Overall, 2024 was a decent year for professional and industrial 3D printer launches, but not stellar for a few key reasons. First, the economy delivered a hit to many (not all) printer manufacturers likely putting a halt in their R&D progress, and secondly, what users were asking for were more efficient, productive, and economical 3D printers, which didn’t require going back to the drawing board. Instead, manufacturers made improvements (some very innovative and significant) to existing models.

Industry leaders launched new machines pushing their technology forward and addressing issues, such as price and accessibility, often on the established platform.

Overall in 2024, we saw new printer releases spanning almost every technology, from large-scale industrial FDMs (BigRep, Landr, Roboze, Massivit), to several multi-laser metal powder bed fusion platforms (Eplus3D, Farsoon, EOS), and machines that indicate a new direction from Prusa Research, Formlabs, and UltiMaker as they reach deeper into the business-use market.

The Best of 2024

Of the nearly 40 major new printers that debuted in 2024, only a few got us really excited.

First, there’s the Prusa Pro HT90 filament FDM. If you’re looking to produce functional prototypes and end-use parts from engineering-grade materials, such as PEI and carbon-fiber-infused PEKK, this machine is worth a closer look because, first off, it’s a Prusa, one of the most reliable names in 3D printing, and secondly, it’s significantly more affordable than the competition in the high-temp FDM market. Our thinking here is that the under $10K market for high-temp and advanced material FDMs will see far more interest from users than the over $50K market.

We’re also excited about the Markforged FX10‘s new ability to 3D print metal along with its core capability of continuous carbon fiber. Perhaps the need for both is overestimated, but it’s a first in the market and something only Markforged can deliver. Couple this with the restructuring of Forward AM, the maker of very popular metal filament Ultrafuse, and alternative metal filament machines, like the FX10, may see a boost.

While we’re talking about FDM, we were delighted to see BigRep quickly bring to market the machines of Austrian 3D printer startup Hage3D, a company it acquired in late 2023. Rebranded and upgraded the Altra 280 and the Ipso 105. The Altra 280 has the usual bells and whistles of a high-temp, large FDM plus backup extruders. With up to four extruders, which the company calls DSX (Direct Synchronized Extruders), the Altra 280 is designed to achieve reliable dual extrusion safeguarded by backup extruders.

In metal laser powder bed fusion, we couldn’t help but be impressed with the Farsoon FS811M 12-laser metal LPBF although we haven’t heard of case studies putting those 12 lasers to good use as of yet. Also from Farsoon, there’s the FS721M-8-CAMS. The CAMS stands for Continuous Additive Manufacturing Solution which is an internal conveyor system, which the company says opens up new potential for series production with increased automation. Farsoon launched four new printers in 2024.

3D Systems’ debut of a dual-projector projection stereolithography (or DLP) resin 3D printer, the SLA 270, was a satisfying innovation from the decades-old company showing that it is still the major force in industrial additive manufacturing.

We’re also impressed with Caracol’s first metal wire arc AM system called the Vipra AM, the (other) hot FDM from BigRep called the Viio 250, the much larger cold spray tech from Spee3D called the TitanSpee3D, the much small WAAM tech from WAAM3D called the MiniWAAM that should expand access to this method, and then there was Formlabs first LCD resin printer, the Form 4, representing a shift away from lasers.

In this article, which we updated monthly throughout 2024, you’ll find the major new prosumer, professional, and industrial 3D printers that hit the market. We’ll be tracking all the new printers in 2025 on a monthly basis. No matter which technology you’re interested in and in which industry you operate, there’s sure to be an interesting new printer for you in 2025!

Farsoon's Flight HT601P-4 SLS

(Nov. 21, 2024) Farsoon has been on a roll in 2024 launching machine after machine. At Formenxt, the company surprise-launched a new SLS called the Flight HT601P-4, a large-format polymer PBF system featuring quad 300-watt fiber lasers. The Flight HT601P-4 platform boasts high-speed, large-scale (600 × 600 × 600 mm) manufacturing with “advanced automation” to maximize production yield and reduce cost per part, the company says.

The fiber lasers deliver scanning speeds of up to 20 m/s to ratchet up productivity and efficiency (the two big buzzwords of 2024).

True to Farsoon’s philosophy, the Flight HT601P-4 features an open parameter strategy, enabling users to fine-tune material processing for unique applications.

Farsoon's FS191M Metal LPBF

(Nov. 20, 2024) Farsoon unveiled its FS191M at Formnext, a compact metal laser powder bed fusion (LPBF) 3D printer with open parameters. The Chinese additive manufacturing company says the new metal powder bed system aims to “elevate productivity, enhance cost-performance, and simplify operations” for users working on early-stage projects and low-volume manufacturing.

Building on the original FS121M launched in 2016, the FS191M has nearly four times the build volume in a similar footprint. The FS191M features a standard ⌀191 x 199 mm build cylinder and a single 500W fiber laser. If you’re looking for a metal LPBF device for R&D, the FS191M can be equipped with a much small build platform to reduces material costs.

This new machine also has the features you may be used to from Farsoon’s long line of metal printers, including in-chamber monitoring cameras and an open parameter strategy for full customization.

Tech Specs for the Farsoon FS191M

- Technology: Metal LPBF

- Build volume: φ191 x 199 mm (+optional φ78mm×80mm build platform)

- Laser: 1x 500-Watt fiber laser

Nano Dimension's Exa 250vx Micro-DLP

(Nov. 19, 2024) Nano Dimension (the company that this year acquired Desktop Metal and is finalizing its acquisition of Markforged) released a new machine in its polymer micro-3D printing specialty. The Exa 250vx is a digital light processing (DLP) 3D printer for micro applications, such as connectors and other miniaturized components for electronic devices, optical uses, and even the jewelry sector, but at production volumes.

Exa is compatible with Nano Dimension’s range of existing proprietary resins for its other Fabrica system. There are no details yet on the use of third-party resins.

When All3DP was interviewing Nano Dimension’s senior VP Nir Sade, who is the general manager of the AM division, we had to ask about the plans to combine Desktop Metal, Markforged, and Nano Dimension’s other brands. Although he couldn’t go into much detail since these are publicly traded companies, the vibe was a major consolidation. This makes sense after any merger, but considering the depth of talent at these companies, it’s likely to position the merged entity as a new force in the industry after the dust settles.

Exa 250vx Tech Specs

- Technology: digital light processing (DLP)

- Build volume: 100 x 100 x 70 mm

- Resolution (XY): 7.6 microns

- Layer height: 10 microns

- Price: not available

EOS' P3 Next SLS

(Nov. 19, 2024) EOS, the German-based manufacturer of some of the world’s most popular industrial 3D printers, launched a new generation of its polymer selective laser sintering (SLS) platform to focus on productivity and cost efficiency while maintaining its established reputation for part quality.

The new EOS P3 Next is just that: the next version of EOS’ P 396 launched in 2016, but it’s more than an upgrade. The new system promises a 50% increase in productivity and a 30% reduction in costs compared to the P 396. Key features include a 36% faster “layer creation time”, the ability to swap out build units, and a high material reuse rate (80% with the new ALM PA 950 HD nylon 12 and 70% with EOS PA 2220 HighReuse).

Virginia Palacios, the chief business officer of EOS’ polymer solutions, told All3DP that this new machine hits an important target for volume manufacturing: machine uptime. She says the P3 Next delivers more than 90% machine availability.

Tech Specs EOS P3 Next

- Technology: selective laser sintering (SLS)

- Build Volume: 340 x 340 x 600 mm

- Laser: 1 x 70 W CO₂

- Laser scan speed: up to 10 m/s

- Build Rate: 5.3 liters per hour

- Min. Layer Thickness: 0.06 mm

- Materials: At launch included PA 2200, PA 2220 HighReuse, PA 2201, PA 1101, PA 3200 GF, PA 2141 FR and ALM PA 950 HD. Additional materials qualified per customer request.

Prusa Core One FDM

(Nov. 19, 2024) The media is usually informed in advance about the launch of new machines, but companies like Prusa are often very tight-lipped. This was the case with their new Core One.

The Core One is Prusa’s second CoreXY system after its Original Prusa XL launched last year. Despite a heated enclosure (up to 55°C) and notably condensed footprint (compared to the MK4S), it boasts a larger 250 x 220 x 270 mm build volume. The system has an active chamber temperature control, which Prusa says eliminates the need to open doors or top covers for prints with low-temperature materials like PLA or PETG, thanks to two high-performance fans.

And, of course, the system is designed for temperatures that thrive with an enclosure like ABS, PC, and PA. Prusa boasts the machine as fast heating without needing any additional heating components.

The Prusa Core One is available to pre-order today for $1,199 as a fully assembled system with DIY kits and MK4S conversion kits following at a later date. That also excludes cameras, which will become available soon for €40.

Core One Tech Specs

- Technology: FDM

- Build Volume:250 × 220 × 270 mm

- Min. Layer Height: 0.05 mm

- Max. nozzle temp.: 290 °C

- Max. bed temp.: 120 °C

- Max. chamber temp.: 55 °C

- Materials: Open materials

- Price: $1,100

Renishaw’s RenAM 500D Metal LPBF

(Nov. 18, 2024) UK-based Renishaw launched the latest offering in its RenAM 500 series of metal LPBF machines at Formnext. The new RenAM 500D has the same Tempus technology that allows the lasers to fire while the recoater is moving, improving overall efficiency. This can save up to nine seconds per build layer to achieve a build rate of more than 200% faster than conventional single laser systems, depending on part geometry, according to Renishaw.

The machine has two 500W ytterbium fiber lasers, a beam focus diameter of 80 μm with dynamic focus, and a build volume of 250 x 250 x 350 mm.

