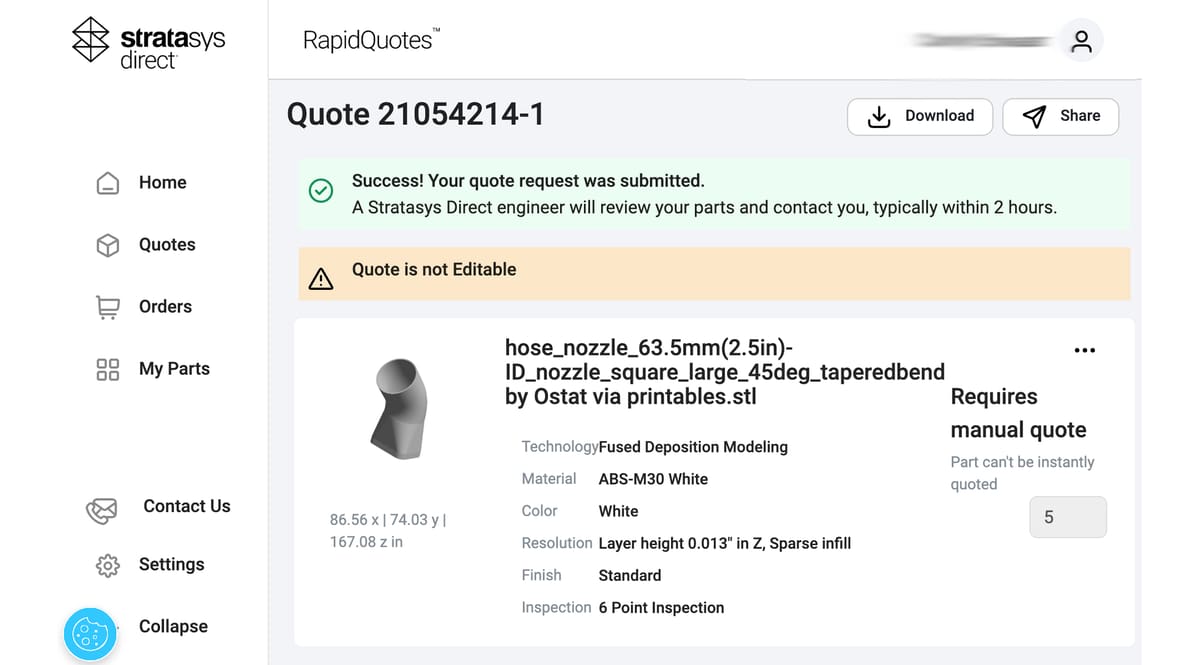

Stratasys Direct

Stratasys is one of the largest 3D printer manufacturers in the world so it makes sense that they would also offer contract additive manufacturing, which they call Stratasys Direct.

Its website offers mountains of resources on additive manufacturing (for free, no login), including case studies, design guidelines, an interactive material wizard to help you select the right plastics or metals for your application, and a “contact an engineer” button for more in-depth help.

The company has seven manufacturing locations throughout the US and one in China, in addition to a global manufacturing network with partners in Europe, Asia, South America, and the Middle East.

In our experience, there was no instant quote option, since every material has a “requires a manual quote” tag on it, yet they did get back to us via email promptly. The company doesn’t bother with standard versions of ABS and instead offers the more industrial version including for medical applications.

