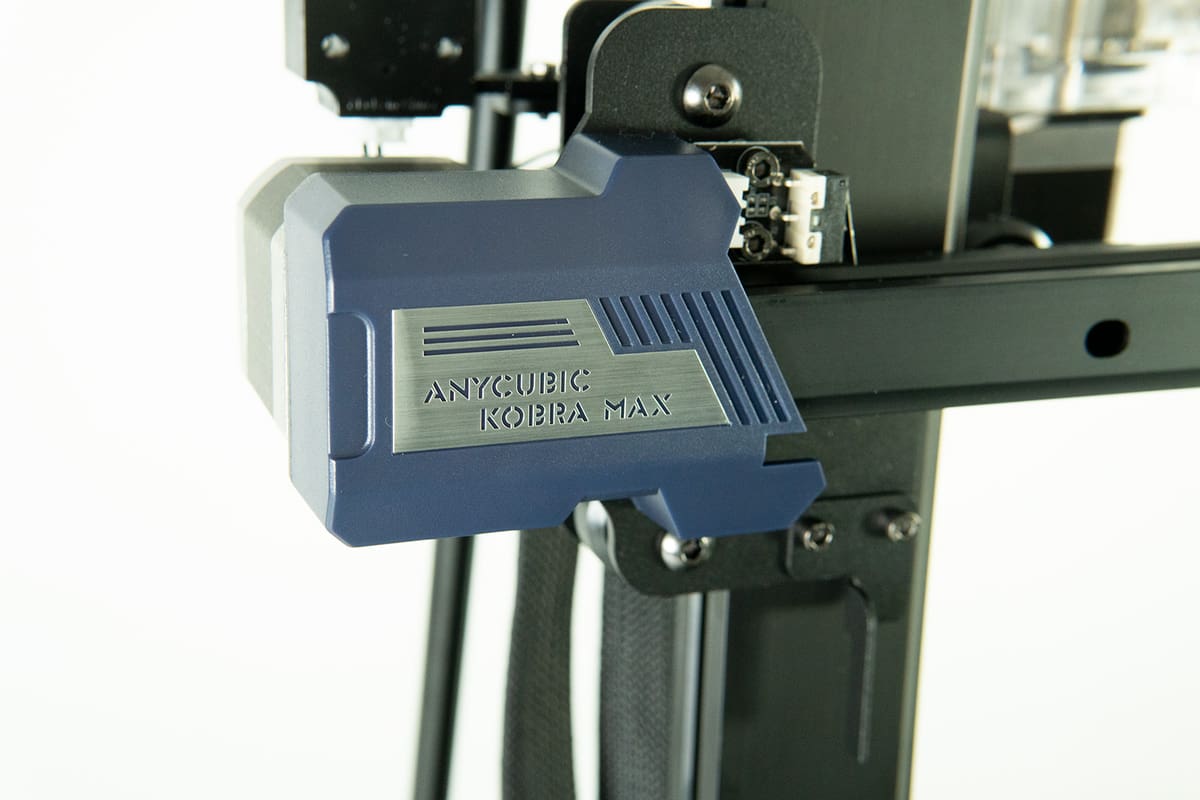

Anycubic just released two new FDM printers that make up its latest line of serpents-turned-3D-printers with the Kobra and Kobra Max. Besides the obvious difference in size, these two printers actually have little in common but their name. In fact, the Kobra Max takes cues from the company’s older Chiron and bears a much closer resemblance to another of Anycubic’s reptiles, the Vyper.

Resemblances aside, with a massive 400 x 400 x 450 mm build volume this particular Kobra lives up to its serpent king name and is most definitely Max – it’s one of the largest commercially available 3D printers available at this price point. Next to the huge build volume, it has a decent feature set, most of which we are familiar with from the Vyper.

We summoned our best parseltongue in the office to see what the Anycubic Kobra Max has to say and how it behaves once we set it free. Read on to find out.

Verdict

Pros

- Massive build volume

- Fast printing capabilities

- Easy to handle

Cons

- Spool holder unsuitable for huge prints

- Print settings need a little fine-tuning

- No large nozzles included

The Anycubic Kobra Max offers a large build volume and an impressive set of features for its price.

Printing large on a budget is a niche, not populated by too many options for users to choose from. In the Kobra Max, Anycubic provides an alternative that could become the go-to option for anyone looking to print big without spending big.

With a massive build volume of 400 x 400 x 450 mm, the Kobra Max allows for huge prints. Thanks to its automatic leveling system, LeviQ, and its carborundum glass bed, first layers and print adhesion are superb and, once set up, required no adjustments between prints. Combined with the printer’s robust chassis, its dual geared extruder, and Volcano-style hot end, the Kobra Max has almost all the tools for large 3D printing. Too bad Anycubic didn’t go all out with a larger spool holder actually suitable for large filament spools or larger bore nozzles to cut back on days-long print times.

Nevertheless, with minor modifications on behalf of the user and some tweaks to the profiles, the Kobra Max can be an absolute beast of a printer. Not just in size but also in performance.

At $569, the Anycubic Kobra Max is not a small investment. But for its build volume, features, and overall print experience, it’s a bargain. If you need a large volume, trouble-free operation, and repeatable performance, the Kobra Max is likely a good fit for you.

The Tech

Before we dive into divulging the Kobra Max’s features, let’s shed light on its nomenclature. While it’s called the Kobra Max, it would’ve made much more sense for it to be the Vyper Max. It has much more in common with Anycubic’s previous printer, from the looks to specific components and features, plus a sprinkle of Anycubic Chiron about it. Besides a mainboard, all it shares with the Kobra is a name.

That being said, let’s dig into Anycubic Kobra Max, an absolute unit of a printer with the potential to print enormous objects. But how well is the machine equipped for the task? Let’s play the flute, charm the snake, and find out what emerges from its basket.

Printing Big Prerequisites

Cobras are typically slender, weary fellows that, while being vertebrates, can bend their bodies in pretty much any shape and form. You know, snake stuff. But while the king of serpents has undoubtfully inspired Anycubic’s latest series’ namesaking, you definitely don’t want any snaking of that sort on your Kobra Max.