Other than the dual laser, the machine is pretty much the same as the core 500 series, which includes the single laser 500S and four laser 500Q.

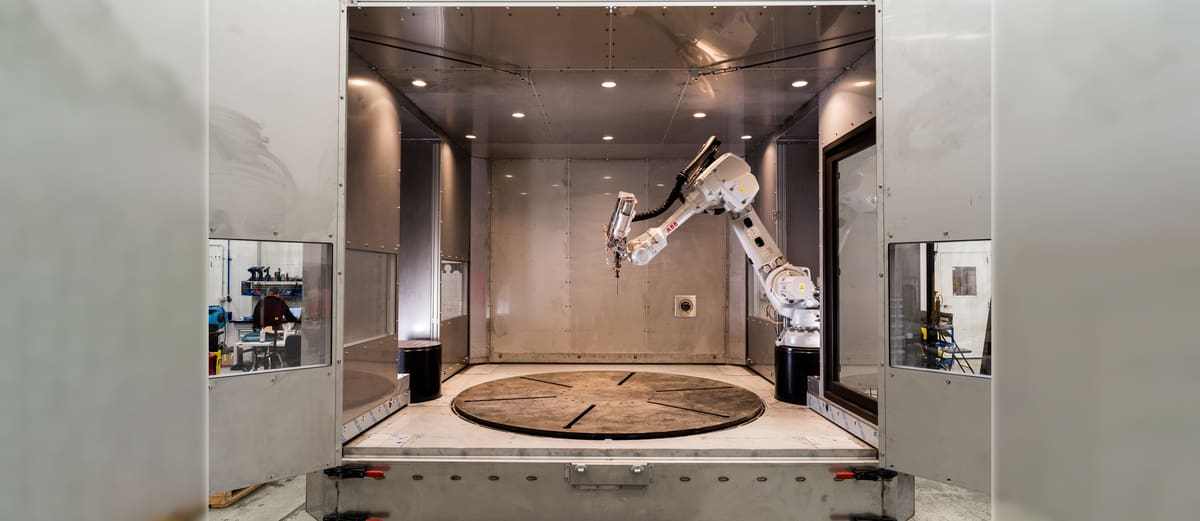

Caracol AM's New Vipra AM Metal WAAM

(Nov. 8, 2024) After making a name for itself as a 3D printing service featuring large-format robotic arm extrusion 3D printers with custom-designed print heads, Italy-based Caracol AM launched its first large-format polymer extrusion 3D printer, Heron AM, in 2022. This week it takes a bold new step into metal 3D printing with the launch of Vipra AM.

“With Vipra AM, we’ve leveraged the extensive know-how developed over years working on advanced process control and software for large format AM with thermoplastics and composites materials, to develop a proprietary cutting-edge metal platform that combines state-of-the-art hardware and software, with advanced robotic monitoring and automation,” says Francesco De Stefano, CEO of Caracol AM.

Vipra AM, available in two configurations (XQ and XP), is a directed energy deposition (DED) 3D printer, or more specifically, a wire arc additive manufacturing (WAAM) 3D printer. This type of 3D printing uses metal wire as the material and a plasma arc as an energy source, similar to welding. The arc melts the wire as it’s deposited layer on top of layer by a robotic arm onto a surface, such as a multi-axis turntable.

Addimetal’s New K2-2 Metal Binder Jetting

(Nov. 7, 2024) French 3D printing start-up, Toulouse-based Addimetal is launching its first machine at Formnext: a metal binder jetting solution that’s more affordable than the competition. It features open perimeters and is open to third-party binders and metal powders from the metal injection molding industry.

After four years of development and a year of beta testing, the K2-2 offers manufacturers what the company is calling a “breakthrough solution” to produce complex metal parts with precision and speed.

The K2-2 features an 8-liter capacity with a 200 x 200 x 200 mm build volume, which makes it the smallest metal binder jetting 3D printer on the market behind the Markforged PX100 at 250 x 217 x 70 mm.

Addimetal K2-2 Tech Specs

- Technology: metal binder jetting

- Build Volume: 200 x 200 x 200 mm

- Resolution: 360 – 1080 dpi

- Layer Thickness: na

- Build Capacity: 8 L

- Materials: Open materials can be qualified, available currently 316L stainless steel and Inconel 718 nickel alloy with binders.

- Price: Starting around $200,00

Lithoz' New CeraFab System S32 Ceramic DLP

(Sept. 26, 2024) Technical ceramic 3D printer maker, Austria-based Lithoz, announced a new, much larger machine for industrial ceramics, the CeraFab System S320. This machine’s build platform and build volume are five times larger than the company’s popular S65 while sharing the same external dimensions.

The S320’s 245 x 130 x 320 mm build volume is large when you’re talking ceramics. It offers a 60 µm resolution and a 4K projection system, with a focus on serial production of mid-size ceramic parts, such as industrial filters, medical implants, casting cores, and semiconductor components.

CeraFab System S320 is not the largest 3D printer for technical ceramics on the market. The Admatec Admaflex 300, which also uses DLP technology is 260 x 220 x 520 mm, but doesn’t have the large range of ceramic material options as the S320.

Tech Specs

- Technology: Digital Light Processing (DLP)

- Resolution (XY): 60 µm

- Build speed: up to 150 layers per hour

- Layer thickness: 20 – 200 µm

- Build volume: 246 x 130 x 320 mm

- Materials: Silica-based materials (such as LithaCore 450). Alumina, Zirconia-toughened Alumina, Zirconia, Tricalcium Phosphate, Lead Zirconate Titanate, Hydroxyapatite

- Price: TBD

Stratasys’ New Origin Two DLP

(Sept. 5, 2024) 3D printer and material manufacturer Stratasys just launched a new version of its Origin One resin (DLP) printer, called (surprise!) Origin Two. The focus is on delivering “injection-molding quality” parts “straight off the printer”, the company says.

Of course, resin parts require post-print light curing, but what’s different with the Origin technology, which Stratasys calls Programmable PhotoPolymerization (P3), is that parts straight off the printer are nearly as strong as the final parts and require only a “few minutes” of post-processing, the company says.

For curing, Stratasys is also launching a curing unit called Origin Cure, with 360-degree multi-wavelength LED curing.

Stratasys acquired the original maker of Origin, Origin Inc., in 2020 and has since launched a dental version of Origin called Origin One Dental (2021).

The updated version features a new 5K DLP projector (Origin One had a 4K projector) for a 38.5 micron pixel size. If you have an Origin One, you can buy an upgrade kit to install the 5K engine, plus a new high-precision build arm and platform.

Origin Two Tech Specs

- Technology: Digital Light Processing (DLP)

- Build Volume: 192 x 108 x 370 mm

- Max speed: 20 mm/hour.

- Resolution/Accuracy: XY: 50 μm (for validated applications, +/- 100 µm in general); Z: 25 – 200 μm

- Surface Roughness: up to 2µm Ra

- Materials: 385-nanometer wavelength resins

- Resin Tray Capacity: 2 liters

- Software: Stratasys GrabCAD Print or optional 3rd party solutions

- Connectivity: Ethernet Offline connectivity available with Origin Two Local

- Price: TBD (The Origin One retailed for around $90,000)

Markforged's FX10 Metal & Continuous Carbon Fiber FDM

(Aug. 27, 2024) It’s not a brand-new printer, but it is an attractive new upgrade for companies seeking a single solution for continuous carbon fiber 3D printing and metal 3D printing. Rather than a new machine, the capability to 3D print with a new metal filament has been added to the FX10 continuous carbon fiber 3D printer introduced in Nov. 2023.

Markforged says the FX10 was designed to be modular and accommodate coming years’ innovations whatever they may be. At launch, the FX10 was touted as “the additive manufacturing platform for the next decade.” Now, existing FX10 owners and new buyers can purchase the optional Metal Kit to enable metal extrusion 3D printing.

The FX10 Metal Kit ($19,000) consists of a swappable print “engine” that includes a metal-specific print head, material feed tubes, routing back, and dual pre-extruders. The swap takes about 15 minutes.

The Metal Kit, however, is not the same system as you’ll find in the company’s Metal X 3D printer first launched in 2019. Just as the FX10 is a step beyond the company’s previous composite 3D printers, the Metal Kit enables faster metal printing than the Metal X. Plus, the FX10’s print volume is larger than the Metal X’s (375 x 300 x 300 mm vs. 300 x 220 x 180 mm). Is the Metal X solution going away? Terem told All3DP that the Metal X solution has capabilities, like more metal material, that, are not yet available on the FX10, but eventually, he does see the system replaced by the FX10.

Technical Specs & Price

- Technology: FDM with or without Continuous Fiber and Metal Filament

- Build volume: 375 x 300 x 300 mm

- Filament bays: Four (heated)

- Heated chamber: Yes to 60ºC

- Materials (Proprietary): Onyx (carbon-fiber filled nylon), continuous carbon fiber, 316L stainless steel

- filament

- Price: $100,000 (optional metal kit is an additional $19,000)

- Software: Eiger, Inspect, Simulate

- Layer Height range (depending on materials): 125 to 250 microns

- Sensors: In-process inspection, active print calibration, bed leveling,

- Security: Two-factor authentication, org-admin access, single sign-on, MFP print files encrypted by default and tamper-resistant

BigRep's New Viio 250 FDM

(July 2, 2024) Making more of a debut at the BigRep booth at the Rapid + TCT show in June, was the Viio 250. This new industrial, heated-chamber, large-format FDM offers some interesting new features. It has a novel backup extruder functionality called Relay Mode that enables a standby extruder to take over should a clog or malfunction happen with the first extruder. Extending uninterrupted printing even more is a new auto filament spool switch-over feature that detects imminent material outages and loads the next of four 8-kg spools.

