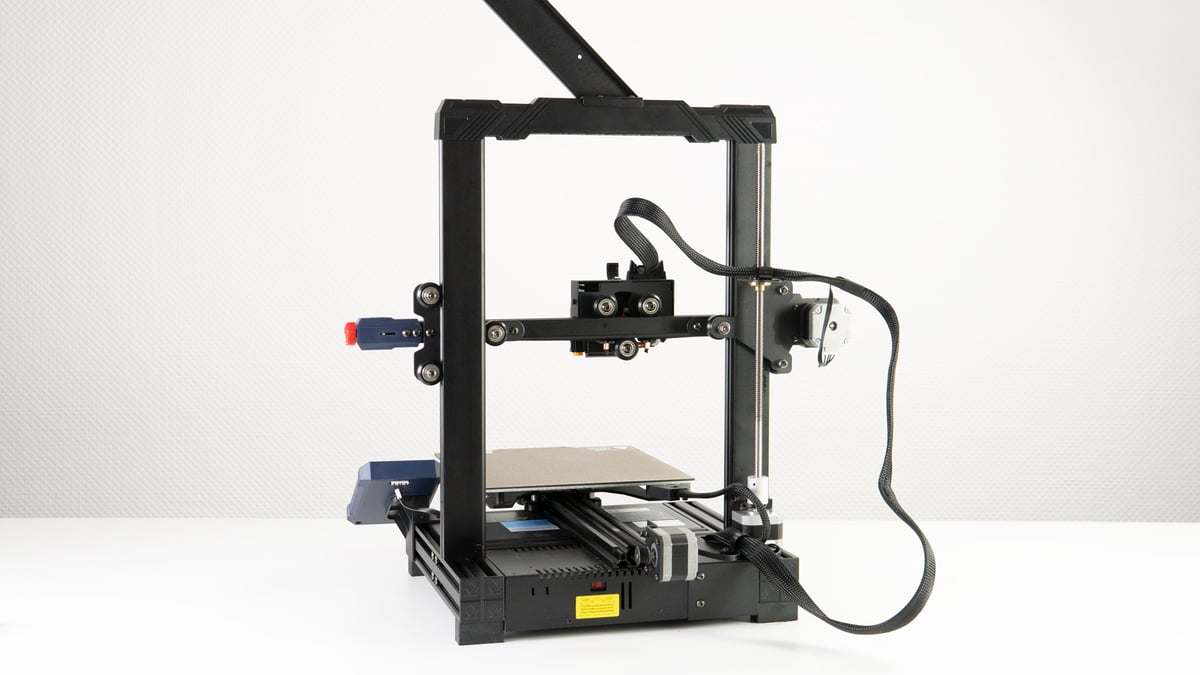

Anycubic continues its new thing for flashily misspelled serpents with an all-new line of machines; each a successor to similar devices in Anycubic’s past. Here we have the Kobra, the wee-est of the company’s new Kobra series and also the most distinctive.

Where the also-just-announced Kobra Max borrows heavily from the Anycubic Vyper that launched in 2021, the Anycubic Kobra stands apart as an almost all-new machine.

Instead of a Vyper-like dual-geared Bowden extruder and Volcano-style hot end combo with integrated bed leveling, the Kobra instead carries a direct extruder with an inductive bed leveling probe sitting shotgun. Two significantly distinctive differences, right there. But there’s much more.

Anycubic gave us early access to the Kobra to get to know it a little better ahead of its launch. Here’s what we found.

Verdict

Pros

- Reliable auto-bed leveling

- Easy filament handling via direct extruder

- Great bang-for-buck ratio – cheap and capable

Cons

- Extruder components could be better

- MicroSD for print transfer is dated and annoying

- Very plastic

The Anycubic Kobra is a surprisingly capable 3D printer, offering some top-drawer features for very little money. The auto-bed leveling, direct extruder, PEI-coated removable bed, and sensorless homing are commonly seen on machines costing much more than the Kobra’s $299. It’s fantastic to see them on a printer that costs barely any more than the prolific Creality Ender 3 V2.

You can see where Anycubic has shaved the price down, though, with the Kobra being incredibly plasticky and some assemblies skimping on parts you expect could easily improve the experience.

Putting this aside, though, the Kobra is a cheap, capable printer that’s easy to take apart and tinker with. It’s Anycubic at its best, with smart, inexpensive machines.

