The recent implementation of massive tariffs has sent shockwaves through every industry, sending manufacturers, importers, and consumers alike into alarm. Although new factories won’t be built overnight, U.S.-based additive manufacturing services, a rapidly growing $13 billion industry, can step in today to deliver critical spare parts, injection molds, custom tooling, and a host of products currently outsourced to overseas manufacturers.

Even if the per-part cost of additive manufacturing is higher, the total cost might be lower without import duties, freight, and delays.

Pivoting from traditional manufacturing to additive manufacturing is not an overnight process either — but it’s very doable with the right approach, which depends on your parts, your industry, and your goals.

If your company already has a digital workflow with parts available as computer-aided design (CAD) models, transitioning to 3D printing becomes smoother. The same digital file you use for traditional manufacturing can be used for additive manufacturing, and in most cases, simply uploaded to an online, on-demand 3D printing service. Yet, shifting your manufacturing method provides an opportunity to rethink and optimize your parts. 3D printing enables most parts to be manufactured to be lighter and more efficient. You could explore new materials, such as engineering-grade plastics, to replace metals. Industries like aerospace, automotive, and defense, however, that require validation and may need new testing for AM-produced parts.

Although massively disruptive, tariffs could become the impetus for many U.S.-based companies to finally modernize their manufacturing.

Whether 3D printing is used as a bridge solution until tariffs are alleviated or becomes a long-term strategy, as we will explore in this article, a transition to U.S.-based, on-demand manufacturing can:

- Eliminate the need for large volumes of inventory, enabling print-on-demand

- Avoid inventory obsolescence

- Ease supply chain disruptions

- Prototype to full production in a matter of days/weeks

- Enable more design freedoms and customizations

There’s never been a better time to explore what U.S.-based additive manufacturing service companies can do for your business. Some can help you identify which parts in your inventory are ideal for 3D printing, how to print them, and introduce you to the full workflow. Others are quick manufacturing solutions that deliver prototypes and final parts in metals, plastics, and ceramics in a matter of days.

If you’re new to 3D printing, we recommend you check out our Get Started With 3D Printing at Work section covering the technologies, materials, and option. If you’re ready to jump in and start ordering parts, but don’t know which U.S.-based additive manufacturing companies to partner with, keep reading.

American 3D Printing Services

Although not every service 3D printing in the U.S.A. can be listed here, these are among the top companies to know when it comes to getting your parts made domestically.