There’s also three times the number of sensors as other BigRep machines. These constantly collect printer data that’s used not only in quality control of printed parts, but in predictive maintenance and ensuring the machine is running optimally.

Viio 250 Tech Specs & Price

- Technology: FDM, filament

- Build Volume: 1,000 x 500 x 500 mm

- Min. Layer Height: 0.2 mm

- Max. Print Speed: 500 mm/s

- Max. Extruder Temp.: 350°C

- Nozzle Diameters: 0.4, 0.6, 1.0 mm

- Max. Chamber Temp.: 50ºC

- Max. Bed Temp.: 120ºC

- Materials: Open

- Price: TBD

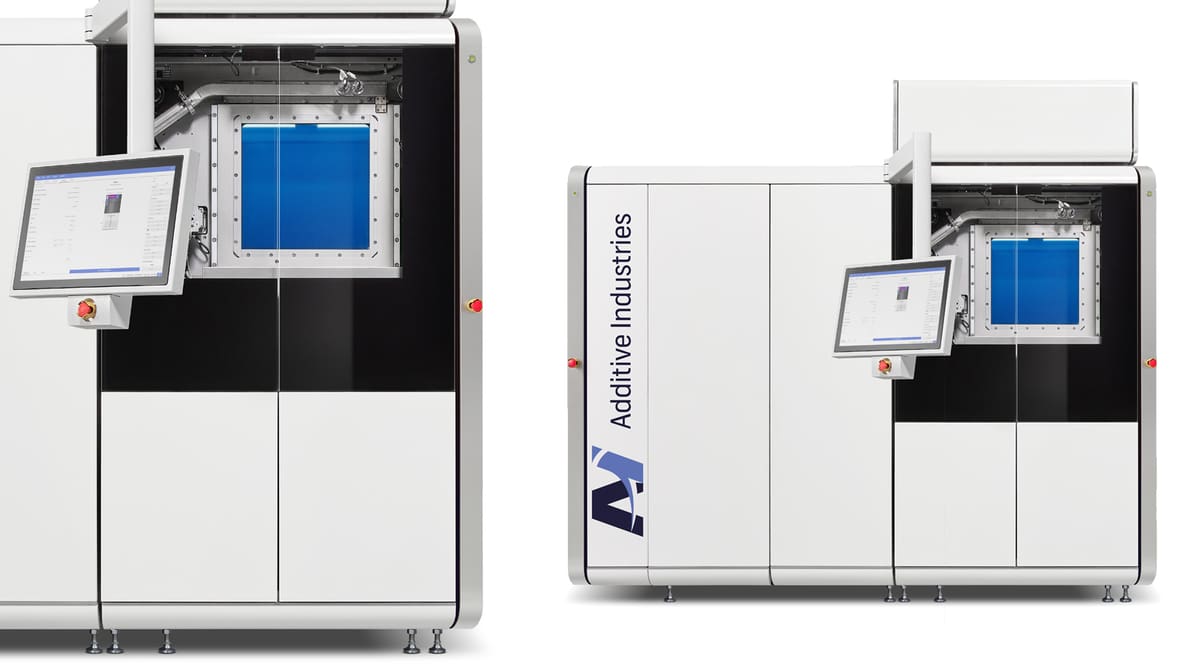

Additive Industries' New MetalFab 300 Flex LPBF

(June 25, 2024) A new mid-size metal laser powder bed fusion (LPBF) machine from Additive Industries boasts optional build envelope expansion. Netherland-based Additive Industries hopes its affordable and flexible new printer will be enough to attract more companies to adopt the technology.

The unique feature on the new MetalFab 300 Flex is its ability to grow its print volume. Shipping with a sizable 300 × 300 × 400 mm build envelope, customers can buy a license to expand that capacity to 420 x 420 x 400 mm on demand. Yet, starting at $730,000, the MetalFab 300 Flex is hardly an insignificant investment. In fact, it’s about six times more expensive than other “starter” LPBF machines, such as the One Click Metal MPrint+ at around $100K or the Xact Metal XM200G at around $150K. These two machines, though, have much smaller build volumes (about a third of the MetalFab 300 Flex) and less laser power.

Under the hood, the MetalFab 300 Flex has two 500-Watt lasers with the option for four lasers. These lasers are tuned to the base build volume with the flexibility to scan the fuller volume with the upgrade package, which is a monthly or lifetime license available to increase the scan field on demand.

MetalFab 300 Flex Tech Specs & Price

- Technology: Metal LPBF

- Build Volume: 300 x 300 x 400 mm (standard), 420 x 420 x 400 mm (optional)

- Lasers: 2 x 500 Watt Yb-fiber, 4 x 500 Watt Yb-fiber (optional)

- Laser Diameter: 110 microns

- Layer Thickness: 20-120 microns

- Accuracy: <0.05 mm

- Price: $730,000

Colibrium Additive's New Spectra M EBM

(June 25, 2024) With the new, smaller titanium EB-PBF, Spectra M, Colibrium Additive – a GE Aerospace company – hopes to lure more medical device makers to additive manufacturing.

Colibrium Additive launched Spectra M at the event, which is the latest addition to its Spectra portfolio of electron beam melting (EB-PBF) metal 3D printers in response to additive manufacturers interested in a smaller build volume, the company says. Its smaller build volume makes the Spectra M an attractive entry option for additive users in the medical and orthopedic implant industry looking to further reduce cost-per-part and additive production costs, according to Colibrium, which is already one of the biggest names in EBM technology. When US industry giant General Electric acquired the lone wolf Arcam AB and its EBM machines in 2016 it kept the Arcam name until April 2024, when GE launched a stand-alone additive manufacturing division called Colibrium Additive.

The Spectra M can be ordered now, with first deliveries expected in early Q1 2025.

Spectra M Tech Specs & Price

- Technology: Metal Electron Beam Melting (EB-PBF)

- Build Volume: Ø270 x 430 mm.

- Beam Power: 4.5 kW

- Materials: Ti6Al4V Grade 5 and Ti6Al4V Grade 23

- Price: TBD

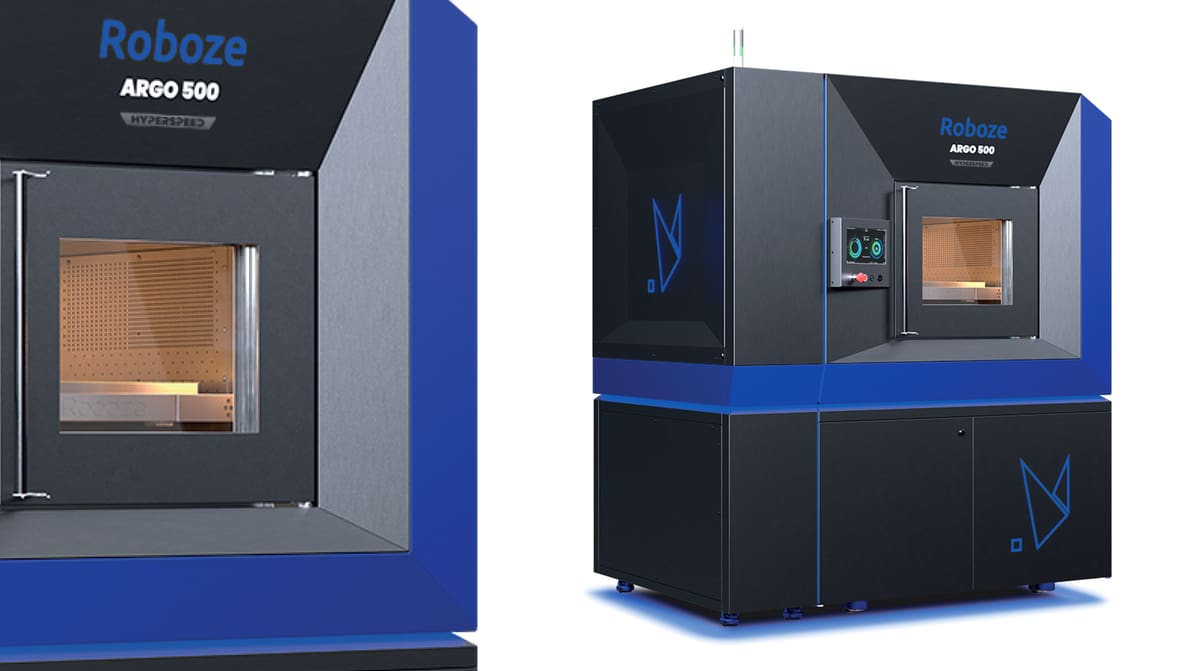

Roboze's New Argo 500 Hyperspeed FDM

(June 25, 2024) The high-temperature industrial Argo 500 Hyperspeed FDM from Roboze is not only faster, it includes software and hardware advances making it vastly more efficient than the original Argo 500. Not only is there a lot of new software and firmware, but there’s also new hardware and other patent-pending elements thrown in. It replaces the existing Argo 500.

Comparing the Hyperspeed edition to the older version reveals a doubling of the maximum printing speed to 120 mm/sec from 60 mm/sec. This translates into a 25% faster print time using a single extruder and up to 62% faster print time using dual extruders. As with almost all 3D printers, high speed and high resolution are mutually exclusive, so the Hyperspeed print profile is aimed at delivering faster prototypes. Roboze still offers its Ultra Quality, Quality Speed, and Productivity profiles on this new machine.

Faster prints ultimately save you money in the form of time, but the new Argo 500 Hyperspeed also uses 10% less compressed air, reduces filament waste (purged filament) by 37%, and the machine’s gear system is expected to last 1,000 hours which is 300% longer than the previous version of the Argo 500.