The Tech

The Anycubic Kobra is, for what you’d assume to be the flagship machine in its namesake series, actually not that at all. Instead, a surprising mix of advances and curious compromises brings to mind the company’s Zero-branded machines – deliberately cut-price printers that sacrificed some of the expected race-to-the-top features in pursuit of lower cost (to mixed success.)

Design & Features

For $299, the Anycubic Kobra gets you a pretty modest 222 x 222 x 252 mm build volume – a fraction larger than your typical Ender 3-style machine but smaller than the Anycubic Vyper, the printer you could suppose the Kobra is softly replacing. Fun fact for you here: cobras are much, much larger than vipers, so what Anycubic is thinking with its naming completely confounds us.

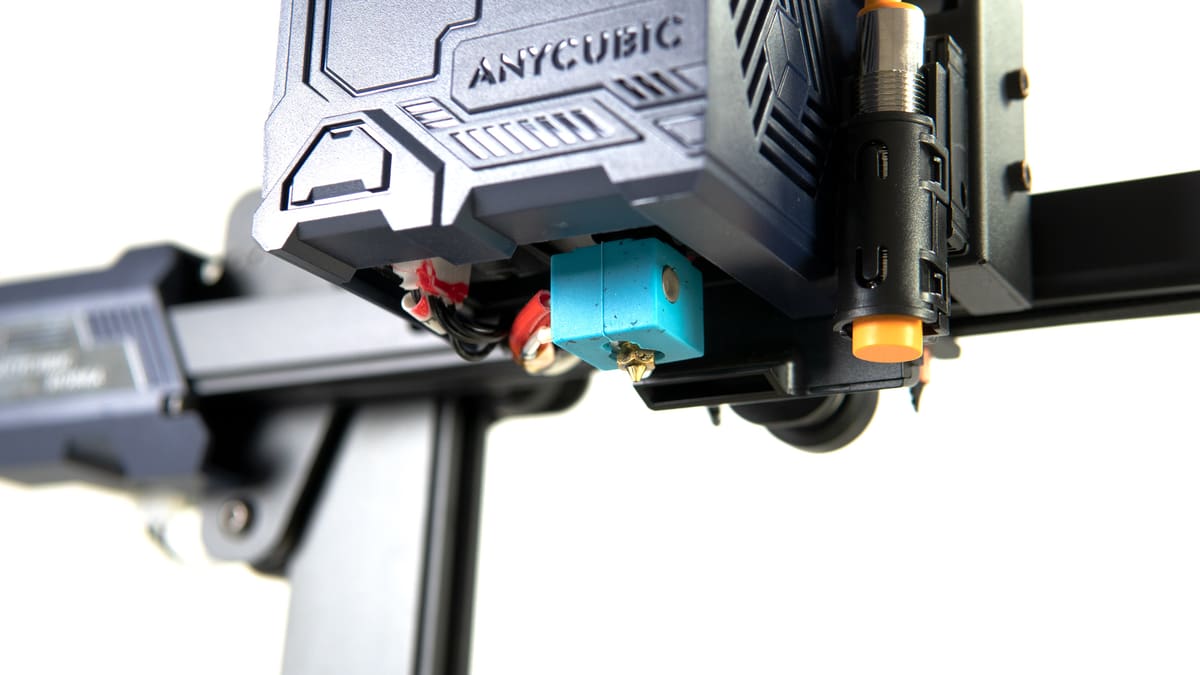

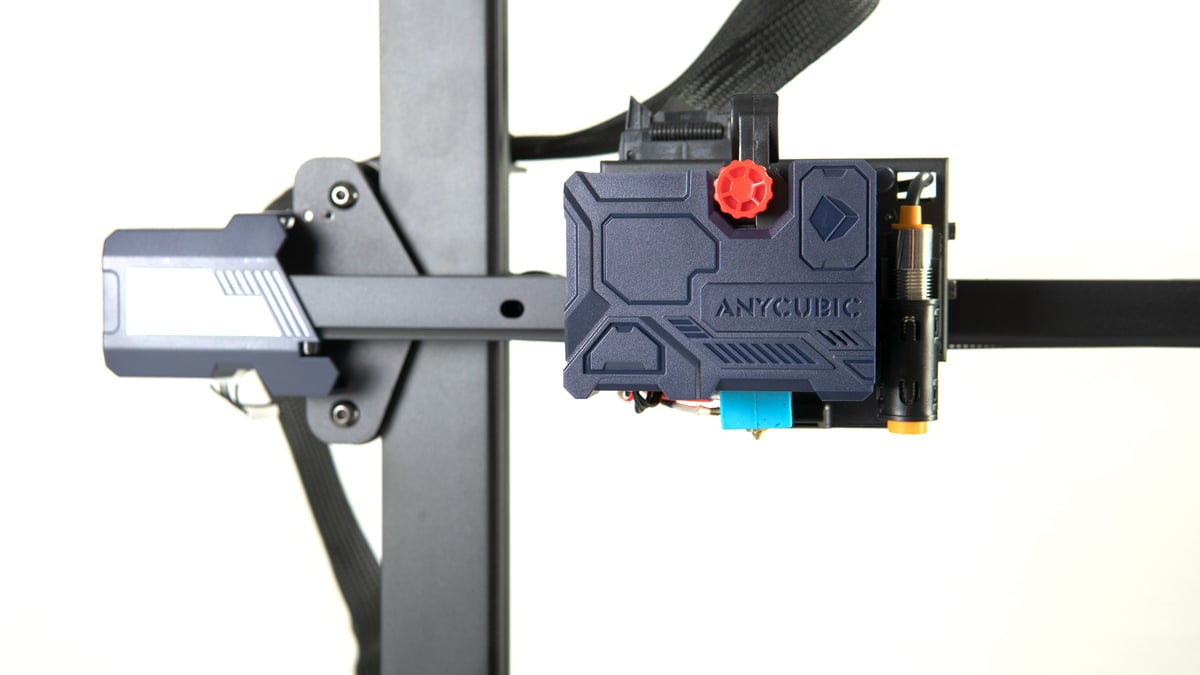

Headlining proceedings is the Kobra’s direct extruder print head. A large, boxy cuboid covered in faux-technological detail, the print head gives off a loot crate vibe. Inside is the printer’s hot end.

It’s difficult to place exactly, but it strongly resembles the E3D Titan Aero, albeit with noticeable differences, including a larger heater block, a Bondtech-like filament release lever, and some shortcomings that we’ll address later. The critical bit is that inside it is a geared extruder that grabs and feeds the filament directly into the PTFE-lined hot end.

