Does it matter where your 3D printer is made? Germany boasts expert engineering, China beats nearly everyone on price, and, for a small country, the Netherlands is home to a surprisingly large number of 3D printer makers. But in the end, most people may not know (or really care) where their 3D printer is made.

Ah, but how quickly times have changed.

The global tariff game has the potential to dramatically increase the price of 3D printers — we’re already seeing it — and affect the availability of materials and spare parts.

There’s a growing interest in buying domestically to avoid supply chain disruptions that can befall overseas equipment manufacturers. Plus, there’s the issue of accessible and reliable service, spare parts, and support. The defense industry and its contractors in the US are often required to purchase only American-made equipment. And, of course, many American consumers and companies prefer to buy American whenever feasible.

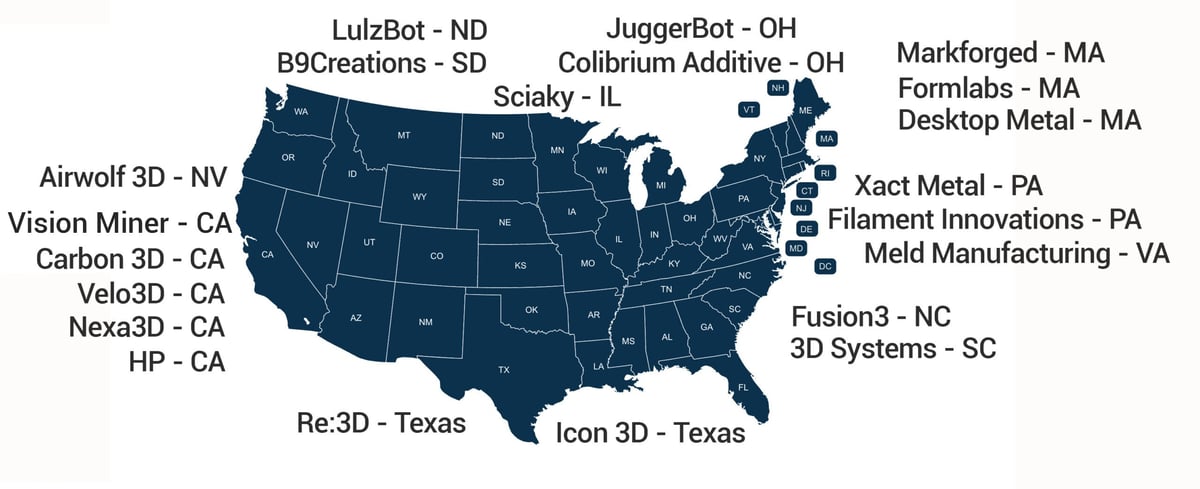

With this in mind, we’ve created a handy guide to the top American-made 3D printer companies. Keep in mind, though, that American made doesn’t always mean 100% American made. Circuit boards and components may still come from overseas so inquire with the manufacturer.

What Qualifies as Made in America?

To the best of our knowledge, these companies manufacture their 3D printers in whole or in part in the U.S.A. — components may come from overseas.

There is a growing list of companies, like Netherlands-based UltiMaker, Germany-based EOS, and Czech Republic-based Prusa, that have assembly lines and offices in the US (and employ Americans), but the companies themselves are not, strictly speaking, American, so not on this list. There are also companies with listed headquarters in the U.S. but are led (CEO, CTO, board of directors) by non-U.S. citizens, so we decided not to list these since they may not meet the U.S. Department of Defense (DoD) definition of “U.S.-based”.

Of course, when it comes to defense contract criteria, there are various levels and compliance standards so it’s best to reach out to the 3D printer maker to ensure that they may qualify.

