3D printed stainless steel is used for a multitude of spare parts, medical tools, and injection molds, as well as for design, automotive, and artistic applications because it’s often faster, cheaper, and more efficient than casting, injection molding, or CNC machining. Yet, affordability has always been a hurdle, considering that most industrial metal 3D printers start at half a million dollars.

But today, you’re not without options for more accessible stainless steel. There’s a growing range of printers and services that can deliver strong, durable, 99%+ stainless steel parts.

Here we look at your 3D printer options under $100k — some as low as $7k — and what you need to know about stainless steel and the related 3D printing technologies. In the coming years, as the technology matures, adoption expands, and the competition grows, expect to see even more affordable stainless steel 3D printing options.

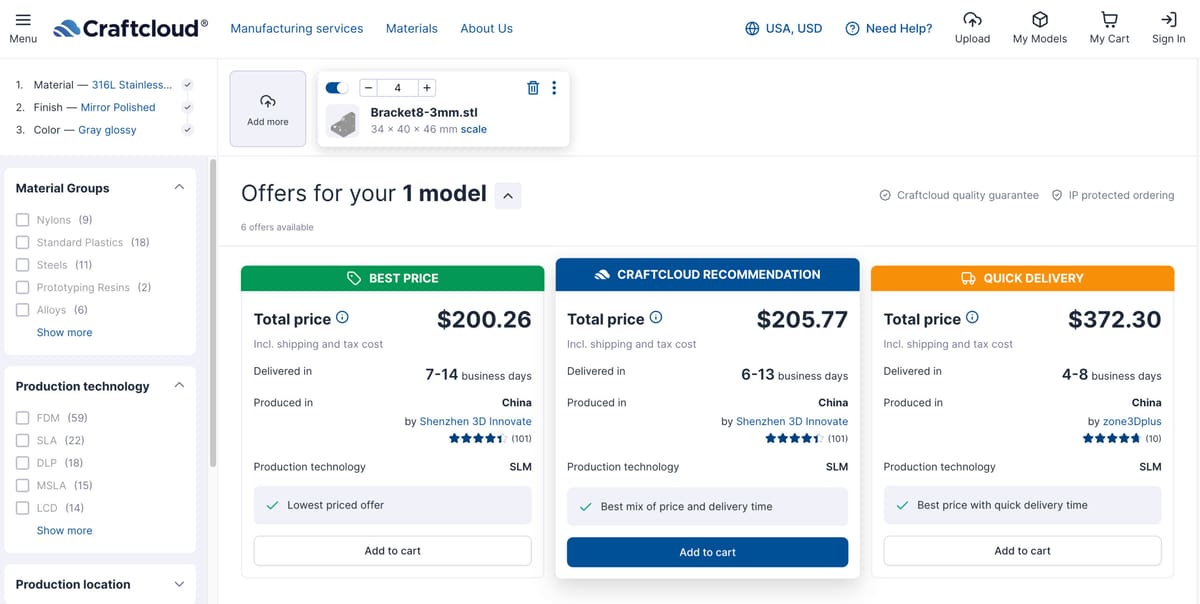

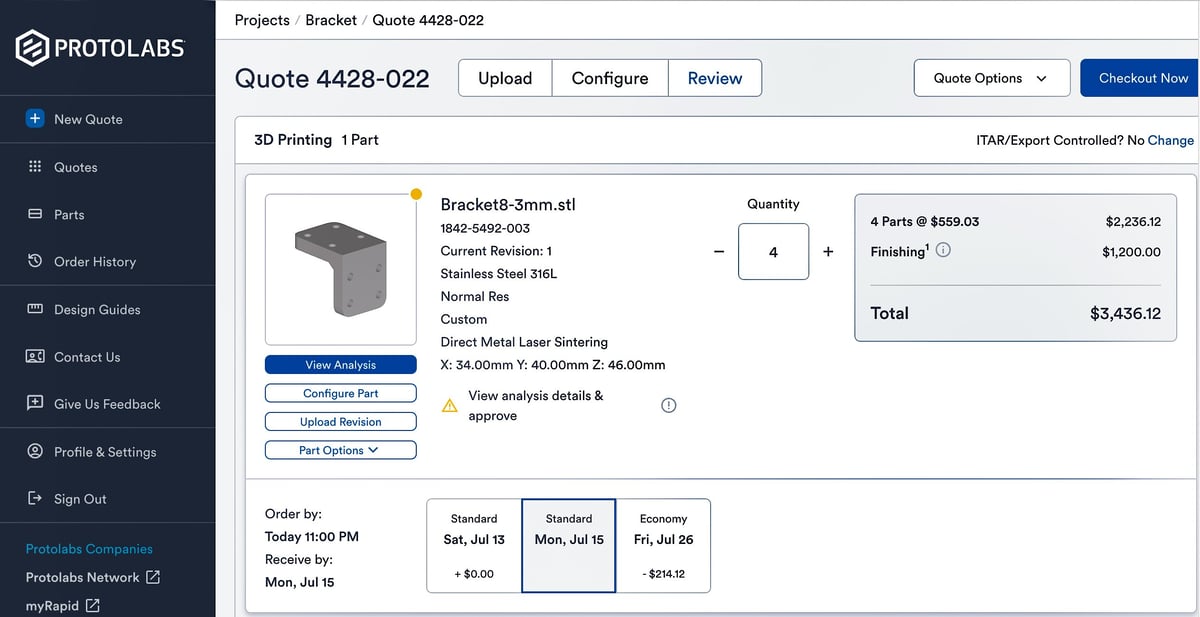

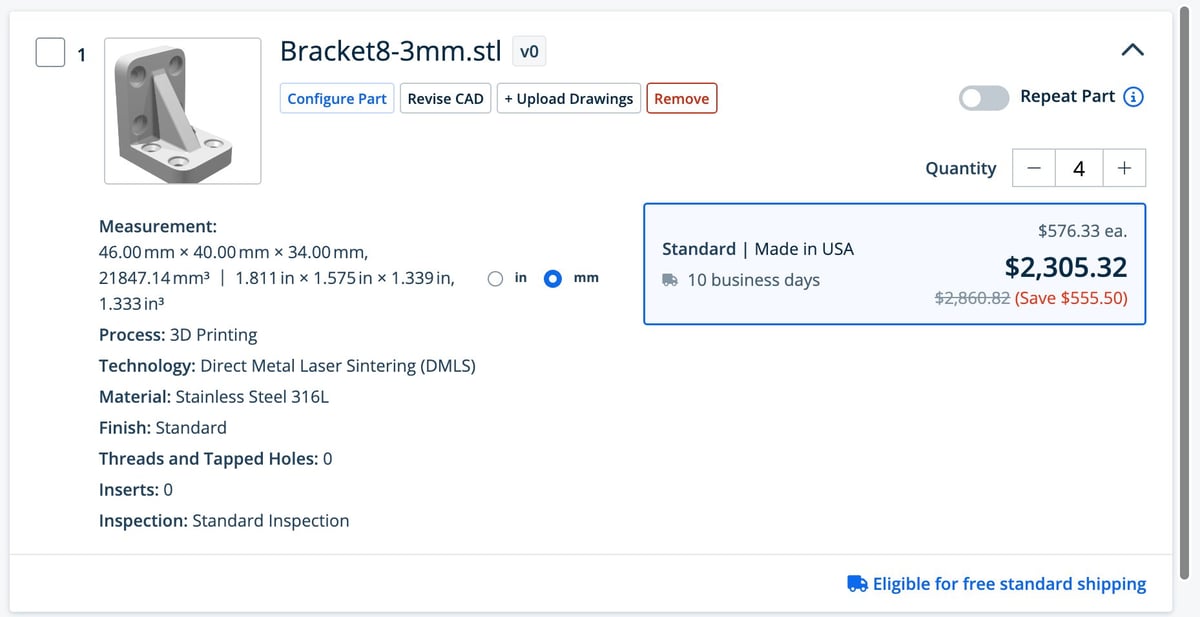