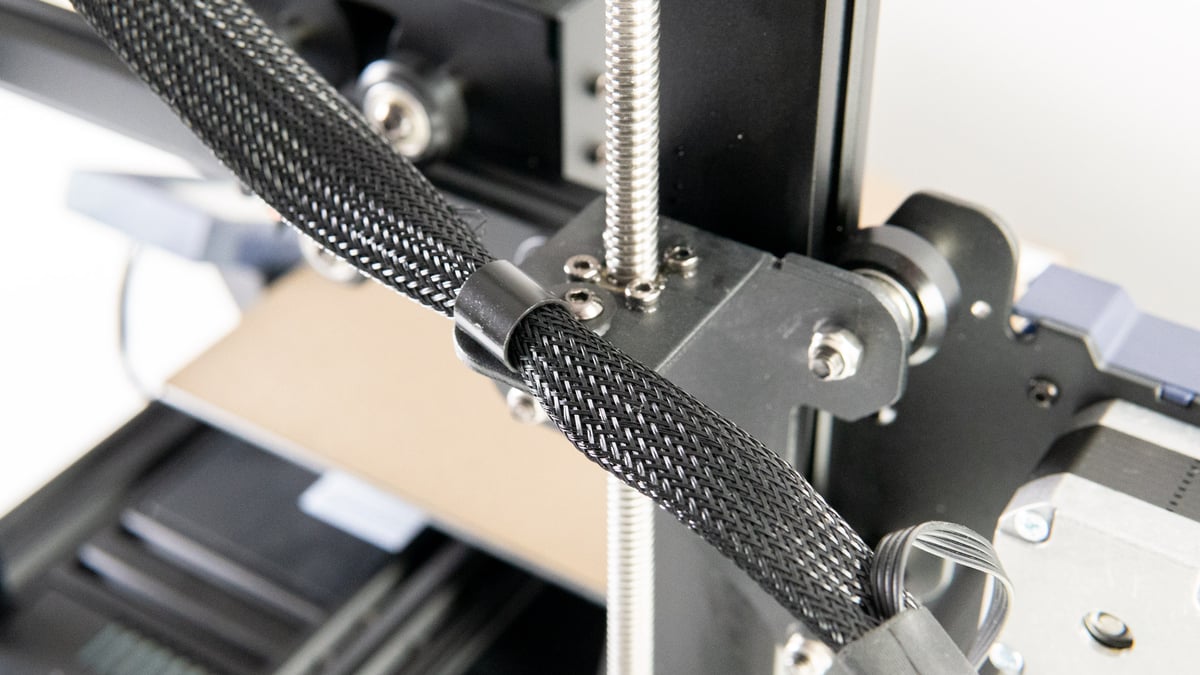

The print head rides along aluminum extrusions, as is typical of this class of desktop 3D printers. Curiously for a direct-extruder-toting machine and the implied print-head mass that goes with it, there’s only a single Z-axis stepper motor to lift the Kobra’s X- and Z-axis assembly. Testing across the width of the print plate to the extremes of the Kobra’s print height, we couldn’t detect any issues from this. It might only be something you’d see over a longer period of time.

There is a lot of plastic about the Kobra’s print head, so we expect some weight-saving measures are at play here.

