For small businesses and large corporations alike, buying your first 3D printers isn’t just an equipment purchase, it’s a significant shift in your manufacturing mindset. You’re changing how you approach your product, its prototyping and production, as well as your expectations for R&D, speed to market, and even target consumers. It goes beyond the engineer’s office or the shop floor to encompass every aspect of your business and its future, whether you are focused on one product or how your company will make all of its products.

For many, adopting additive manufacturing is the first step toward Industry 4.0 or the digital transformation of manufacturing. To make this change in the best way with the least amount of stress and the maxim amount of impact, efficiency, and ROI, more companies are turning to additive manufacturing consultants and firms.

With decades of experience, these professional advisors and teams can take the mystery out of 3D printing and guide you in establishing the business case and roadmap you’ll need to be successful.

Additive manufacturing consultants can help you:

- Determine if 3D printing is the right technology for your business

- Determine which, if any, products you make would be better 3D printed

- Advise on redesigning or reengineering your existing products for 3D printing

- Help you select the most appropriate type of 3D printing technology

- Help you select and purchase the best 3D printers

- Help you implement and integrate 3D printing technology into your existing workflow

- Advise on software ecosystems and integrations to optimize production

- Train staff on 3D printing technology and printers

- Help communicate (“sell”) AM to stakeholders

The sales staff at 3D printer manufacturers can provide mountains of information and expertise about implementing additive manufacturing but can’t be expected to be completely unbiased when it comes to which brand or which technology is your best fit.

If you’re looking for independent and experienced additive manufacturing consultants to cover the full business case for AM, the list isn’t lengthy. Considering the vast differences between the seven types of 3D printing technology, the massive amount of material options, and the unique needs within distinct industries, perspective is a rare skill. Note that we do include the consulting wing of one 3D printer maker because of its large size and broad scope.

To spotlight the leading names in additive manufacturing consultants today, we’ve asked them to answer the essential question:

Why Move to Additive Manufacturing?

The Barnes Global Advisors

- Consulting region: Global

- Consulting areas of expertise: Engineering, industrial applications, qualification and certification, strategy, business case and economics, investment, M&A, technical due diligence, training and workforce education, supply chain and industrial base, government, strategy and funding, regional ecosystems, communications, messaging strategy

- Years in business: 6

- Contact: barnesglobaladvisors.com

To AM or not to AM? That is the question. All new technology requires a balance of evangelism and pragmatism. The suite of processes known as additive manufacturing is no different.

We must understand the art of the possible but also balance that with the technical requirements, qualification plans, business case, and people and skills required for success.

When used wisely, AM can improve schedule, scope and cost; these opportunities have only increased with recent supply chain issues related to a pandemic, war, and rising global tensions.

When considering a move to AM, some players are driven by the blue-sky opportunity and others by a fear of missing out. AM adoption should be driven by the ability to solve a problem or achieve an outcome of which there are many; increase product customization, reduce inventory, improve performance, reduce low volume pricing, decrease lead time, enable point of use manufacturing, etc. However, not all AM use cases are created equal.

Prototyping a new design for a fish tagging hook, replacing a long lead time casting for a nuclear submarine, and building an integrally cooled rocket nozzle are all interesting AM use cases, but they all have very different requirements.