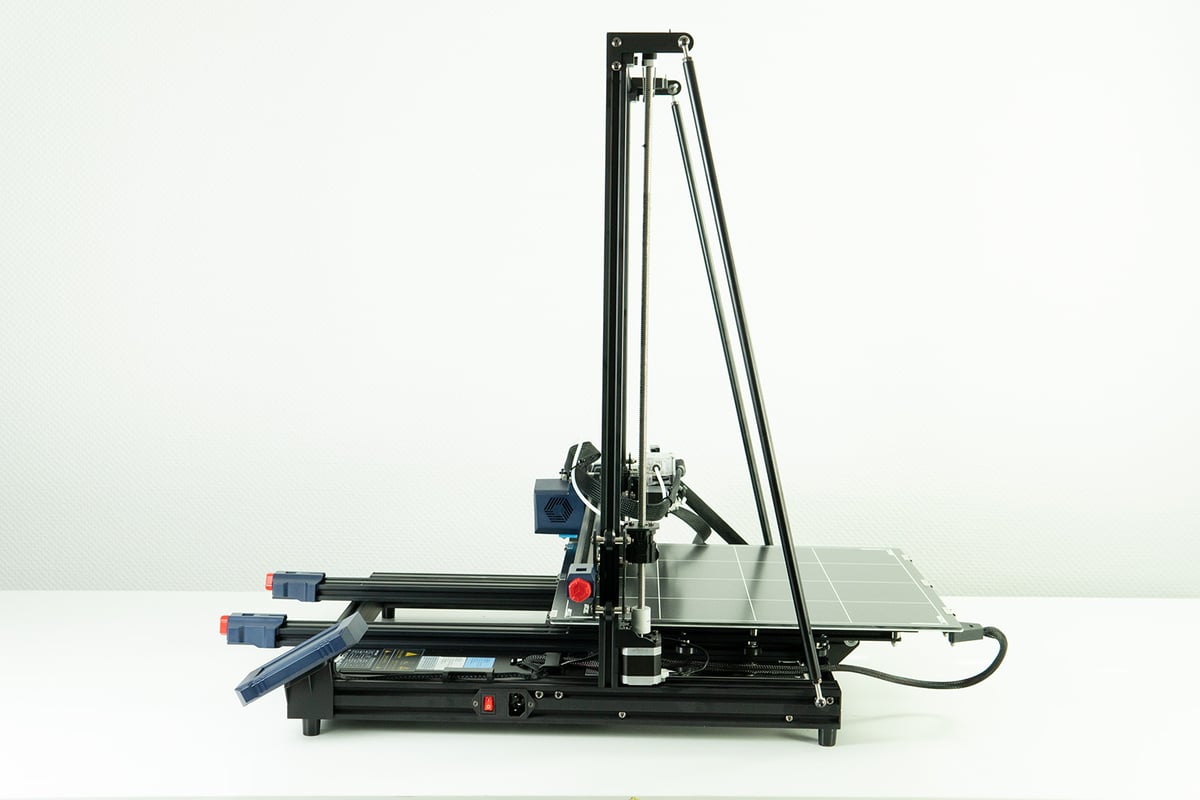

The Kobra Max comes with a sturdy spine; a reinforced frame with two Z-axis braces connecting the top to the base. With a total Z-axis height of 450 mm, any gantry movement is bound to cause metronome-like vibrations, even with its sturdy 40 x 20 mm aluminum extrusion profiles, which would come close to resembling a dancing snake. Needless to say, this would significantly affect the quality of prints. With the braces, though, the Kobra Max is well set for tall prints and fast gantry movement.