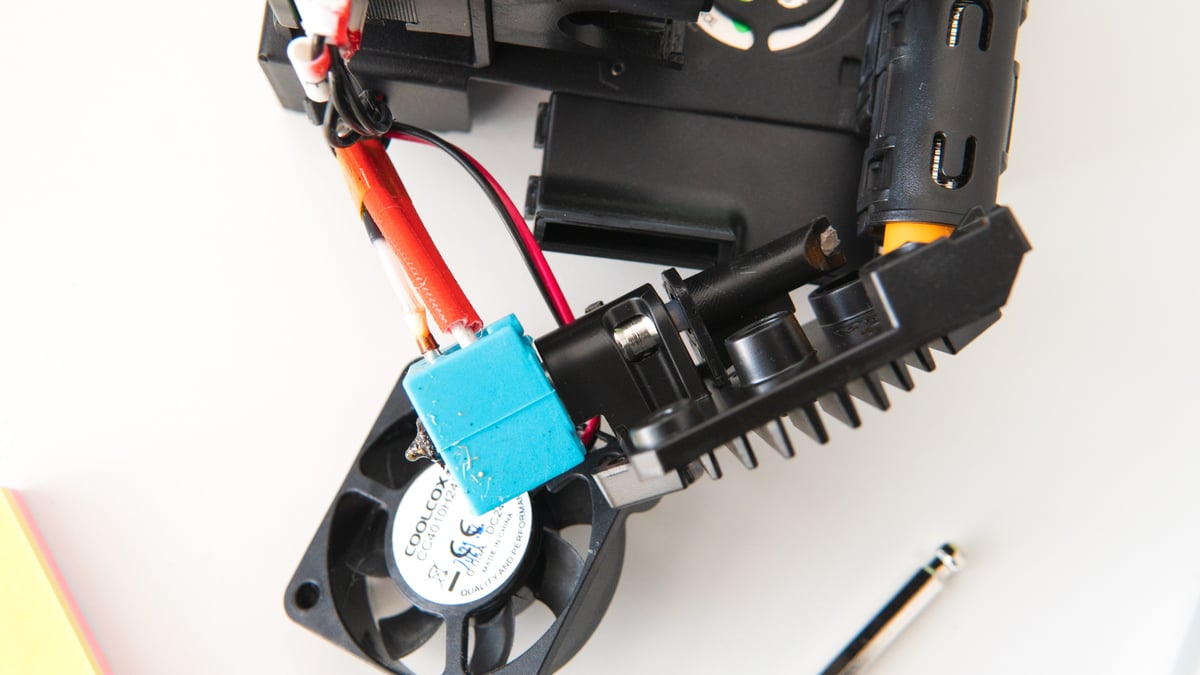

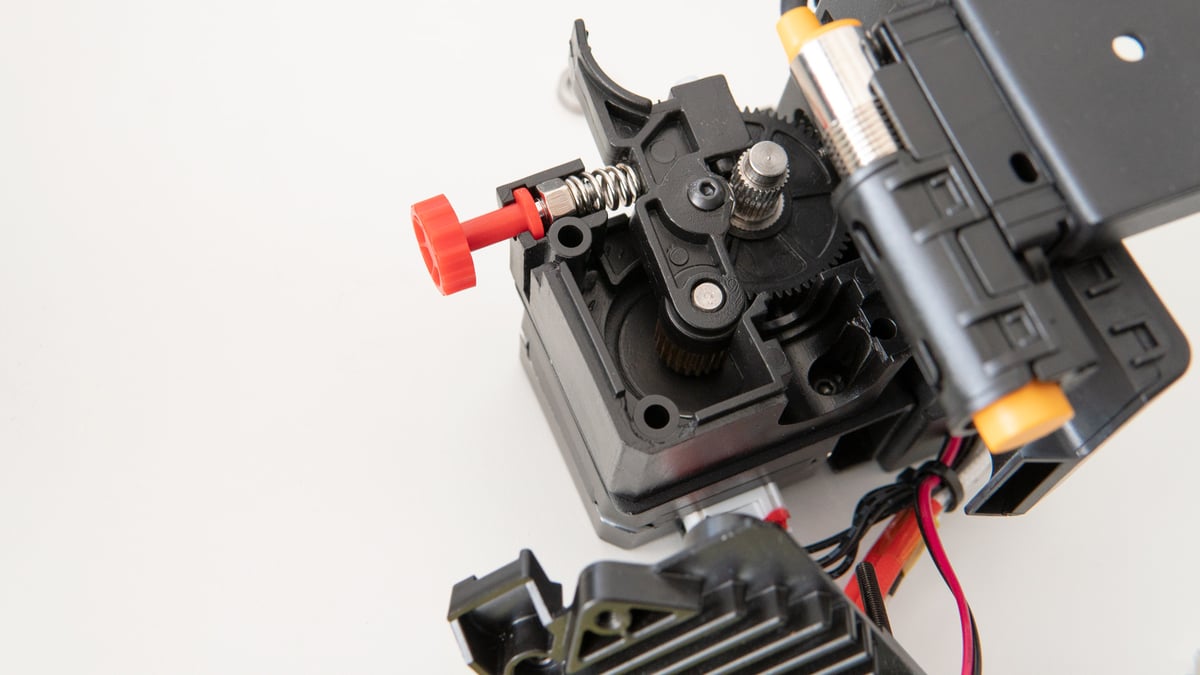

Ripping the print head open we found that, handily, it’s a cinch to disassemble and troubleshoot. The “loot crate” shroud can be discarded entirely with the removal of two screws, giving you quick and easy access to the components beneath.

The print head is held on its carriage with four screws, and you need just five more screws (two on the hot end fan, three for the heatsink) to separate the hot end from the extruder. Anycubic’s weight- (and, possibly, cost-) saving measures are plain to see with plastic extruder armatures and a disappointingly basic toothed gear to pinch the filament. There is no subtlety to it, and with improper extruder idler tension, it took no time at all for chewed up filament to bed into the grooves, reducing the gear’s effectiveness.