Markforged

- Headquarters: Waltham, Massachusetts

- Founded: 2013

- Technology: FDM

- Materials: Polymers, Composites, Metals

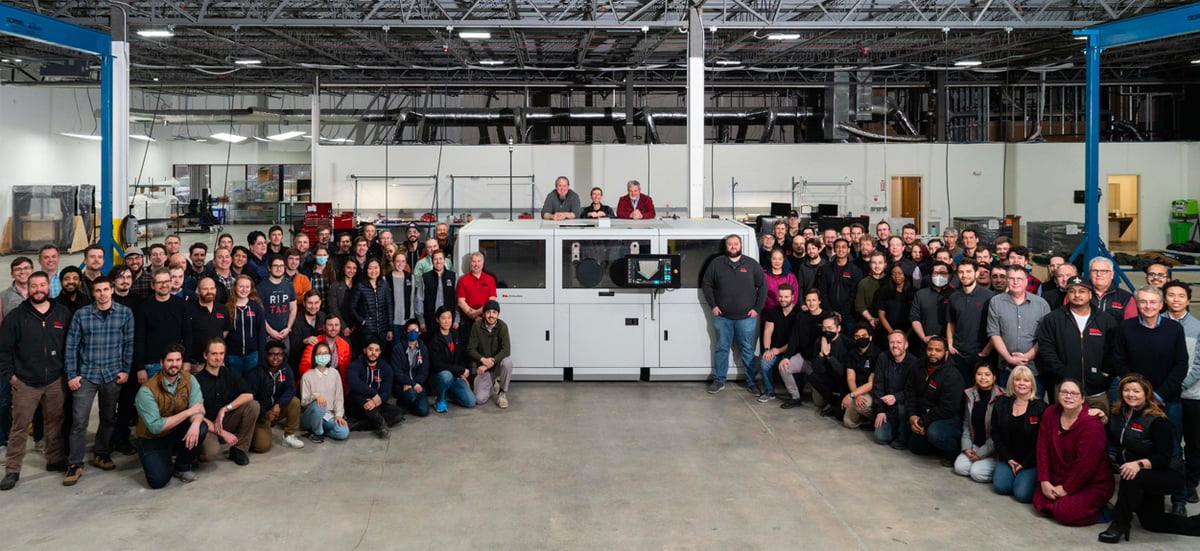

Markforged is an American publicly traded additive manufacturing company (currently in talks to be acquired by the Israel-based company Nano Dimension) that designs, develops, and manufactures a range of professional 3D printers, materials, and software. It employs nearly 400 people.

Widely known for its tough and rugged carbon-fiber nylon material, Markforged is a favorite on shop floors for the rapid production of tools, jigs and fixtures, and a wide range of functional prototypes and final parts used in automotive, manufacturing, and industry. Markforged machines also 3D print metal, which has proven to be a cheap and fast solution for companies that need one or low volumes of metal replacement parts, such as military units.

Formlabs

- Headquarters: Somerville, Massachusetts

- Founded: 2011

- Technology: SLA, SLS

- Materials: Polymers, Composites

Formlabs is one the world’s largest 3D printer makers focused on expanding access to digital fabrication, “so anyone can make anything,” the company says.

Formlabs makes some of the most popular resin 3D printers used in manufacturing, prototyping, dental care, and jewelry making. It also offers a selective laser sintering solution. The company also develops its own suite of materials and 3D printing software.

Formlabs opened a 20,000-square-foot facility in Milwaukee in 2022 to house more than 100 workers and has offices around the world for its nearly 1,000 employees.

3D Systems

- Headquarters: Rock Hill, South Carolina

- Founded: 1986

- Technology: FDM, SLA, SLS, LPBF

- Materials: Polymers, Composites, Metals

One of the world’s largest 3D printing companies, 3D Systems launched in 1986 and has been leading additive manufacturing innovation ever since. The publicly traded company has a broad portfolio of hardware, software, and materials (plastics and metals). 3D Systems was founded in Valencia, California by Chuck Hull, the inventor and patent-holder of the first stereolithography (SLA) 3D printer.

3D Systems’ solutions address a variety of advanced applications in healthcare and industrial markets such as medical and dental, aerospace & defense, automotive, and durable goods. The company employs nearly 3,000 people worldwide.