We also took the top 3D printing services for spin, uploading the same digital file of a bracket to be 3D printed in stainless steel. The results range from a few hundreds dollars to a few thousand.

| Metal 3D Printer | Technology | Build Volume (mm) | Raw Material | Printer Price |

|---|---|---|---|---|

| Zortrax M300 Dual | FDM | 265 x 265 x 300 | Metal Filament | $4,300 |

| UltiMaker S5 | FDM | 330 x 240 x 300 | Metal Filament | $7,000 |

| BCN3D Epsilon W27 | FDM | 420 x 300 x 220 | Metal Filament | $7,500 |

| Raise3D Forge1 | FDM | 300 x 300 x 300 | Metal Filament | $10,000 |

| Rapidia Conflux 1 | Extrusion | 200 x 240 x 150 | Metal Paste | $75,000 |

| One Click Metal MPrint | LPBF | 150 x 150 x 150 | Metal Powder | $92,000 |

| Xact Metal XM200G | LPBF | 150 x 150 x 150 | Metal Powder | $95,000 |

Ways to 3D Print Stainless Steel

There are several 3D printing technologies used to 3D print stainless steel. These vary in the raw material, the steps in the process, speed, cost, and other factors we cover in-depth in our Stainless Steel 3D Printing – The Ultimate Guide.