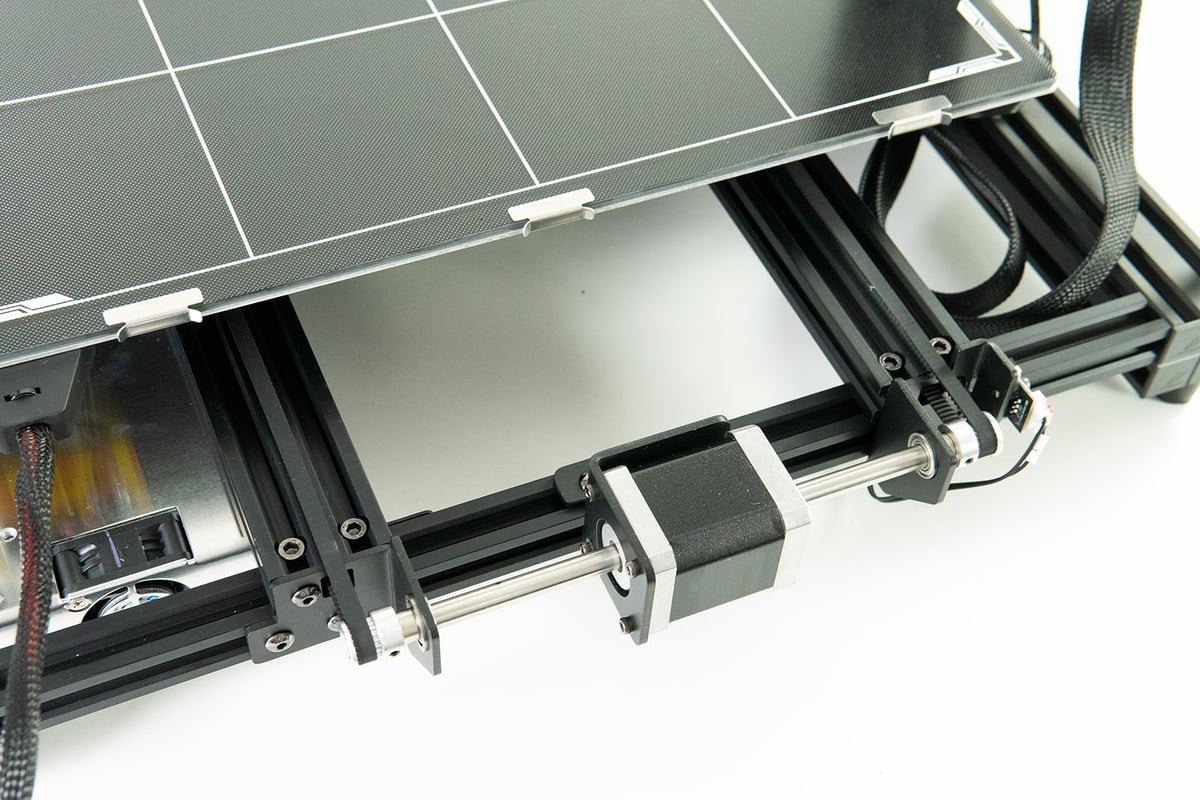

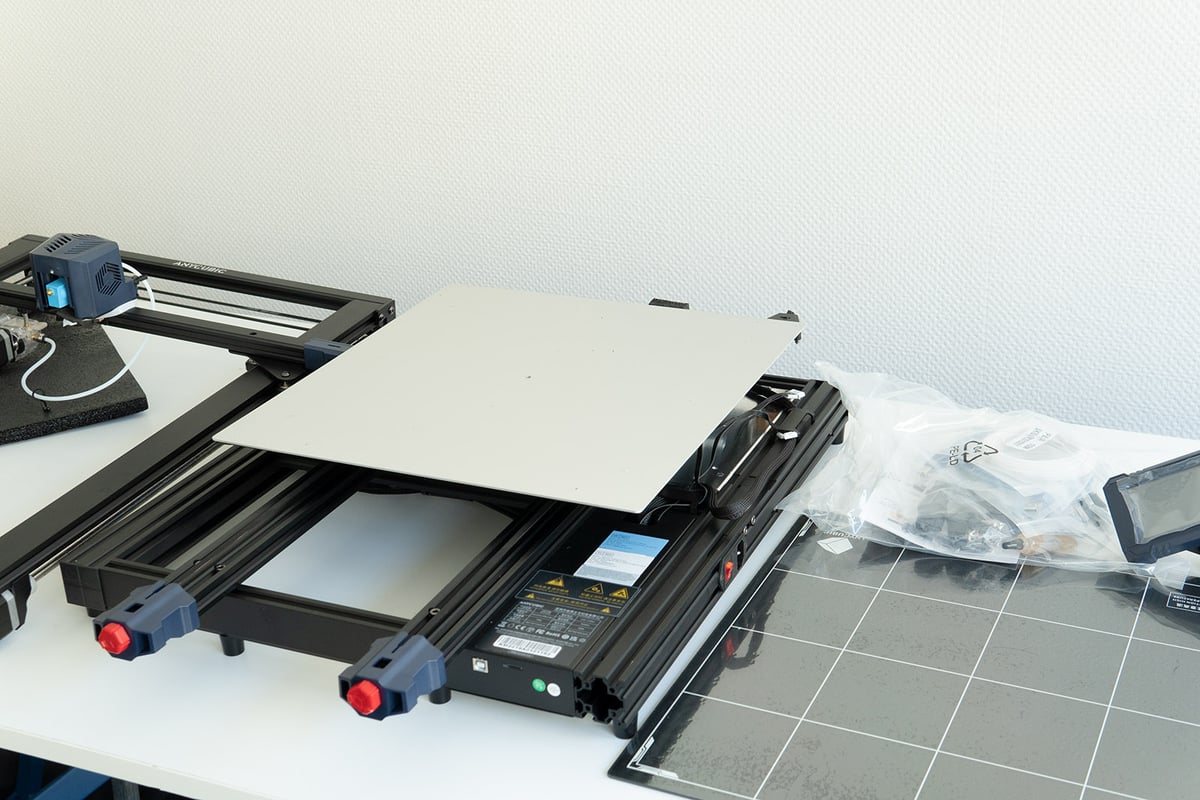

In fact, there are a few key features that ensure the Kobra Max is up to the task of printing big. Another potential wobble-prone bottleneck is the print bed suspension. With the 400 x 400 mm print bed, the Y-axis has a lot of mass to move back and forth throughout a print. And, it’s not just the bed. When using the entire build volume, large prints can make up to 2-3 kilograms of weight. As such, the Kobra Max comes with dual rails to support the bed, adjustable belts, and a single but powerful motor to drive it.

The manual belt tensioners, found on the Y- and Z-axis, add to the large footprint of the Max, which sprawls out to 720 x 715 x 665 mm. Note the print bed moves even beyond this footprint during printing, too. On the Vyper, tightening of the belts had to be done with an Allen key, which Anycubic ditched and went for simple turning knobs. We like, both the inclusion of belts and their simplified handling.