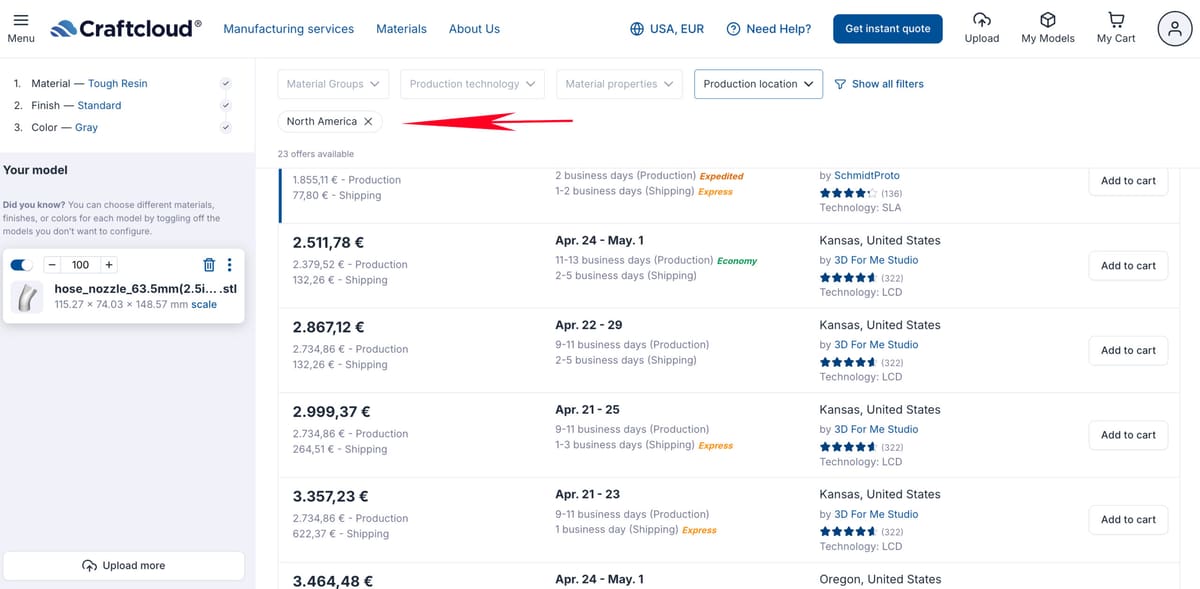

Craftcloud

Craftcloud is a live online marketplace with hundreds of manufacturing partners, including 35 in the U.S.A., including JawsTec, Autotiv, and Advanced Additive Innovations. Even though Craftcloud, with headquarters in Munich, Germany, manages your part production from first quote through to delivery, you’ll never pay import tariffs if you select a manufacturer within your country.

Once you upload your parts to Craftcloud’s instant quoting platform, you can select “North America” under the location tab to see all of the available printing services and their prices, weeding out the few from Canada and Mexico.

Trade policies and tariffs change frequently, so with Craftcloud, you’re not locked into one manufacturing location. With a geo-flexible manufacturing strategy, you can dodge tariffs worldwide by choosing where parts are made and stay agile in an unpredictable trade landscape.

Because of its wide range of service partners worldwide, Craftcloud can be your single hub connecting you to 3D printing services anywhere you need parts made and delivered. This means you can minimize or even avoid tariffs on manufactured parts. If a specific part would incur heavy import tariffs from China, for example, you could choose to have it made and shipped from within the U.S. or another tariff-exempt country.

Craftcloud offers an array of technology options, with over 120 materials and finishes, dozens of colors (including a full color option), and metals.

Craftcloud technologies:

- FDM

- SLS

- SLA

- MJF

- Binder Jetting

- Metal (DMLS/SLM)

In addition to 3D printing, Craftcloud also offers CNC machining, sheet metal fabrication, and casting and molding.

American Additive Manufacturing

Penn.-based American Additive Manufacturing bills itself as a solution to supply chain problems, specifically “catering to businesses seeking to onshore or reshore their operations and support the Made in USA initiative.”

The goal of AAM is to circumvent issues that arise from “original equipment manufacturers” overseas, instead opting for the 3D printing of parts that were once imported. They print a variety of parts, from HVAC systems for airplanes to a working prototype of a car part.

AAM technologies:

- FDM

- SLS

- SLA

- MJF

- DMLS/SLM

Through its engineering department, you can also work directly with AAM’s engineers to tailor the printing process directly to your project’s needs. This includes:

- Application engineering

- CAD file generation

- File conversion

- 3D laser scanning

Endeavor 3D

Ga.-based Endeavor 3D is an additive manufacturing company that specializes in high-volume production of both polymer and metal 3D printed components. Operating from a 65,000-square-foot advanced manufacturing facility, the company offers product design, prototyping, production, post-processing, and quality assurance.

Endeavor is ITAR Registered and an officail HP Digital Manufacturing Network Partner specializing in Multi Jet Fusion (MJF) and HP Metal jet technology.

The company’s services cater to a variety of industries, including automotive, aerospace, and industrial Manufacturing.

Endeavor 3D technologies:

- MJF

- Metal binder jetting

- FDM

JawsTec

Idaho-based JawsTec expedites the 3D printing process through its short lead times (2-5 days) and instant online quoting platform. Although its quote platform isn’t a work of art, it is organized, informative, and clear. Users can toggle between 3D printing, sheet metal, injection molding, and CNC machining quotes at the top of the page; there are options for economy, standard, or expedited processing, and lead time is calculated based on the process and materials chosen.

JawsTec technologies:

- MJF

- SLS

- SLA

- MJF

- CMF (Cold Metal Fusion)

Since its inception in 2017, JawsTec has produced parts for companies such as MIT, Ford, Delta, Tesla, and Apple. Its quick turnaround times make it a leader in expedited manufacturing, and NDAs are available to keep your project 100% confidential. JawsTec also offers CAD design help at $50/hr.