Argo 500 Hyperspeed Tech Specs & Price

- Technology: Technology: FDM (filament)

- Build Volume: 500 x 500 x 500 mm

- Accuracy: (XY) 10 µm, (Z) 25 µm

- Nozzle sizes: 0.4, 0.6, 0.8 mm

- Max. Print Speed: 120 mm/sec

- Materials: PEEK, PEKK, carbon fiber PA, PP, Ultra PLA, Ultem, +

- Price: TBD

3D Systems' New Ext 800 Titan Pellet FDM

(June 25, 2024) The economy and speed of 3D printing with pellet materials have attracted a lot of attention over the past few years as robotic arms enable larger and larger 3D printers. Yet, pellet 3D printing offers a wide range of benefits for mid-size and even small parts. The new Ext 800 Titan Pellet from 3D Systems is still large by polymer extrusion standards (800 x 600 x 800 mm), but is the smallest in the now three-member Titan family. It boasts 10 times the output of competing extrusion printers that use filament and up to 10 times less material costs, according to 3D Systems. Like the two other Titan pellet extrusion systems (1070 Titan Pellet and 1270 Titan Pellet) the 800 is aimed at industrial production with applications from foundry patterns and manufacturing fixtures to prosthetics and durable goods.

The Ext 800 Titan Pellet is available for immediate ordering with delivery of the first printers anticipated for the third quarter of 2024.

Ext 800 Titan Tech Specs & Price

- Technology: FDM, pellet

- Build Volume: 800 x 600 x 800 mm

- Print Speed: Up to .5m/sec

- Pellet Extruder Throughput: 0.45kg – 13.6kg per hour

- Min. Layer Height: 0.4 mm

- Max. Extruder Temp.: 400°C

- Max. Chamber Temp.: 80ºC

- Price: TBD

3D Systems’ New PSLA 270 DLP

(June 24, 2024) Last year, at Formnext 2023, we noticed 3D Systems’ new industrial resin printer standing off to the side of the company’s booth. Representatives were very short on details leaving us until this past June to learn more about the PSLA 270, which will be again at Formnext (Booth D11, Hall 11.1), but this time, in the spotlight.

The PSLA 270 is the company’s “fastest, most versatile, resin printer yet,” it says, producing parts in hours not days.

The PSLA 270 is indeed the company’s fastest resin 3D printer. 3D Systems doesn’t provide technical data in the same format for all of its machines, so comparisons are not simple, but the PSLA 270 appears to have a lower resolution (although still very high) than the slower Figure 4 series machines, while accuracy is lower than the company’s other laser-based 3D printers. Speed always comes at a compromise.

PSLA 270 Tech Specs

- Technology: Digital Light Processing (DLP)

- Build Volume: 242 x 265 x 300 mm

- Light Engine: 2 x 7-watt, 90 µm combined 3840 x 2160 dpi

- Resin Wavelength: 405 nm

- Resolution: 90 µm pixel size

- Accuracy: +/- 100 µm < 25 mm, +/- 0.2% > 25 mm

- Layer Thickness: 50-150 µm (material dependent)

- Max. Speed: 38 mm / hour (material dependent)

- Vat Capacity: 55 L

- Price: 3D Systems is not releasing a price. When we proposed maybe “$225,000 – $300,000”, the company said that was “wildly wrong” so it’s likely more in the range of the company’s SLA 750 Dual which starts around $425,000.

Stratasys’ New J5 Digital Anatomy PolyJet

(June 24, 2024) Multi-color, multi-material anatomical modeling just got more accessible with the new J5 Digital Anatomy from Stratasys. The company just launched what could be described as a smaller version of its J850 Digital Anatomy 3D printer in hopes of luring more medical industry professionals to adopt 3D printing.

If the J5 Digital Anatomy looks familiar, perhaps exactly like the company’s J5 MediJet, there’s an easy explanation. These two J5s offer near-identical capabilities, build volume, and resolution, but with a few new features in the “Digital Anatomy” version. In fact, if you have a J5 MediJet you can upgrade it to become a J5 Digital Anatomy for $60,000. Digital Anatomy offers more materials, for example, a third biocompatible material called Digital ABS Plus, a second rubber-like material called ElasticoBlack, and four anatomy-specific materials: TissueMatrix, GelMatrix, BoneMatrix, and RadioMatrix for visibility under X-Ray and CT scan. These materials can be Gamma sterilized, which is also new.

J5 Digital Anatomy Tech Specs & Price

- Technology: PolyJet

- Build Volume: 140 x 200 x 190 mm

- Minimum Layer Thickness: 18 microns

- Network Connectivity: LAN – TCP/IP

- Software: GrabCAD Print

- Materials: Proprietary Resins

- Price: $135,000

Spee3D's New TitanSpee3D Cold Spray

(June 8, 2024) The new TitanSpee3D cold spray metal 3D printer is essentially the company’s existing technology in a larger form with a few changes to the way it operates. For example, to better account for the weight of the large metal parts, it is not the deposition head that’s stationary, but rather the part is stationary and the cold spray nozzle works around it on a robot arm.

Most of the new technology in the Titan is in its software and control systems that enable planning and remediating the various stages of the part build as it’s printing.

Not only are the physics and technology requirements of large-scale metal additive manufacturing different than small-scale, such as metal binder jetting or metal laser powder bed fusion, but the materials, processes, workflow, and market are completely unique, according to company co-founder and CTO Steven Camilleri, who sat down with All3DP for an exclusive Q&A on the new machine.

TitanSPEE3D will be available to a limited number of beta customers in 2024, with the commercial release slated for 2025.

TitanSpee3D Tech Specs

- Technology: Cold Spray

- Build Volume: Ø2,400 x 1,000 mm

- Materials: aluminum, aluminum bronze, stainless steel, and more

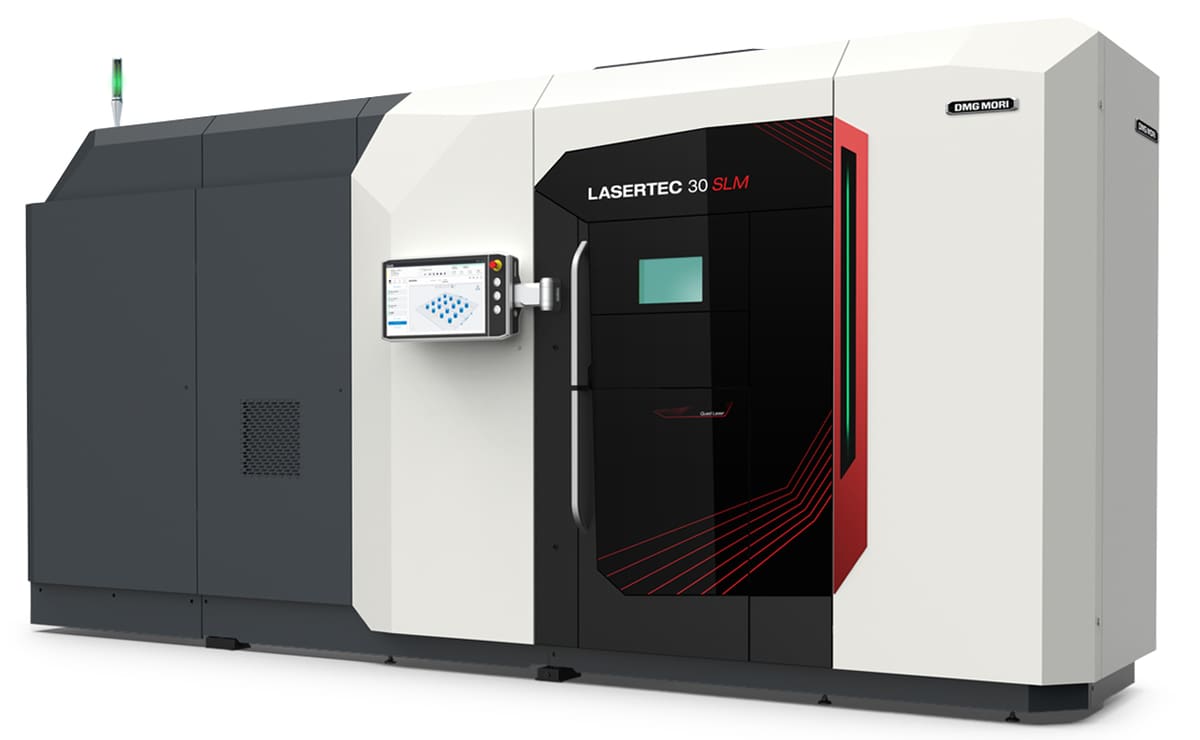

DMG Mori's LaserTec 30 SLM LPBF

(June 11, 2024) DMG Mori’s new metal laser powder bed fusion (LPBF) platform, LaserTec 30 SLM 3rd Gen, has been designed from the ground up using all the additive and machine tool design know-how, the company says. With a quad-laser, full-overlap working area, and a model build volume of 325 x 325 x 400 mm, the company is targeting the center of the metal 3D printing market.

The LaserTec 30 features a removable build chamber so it’s no longer necessary to wait for the build job to cool down before starting another job. There’s also camera monitoring of the surface of the powder bed and after each layer, the surface is scanned for anomalies before the re-coater moves.

A bi-directional re-coater speeds up the overall process while a newly designed inert gas flow over the powder bed ensures consistency during operation.