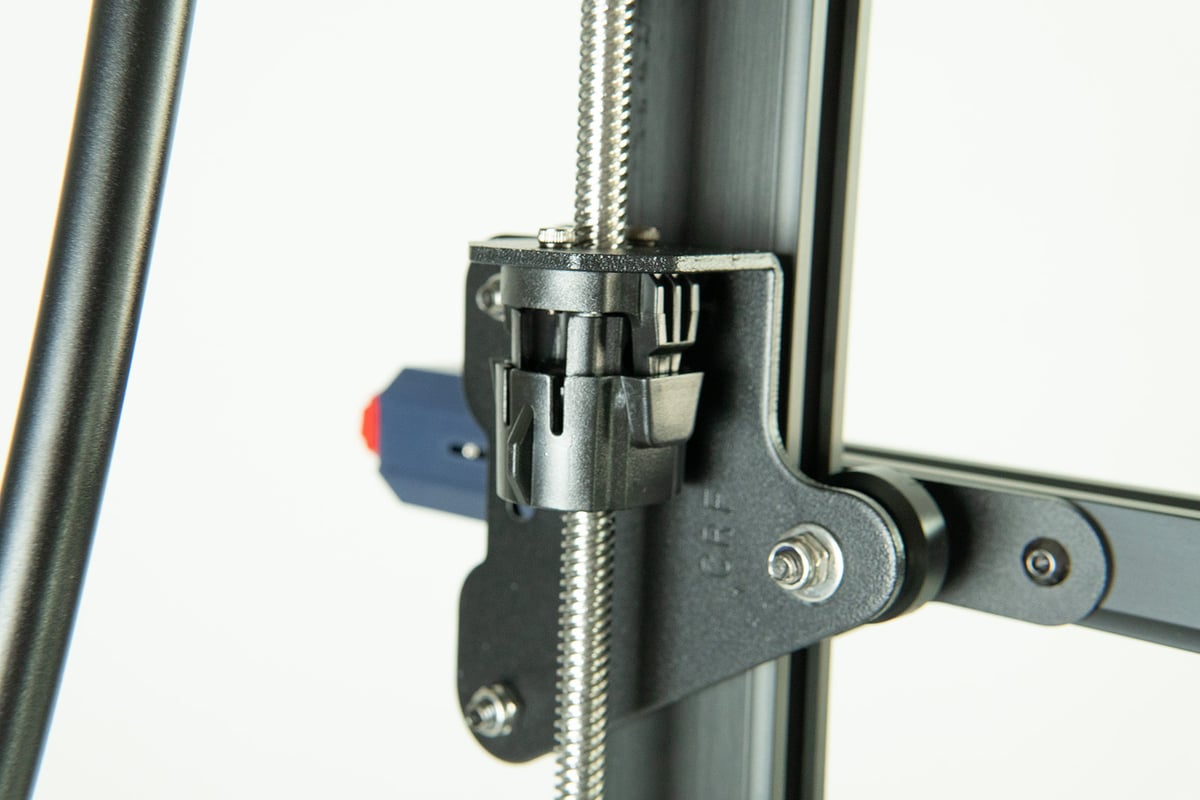

The Z-axis gantry itself features a dual motor with dual lead screws to ensure the smooth traveling of the Z-axis. To make sure it’s synchronized comes with a timing belt on top. The Kobra Max also features Anycubic’s custom plastic anti-backlash nuts, which we first saw on the Vyper. Curiously, for the “normal” Kobra, Anycubic opted for the more common brass nuts. Why? We can’t say, maybe it has to do with the strain gauge-based automatic-bed leveling system present on both the Max and the Vyper.

All in all, from a mechanical standpoint, the Kobra Max seems to have the frame licked for printing big.

Large bed

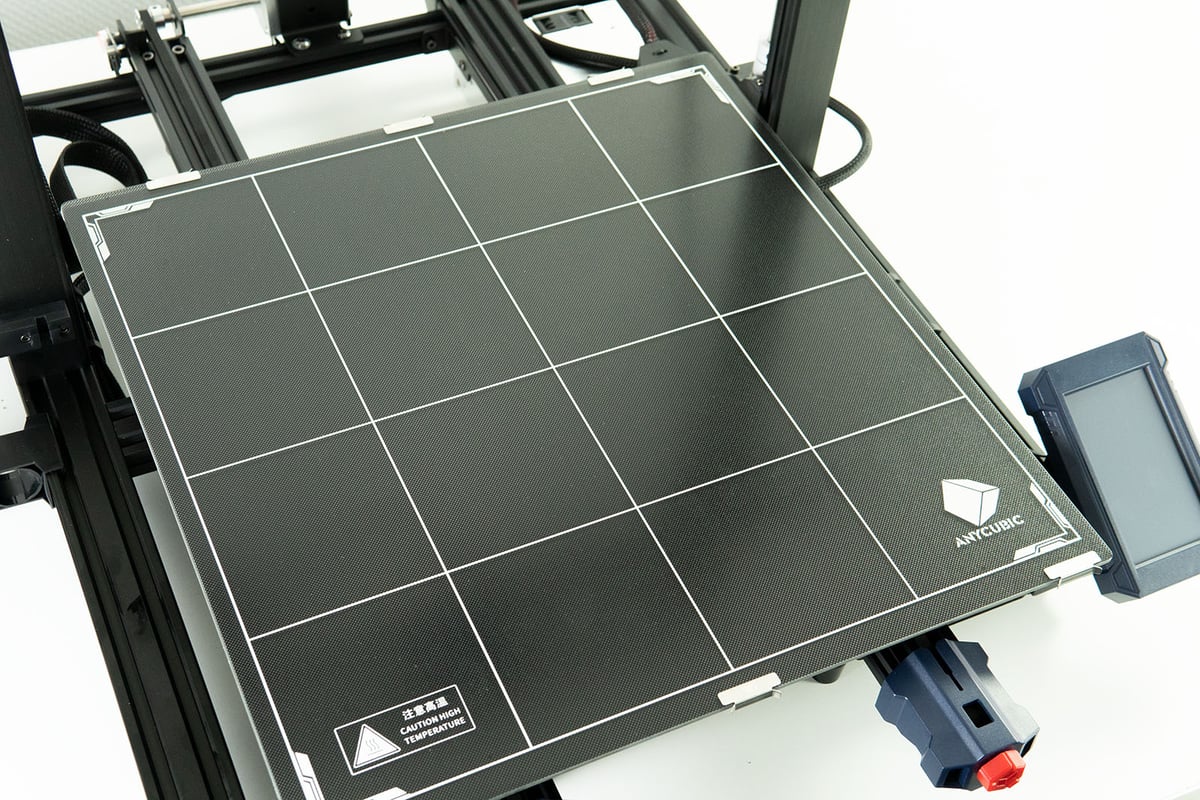

Unlike the other snakes in Anycubic’s vivarium, the Kobra Max does not come with a removable, flexible PEI sheet as found on the Kobra and Vyper. Instead, you get a tempered glass bed, carrying over from Anycubic’s past large-format printer, the Chiron.

This large slab of carborundum glass bed is held in place with metal clips. We found it provides good adhesion throughout even the longest of prints without the need for glue or other adhesives, largely thanks to its good thermal equilibrium. The print bed is not AC-powered, which would have been nice, given its sheer size. It heats quickly enough though, taking about four to five minutes to reach 60 °C.

We don’t mind the tempered glass approach. A huge flexible plate would’ve been awkward to handle with a bed-spanning print.

First layers look and lock great, and finished prints barely need a tickle with a scraper before they pop free. Especially so the larger they are. Should you find yourself printing small objects on the Max (they will look tiny by comparison), a little more care might be in order to remove them, but it really comes down to personal preference which surface you prefer to print on.