Additive Manufacturing LLC

Nev.-based Additive Manufacturing LLC brings 100 years of manufacturing history to the table for companies such as Airbus, NASA, Lockheed Martin, and Honeywell. Additive Manufacturing bills itself as a bridge between prototypes and high-volume production, “from a dozen to a few hundred.”

The company holds ISO 9001:2015 certification and has been ITAR certified since 2014, demonstrating its commitment to quality management and compliance with defense-related regulations.

To get a quote, register on their website and fill out a quick web form describing the project and upload your 3D files. The team will then send you a personalized quote.

Additive Manufacturing LLC technologies:

- Metal (DMLS)

- FDM

- MJF

- SLS

- SLA

- PolyJet

In addition to 3D printing, there is a plethora of other manufacturing options available, including:

- CNC machining

- Sheet metal fabrication

- RTV molding/urethane castings

- Die cutting/casting

- Injection molding

Quickparts

Wash.-based Quickparts in an on-demand manufacturing service offering a suite of solutions that encompass both additive and traditional manufacturing processes.

With multiple facilities worldwide, Quickparts leverages a vast network to provide localized support and efficient delivery, ensuring that clients receive their parts promptly, regardless of location.

The company has experienced engineers, dedicated project managers, and five well-equipped facilities to handle your low-volume production, although for mass production, it relies on its casting and injection molding services.

Quickparts offers what it calls “Lifecycle Support,” which promises to provide you with a dedicated program manager to oversee your part from design to prototype and through to the final parts and even scaling up to full production.

Quickparts technologies:

- Metal (DMLS)

- SLS

- SLA

Azoth 3D

Mich.-based Azoth 3D’s philosophy is all about upending the status quo. It was the first company to provide a metal 3D printed part on a Cadillac in 2021; it was the first manufacturer to offer binder jetting at an industrial scale. It’s now the first US additive manufacturer to offer nano-particle jetting (NPJ). Whether it is a crown for your back tooth, parts for firearms, or luxury watches, Azoth 3D is certainly a major player in the American metal 3D printing industry.

For small, complex parts, Azoth 3D finds metal binder jetting ideal; the process can reduce lead times for metal parts from weeks to 10-15 days. FDM, SLA, and SLS are also offered, with more than 55 materials to choose from.

Azoth 3D prides itself on reducing the friction that occurs from traditional manufacturing with its TOMO process. TOMO (“take one, make one”) is designed to convert physical inventory to a digital one — producing a new part on demand only as soon as a replacement part is taken from inventory. By designing a leaner supply chain, businesses can reduce their inventory costs and adapt more quickly in the face of inventory obsolescence.

Azoth 3D technologies:

- SLS

- FDM (metal & polymer)

- SLA

- MJF

- Metal Binder Jetting

Stratasys Direct

Minn.-based Stratasys Direct is a division of Stratasys that offers online quoting and on-demand 3D printing. Stratasys is a globally recognized brand; for over 35 years, it’s been a leader in the 3D printing industry, with Stratasys’ printers appearing on the manufacturing floors of many of the companies we mention in this article.

The Stratasys Direct website has a handy Material Wizard tool that lets you compare the physical properties of different PolyJet materials in real time. The wizard can make finding the appropriate printing material for your application fast and easy with instant quotes. The company also offers design services and can provide CAD modeling and model customization, training, and consultation.

Stratasys technologies:

- FDM

- PolyJet

- SLS

- DLP

- SLA

Xometry

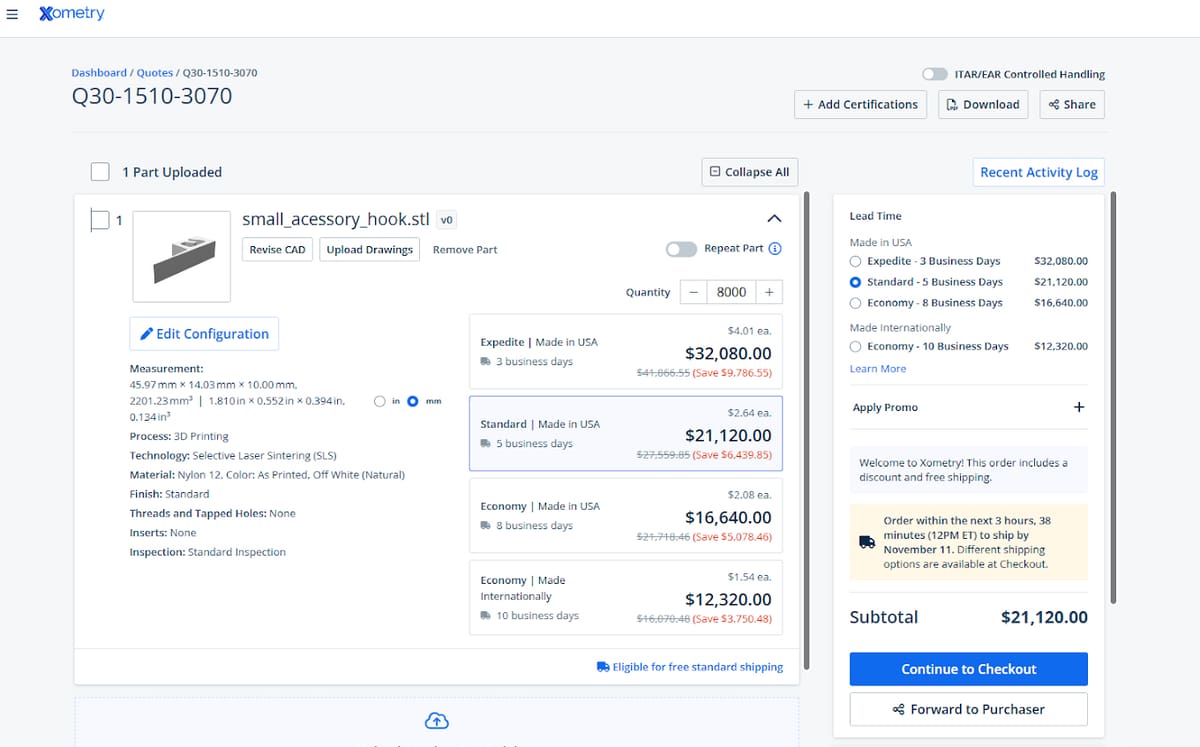

Md.-based Xometry has become one of the world’s largest online 3D printing services, using a nationwide network of manufacturing partners. It provides instant quotes for many projects filtered by production method, material, and lead time. Beyond 3D printing, Xometry offers a wide range of pro-manufacturing services like CNC machining, sheet metal parts, injection molding, supply-chain solutions, and services you need for high-volume production.

When it comes to 3D printing metal parts, Xometry has the most common technologies in store, namely metal binder jetting and direct metal laser sintering. Material-wise, you get a broad choice of materials like stainless steel, aluminum, titanium, Inconel, or copper, with a variety of finishes.

Using the service is straightforward, but registration is mandatory to get a quote from Xometry. Also, their price transparency isn’t as open as, for example, Craftcloud’s overview of production partners. Nevertheless, big business clients find Xometry’s features to their liking. Its Instant Quoting Engine, geared towards industrial clients, includes a printability check and part certifications.

Xometry technologies:

- Metal (DMLS)

- MJF

- SLS

- SLA

- PolyJet

Addman

A relative newcomer to 3D printing as a service, Addman, founded in 2020, seems to have jumped in with both feet, acquiring a stable of existing additive and traditional contract manufacturing companies to quickly build up its machine inventory and service menu. In 2022, it acquired Castheon, a leading provider of metal additive manufacturing technologies for mission-critical space applications.

The Florida-based company offers metal and polymer 3D printing, CNC machining, and other post-processing at six facilities across the US.

When it comes to applications and industries served, Addman says it covers aerospace, medical, energy, and industrial, and produces everything from rocket thrusters to tooling to mission-critical hinges. They’ll even send you a free part sample.

The company’s metal 3D printing is carried out on an enviable collection of the industry’s top laser powder bed fusion printers, including a Velo3D Sapphire, a collection of EOSs, and machines from 3D Systems, GE Additive, and Renishaw. Engineers on staff can guide you to the right machine, materials, and post-processing for your application. In fact, the engineering consultancy can start with your part requirements and develop your part’s application-specific design, material, and manufacturing process.

Addman technologies:

- FDM

- SLS

- MJF

- SLA

- DLP

Aside from polymer and metal printing, Addman also offers injection molding, CNC machining, and engineering help.