LaserTec 30 SLM 3rd Gen Tech Specs & Price

- Technology: Metal LPBF

- Build Volume: 325 x 325 x 400 mm

- Laser: 600 Watt

- Laser Diameter: 80 microns

- Min. Layer Thickness: 30 microns

- Accuracy: <0.05 mm

- Price: $730,000

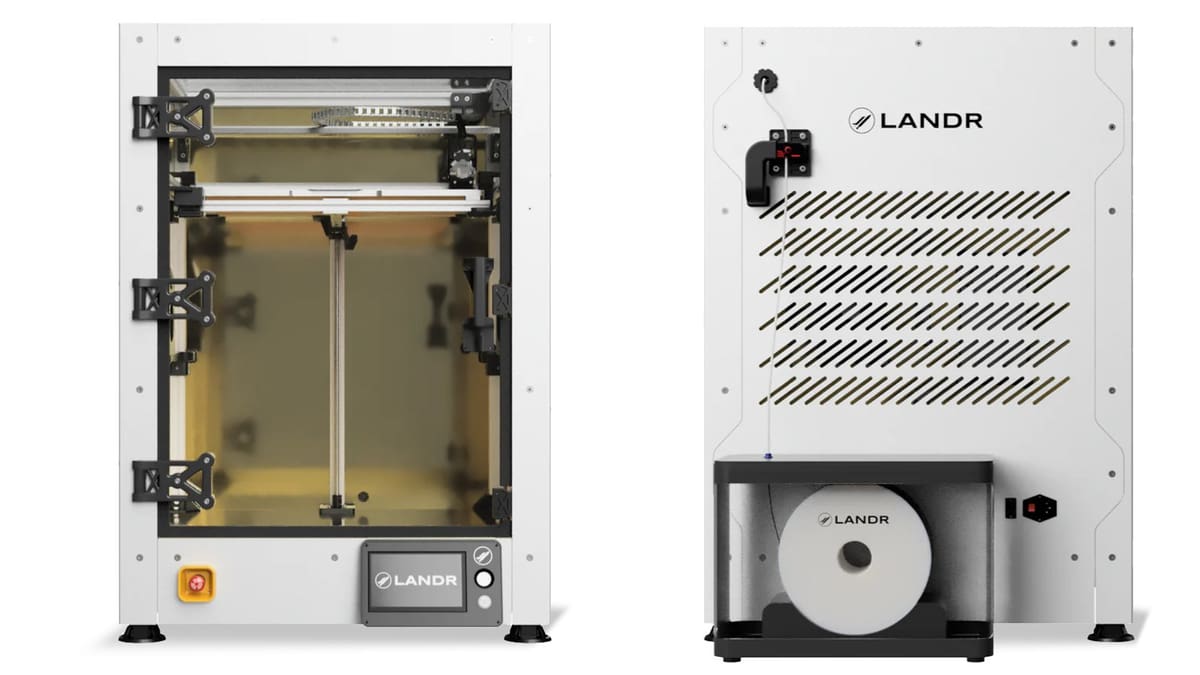

Landr's New Landr 500 FDM

(June 5, 2024) UK-based 3D printing company Ryse 3D created Landr for its own use because there was nothing affordable on the market that could meet the needs of a high-volume print shop working with engineering-grade materials, the company says.

The Landr 500 is a large-scale (500 x 500 x 500 mm build volume), full aluminum chassis FDM 3D printer that features a heated chamber to 100ºC, hot end to 500°C, a heated bed to 140°c, and a maximum print speed of 500 mm/s (even while printing nylon-carbon fiber). Landr 500 also sports a Bondtech LGX extruder, a built-in camera, 7-inch touchscreen, Wifi-enabled closed loop and ethernet port standard, plus an auto nozzle wipe and nozzle purge. The heated filament dryer is standard and there’s double-skin, gold-reflective insulation to give the Landr that’s space vehicle feel.

At $14,500, the Landr 500 is about four times less expensive than the next industrial FDM.

Made in the UK and available initially only in the UK (shipping is planned by August), then launching globally in Nov. 2024.

Landr is launching its own slicer with the 500 model and introducing its own materials, although the printer is an open-material platform. On the material menu is grey Landr PA6-GF (glass filled nylon 6) and Landr PA6-CF (carbon fiber nylon 6).

Landr 500 Tech Specs & Price

- Technology: FDM

- Build Volume: 500 x 500 x 500 mm

- Max. Print Speed: 500 mm/s

- Extruder Temp.: 450°C

- Chamber Temp.: 100°C

- Bed Temp.: 180°C

- Materials: Open, can accommodate carbon-fiber and glass-fiber infused nylon

- Software: Landr Slicer

- Price: $14,500

WAAM3D's new MiniWAAM

(June 4, 2024) WAAM3D, the manufacturer of large-scale metal wire arc additive manufacturing (WAAM) machines launched a new compact version of its technology: MiniWAAM. It brings WAAM to a wider audience, the company says.

Sitting alongside the much bigger RoboWAAM brother, the MiniWAAM features the company’s proprietary end-effectors, sensing hardware, and software aimed at aerospace, defense, oil & gas markets. Instead of the robotic arm in the RoboWAAM, the MiniWAAM features a 3-axis overhead CNC system, plus an additional 500 mm rotational table with a 60 kg payload.

MiniWAAM Tech Specs & Price

- Technology: Wire Arc Additive Manufacturing (WAAM)

- Build Volume: 600 x 600 x 500 mm

- Materials: Titanium alloys, stainless steel, nickel alloys, and others

- Software: Siemens PLC Control System

- Price: TBD

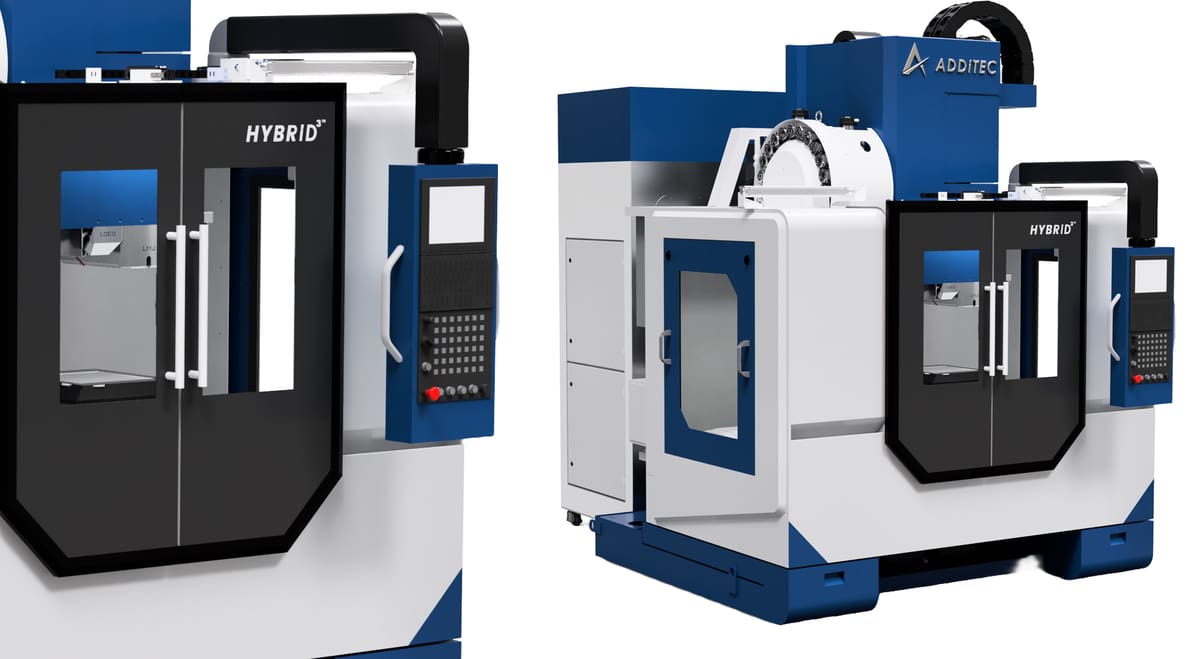

AddiTec's New Hybrid 2 & 3 LDED, MDED, CNC

(June 3, 2024) AddiTec launched an interesting new machine combining two separate metal manufacturing technologies with CNC machining. The Hybrid 2 combines Liquid Metal Jetting (LMJ), also called molten direct energy deposition, a type of metal material jetting, with CNC machining to finish parts to tighter tolerances. The Hybrid 3 adds laser direct energy deposition (LDED) to the mix and integrates both LMJ and LDED heads in one system, allowing you to create complex components with varying materials and properties using commercial, off-the-shelf welding wire.

AddiTec acquired its LMJ technology from Xerox, when it sold off its ElemX molten DED aluminum 3D printer.

LMJ offers high-resolution printing capabilities, while LDED provides high deposition rates. The inclusion of two additive processing heads within a single system also enables multi-material capability.

Hybrid 2 & 3 Tech Specs & Price

- Technology: FDM

- Build Volume: 1,016 x 508 x 635 mm

- DED Laser Power: 6 kW

- Layer Thickness: 0.8 – 1.2 mm (DED), 0.24 min. (LMJ)

- Max. Deposition Rate: 4 kg/jr (DED), 0.5 kg/hr (LMJ)

- Resolution: 2.5 mm (DED), 0.5 mm (LMJ)

- Materials: Iron, Nickel, Aluminum, and Copper Alloys

- Software: AddiTec

- Price: TBD

BigRep's New Altra 280 & Ipso 105

(May 28, 2024) BigRep, known for its large scale FDM 3D printers, just launched two new machines taking the company in a new direction: high-temperature, large-scale industrial part production.

The Altra 280 and the Ipso 105 are automated large-volume FDM 3D printers engineered to be fast, reliable, and precise, the company says.