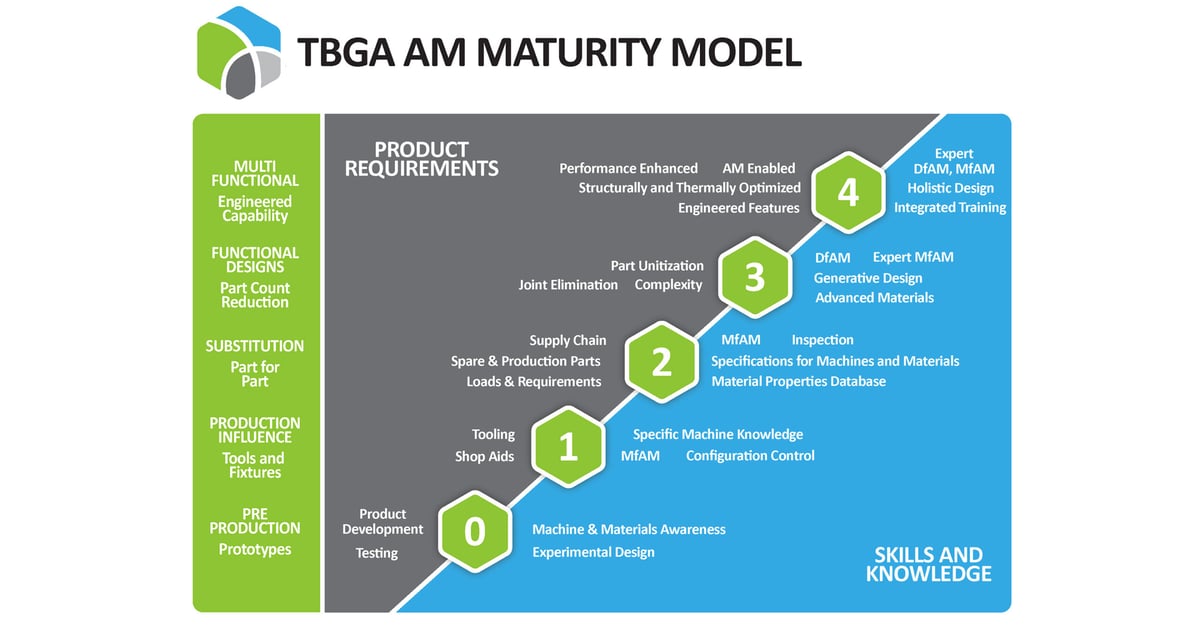

Pulling from our deep industrial experience, TBGA leverages data and custom-built tools to produce insights and actionable plans. The TBGA toolbox includes our Qualification Framework, Process Economics Models, Training, Maturity Model, Readiness Model, and Elements of Safety Checklist, all aimed at breaking down the customer journey into manageable steps, understanding requirements, and aligning to a common language.

The Maturity Model describes the application criticality and associated increasing risk and requirements, with the knowledge and skills required to successfully implement. The application maturity then drives the investment, time and skills required to execute; we advocate for a crawl-walk-run philosophy that achieves ROI and builds knowledge and skills to tackle increasingly difficult requirements. Every group, whether a start-up, precision manufacturer, or the US government, follows a similar approach; understand requirements, choose the right AM process, work through the process to qualify, and guide the business case.

Our job is not to convince you to use AM but rather to arm you with the data and insights to decide whether or not you move to AM.

AMPOWER

- Consulting Regions: Europe, North America, Japan

- Consulting areas of expertise: M&A and due diligence, market intelligence and data, operational excellence, market strategy

- Years of business: 6

- Contact: ampower.eu

AM is an extremely versatile manufacturing technology, so there is not one answer to the question, “why move to AM”. Instead, I recommend evaluating all four areas where AM can add value to a company.

Fast and better product development: With AM, you can bring a prototype to physical form very fast, which enables you to save time and generate better products. Although this reason is obvious, don’t underestimate its impact on your operation.

Tools, jigs and fixtures: Tools are often generating high cost and delay SOP. AM can accelerate by fast availability of even complex Jigs, Fixtures and tools. Also, the cost can be considerably lower. This added value is existent at almost every manufacturing shop floor in the world and is by far the most underestimated market potential.

Spare parts: Especially for casted parts in polymer or metal, AM can offer fast and economical replacements. But don’t underestimate the qualification efforts.

End-use parts: The premier league of AM. The technology can allow you to increase the efficiency of your product, make them more reliable, or simply more functional. But often, the main use case for why companies move to AM for end parts is cost savings. Most of the well-known applications reduced the cost of manufacturing by reducing the complexity of traditional process chains.