Temperature-wise, the bed can heat up to a maximum of 110 °C. And evenly, too. We pointed the laser-end of our thermometer across the build plate to find only a minor deviation of 3 – 5 °C across its 400 x 400 mm span. Thermal uniformity is essential in (large) 3D printing, especially on a tempered glass bed. Any premature cooling and the print may warp free of the bed. We had no problem with adhesion, whether during printing or when trying to remove it afterward. No adhesives were necessary.

Snakehead

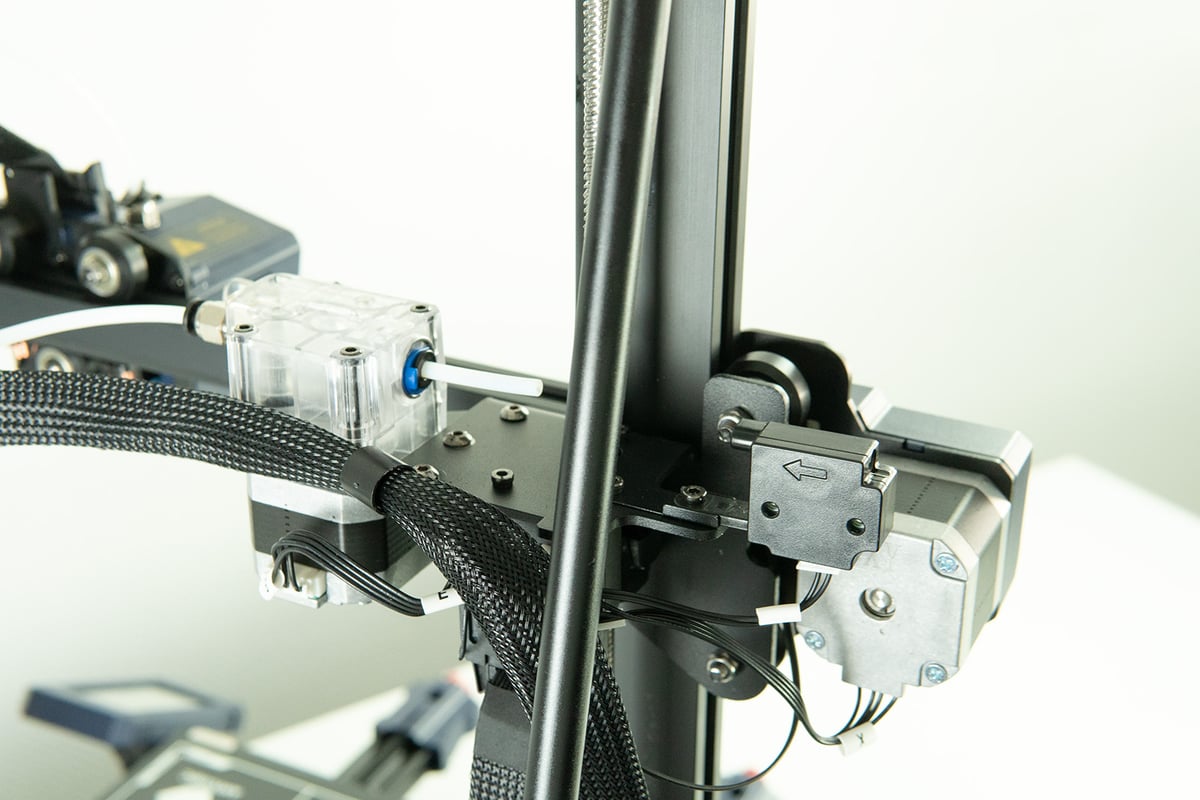

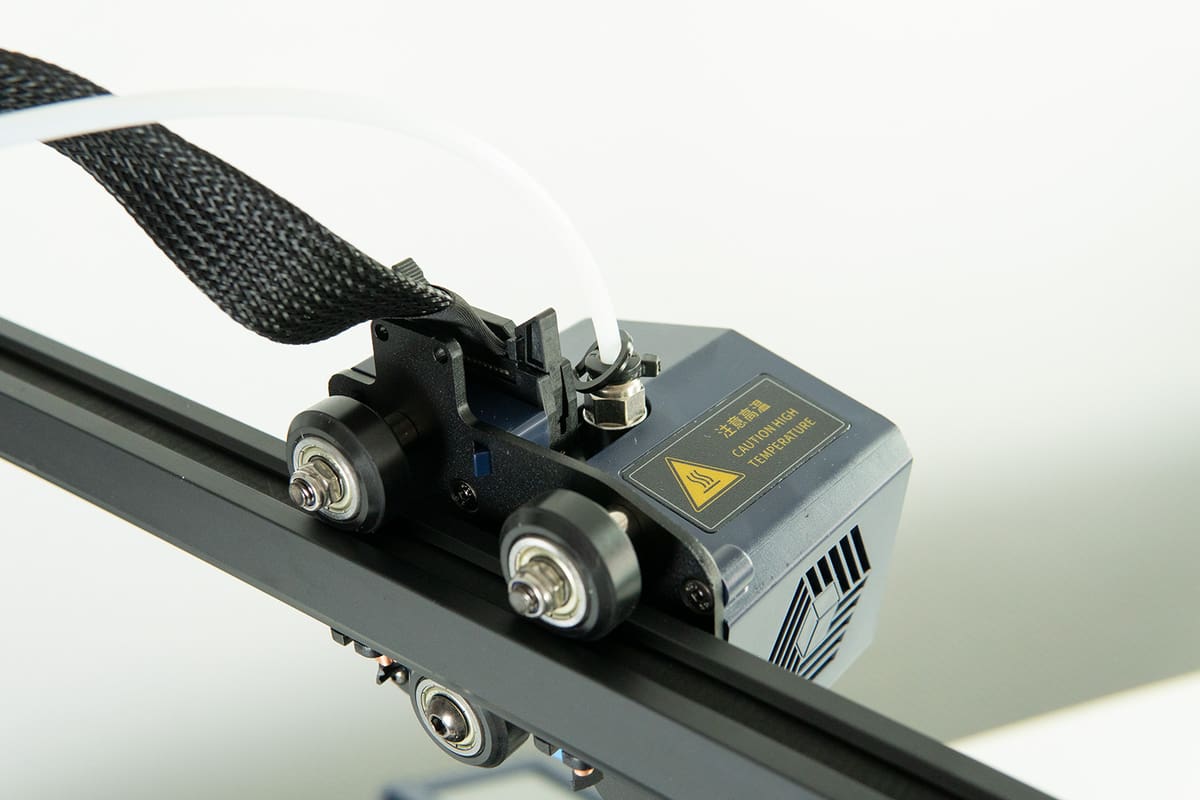

The Kobra Max’s print head actually is that of another serpent native to the Anycubic wildlife, the Vyper. The Volcano-style hot end, accompanied by two part-cooling fans that blow (hiss) from each side, made it over to the Kobra Max alongside the Vyper’s Bowden extruder – a dual-gear, Bondtech-style apparatus that gives smooth feeding of filament to the hot end.