Carbon 3D

- Headquarters: Redwood City, California

- Founded: 2013

- Technology: SLA

- Materials: Polymers

Carbon 3D makes software, hardware, and materials that leverage its patented Digital Light Synthesis, a type of resin 3D printing, to produce mostly end-use parts, such as the well-known Adidas running shoe, Ridell helmets, and Rawlings baseball gloves.

Rather than offering a range of technologies, Carbon has focused on DLS for years bringing it to production levels for consumer products. Carbon does offer various hardware models that have different build areas for building either more parts or larger parts.

Carbon employs more than 500 people worldwide.

Colibrium Additive

- Headquarters: West Chester Township, Ohio

- Founded: 2016

- Technology: LPBF, Binder Jetting

- Materials: Metals

Offering metal 3D printers spanning three technologies, plus metal powder materials and consulting, Colibrium Additive — a GE Aerospace company — is widely known in aerospace, defense, and healthcare.

Colibrium Additive is not just a new name for the wing of GE Aerospace that focuses on additive manufacturing, but also a new focus on solving all manner of manufacturing challenges. The company’s metal additive design and manufacturing includes an integrated offering of additive experts, advanced 3D printers, services, and metal powder materials.

Velo3D

- Headquarters: Campbell, California

- Founded: 2014

- Technology: LPBF

- Materials: Metals

Velo3D provides an integrated metal 3D printing solution for parts used in aerospace, automotive, energy, and defense.

In 2023, NASDC-listed company, Velo3D became the first metal AM OEM to achieve Green Security Technical Implementation Guide (STIG) Compliance with the US Department of Defense. Green is the highest STIG compliance rating available, enabling Velo3D’s Sapphire family of 3D printers to be connected to the DoD’s Secret Internet Protocol Router Network (SIPRNet).

Icon 3D

- Headquarters: Austin, Texas

- Founded: 2017

- Technology: Extrusion

- Materials: Proprietary concrete-like

Icon is a Texas-based developer of construction technologies, including robotics, software, and building materials, collectively known as house 3D printers. Starting with smaller charity-backed projects to build homes in impoverished areas, the company has since gained hundreds of millions of dollars in investment financing to expand its technology. Currently, Icon is working with NASA on possible construction methods for habitats on the moon while at the same time expanding its house-building pursuits here on Earth to more extensive, mainstream American homes.

The company launched a new robotic-arm 3D printer that enables multistory construction. It also launched a new concrete material that will help its homes withstand hurricanes, heavy storms, and other severe weather in Texas that is becoming more frequent and severe due to climate change, the company says.