On the Level

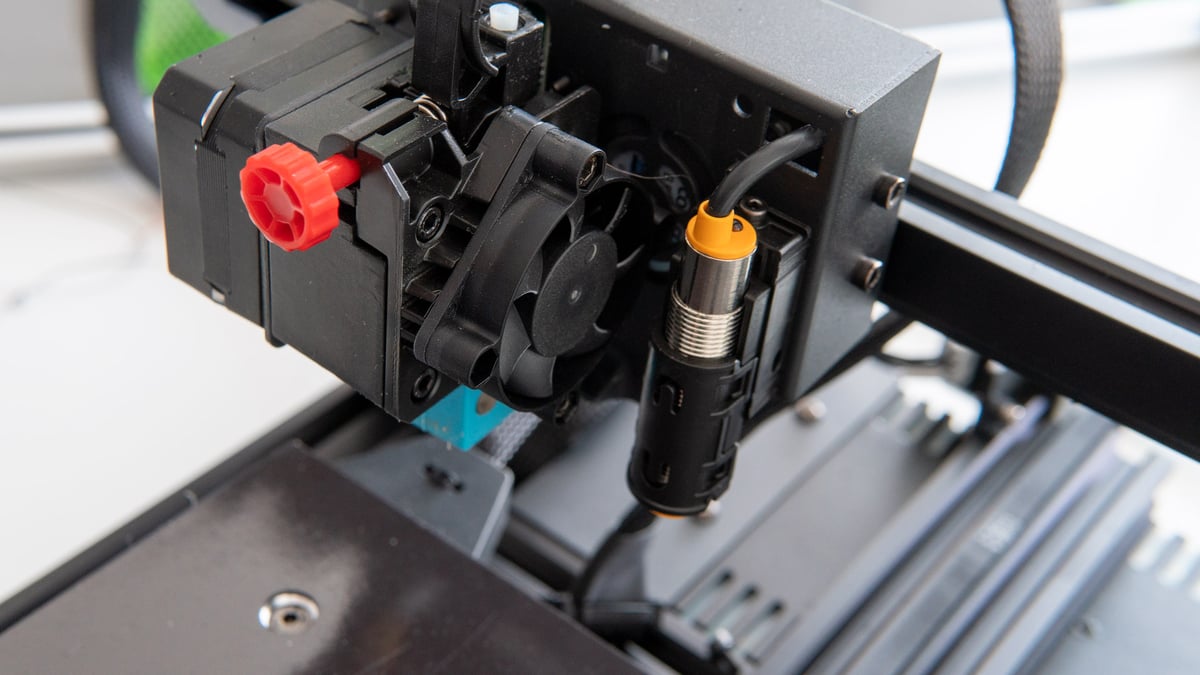

Like the Vyper before it, the Kobra features automatic-bed leveling. Unlike the Vyper, it uses an inductive sensor to detect the metal print bed beneath it. Housed in an adjustable plastic cage, we found the sensor did its job without fuss or fail.

The printer maps a 16-point mesh on each leveling routine, with the Kobra automatically accounting for variances in its print bed. This gives a smooth and consistent first layer. The bed sits atop spacers, so all bed leveling duties are carried out by this system – no manual adjustments are possible, save for a universal Z-offset you can apply when running the bed calibration routine or live during prints.

The print bed provided with the Anycubic Kobra is a flexible, PEI-coated metal sheet that rips free of its magnetic base with ease and pops prints free with a cheeky flex. Above this flexible sheet, you have 222 x 222 x 252 mm of printable volume.

Another similarity with the Vyper is here – the chunky-grainy texture of the PEI surface of the print bed. We didn’t like it much on the Vyper – prints relying on fine detail on the first layer could end up with that detail obliviated and the first layer with a uniform, grainy finish. It can look nice, but the effect takes away some of your options for using the first layer of your print for particular effect. There’s no denying that it’s effective though – prints stick very well.

Anycubic provides a plastic scraper to help clean the bed without risking the PEI surface getting scratched – something we noted could happen all too easily in our review of the Vyper.

Bump in the Night

Something conspicuous about the Anycubic Kobra is its lack of endstops. The printer gives off a slender, uncluttered appearance (loot crate print head notwithstanding), and it took us a while to figure out why. There’s less clutter on the printer. Period.

The Kobra does something we did not expect: having Stallguard active out of the box. This is a feature of some Trinamic-brand stepper motor drivers that gives “sensorless” homing, eliminating the need for switches at the end of the X- and Y- axes.

Typically only seen in higher-end systems, the print head or print bed carriage will travel in the direction of its origin and cut the motion at the point it meets resistance. In other words, it’ll crash on purpose. But that’s fine.

Besides being cool to see in action (you can trigger it yourself by pushing back against the printer while trying to find its origin), it also simplifies the printer, reducing the number of parts that can go wrong.

Same Song, Different Tune

It’s unavoidable to draw parallels between the Kobra and the Creality Ender 3 S1, an also-new 3D printer that offers an admirably comfortable and high-quality printing experience (albeit a pricey one).

Creality pursues a premium price point and offers what we concluded in our review was a pretty deluxe printing experience over the Ender 3 machines that came before it. Anycubic’s approach is different, and we’re happy to see this.

Yes, it’s a direct extrusion Ender-3-like printer. But the Kobra, like Anycubic’s Zero subset of machines, plants its flag on a different patch of turf, using a lot of visible cost-saving while without compromising too much.

Under the Hood

Powering the Anycubic Kobra is the 32-bit Anycubic-designed Trigorilla Pro A V1.0.4 mainboard. One benefit of the Kobra’s embrace of plastic is that the bottom plate of the printer is a mainly snap-fit affair. To get to the mainboard you need to remove two channeled screws fixing the baseplate to the frame. Coax the snap-fit plate free, and you’re in.

There aren’t any real surprises that we can detect under the hood. The stepper motor drivers are soldered to the board, so swapping them out is more-or-less out of the question. Fortunately, the drivers must be in the desirable UART or SPI mode rather than the more often seen-at-this-price-point standalone mode. Because of this, advanced features are possible, including StallGuard – the ersatz “endstop.”