Not built from the ground-up by BigRep, but rather adopted when it acquired Austrian 3D printer startup Hage3D, these two machines were formerly know as Precise and Mex. All3DP noticed these two from Hage3D at the 2022 and the 2023 Formnext expo, and they really stood out.

Hage3D has actually been making printers since 2014, mostly for the EU and Asian market, but now, as part of BigRep, the Altra and Ipso are going global. Yet, for now, only available in Europe, the Middle East, and Africa.

The Altra 280 and Ipso 105 have an open material system for a broad filament choice, either with BigRep’s filaments or third-party materials.

The highlights of the BigRep Altra 280 are the large, heated 280-liter build chamber (500 x 700 x 800 mm), that reaches temperatures up to 180°C and quad extruders reaching up to 450°C, and the fully automated quick start. With up to four extruders, which the company calls DSX (Direct Synchronized Extruders), the Altra 280 is designed to achieve reliable dual extrusion safeguarded by backup extruders.

Altra 280 Tech Specs

- Technology: FDM

- Build Volume: 500 x 700 x 800 mm

- Layer Height: from 0.05 mm

- Max. Print Speed: 350 mm/s

- Dual – Quad Extruder Temp.: 450°C

- Nozzle Diameters: 0.4 mm, 0.6 mm, 1.0 mm

- Chamber Temp.: 180ºC

- Bed Temp.: 180ºC

- Materials: Open, can accommodate ULTEM 9085 and PEEK (AM200)

- Price: TBD

Ipso 105 Tech Specs

- Technology: FDM

- Build Volume: 400 x 600 x 440 mm

- Layer Height: from 0.05 mm

- Max. Print Speed: 200 mm/s

- Dual Extruder Temp.: 450°C

- Nozzle Diameters: 0.4 mm, 0.6 mm, 1.0 mm

- Chamber Temp.: 100°C

- Bed Temp.: 180°C

- Materials: Open, can accommodate PEKK and PEKK-CF

- Price: TBD

Massivit's New 3000 Large-Format Gel Extrusion

(May 8, 2024) Massivit 3D Printing Technologies is a maker of very large-volume industrial 3D printers, but they have a unique method that sets them apart from the rest for one application in particular: directly casting industrial molds.

Instead of using polymer filament, Massivit 3D printers have extruders that dispense a photopolymer gel at high speeds before curing it into solid layers under UV lights attached to the extruder. One printhead prints the sacrificial outer shell of the mold, while another printhead fills the mold with an industrial-grade polymer casting material. The outer shell is removed by soaking in water, and what’s left is an industrial-grade mold with no layer lines or supports, which can also be machined for surface finish or tighter tolerances. Taking just a couple of days, the system speeds up traditional mold production processes and is also used to create jigs and fixtures.

An advantage of photopolymer gels is that you can print with practically no support structures, the company says.

Massivit machines comes in various sizes and the new Massivit 3000 could hit the sweet spot customers are looking for.

“The launch of the Massivit 3000 brings to market a more affordable 3D-printing solution for businesses seeking to leverage high-speed, large-format production capabilities without putting a strain on their finances,” the company says.

Its unique print volume of 1.2 x 1.5 x 1.8 m enables you to produce giant displays in a single print, significantly cutting down on production time.

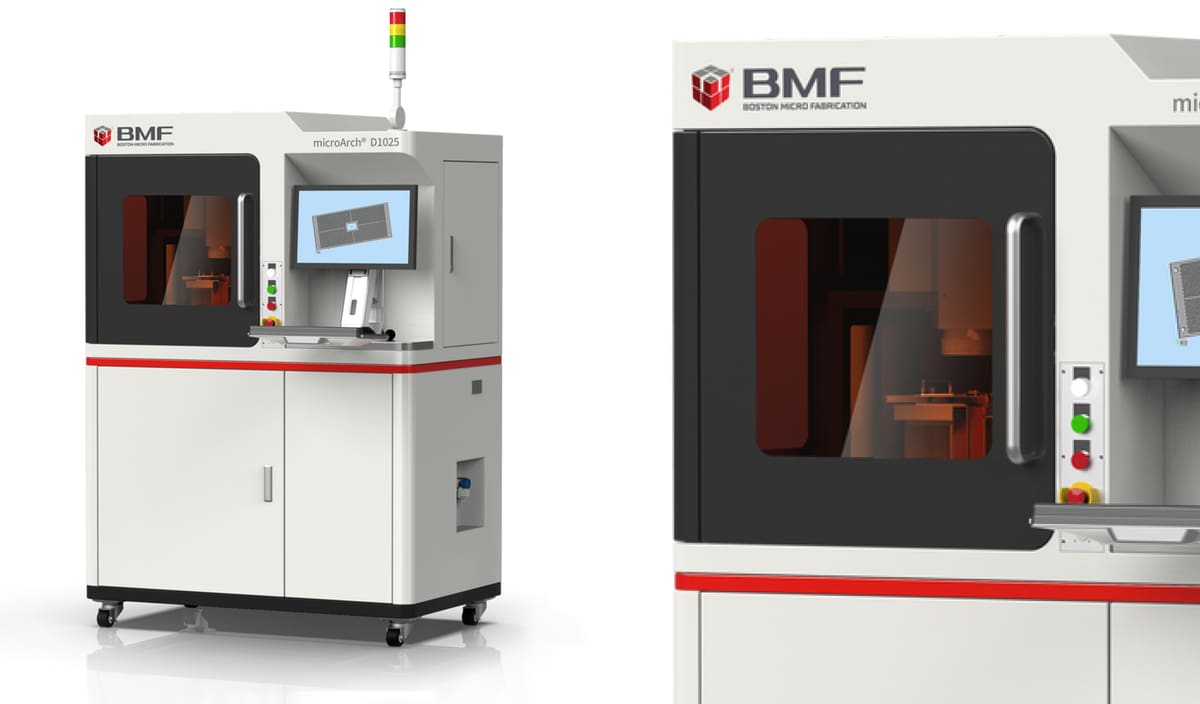

BMF's microArch D1025 Micro Resin DLP

(May 7, 2024) BMF (Boston Micro Fabrication) launched a new dual-resolution microArch D1025 3D printer for producing micro-scale and ultra-high resolution applications.

The microArch D1025 is the first printer in a new series from BMF and is capable of printing in both 10-micron and 25-micron resolution, or in hybrid mode with both resolutions in the same print layer or in different layers.

For engineers and researchers requiring extremely high resolution, the microArch D1025 features what the company calles improved built-in automation for greater efficiency.

The microArch D1025 is based on BMF’s innovative projection micro stereolithography (PµSL) technology, a technique that allows for rapid photopolymerization of a layer of liquid polymer using a flash of UV light at micro-scale resolution.

microArch D1025 Tech Specs

- Technology: Micro Stereolithography

- Build Volume: 100 x 100 x 50 mm

- Layer Height: 10- 50 μm

Farsoon's 12-Laser Metal LPBF

(May 6, 2004) Farsoon has yet another multi-laser metal laser powder bed fusion machine to introduce to the global market. The FS811M series (meaning there are different configurations available) has a build volume of 840 x 840 x 960 mm and up to 12 fiber lasers.

The FS811M platform can be equipped with 6, 8, 10, or 12 x 500-watt fiber lasers.

“We’ve spent the past 2 years developing and optimizing the FS811M platform for specific application projects,” the company says. “Starting one year ago, we started to see the rapidly expanding large-format metal 3D printing application in aerospace, oil & gas, energy and automotive sectors … This is when we decided to fully commercialize the FS811M platform to scale up metal series production.”

Farsoon says its latest machine features innovations, including a “multi-layer gas flow with advanced wind-wall design”, which can ensure real-time particle removal throughout the entire oversized chamber. The air tightness of the chamber design enables low inert gas consumption during the build process, and the permanent filtration system facilitates uninterrupted, reliable process for extreme build times.

UltiMaker's Factor 4 FDM

(Apr. 22, 2024) UltiMaker’s new FDM aims to fill a gap in 3D printing between consumer and industrial machines, marrying ease-of-use with engineering-grade materials.

Rather than beef up its S7, which is just one year old, UltiMaker created something new that still looks very UltiMaker. Factor 4 has a sturdy steel and aluminum chassis, an actively heat-controlled chamber up to 70ºC, triple-insulated build volume, a direct-drive extruder with a bigger motor, and a nozzle temperature that can reach 340ºC to enable materials, such as PPS-CF, PEKK, and Ultrafuse metal filaments.

Factor 4 has a 50% increase in productivity compared to the S series, the company says. The UltiMakers’ dual extruder effectively prints two materials at the same time without the filament retraction of the material changers found on Bambu Lab and now also on Creality and Anycubic.

Also contributing to the predictability of the Factor 4 is new software designed to track and trace the full printing process. There’s a new suite of sensors that monitor real-time print data and material performance delivering reports after every print job to provide a level of part validation and quality control.

Tech Specs & Price

- Technology: FDM

- Build Volume: 330 x 240 x 300

- Dimensional Accuracy: within ± 0.2 mm or ± 0.2%

- Air Filtration: HEPA filter

- Materials: Available at launch: UltiMaker PPS CF and other UltiMaker-branded materials, such as PLA, Tough PLA, nylon, PETG, PET CF, and PVA, plus validated materials from BASF Forward AM, Kimya, Polymaker, LEHVOSS, Jabil, and others. Factor 4 will be compatible with materials on the UltiMaker Marketplace, with 250 pre-tuned print profiles.