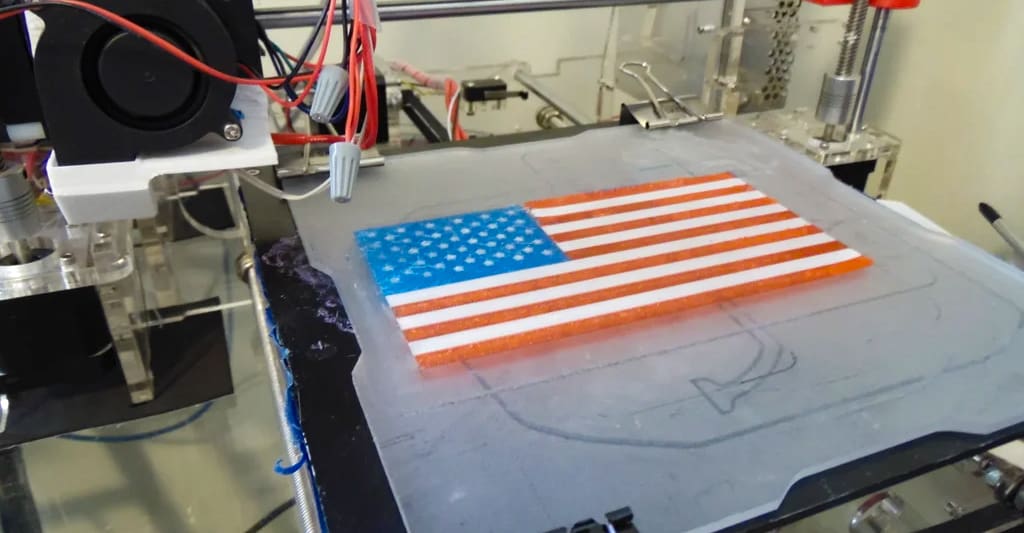

LulzBot

- Headquarters: Fargo, North Dakota

- Founded: 2011

- Technology: FDM

- Materials: Polymers

Based in Fargo, North Dakota, LulzBot is one of the largest manufacturers of desktop 3D printers in North America. All LulzBot machines are American-made, the company says.

LulzBot offers a wide range of desktop machines for education and professional use popular with consumers, small businesses, military branches, and maker spaces alike. Most of the company’s 35 employees are located in the Fargo area.

Desktop Metal

- Headquarters: Burlington, Massachusetts

- Founded: 2015

- Technology: FDM, Binder Jetting

- Materials: Polymers, Metals

Desktop Metal is a publicly traded American technology company (currently in the process of being acquired by the Israel-based company Nano Dimension) that designs and markets 3D printing systems for plastics, ceramics, and metals. The company’s 3D printers, materials, and software deliver on speed, cost, and part quality for customers worldwide.

With a growing team of 1,000+ employees, Desktop Metal now has engineering facilities in California, Michigan, New Jersey, Ohio, Pennsylvania, and Texas.

HP

- Headquarters: Palo Alto, California

- Founded: 1939

- Technology: Mult-Jet Fusion, Metal Jet

- Materials: Polymers, Composites, Metals

HP (formerly known as Hewlett-Packard) is the well-known American maker of personal computers, printers, and 3D printing solutions. The company uses its patented Multi Jet Fusion technology in a range of 3D printers popular worldwide and recently launched its metal solution, Metal Jet.

Although the company’s 3D printing R&D and operations are based in Barcelona, Spain, HP is very much an American multinational company.

Xact Metal

- Headquarters: State College, Pennsylvania

- Founded: 2017

- Printer Technology: LPBF

- Materials: Metals

Xact Metal offers three metal laser powder bed fusion 3D printers, with the smallest, the XM200G, as one of the most affordable options in its category aimed at companies that are just starting their entry into metal 3D printing

The printers offer multi-laser options with either a 100% overlapping work area using a 100 µm spot size or a 66% overlapping work area using a 50 µm spot size. This multi-laser system further increases build print speeds.

The company’s printer is featured in our guide to Affordable 3D Printers for Stainless Steel Parts.