When you consider moving to AM, don’t always look at the end parts first. Often the low-hanging and very tasty fruits are in engineering and on the shop floor. The one answer that all four areas have in common, though, is a simple fact that AM can reduce your cost. Only if this is the ultimate goal should you move to AM!

Wohlers Associates, powered by ASTM International

- Consulting region: Global

- Consulting areas of expertise: Market intelligence, business strategy, technical engineering advisory, DfAM and part identification services, training and workforce development, landscape analysis and roadmapping, facility design and build-out support, M&A support, supply chain qualifications, material/process capability studies, and qualification and regulatory acceptance support

- Years in business: 36

- Contact: wohlersassociates.com and amcoe.org

Why move to AM? Consider AM when it adds value. Most organizations start by using 3D printing for basic applications, such as modeling and essential prototyping. Over time, they advance to more rigorous fit, function, and testing applications.

A growing number of companies are considering AM for series production. Justifying its use for end-use parts can involve significant time and effort, and it comes with increased risk. Usually, it requires more than simply comparing the cost of building parts the old way with the new way.

Design for additive manufacturing (DfAM) can be a major factor in determining whether to move to AM for series production. Methods of consolidating many parts into one can make an enormous difference in overall product manufacturing time and cost. Fewer part numbers mean fewer manufacturing operations and less inventory, assembly, labor, maintenance, and certification paperwork. DfAM can also help improve a product’s performance.

Methods of DfAM can help reduce material and weight, which can contribute to building a business case in favor of AM. Advanced design software tools and know-how can result in optimized designs that use a minimal amount of material. Topology optimization and the generation of lattice structures are two approaches. Using DfAM to reduce time-consuming and expensive support material also impacts cost, sometimes significantly.

Whether you choose to produce parts in-house or outsource them, AM needs to be a good fit for the application. When AM adds value, consider putting AM to work. Begin with basic modeling and prototyping before advancing to the production of end-use parts. A growing number of companies are using AM for custom and limited-edition products and are receiving a premium for them.

AM-Cubed

- Consulting Region: Global

- Consulting Area of Expertise: Go-to-market strategy, market intelligence, marketing strategy, startups & emerging additive manufacturing companies

- Years in Business: 4

- Contact: AM-cubed.com

Why move to AM? A better question might be, “When should I not use AM?”. Too often, we see large organizations declare, “We must get into 3D printing!” but with no clear reason why. Or we’ll see a company buy an industrial 3D printer with great enthusiasm only to find the printer sitting idle 12 months later. What happened? Well, there are multiple possibilities, but it often boils down to one thing: If it can be manufactured any other way, it’s likely that additive manufacturing is not the solution for you.

Additive manufacturing is best used to improve upon a design in a way that no other manufacturing solution can provide. While AM can certainly provide cost benefits for low-to-medium unit volumes, you’ll hit a break-even point when unit volumes start to exceed 50,000 – 100,000 parts. This doesn’t mean that it still won’t provide a benefit, but the benefits need to be carefully weighed at this point.

With that said, the business case for additive manufacturing depends on the specific needs and circumstances of each business. But one thing is clear, not every application makes sense for additive manufacturing. Additive manufacturing excels when the application requires light-weighting, part consolidation, customization, supply chain flexibility, frequent design iterations, cost-effective prototyping, or a fast-turnaround time. If your application can benefit from any of these things, then additive manufacturing is very likely a solution you’ll want to explore.

At AM-Cubed we set out to bridge the gap between simple awareness of additive manufacturing and getting it accepted as a mainstream manufacturing technology. We’re inspired by the recognition that for the additive manufacturing industry to flourish, those looking to enter it need to have the proper technical foundation and a good understanding of the business considerations needed to make it a success. Once we have the foundation and tools needed to begin implementing additive manufacturing, all that remains is giving ourselves the permission to start thinking differently.