- Filament Size: 2.85 mm

- Price: around $20,000

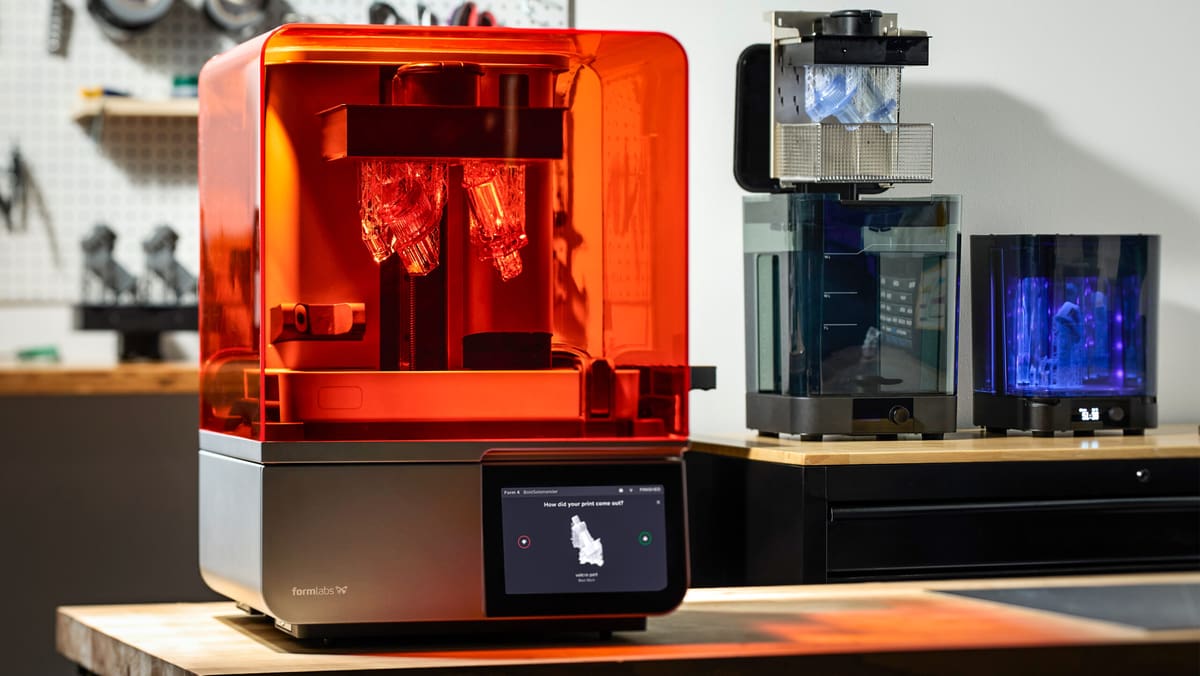

Formlabs' Form 4 LCD

(Apr. 18, 2024) At under $5K, the new Form 4 from Formlabs may set a new benchmark in resin 3D printing accessibility for professionals. Not only does its new LCD technology instead of the company standard SLA makes it much faster but it more affordable that other professional resin solutions.

In its shift from SLA to LCD, Formlabs brings its years of innovation with it in terms of what customers have always liked: an integrated ecosystem of hardware (including post-processing machines), software, materials, automation, and support.

The the trade-off for Form 4’s LCD speed is a small difference in print resolution when comparing the Form 4 to the Form 3+ (50 microns in the XY vs. 25 microns). The Form 4, being LCD technology, lists resolution slightly differently – it has a 50-micron pixel size, yet, couple this with “pixel smoothing,” which is technology in a printer’s slicing software, and the resolution of the Form 4 should effectively equal the Form 3+ in most applications.

In addition to the Form 4, there’s the also-new Form 4B ($6,300) for dental and medical applications.

Tech Specs & Price

- Technology: LCD (Formlabs is calling its take on LCD “Low Force Display, LFD”)

- Build Volume: 200 x 125 x 210 mm

- Layer thickness (Z resolution): 25 – 300 microns

- XY resolution: 50 microns

- Print Speed: up to 100 mm / hour

- Camera: Built-in

- Materials: 23 validated, optional license for open material platform

- Price: The Form 4: $4,500, Form 4B: $6,300

Nikon's Lasermeister LM300A DED

(Apr. 10, 2024) Nikon (yes, the camera company, which has been in additive manufacturing since 2019 and acquired SLM Solutions in 2023) just released its “next-generation metal additive manufacturing system”, the Lasermeister LM300A, which is a laser directed energy deposition (DED) metal 3D printer. DED is largely used for 3D printing complex structures, adding features to existing parts, and repair.

Considering it’s German sounding name, the Lasermeister LM300A system was likely already in development at SLM Solutions, which is based in Germany, prior to the merger.

This system is mainly targeting researchers and industrial R&D, the company says. What’s exciting about this offering is the accompanying 3D scanner unity, the Lasermeister SB100. By simply placing a workpiece, such as a worn-out blade, inside the scan chamber, the module begins to scan and measure the workpiece. It then compares its current actual shape with its ideal CAD model to extract the difference, using a built-in scanning feature. The machine then automatically generates the tool path data for repair specific to each damaged or worn-out workpiece. This tool path is fed to the LM300A 3D printer for repair of the part.

Once the additive process is completed, the workpiece can be placed back into SB100, where it will scan and inspect to confirm the repair was performed to its ideal model.

Tech Specs & Price

- Technology: Directed energy deposition

- Build Volume: 297 x 210 x 400 mm

- Accuracy: XY -0mm / +0.5 mm, Z +0.5 / +1.5 mm

- Chamber: Inert gas, nitrogen gas or argon

- Materials: Ni625, Ni718, Stainless Steel, Titanium, +more

- Price: >$500,000

EasyMfg's M550Max and M150Inno Binder Jetting

(April 16, 2024) EasyMfg, based in Wuhan, China, expanded its range of metal binder jetting 3D printers with the launch of the M550Max and M150Inno.

Founded in 2013, EasyMfg is focused exclusively on binder jetting technology offering metal, sand, and color machines, most of which are not available outside of China but the company is working on expanding globally.

The M550Max is designed to produce medium- to large-sized parts in a wide range of metals, including titanium alloys, steels, copper, and stainless steel.

The M150Inno is much smaller and aimed at research institutes seeking precision in a smaller form.

Tech Specs & Price M550Max

- Technology: Metal binder jetting

- Build Volume: 550 x 370 x 200 mm

- Build Volume: 40.7 liters

- Max Build Rate: 2442 cc/hour

- Print Speed: 12-15 s/layer

- Resolution: Printhead NPI: 600; Print Resolution: 1,200

- Layer Height: Adjustable from 30~200 µm

- Materials: Titanium alloy, iron-based powder, copper powder, stainless steel powder, +

- Price: TBD

Tech Specs & Price M150Inno

- Technology: Metal binder jetting

- Build Volume: 150 x 70 x 70 mm

- Build Volume: 0.735 Liters

- Max Build Rate: 189 cc/hour

- Print Speed: 8-15 s/layer

- Resolution: Printhead NPI: 600; Print Resolution: 1,200

- Layer Height: Adjustable from 40-200 μm

- Materials: Titanium alloy, copper powder, stainless steel powder, +

- Price: TBD

EOS' New M 290 1kW Metal LPBF

(Mar. 30, 2024) The large 3D printer maker EOS officially launched its newest metal laser powder bed fusion machine initially focusing on copper (CuCp and CuCrZr).

M 290s from EOS have been popular for years and the boost in laser power to 1,000 Watts isn’t completely unexpected. The manufacturer has been custom-fitting its machines with this power at its AMCM customization wing and decided it was time to let this unit out into the wild particularly to cater to customers in space, energy, and mobility.

One early adopter, GBZ Mannheim, a German tool and part maker, has been using the machine to fabricate copper inductors with more optimized cooling channels.

Nearly everything else about the M 290 1kW is the same as the older version with the 400-watt fiber laser except for a slight smaller laser focus diameter (90 µm vs. 100 µm)

Tech Specs & Price

- Technology: Metal laser powder bed fusion

- Build Volume: 250 x 250 x 325 mm

- Laser: 1 x 1,000 W

- Scan Speed: up to 7.0 m/s

- Laser Diameter: 100 µm

- Software: EOS Build/Build+, EOS Smart Monitoring, EOS Data Insights, EOS Systems Suite

- Price: >$500,000

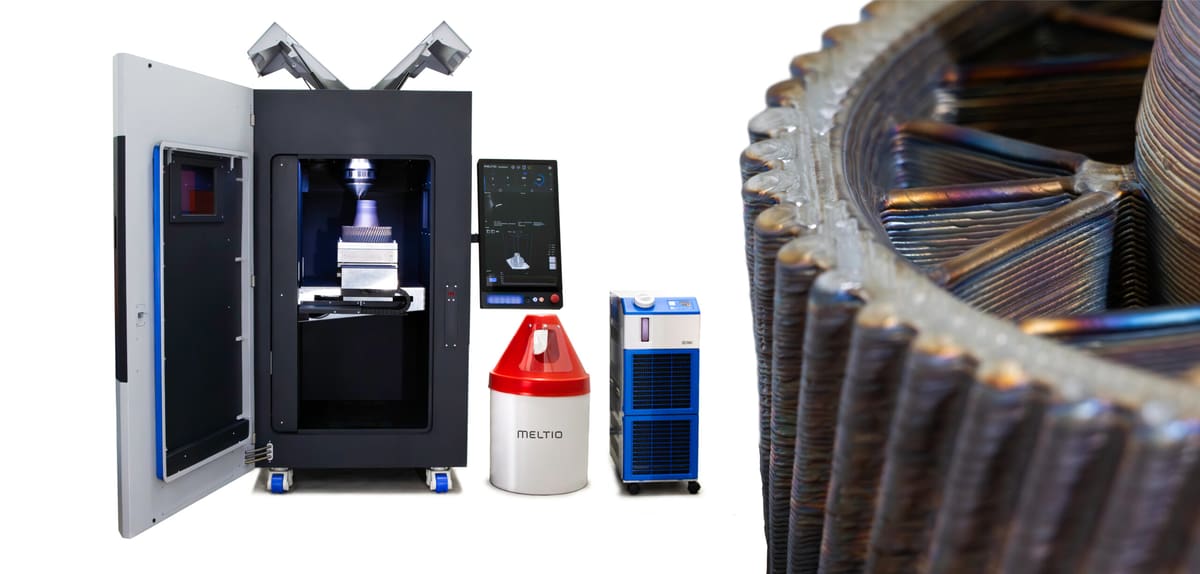

Meltio's New M600 Laser Wire DED

(Mar. 12, 2024) Meltio, which makes a host of wire-laser metal deposition systems, aims to make the technology less intimidating and more accessible for machine shops and small to mid-size manufacturers.