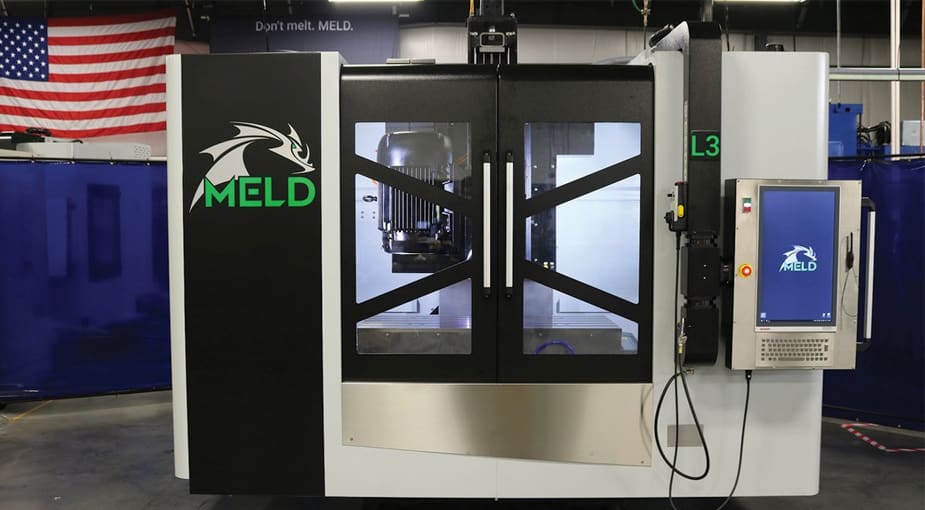

Meld Manufacturing

- Headquarters: Christiansburg, Virginia

- Founded: 2019

- Printer Technology: Meld technology

- Materials: Metals

Meld Manufacturing makes large-scale metal 3D printers using its unique solid-state process (meaning the metal does not reach the melting point) technology similar to cold spray. It uses off-the-shelf metals in solid or powder form to create fully dense parts by using high pressure and friction to make the metal malleable.

Its printers offer a wide range of capabilities, including additive manufacturing, coating applications, component repair, and metal joining. The Meld solid-state 3D printing process was chosen by the National Shipbuilding Research Program to reduce the lead times and efficiency of large steel castings.

Filament Innovations

- Headquarters: Coplay, Pennsylvania

- Founded: 2015

- Printer Technology: FDM

- Materials: Polymers

Filament Innovations is a small family-owned company that focuses on high-flow, pellet-fed FDM 3D printers. The company’s Icarus, Ares, and Poseidon 3D printers are used in a wide range of industries, especially healthcare.

The Poseidon can switch seamlessly between pellets and filament and the machine is also designed to be customizable so you can choose dual filament extrusion or only a pellet system. The hybrid version includes the entire ecosystem including a pellet system, high-flow filament system, 25kg pellet dryer, and the Odin slicing system for about $125,000.

The company’s printers are featured in our list of The Best Pellet 3D Printers.

Re:3D

- Headquarters: Austin, Texas

- Founded: 2013

- Technology: FDM

- Materials: Polymers

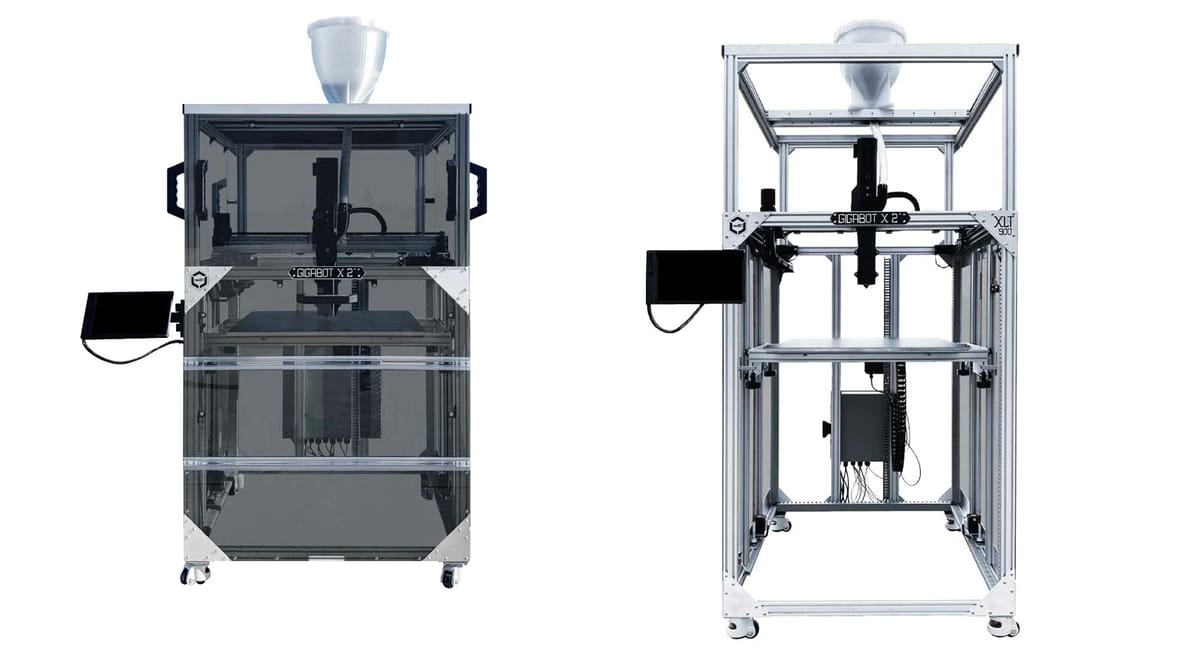

Spun out of Engineers Without Borders at the NASA Johnson Space Center a decade ago, Re:3D builds large and affordable FDM 3D printers.