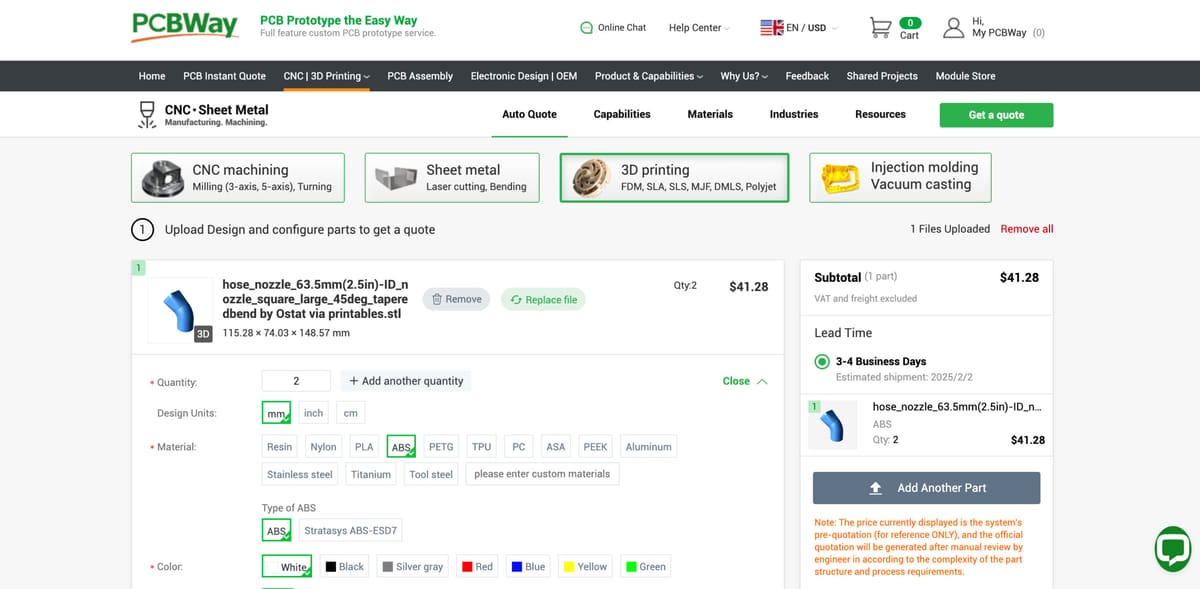

PCBWay

Based in Shenzhen, China, PCBWay is known for its competitive pricing, fast turnaround times. It offers a wide range of manufacturing options in addition to 3D printing, which makes for a bit of a cluttered online ordering experience.

Although PCB prototyping, not industrial parts, is their specialty, the company offers ABS 3D printing with a choice of seven colors. Yet, in addition to standard ABS, they also offer Stratasys ABS-ESD7, an ABS plastic that is static-resistant.

There were no finishing options listed as available on our print projects.

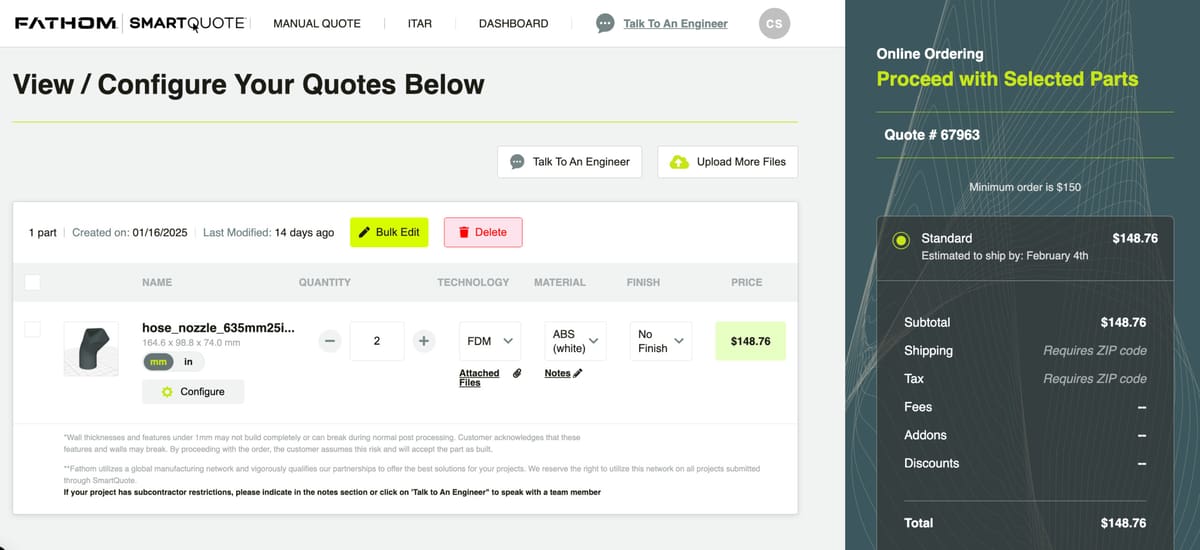

Fathom Mfg.

Fathom is a US-based manufacturing company that offers a range of technologies and materials, offering a few ABS options, such as black, white, and ABS-ESD7. They offered a nice range of finishes for FDM-printed parts, including vapor smoothing.

Although they do not offer a complete list of colors available, they can paint your 3D object upon request. We ran into the company’s $150 minimum order wall with both of our projects and unfortunately the shipping charge isn’t disclosed until after you upload your credit card information. On other sites you submit your address upon registering and shipping is calculated automatically.

Our parts that included vapor smoothing required a manual quote.

ABS-Like Materials & Alternatives

ABS doesn’t come in resin form, but if you’re looking for the qualities of ABS in a resin, there are several “ABS-like” materials for SLA, DLP, and LCD.

ABS on Resin Technologies

3D printing resins do not contain ABS but many, the manufacturers, say produce parts with the same type of strength and stiffness you’d find in ABS parts. Why choose a resin technology instead of FDM? The benefits include a smoother, nearly layer-line-free, surface; the ability to print larger batches of parts is less time, and finer detailed parts.

You 3D printing service provider can detail which resins and which resin technologies may product the ABS-qualities you’re looking for, but below are a few examples.

Digital ABS Plus is a “simulated” ABS material from 3D printer maker Stratasys that’s used with the company’s PolyJet technology. Digital ABS Plus combines high-temperature resistance with toughness and is suitable for parts that require impact resistance and shock absorption.

Tough 2000 Resin is another resin material, this time for stereolithography (SLA) on Formlabs printers, that’s touted as “simulating the strength and stiffness of ABS.” It’s the company’s strongest and stiffest material designed for prototyping strong and sturdy parts that should not bend easily, such as jigs and fixtures.

Lead image source: ABS parts from Stratasys and filament from CoLiDo.

License: The text of "7 Top ABS 3D Printing Services Put to the Test" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.