Such a configuration could mean the user can control the motors, configuring the micro-stepping, voltages, and whatnot via the software. If the manufacturer gave you the means to do so on the printer, that is. Anycubic doesn’t. We reason the vast majority of users won’t need to touch those settings; Anycubic’s bright default menu and options are sufficient. Power users can do that stuff using Gcode directly with the printer if they wished.

Out of the box, we found basic values such as the eSteps and flow in needing of a tune-up. We cover the processes to correct these our handy guide to extruder calibration. Linear advance, a popular setting to consider for ironing out flared corners on speedier printers, is not enabled by default. Custom or updated firmware would be required for this.

Power users will want to tap into the machine language of the printer using a host and control platform, such as OctoPrint or Pronterface, to make changes and poke around the deeper settings via G-code. Anycubic’s default UI and its options are limited to basics like filament loading, temperature control, movement, leveling, and Z offset. That’s about it.

It’s not much different from most inexpensive 3D printers today, although skewing more on the basic side of bare compared to something like the Biqu B1, which offers a terminal view to tap G-code directly into the printer.

Tinker-Friendly

The Anycubic Kobra’s print head is pleasantly modular and can be taken apart with ease.

We experienced a severe blockage after printing with a TPU that resulted in charred filament baking into the nozzle, rendering the printer inoperable for a time. Taking the shroud, fan, and hot end assembly off the extruder – in combination with tidy cable routing that allows everything to separate easily – gave ample access to assess the situation.

In checking this out, we found the PTFE lining inside the hotend was a little shorter than the space it sits in – there was a little play in the fit. Loading filament into the heated hot end by hand, we could see the molten filament backing up and pushing this piece of PTFE tubing out of the heat break.

In clearing the blockage, we replaced both the nozzle and PTFE tubing with spares (note the spare PTFE tube was longer and fit more snugly inside the hot end.) The Kobra has been printing without a hitch across multiple filament types since. Possibly a pocket of TPU had built up in this gap, burning up and causing the blockage. Difficult to say with certainty, but that’s our theory.

So the Kobra seems to be a tinker-friendly device. Given the simple nature of the print head, we’d guess it’s easily upgradable, too. The LeviQ probe sits within an adjustable plastic cage, so any new nozzle heights from equipment changes should be easy to accommodate.

Printing & Usability

While the Kobra’s “cheapness” comes to the fore in some areas – we’re thinking mainly about the quality of components and the innate plasticky nature of the machine – the Kobra does land a few swings above its weight.

The presence of a direct extruder is excellent (though it is not the greatest, as evidenced by our relatively light usage resulting in a clog). The convenience of the spring steel print bed is undeniable. In general, there’s an easy-breeziness to using the Kobra. It’s easy to load the filament, it heats quickly, and Anycubic’s basic UI offers enough for undemanding users to get on with.

Some minor UI quirks may annoy, such as the inconsistency in entering values. Temperature setting; type the number: good. Raising the print head to work on the machine; repeated incremental taps on 0.1, 1, or 10mm movements: annoying.

Generally speaking, though, the Kobra is a great example of cheap printing done right. It’s not a quantum leap forward but an attractive alternative to the status quo. It would’ve been nice to see more small, thoughtful touches – the mind wanders to a guide for snapping the print bed into position, for example.

Material World

During our time with it, we threw PLA, PETG, and TPU at the Kobra, initially using Anycubic’s preferred settings. As best we can tell, these preconfigured parameters for Cura mainly slow things down.

You’ll have as much luck customizing a profile to suit your particular filament. We saw little in the completed prints to suggest they were much better than Cura’s default settings for the same layer heights.

TPU is where you’d naturally want to test out a direct extrusion machine. Unfortunately, with TPU, we had our only real issue with the Kobra – a blockage. Maybe other printing conditions wouldn’t have triggered the problem we had. Maybe they would. It was an easy fix with a nozzle and PTFE tube swap (the nozzle because it was backed up and blocked, and the tube as a precautionary measure against future blockages.)