The company sells its popular Gigabots in more than 50 countries and consistently donates one 3D printer to someone trying to make a difference in their community for every 100 units delivered. Recently Re:3D modified Gigabot to 3D print from pellets and reclaimed plastic waste in order to enable affordable, sustainable, and locally driven manufacturing.

JuggerBot

- Headquarters: Youngstown, Ohio

- Founded: 2014

- Printer Technology: FDM

- Materials: Polymers, Composites

JuggerBot 3D builds large industrial-grade, pellet-fed 3D printers called the Tradesman Series. The P3-44 machine, for example, comes in variations, thus the “series,” is a fully enclosed 3D printer capable of printing at a speed of 13.6 kg of material an hour. The bed can be heated to 120°C and the chamber to 95°C, so you can print with a wide range of materials, including glass- or carbon-fiber-reinforced polymers, PEEK, PEKK, Ultem, and more.

JuggeBot 3D machines are featured in our guide to The Best Large-Format 3D Printers.

Fusion3

- Headquarters: Greensboro, North Carolina

- Founded: 2013

- Technology: FDM

- Materials: Polymers, Composites

Fusion3 is a small manufacturer of affordable 3D printers for business and education with six employees, according to LinkedIn. The company’s Edge 3D printer is an industrial FDM designed for high-precision printing in carbon fiber, glass fiber, and kevlar-filled variants of all materials. The Edge is featured in our guide to the best polycarbonate 3D printers.

All Fusion3 3D printers operate on open-source software for easier integration into your business processes and Fusion3 has developed its own slicer software, F3Slic3r.

Sciaky

- Headquarters: Chicago

- Founded: 1939

- Technology: EBM

- Materials: Metals

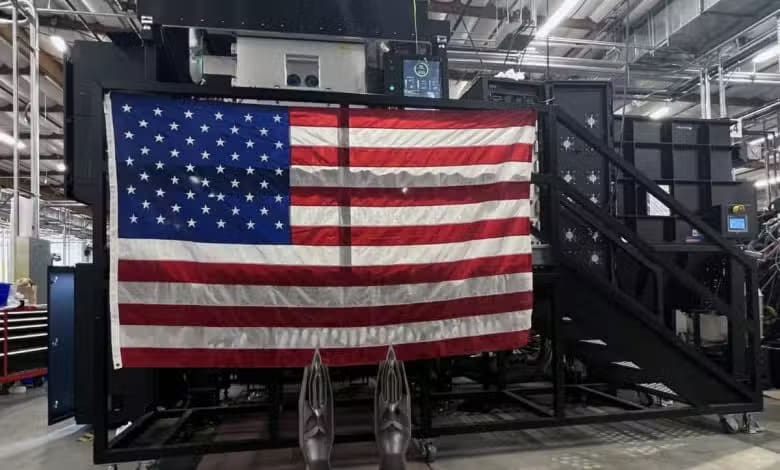

Sciaky, a subsidiary of Phillips Service Industries (PSI), is an American manufacturer of metal 3D printing systems and industrial welding systems, specializing in electron beam directed energy deposition (DED) systems and services mostly for aerospace manufacturers.

Sciaky builds truly massive wire electron beam 3D printers that make part geometries of up to 579 x 122 x 122 mm possible. Their smallest machine, the EBAM (electron beam additive manufacturing) 110, still has an impressive work envelope of 1778 x 1194 x 1600 mm.

B9Creations

- Headquarters: Rapid City, South Dakota

- Founded: 2005

- Technology: SLA

- Materials: Polymers

B9Creations offers a full solution to resin 3D printing for the medical and jewelry industry that includes printers, materials, software, washing and curing stations, and a 3D scanner.