Protolabs

Minnesota-headquartered Protolabs makes its claim to fame with speed. The company promises very short lead times. They also have a digital quoting platform, which provides not only instant quotes but also design analysis, to make sure what you want to print is printable. Back in 2021, Protolabs joined forces with the online manufacturing platform Hubs, which has greatly enhanced its production capabilities. The Hubs division changed its name to Protolabs Network in 2024, but its services stayed the same.

In November 2023, Protolabs opened a new 120,000-square-foot facility in North Carolina primarily dedicated to metal 3D printing.

Although Protolabs doesn’t provide 3D modeling services, if you have questions after the online quotation process, their expert engineers will walk you through your material and design choices, but this option is for companies that already know exactly what they’re looking for and want the convenience of a user-friendly online platform.

Protolabs technologies:

- Metal (DMLS)

- FDM

- MJF

- SLS

- SLA

- PolyJet

Forecast3D

Brothers Corey and Donovan Weber started Forecast3D in a small garage in California with a single machine. Now, more than thirty years later, they house over 60 in-house 3D printers across three facilities, focusing on polymers and metals. Then, the huge metal powder supplier GKN, purchased the 3D printing service, and it became Forecast 3D Powered by GKN.

The group offers one of the world’s largest global networks of industrial 3D printers serving clients in the aerospace, automotive, industrial, healthcare, defense, electronics, and consumer products markets. From an intricate surgical device to a large intake manifold for a jet engine to a production run of 4,000 metal parts, GKN has the technology and experience to deliver, they say.

Forecast3D has a full suite of solutions for US manufacturers, from pilot plans to bridge manufacturing to full production.

Forecast 3D technologies:

- MJF

- SLS

- FDM

- SLA,

- Metal (DMLS, SLM)

- PolyJet

Users can take advantage of the instant quoting system and a digital inventory that makes it easy to re-order their parts.

SyBridge

SyBridge Technologies boasts over one million square feet of manufacturing capacity and is growing. Established in 2019, SyBridge acquired FastRadius in 2022, which is described on its website as a “manufacturing innovation company.” FastRadius still operates under its existing brand name but falls under the SyBridge umbrella of manufacturers.

SyBridge technologies:

- DLS

- MJF

- FDM

- SLA

Separate from SyBridge On-Demand, users can also turn to the more design-focused SyBridge Studio as part of their design workflow. The company is focused on both high-precision small parts in fields such as life sciences and consumer goods, as well as large-format molds for the industrial and auto sectors.

A3D Manufacturing

Formerly Athena 3D Manufacturing, Ariz.-based A3D specializes in plastic and metal printing for the aerospace, defense, life science, transportation, and consumer industries, offering a diverse range of services. In 2023, the company earned HP’s Digital Manufacturing Partner (DMP) certification — a testament to its high-quality standards across a high volume of production.

Through A3D’s professional 3D scanning services, you can build an inventory of digital parts through reverse engineering, eliminating the need to house old, rarely used parts in-house. The entire process is quick and streamlined, and you can receive your digitized files in an STL, OBJ, or CAD file if you plan on revising the design later.

A3D technologies:

- MJF

- SLS

- FDM

Other Technologies:

- CNC Machining

- Injection Molding

- Cast Urethane

- 3D Scanning

iDeal Technology

Mich.-based and family-owned since its inception in 1985, iDeal Technology is building itself out to be a major player in the automotive and aerospace manufacturing chains. In addition to its fleet of eighteen CNC machines, they hold several Stratasys and 3D Systems printers for rapid prototyping, offering SLA, SLS, FDM, DMLS, and PolyJet technologies. For large production runs, iDeal can also 3D print a master model of your part to create a silicone mold from which up to fifty parts can be cast, making it easy to scale up production quickly and efficiently.

iDeal can not only produce parts for you, but can also custom build assembly equipment to your company’s exact needs — from a simple tabletop manual assembly to a full-blown automated assembly line. The capabilities of this equipment span many industries, and include things such as hydraulic punches, ultrasonic welding, pressure & vacuum testing, and drill stations.

iDeal technologies:

- SLA

- SLS

- FDM

- Metal (DMLS)

- PolyJet

License: The text of "American 3D Printing Services Available to Bridge the Supply Chain Gap" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.