When it comes to affordable, or under $100k, there are only two technologies to choose from: extrusion or laser powder bed fusion. If you order parts from a service you may find more options, such as metal binder jetting and even micro 3D printing often used for medical devices.

Extrusion and fusion both produce solid metal parts but their mechanical characteristics vary. Companies turn to fusion for more detail and more consistent strength in all directions. It’s also the better choice for small or medium volumes of metal parts.

Extrusion is often the cheaper option and ideal for metal prototypes. It can create relative weaknesses along the layer lines but orienting your prints can negate these factors. Extrusion is a multi-step process involving first the printing, then debinding, then sintering in a oven. We cover all you need to know about extrusion 3D printing with metal filament in our guide: Metal Filament 3D Printing – The Ultimate Guide.

Most Affordable Stainless Steel Extrusion 3D Printers

Zortrax M300 Dual

Zortrax is another 3D printer maker that working with BASF Forward AM to develop a packaged solution that enables metal 3D printing on its dual-extruder M300.

Called the Full Metal Package, available in 316L stainless steel or 17-4 PH stainless steel, the kits contains a 1kg spool of Ultrafuse filament, the Ultrafuse Support Layer, a Magigoo Pro Metal adhesive, a M300 Dual hotend module with steel nozzle, and a PTFE tube with adapter. For shipping your printed parts to a third-party there’s also included a voucher good for 500 grams of metal parts and bubble wrap to secure your 3D printed parts for transit.

The Full Metal Package is also available for the Zortrax Endureal 3D printer ($58,000), the company’s higher-temp, more industrial FDM. The Endureal package costs around $800.

UltiMaker S5

UtliMaker took its time developing a metal material ecosystems to accompany its popular S5 3D printer. To ensure quality metal parts, UltiMaker started with the BASF Forward 3D metal filament, then added a print settings in its Cura software for optimized metal part slicing, it says.

The bundle that turns the standards S5 into a metal 3D printer is called the UltiMaker Metal Expansion Kit. It includes one roll of BASF Forward AM Ultrafuse 17-4 PH, the BASF Forward AM Ultrafuse Support Layer filament that created easy breakaway supports for metal parts (only available in Europe), packaging and a voucher for sending one set of green parts to a third-party post-processer (for debinding and sintering), the Ultimaker Print Core CC 0.4, and Ultimaker Print Core DD 0.4 (only available in Europe), and Magigoo Pro Metal adhesive. In addition, you’ll get access to metal e-learning content on Ultimaker Academy.

The one-hour e-learning course covers the full metal 3D printing workflow. By the end of this training, UltiMaker promises, you’ll be fully equipped to create high-quality metal parts with an UltiMaker printer.

The UltiMaker Metal Expansion Kit is also compatible with the company’s S7 3D printer and its MakerBot Method.

BCN3D Epsilon W27

The Metal Pack is BCN3D upgrade offers to the current Epsilon series that opens up metal part production. The parts produced by this process have practically identical behavior to those produced by MIM or CNC, BCN3D says.

The Metal Pack includes both Ultrafuse 316L and 17-4 PH (3kg spools), two metal hotends, Magigoo Pro Metal adhesive, two brass wipers, and an activation code for post processing.

BCN3D has developed a specific metal printing profile for the BCN3D Stratos Slicer that avoids the internal stresses of the printed part during the printing process, the company says. Once printed, debinding and sintering processes can be performed externally through Forward AM’s current network of service providers, which is the same for practically every printer on this list.

Metal Pack is also compatible with BCN3D’s larger (420 x 300 x 400) Epsilon W50 at $8,500.

Raise3D Forge1

The Forge1 from Raise3D is a large-format metal 3D printer designed to print with the BASF Forward AM Ultrafuse stainless steel filament so there are no accessory kits to buy. The Forge1 printer boasts a dual-extruder, automatic bed leveling, filament run-out sensor, and HEPA filter with activated charcoal.

Unlike the desktop FDM printers mentioned above, Raise3D is the first company out of the gate with a complete three-part solution (printer, debinder, and sintering oven) for metal 3D printing so you don’t have to send your parts to a third-party provider for post-processing. Of course, you can send your parts to a third-party if you don’t want to buy the company’s other equipment.

The three-part metal solution is called MetalFuse includes the Forge1 3D printer, the D200-E debinding device that removed the polymer from the green part creating a brown part, and the company’s S200-C vacuum sinter furnace that can reach 1,500 ℃, which turns your brown parts into solid metal parts, all in-house. Note that the printer alone is $10,000, the full suite of equipment is around $130,000.