B9Creations is featured in our guide to The Best Professional & Industrial Resin 3D Printers.

Airwolf 3D

- Headquarters: Las Vegas, Nevada

- Founded: 2012

- Printer Technology: FDM

- Materials: Polymers

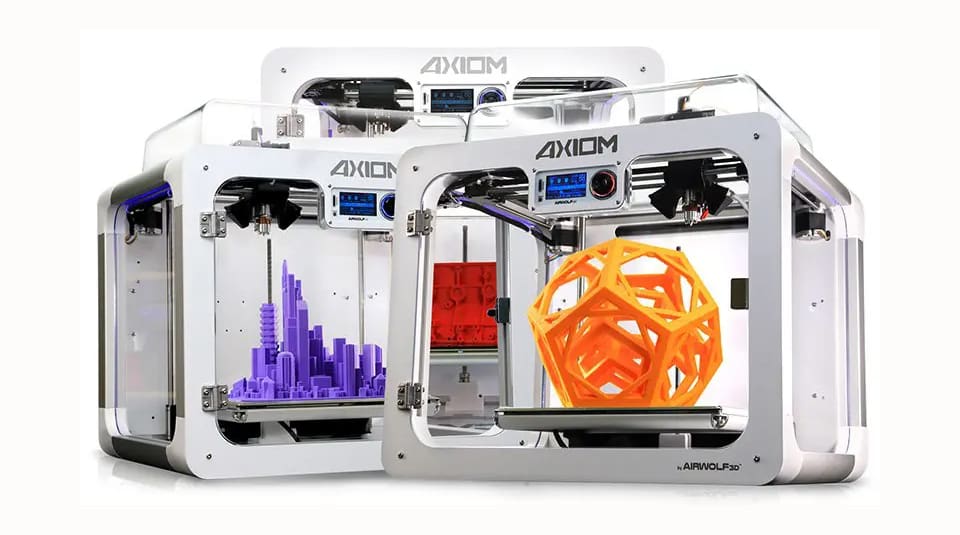

Airwolf 3D was founded by Erick and Eva Wolf, who say they are committed to manufacturing in the USA, creating jobs, and educating a skilled workforce for the future.

The company makes desktop FDM machines for engineers, hobbyists, and students alike. Airwolf also makes its own filament line.

Vision Miner

- Headquarters: Santa Ana, California

- Founded: 2017

- Printer Technology: FDM

- Materials: Polymers

Vision Miner, a 3D printer and reseller, designed and built its own 3D printer called 22 IDEX and debuted it in 2021. The machine, now in version 3, is billed as an industrial-grade 3D printer tailored for high-temperature materials and demanding applications. It has a build volume of 350 x 350 x 450 mm and features independent dual extruders capable of reaching temperatures up to 500°C, enabling printing with various engineering-grade thermoplastics, such as PEEK and Ultem.

The printer’s build volume measures 350 x 350 x 450 mm, providing ample space for sizable projects. Its heated bed can reach up to 200°C, and the actively heated chamber maintains temperatures up to 90°C, essential for minimizing warping in high-temperature prints.

Connectivity options include a web interface with remote access, compatible with MacOS, Windows, and Linux operating systems.

More American Made 3D Printers

In our search for American-made 3D printers, we came across a few more manufacturers that fall into specialized niches that may be just what you’re looking for.

Craitor’s FieldFab

Creative 3D Technologies

Austin, Texas-based Creative 3D Technologies makes 3D printers in-house out of Austin, Texas, offering what it calls an “all-in-one solution,” which is large enough for light furniture, precise enough for laser-comparable levels of detail, and tough enough to handle abrasives and metals.

Did We Miss Any?

Please let us know of any American 3D printing companies with commercially available 3D printers that we missed in the comments below or send a note to Pro@All3DP.com.

Never Miss Any News:

License: The text of "American-Made 3D Printers, 20+ Leading U.S. Brands" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.