Additive Minds

- Consulting region: Global

- Consulting Area of Expertise: AM potential assessment and business case analysis; definition of AM entry strategies and innovation/production center implementation; application design, engineering, and process development; qualification of machine, process, and material; development and ramp-up of AM production factories; scaling and automating AM production activities in digital factories

- Years in Business: 9

- Contact: EOS.info

Additive Minds is the technical consulting department of 3D printer maker EOS, combining additive manufacturing know-how from a wide variety of fields and industries. We come from practical backgrounds, and we put the success of our customers first in additive manufacturing applications:

How can you take advantage of additive manufacturing to develop completely new business models, improve the efficiency of existing products and productions and create disruptive innovations?

With more than 100 experts worldwide, we work together with you to develop viable solutions for the future. We offer all-around consulting to analyze your AM potential as well as develop, optimize, and scale your additive manufacturing production activities.

Our experience from more than 500 successful projects shows that AM offers incredible value for organizations beyond the well-known buzzwords freedom of design, lightweight, customization, supply chain resilience, and demand-focused production.

SmarTech Analysis

- Consulting region: Global

- Consulting Area of Expertise: AM Market Data & Intelligence, Business Strategy Consulting, Custom Research

- Years in Business: 10

- Contact: SmarTech Analysis

Why move to AM? There are a variety of reasons. We understand the driving forces behind those reasons, and a review of SmarTech Analysis’ business shines a light on those.

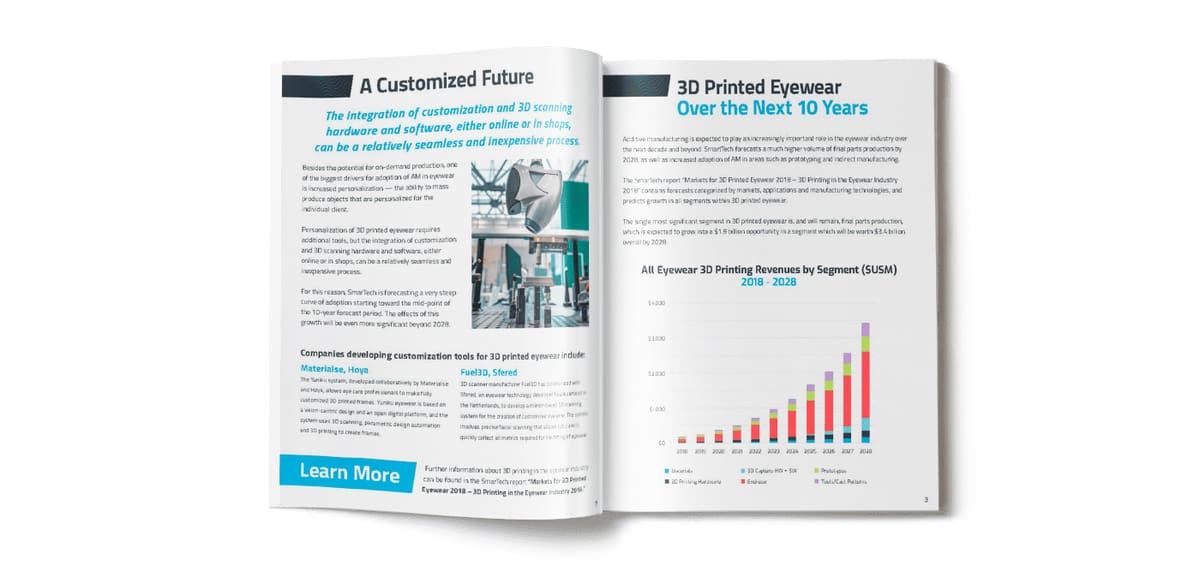

SmarTech’s leading product is its quarterly Market Data which for many years now has charted the industry’s consistent and enduring growth. So we know there is naturally a growing need for AM implementation, and we know where that need is focused at any given time across industries, geographies, and printer technologies.