The longer heat block of the Volcano clone allows for a larger melt zone, which allows the Max to print at the rapid speeds that it does and makes it suitable to upgrade to larger nozzles for even greater output. This can dramatically shorten print times. Prints at full build volume take days to print, but upgrading your nozzle to 0.6 or 0.8 mm makes printing these objects much more efficient and can cut print times by more than half. Too bad Anycubic didn’t think of including a few larger-sized nozzles.

The downside to a Volcano-style hot end is the tendency to struggle a bit more with retraction, which we found to be an issue on some prints during our review and may require some fine-tuning of slicer settings.

Unlike the Kobra, which got a completely new direct extruder, the Max uses a Bowden extruder. With the Kobra Max’s large build volume and the potential for Z-wobbling, sticking to a Bowden extruder reduces the weight on the Z-axis. However, it is not just the extra weight of the extruder that gets added to the Z-axis, but the spool holder would also need to be above the print head, ergo, mounted on the gantry. That’s a lot of extra mass, which could contribute to vibrations in the frame.

Throughout our review, we found the extruder to churn through materials with ease, even the occasionally tricky flexible materials fed through well.

LeviQ

Another feature that made the evolutionary jump from one species to another is the Kobra Max’s strain gauge-based auto-leveling system, which Anycubic brands LeviQ and was found on the Vyper as well. Mind, Anycubic calls the Kobra’s inductive probe leveling LeviQ, too – its not strictly the hardware as seen here, more its name for mesh-bed-leveling. Unlike the sensor on the Kobra, though, or a BL-Touch probe, the automatic leveling on the Max is done by the nozzle directly, or rather the strain gauge behind it, which will trigger once the nozzle makes contact with the build plate. To do so, the printer sets off on a 25 point mesh leveling route across the heated bed.

That being said, we found the leveling on the Kobra Max to be on point, and quite frankly, it has to be. There are no manual leveling knobs underneath the print bed, so there is no chance to ninja in and adjust a corner mid-first layer. During our time with it, we didn’t need to, though. We ran the auto-leveling once when setting the printer up and that was it.

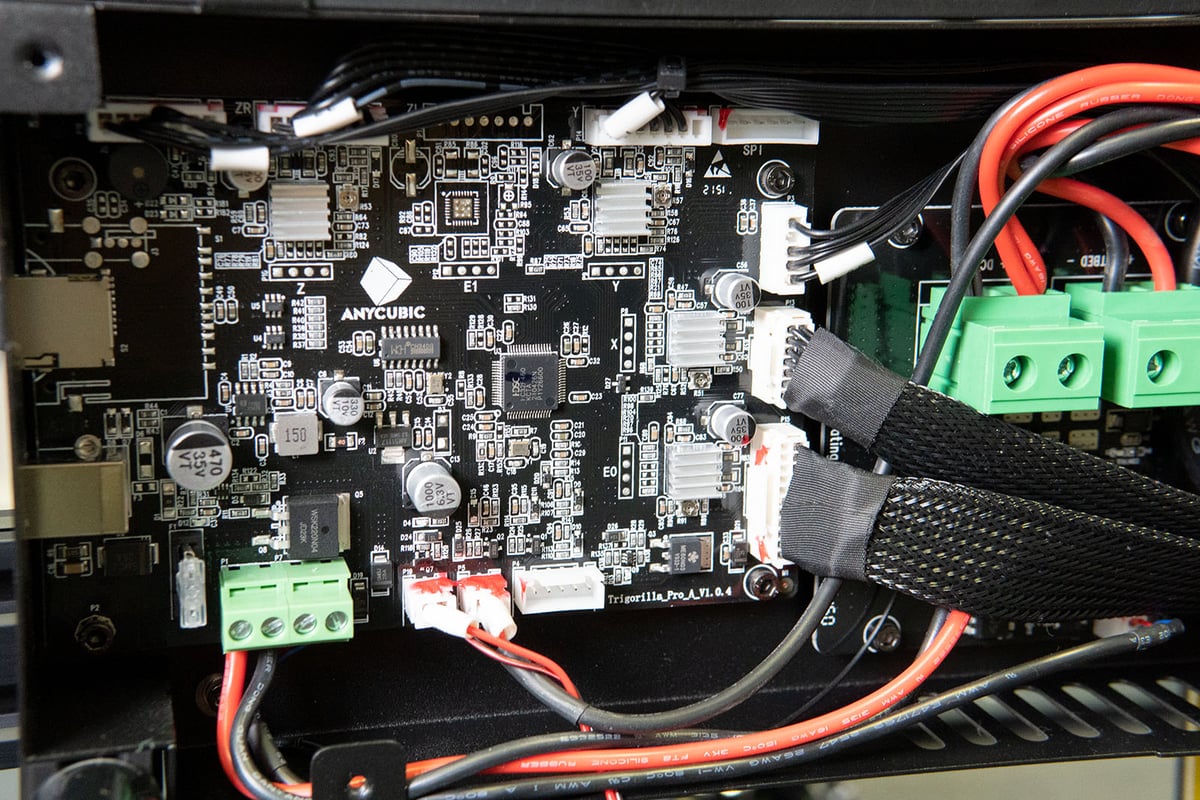

The Brain

A quick google search will tell you that a snake’s brain consists of five different parts. For the Kobra, this brain comes in the form of the Anycubic Trigorilla Pro A (V1.0.4) control board. Toting a 32-bit chip with a Cortex-M4 core at 200 MHz, the Kobra Max has plenty of computing power at its disposal. An extra power control module is installed on the Max, to help the printer handle the high current required by the print bed. Plus, for silent movement (though the tall grass), the Kobra Max comes with TMC2209 stepper motor drivers. In general, the printer is pretty silent given its size. As always, it’s the cooling fans that make the most noise during printing.