Raise3D also includes software that automatically accounts for print shrinkage so that the final size after debinding and sintering will be accurate, it says.

Rapidia Conflux 1

Canadian 3D printer maker Rapidia offers the Conflux 1, which uses a water-based paste material inlaid with metal or ceramic powders. Parts do not require a debinding step before sintering like all of the filament solutions above so you can take your printed parts right to the furnace for sintering. The metal paste replaces 98% of the plastic binder with water, which evaporates while printing.

Designed for an office environment and easy to operate, the Conflux 1 is offered with a sintering unit and software for about $100k.

Current materials include 316L stainless steel, 17-4PH stainless steel, and Inconel 625.

Most Affordable Stainless Steel Powder 3D Printers

Most metal 3D printing is done with a technology called metal laser powder bed fusion (M-LPBF), also known as selective laser melting (SLM) or just metal laser sintering. These machines can range into the millions, but a few under $100,000 are touted for delivering an easy entry into metal 3D printing and a way for companies to experiment with the technology before investing in a much larger, more sophisticated metal printer.

Note, at the time of this publication, these printers hovered around the $100 mark, but your custom quote could be more depending on the options you select and your location.

One Click Metal MPrint

One Click Metal started as a spin-off from well-known printer maker Trumpf with the goal of producing affordable, easy-to-use metal 3D printing systems perfect for companies new to LPBF. One Click Metal works with cartridges eliminating the mess of metal powder, and it’s meant to be deployable with fewer requirements in terms of accessories and space.

It has a build volume of 150 x 150 x 150 and comes with the MPrep software and is meant to be paired with the MPure, which is the company’s 3-in-1 unpacking station that depowders the component, screens the powder, and provides recycled powder for reuse. The cartridge system of both the printer and the depowder station ensures easy and safe powder handling so that you have limited contact with the powder. With the side connection for a vacuum cleaner, you can efficiently remove excess powder from the unpacking chamber. The printer and unpacking station are sold as a bundle called the Boldseries.

The MPrint+ printer comes with a signal 200-watt fiber laser power generating a spot size of 45 microns. This affordable metal solution is also relatively zippy at a scanning speed of up to 3000mm/s.

Xact Metal XM200G

US-based Xact Metal offers three laser powder bed fusion 3D printers with the entry level being the XM200G.

The XM200G is aimed at companies that are just starting their entry into metal 3D printing in various applications, including product development and tooling manufacturing. The machine is highly configurable to match different applications. You can select from 100-, 200-, or 400-watt fiber lasers, and to keep costs down some features are optional, such as the glovebox option to ease powder handling and additional sensors for build monitoring.

The XM200G integrates a galvanometer system to move the laser beam over the powder bed. This architecture allows for faster printing times and the ability to support multiple lasers, the company says. The printer offers the option of using two lasers simultaneously with either a 100% overlapping work area using a 100-microns spot size or a 66% overlapping work area using a 50-microns spot size. This multi-laser system further increases build print speeds.

Finely detailed parts are possible due to the machine’s laser spot size range (50 or 100 microns) with a minimum layer thickness of 20 microns.

Most Affordable Stainless Steel 3D Printing Services

Ordering a part in stainless steel from a 3D printing service isn’t complicated but there are some things to know first so you receive the part that you expect.

First, many metal 3D printing services offer a variety of technologies. For example, you can order your stainless steel part made via metal laser powder bed fusion (LPBF), the most common option, or you can order it made via DMLS (direct metal laser sintering), which is actually LPBF but it refers to the process specifically on an EOS brand 3D printer. Some services may call their LPBF process SLM for selected laser melting. These parts should all have the same general mechanical characteristics. You may also select metal binder jetting or metal filament.

Along with the printing technology, you also can choose finishing options. Some services will CNC your part to tight tolerances, some will polish or even paint your part.

We uploaded the same STL file to a variety of metal 3D printing service providers. We selected laser powder bed fusion for all and mirror polishing where available. The given location was Chicago. Below are the results.

Ordering Four Stainless Steel Brackets

Note the dramatic price difference between Craftcloud and the others is due to the fact that Craftcloud does not have a minimum order number. Many others can deliver one part, but then the next price level is for 10 parts or more.

Because metal 3D printing can be pricy, it’s common to order a prototype of your part in a very economical basic plastic, such as PLA, before you go to metal. This enables you to test the printability of your digital file and make any last-minute changes. For a functional prototype, you could print the part in a carbon-fiber nylon, also typically cheaper than metal, for practical testing.

License: The text of "Affordable 3D Printers for Stainless Steel Parts" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.