The new M600 offers a range of automatic features that Meltio hopes will ease the introduction of the technology into more places, outside of its current niche areas, where it can offer increased metal part production speed with less waste.

Designed to perform 24/7 with minimal operator interaction, the M600 is a 3-axis 3D printer that uses common welding wire as its feedstock, which is much cheaper than metal powder and safer to handle.

Meltio says the material properties of parts from the M600 are comparable to conventionally manufactured parts.

New for laser DED technology is Meltio’s use of a blue laser it says increases printing speed while reducing energy consumption. This short wavelength light is better for reflective materials, such as copper and aluminum alloys, and, combining this with the enclosed printer’s fully inert workspace, expands the available range of materials. The DMG Mori Lasertec machines also feature a blue laser but use metal powder instead of wire.

The laser head, which is calibrated at the factory, not by users, includes new sensors for monitoring the printing process.

The M600 is not only for fabricating parts from scratch but enable you to add or repair existing parts.

Meltio Horizon, is the dedicated slicer for the Meltio M600 and the backbone to its automation. It features a simpler profile selection and premade profiles that cover a large range of geometries and qualities. Workers can select a stored presets and the machine workspace adjusts automatically. Engineers can use the slicer to also configure different sections of the build for print quality and speed and generate infills, including gyroid lattices.

Tech Specs & Price

- Technology: wire laser direct energy deposition (L-DED)

- Build Volume: 300 x 400 x 600 mm

- Laser Type: 9x direct diode blue laser (450 nm wavelength)

- Materials: Metal wire (0.8 – 1.2 mm)

- Price: TBD

Farsoon's new FS721M-8-CAMS Metal LPBF

(Mar. 11, 2024) Farsoon, the large Chinese manufacturer of both metal and polymer laser powder bed fusion 3D printers, just launched its latest edition, the FS721M-8-CAMS, whew, that’s a mouthful. We’ll just call it Cams, which stands for Continuous Additive Manufacturing Solution.

This metal LPBF machine features an internal conveyor system, which the company says opens up new potential for series production with increased automation.

Integrating eight 500W or 1000W lasers, Cams automatically transfers a completed build unit to an “inert breakout station” and loads a second build unit to start another print job. Billed as “continuous production capability” this system ensures minimal machine downtime between build jobs.

In addition to the print automation, the powder handling is also automated. The closed-loop powder handling system integrates multiple powder processes, including powder recycling, storage, sieving, and new powder supply.

Print speed on the Cams can be up to 300 cm3 per hour.

Hardware advancements on the Cams over the company other metal LPBF machines include an updated chamber design with “multi-layer gas flow” and a new recoater design to improve powder surface flatness and consistency throughout the build area.

Like all Farsoon systems, the Cams is powered by Farsoon’s MakeStar software that offers build process control and real-time monitoring of the build environment, including laser power, air flow, temperature, and humidity. In-chamber cameras monitor and record each layer for build quality.

Tech Specs & Price

- Technology: metal laser powder bed fusion (M-LPBF)

- Build Volume: 720 x 420 x 390 mm

- Min. layer thickness: 0.02 mm

- Max. Laser Scanning Speed: 10 m/s

- Laser Type: 8 x 500W or 8 x 1000W

- Inert Gas: Argon/Nitrogen at 6-8 l/min

- Materials: Stainless steels 316L & 17-4PH, TA15, Ti6Al4V, AlSi10Mg, Al5250

- Price: TBD

Prusa's New Pro HT90 FDM

(Mar. 5, 2024) The long-awaited Pro HT90 FDM from Prusa Research is finally available to order, but not shipping until June. This FDM 3D printer targets engineers, as opposed to Prusa’s mainly consumer customer base, who want to 3D printing functional prototypes and end-use parts made from engineering grade materials, such as PEI and carbon-fiber-infused PEKK.

The HT90 is the company’s first delta kinematic 3D printer standing apart from its extensive line of Cartesian-style 3D printers. This type of printer can have faster changes in direction and quicker movements than most Cartesian machines. Prusa says the Pro HT90’s acceleration reaches up to 20,000 mm/s², but the company hasn’t release an actual print speed.

Describing speed in a more practical way, Prusa says the HT90 can deposit 1kg of PETG or ABS filament in just eight hours.

In another first for Prusa, the HT90 is fully insulated and enclosed with an actively heated and cooled chamber. The heat — from the heated bed to 155ºC, heated nozzle to 500ºC, and the chamber heater to 90ºC — makes printing with industrial materials more predictable, while the active cooling ensures that, when you’re printing with PLA, you don’t have to keep the door open to prevent overheating. This feature lets you take full advantage of the professional-grade HEPA air filter for every print.

Tech Specs & Price

- Technology: FDM

- Build Volume: Ø 300 x 400 mm

- Max. Nozzle Temp.: 500°C

- Max. chamber temp.: 90°C

- Max. bed temp.: 155°C

- Print Preparation: Prusa Slicer

- Price: $10,000

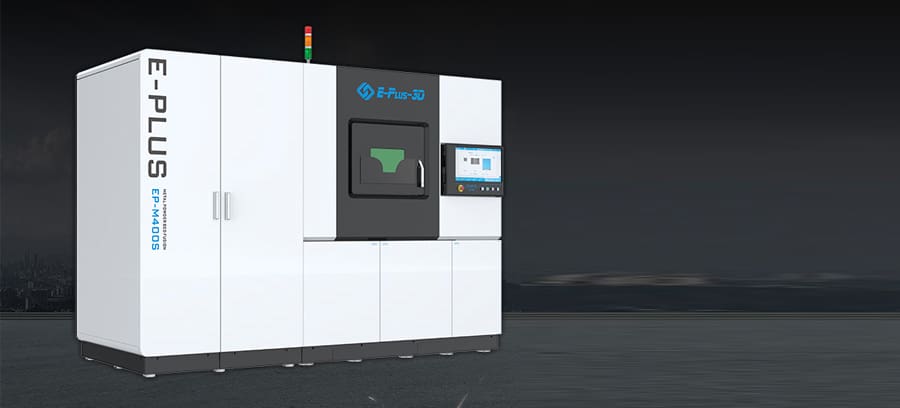

Eplus3D's New EP-M400S Metal LPBF

(Jan. 31, 2024) Eplus3D, a maker of metal laser powder bed fusion 3D printers, just launched a new edition of its quad-laser printer originally launched in April 2023. The EP-M400S builds on the success of the EP-M400, the company says. This new model brings “significant enhancements” including a new top feeding powder hopper and bi-directional powder re-coating, which reduces powder-spreading time by up to 30%.

The EP-M400S is also 10% smaller than the non-S version while reducing the build volume just a touch from 405 x 405 x 450 mm to 400 x 400 x 450 mm. The laser spot size is a touch smaller (70 µm vs the previous 80 µm) Eplus3D says new features added to the EP-M400S provide easier access for cleaning and maintenance locations on the machine. Otherwise, the specs of the EP-M400S are pretty much the same as the EP-M400.

Tech Specs & Price

- Technology: Metal Laser Powder Bed Fusion (LPBF)

- Build Volume: 400 x 400 x 450 mm

- Laser: 1, 2, 3, or 4 fiber lasers with multiple power levels (500W, 700W, and 1KW) for each

- Laser Spot Size: 70 – 120 µm

- Max Scan Speed: 8 m/s

- Layer Thickness: 20 – 120 μm

- Materials: Open. Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, and more.

- Gas Supply: Ar/N₂

- Software: Eplus3D EPHatch

- Price: not yet available

CreatBot's New D1000 FDM

(Jan. 03, 2024) The new D1000 large-volume industrial FDM 3D printer from CreatBot is the latest machine to join the square-meter club with its 1,000 x 1,000 x 1,000 mm build volume.

CreatBot’s D1000 doesn’t just print large objects, it also supports large-sized spools of filaments, including PLA, ABS, ASA, PC, Nylon, PA-CF, so you can print big models without worrying about having to replace the filament in the middle of a project.

The D1000 also sports a new auto-rising dual extruder hot-end kit that enables the nozzle temperature to reach up to 420℃. There’s a convenient magnetic build plate for easy removal of large prints, a chamber that reaches 60°C, and a HEPA air filter.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 1,000 x 1,000 x 1,000 mm

- Max. Nozzle Temp.: 420ºC

- Max. Bed Temp.: 100ºC

- Max. Chamber Temp.: 60ºC

- Max. Print Speed: 120 mm/s

- Min. Layer Height: 50 μm

- Materials: Open

- Software: CreatWare, Simplify 3D, Cura, Slic3r, etc.

- Price: Aprox. $45,000

License: The text of "All the Best Professional 3D Printers Launched in 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.