The printer itself can be controlled via a 4.3-inch touchscreen. The control menu is clearly arranged, and you can access print and fan speed as well as temperature settings mid-print. We did miss the possibility to alter Z-offset during printing, though.

Beast of prey

Lastly, the Kobra Max gets fed by a microSD, which seems almost like an appetizer for the king of serpents. Mind, the Vyper fed on proper SD cards which are just a bit handier in use and don’t go missing as easily. With the size of the Max, having to use a microSD feels even tinier. Oh yeah, and don’t get mixed up: the printer and the touchscreen both feature a microSD card slot. It is the printer you want to feed, though, not the touchscreen. Otherwise, you will be left wondering why nothing loads up.

Printing & Usability

Setting it Up

Unfortunately, busting out the snake-charming flute won’t help you with getting the Kobra Max out of its box and assembled. Handily, the Kobra Max comes semi-assembled, leaving you to simply attach the gantry with four bolts, install the Z-axis braces, clip the print bed into place, and you are pretty much good to go. Best take an extra moment and make sure to remove all the cable ties and check the belts and rollers to be adequately tightened. No flute neccessary.

Leveling the bed is a simple button selected in the menu, followed by you giving the nozzle a calibration touch with a metal tool. The printer will start its bed-leveling routine by measuring a 25 point mesh on the glass to compensate for any unevenness during the print. The leveling is done with the bed heated, so thermal expansion is accommodated.

If your first layer does not come out as planned, you can adjust the Z-axis offset. This is done during a print instead of a separate calibration option, so you may need to repeatedly start over a print until you get it right. With the auto-bed leveling and decent adhesion given by the print bed, we saw very few first-layer failures.

Prints

After churning through the included test print, we decided it was time to put the Kobra Max up to a real challenge. After all, what is this almost half a meter cubed build volume good for? Absolutely right: massive prints. Before embarking on a three-day print journey, though, we would advise playing around with the slicer settings bit.

To set up the printer in Cura, you will need to follow the instructions provided in the manual. The Max comes with two profiles, PLA and TPU. Interestingly, both are set with a default print speed of 80 mm/s, which we thought to be a little too ambitious, especially for flexibles. To our surprise, speed is not an issue for the Kobra Max. The Bowden setup and the rigidity of the frame really do come into play here, allowing the Kobra to print fast and relatively wobble-free even in higher altitudes of the Z-axis.

Off the top of our heads, we don’t think we’ve ever seen a TPU profile printing at such a rate on a Bowden setup, but we found it to work just fine. Retraction settings, support distance, and potentially the above-mentioned Z-axis offset are what we would advise playing around with, though. Especially retraction settings could do with a few tweaks and become all the more prominent when trying out PETG.

Prints that need little to no retraction come out marvelous. Where retraction is needed, you will notice some artifacts. All in all, it should be minor fine-tuning to get nice-looking prints off the plate.

Missing Link

With the 400 x 400 x 450 mm build volume, truly large prints are possible. The problem, though, besides its large build volume, is that the Kobra Max isn’t really prepped for such tasks. In particular, the spool holder and nozzle are a hindrance. The nozzle has a bore of 0.4 mm — standard for most smaller printers. For a printer the size of the Kobra Max, larger diameter nozzles, say 0.6, 0.8, or even 1 mm, would absolutely shred print times down to hours, instead of days. The hot end can pump the filament well enough for speedy 0.4 mm printing. But even a slower, but larger bore print would be faster.

The same goes for the spool holder. With the Max’s print volume, you most certainly will need more than 1 kilogram of filament for large and dense prints. More like two to three kilos, even with little infill. For this, the preinstalled spool holder is entirely useless. Large spools don’t fit.

Of course, you could 3D print one yourself, but that’s not the point. We deem it kind of a missed opportunity here by Anycubic, not to give users the possibility to 3D print at full scale on the stock Kobra Max without having to modify the printer first.

Is It Worth It?

The Anycubic Kobra Max is a mix of a couple of Anycubic’s previous printers: the Vyper and Chiron. Taking the features of the former and combining them with the frame, bed, and size of the latter results in 3D printer that should interest anybody looking to print big on a budget.

With a build volume of 400 x 400 x 450 mm, the Kobra Max not only provides ample room to materialize some of your most ambitious projects but, thanks to a handful of features, makes for a printer that’s an easy entry point into large format printing. Anycubic’s new automatic leveling system, LeviQ, delivers clean first layers for trouble-free print preparation. Its carborundum glass plate grips prints firmly, whether for a couple of hours or days on end. And its sturdy skeleton, Volcano-style hot end, and extruder setup allow the Kobra Max to print accurately at an impressive speed, making it an incredibly versatile machine, capable of not only printing large but also precisely.

Some adjustments to the printer profile were needed, mainly with retraction and support distance. With the stock profile, we found some supports welded into prints and retraction settings were a little off, given its Bowden setup. Still, overall, the Anycubic Kobra Max works for its $569 ask, with out-of-the-box print quality on par with many smaller and great 3D printers. You get repeatable results and trouble-free operation.

That being said, the stock printer misses some conveniences that would’ve made printing huge on the Max better. Instead, you’re forced to DIY quick fixes on areas such as the spool holder, which only holds standard 1kg spools to fit – a mere snack compared to the material the Max really needs to print full volume. If you want to put the entire build volume to use, you will most likely need to source an external spool holder for large, 2-3 kg spools or print one yourself. Also, the 0.4 mm stock nozzle is woefully slow for large prints – printing extra-large takes an obscene amount of time. Both nozzle and a spool holder can be obtained at little cost, but this is one area you’d expect Anycubic to help the user out.