Beyond market data, we also publish a wide range of research reports covering different segments of the 3D printing market, including materials, hardware, software, and applications. Some of our recent reports include “Additive Manufacturing Opportunities in Automotive Production,” “Metal 3D Printing Opportunities in Healthcare,” and “3D Printed Composites: A Market and Technology Analysis.”

Market data and research help us inform the work we provide for our Consulting clients, working with incumbent players and new adapters alike. Founded in 2013, SmarTech Analysis has established a strong reputation for delivering accurate and actionable market intelligence to its clients, including major corporations, venture capitalists, and government agencies.

AM is a healthy and growing industry with unique characteristics that only increase its value over time. SmarTech is here to help any company on its AM journey.

3Degrees Consulting

- Years in business: 10

- Contact: 3Degreescompany.com

Why move to AM? Because it is difficult. That may sound counterintuitive as a rationale for investing hundreds of thousands — if not millions — of dollars on a technology, but here’s my pitch: The companies and individuals that are able to see the opportunity that 3D printing presents and charge down the difficult path towards making it work will see the payoff. Those that do it the right — bring more sophistication, discipline and proper management to the space — will not only benefit themselves but will be part of building the future of manufacturing here in the US.

I think that’s what ultimately drew me to the space — I loved the challenge of building something new (in more ways than one) and really wanted to help companies realize the potential of this technology. I started my company 10 years ago, right out of school. I had never started a company, much less advised billion-dollar organizations on how to do anything. I made a ton of mistakes but figured it out with a lot of zigs and zags along the way. Now we have multiple employees, a fast-growing AM data management software spinout (TraceAM), and a free training program run to help adults in underserved communities take advantage of the opportunities I see for those with the skills to work in this space.

There will continue to be new technologies, applications, and opportunities to leverage the technology to increase manufacturing competitiveness. My advice to you is don’t be afraid to take some risks. But also, use the fact that it’s still a small industry to your advantage — reach out to those you think can help you, ask lots of questions and get engaged. If you’re new and need to find out who these individuals are, check out the 3Degrees Discussions Podcast (shameless plug) where we interview leaders, entrepreneurs, and innovators in the AM industry.

Rick Neff, LLC

- Consulting region: USA, Europe

- Consulting areas of expertise: Large-scale additive manufacturing, laser systems, all AM processes, composites, metal fabricating, business-to-business marketing, and sales

- Years in business: 4

- Contact: rickneffllc.com

Consultants guide companies to use their capabilities and understanding of their products and market to innovate and be more competitive.

Like any technology, there is a learning curve to additive manufacturing, and adopters have to understand that they will need to get good at designing for additive manufacturing, programming or slicing, optimizing the additive process, managing the data and workflow, and post-processing the parts. But why take on this challenge?

One path to success in business is innovation. Adopting the right innovation mindset can allow you to look at all aspects of your business with a critical eye. It is a great exercise to look at each component you manufacture and find the best way to redesign it or manufacture it to make it better, faster, cheaper, lighter, stronger, or more durable.

One way to accelerate innovation is collaboration. When people with diverse education, background, and experience collaborate, they can see things that individuals cannot ever hope to see. You can strike out on your own and buy a 3D printer and try to see how it will help your business. Or you can collaborate with an expert or a team of experts and achieve quick success.

Most consultants have big networks, so they can introduce you to the right supplier, lab, service bureau, university, or value-added reseller to get you started on your learning curve.

You have optimized your business for the processes you know. Your knowledge of your product and industry, combined with experts in advanced manufacturing processes, can bring amazing results. Collaborating with a consultant as a guide can allow you to find the innovations to transform your products and your business to be the leader in your industry in performance, sales, and profitability.

License: The text of "Top Additive Manufacturing Consultants & Advisors Answer: Why Move to AM?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.