Priced at $569, the Anycubic Kobra Max poses as an affordable entry into the niche that is large format 3D printing. You will have to look far and wide to find a similarly sized and specced alternative if you’re aiming for big projects and ideas.

Features

Huge build volume

With a more-than-decent build volume of 400 x 400 x 450 mm, the Kobra Max stands out even among large-ish 3D printers of its price class. Whether you want to 3D print life-sized helmets or scale up your favorite models, the Kobra Max offers ample build volume to let your creativity run wild.

It’s big, though. The footprint of the Kobra Max is 720 x 715 x 665 mm, but you will actually need even more room as the bed travels on the Y-axis and exceeds the frame’s footprint.

Sturdy design

Speaking of the frame, the Anycubic Kobra Max comes with braces for the frame, a measure to make the printer as rigid as possible and cut out unwanted Z-wobble caused by print head movements. In testing, we found little print defects caused by wiggling, even in high Z-axis latitudes.

Furthermore, the Z-axis is dual stepper motor driven and synchronized by a timing belt on top, which allows the gantry to travel steadily up and down without becoming askew.

LeviQ Leveling

The Kobra Max uses the same print as found on the Vyper. Confusing? Possibly. Seems Anycubic should have dubbed it the Vyper Max, as it is essentially a bigger version of that printer. It’s not just the print head; the Kobra Max also features the Vyper’s auto-bed leveling system.

Unlike the Kobra, which comes with a new print head assembly and inductive probe for bed leveling, the Kobra Max uses the strain gauge system as found on the Anycubic Vyper. Anycubic refers to this mesh-bed leveling as LeviQ. The nozzle will probe 25 points on the build plate to build a map of the unevenness, which the firmware will then compensate for at the beginning stages of a print.

Like the Vyper, there are no manual leveling knobs present, but we didn’t miss them one bit during our time with it. The auto-leveling worked perfectly, and after initially setting it up, we needed not to tamper with it anymore. Should you need to adjust the distance slightly, you can play around with the Z offset.

Print Head

The print head on the Kobra Max consists of a Volcano-style hot end, two cooling fans, and is fed by a double-geared extruder, which sits on the frame and feeds filament through the Bowden tube to the hot end.

The hot end can reach 260 °C, which means consumer filaments such as PLA, PETG, and flexible are on the menu for the Kobra Max. The Volcano-style hot end allows for a great throughput, in theory making the printer suitable for larger nozzles such as 0.6, 08, or 1 mm (though we haven’t tested this.) If you plan to print big, a larger nozzle would dramatically decrease print time.

It is worth noting that the Kobra Max profiles’ default print speeds are set rather ambitiously at 80 mm/s, especially for flexible materials. To our surprise, the Kobra Max does produce great results even at these high-speed settings.

Glass print plate

Unlike the Vyper, the Kobra Max comes with a carborundum glass bed instead of the removable, flexible PEI sheet. The plate heats up to 100°C and provides good adherence and easy model release without the need for extra adhesives.

During our review, we had no gripes with the tempered glass bed. It heats up fairly quickly, about four minutes to reach 60 °C, and has even heat distribution. Especially for prints lasting days on end, having a good thermal equilibrium throughout the print bed is essential as prints may otherwise start to wrap or detach from the print plate completely.

Further Features

- 32-bit motherboard: The Kobra Max comes with Anycubic’s Trigorilla Pro A (V1.0.4) control board. It runs on a Cortex-M4 core at 200 MHz and comes with TMC2209 silent stepper motor drivers.

- Y &Z-axis belt tensioners: You can manually tighten the Kobra Max’s belts. Easy maintenance.

- Touchscreen display: The Max has a bright, responsive 4.3-inch touchscreen display.

- MicroSD: You port prints to and from the printer using microSD cards. Compared to the size of the printer, they are super petite.

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2022

- Assembly: Partially assembled

- Mechanical arrangement: Cartesian-ZX-head

- Manufacturer: Anycubic

3D Printer Properties

- Build volume: 400 x 400 x 450 mm

- Feeder system: Bowden

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 ℃

- Max. heated bed temperature: 100 ℃

- Print bed material: Carborundum glass

- Frame: Aluminum

- Bed leveling: Automatic

- Connectivity: MicroSD

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, Flexibles)

Software

- Recommended slicer: Cura

- Operating system: Windows, Mac OSX, Linux

- File types: STL, OBJ, AMF

Dimensions and Weight

- Frame dimensions: 720 x 715 x 665 mm

- Weight: 11.8 kg

Featured Prints

Like what you see? Here’s a list of the 3D models we printed over the course of the review.

- Airpods Cover by quentin01301, via Thingiverse

- Peace Hand by 3tte, via Thingiverse

- Articulated Shark by McGybee, via Thingiverse

- Unicorn Head by kellesabelle, via Thingiverse

- Batman Bust by Geoffro, via Thingiverse

- Mandalorian Statue by iczfirz, via Thingiverse

- Filament Spool Holder by Nine_bcc167, via Thingiverse

- Articulated Cobra by Anycubic, via Anycubic

- Stress Ball by mattbagshaw, via MyMiniFactory

Similar Printers

You may also be interested in the following printers:

For further information, feel free to check out our Best Large 3D Printers Guide.

Creality CR-6 Max

Creality’s CR-6 Max is a hybrid of Creality’s CR-10 series combined with the CR-6 SE. The printer comes with a spacious 400 x 400 x 400 mm build volume, automatic leveling via a strain gauge-based sensor, Bowden extruder, glass print bed, and a 32-bit mainboard. In essence, it’s as close to the Kobra Max as it gets, minus the extra Z-axis height. At $799, it is considerably pricier, though.

Creality CR-10 Smart Pro

Another printer from Creality’s lineup might tickle your fancy should you look for alternatives to the Kobra Max. The CR-10 Smart Pro comes with similar features, albeit at a smaller build volume. Besides 300 x 300 x 400 mm of space to print with, the CR-10 Smart Pro also offers a direct drive extruder and a hot end capable of reaching 300 °C. This allows for printing with more engineering-grade materials. The printer also features a removable flexible PEI print plate. It’s also pricey, it’ll set you back $799.

License: The text of "Anycubic Kobra Max Review: Best Large 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.