We notice a touch of under extrusion at layer changes across some of our prints when using Anycubic’s provided settings. Models with sharp corners where layer-change seams can hide aren’t as affected, but larger prints with nowhere to hide surface imperfections are particularly noticeable. Disabling the “Coasting” setting in Cura improves this, though this then left us with zits (blobs) on the surface. Enabling “Retraction on Layer Change” (which is off by default using Anycubic’s settings), increasing the retraction speed, and decreasing Anycubic 6mm retraction suppresses these somewhat. We’ve found a clear settling-in period is necessary with the Kobra and its settings. Our advice above only applies to Cura – other slicers’ defaults may be better from the outset.

Material performance is as expected for a PTFE-lined direct extruder. Decent printing with flexibles; no high-temp fancy stuff allowed. Flashes of under extrusion aside, there’s nothing of note that we can complain about with the Kobra. It can hit dimensional accuracy well (with eSteps and flow adjusted), and there’s uniformity in the prints—no unsightly aberrations or artifacts on surfaces.

Across our various printings with the Kobra, print cooling appears to be a strong suit. It’s just a single ducted pancake fan blowing from behind the hot end, but we’ve seen terrific bridging on the Autodesk x Kickstarter test print, plus sharp and clean overhangs.

For models with sheer overhangs, adaptive layers are your friend. But by and large, the Kobra appears to cope well with challenging print features.

Tap Tap Tapping on Anycubic’s Door

As has been the case for almost all of Anycubic’s 3D printers over the years, the Kobra features a large touchscreen display. Here, with the company’s current, bright, white UI. Large icons and a simple menu structure leave little doubt about where you are, what you’re doing, and how to achieve basic functions with the printer.

There’s minor inconsistency in inputting values – some you can type the number, others require repeated taps in the positive or negative (no pressing and holding or stacking presses of the button.) The filament loading process via the UI could be a little more user-friendly, especially for users attempting to fine-tune the printer. Instead of granular control over advancing and withdrawing the filament by distance, you have “on” or “off.” Or “stop.” There’s a bit of a lack of sophistication.

Anycubic provides a copy of Ultimaker Cura 4.2.1 with the Kobra and instructions for creating a printer profile that matches the printer’s dimensions, plus material profiles for PLA, ABS, and TPU. The process of importing and activating these is a little fussy, but once in, they’re available as one of many drop-down print-quality settings for you to choose from. They’re okay, but you’ll undoubtedly be exploring the deeper setting to accomplish specific properties of your prints.

MicroSD, Maximum Letdown

Can microSD cards just go away now? Please?

Hey, guess what. The Anycubic Kobra uses microSD (also known as TF cards) for porting the G-code you’ve sliced to print from your computer to the printer. Yes, they’re fiddley. Yes, it’s too easy to jam them into the port upside down. And yes, drop it in a shag carpet, and you might as well give it up for lost.

We’re sure it’s a matter of cost and convenience for the manufacturer, but microSD cards are a pain for users. To our knowledge, no printer in the Kobra’s price range doesn’t use microSD, so we’re not criticizing Anycubic directly for this. But they also didn’t not choose to use microSD.

Is It Worth It?

The Anycubic Kobra threw a curveball at us here. We’d known it was coming for a long time, and, before clapping our eyes on any details or specifications, we assumed it’d be a new flagship of sorts.

The printer we got, however, is entirely different. It’s compact, cheap, and mostly plastic, but feature-packed and enjoyable to use. Although we found our test unit required a little tuning out of the box to reign in some minor issues, the print quality impresses. Some of the extruder components leave a little to be desired, but it is still only $299.

And that’s the critical factor here; less than $300 for a direct extrusion printer with the convenience of a removable, flexible bed and reliable automatic mesh bed leveling? That’s a steal.

If you don’t have a 3D printer, but do have $300 to spare for one, the Kobra should be high on your list. Despite potentially needing a little more work from the user, it’s a step up on the Ender 3 V2, the stalwart recommendation for (close-to) this price range. We wonder how long those plastic components will last under heavy use, but we suppose the beauty is that they’re easily replaceable – a rock-solid 8 out of 10. You have to put a little work in, but the package is great value.

Features

The Anycubic Kobra is a new FDM 3D printer from Anycubic, introducing premium features through a budget lens.

Build Volume, Bed Adhesion

The Kobra’s 222 x 222 x 252 mm build volume is marginally larger than average by a couple of millimeters in all directions. This build volume has a grainy PEI-coated flexible magnetic bed that offers terrific grip on PLA and TPU prints. PETG sticks very well but may benefit from a layer of glue as an interface to prevent oversticking.

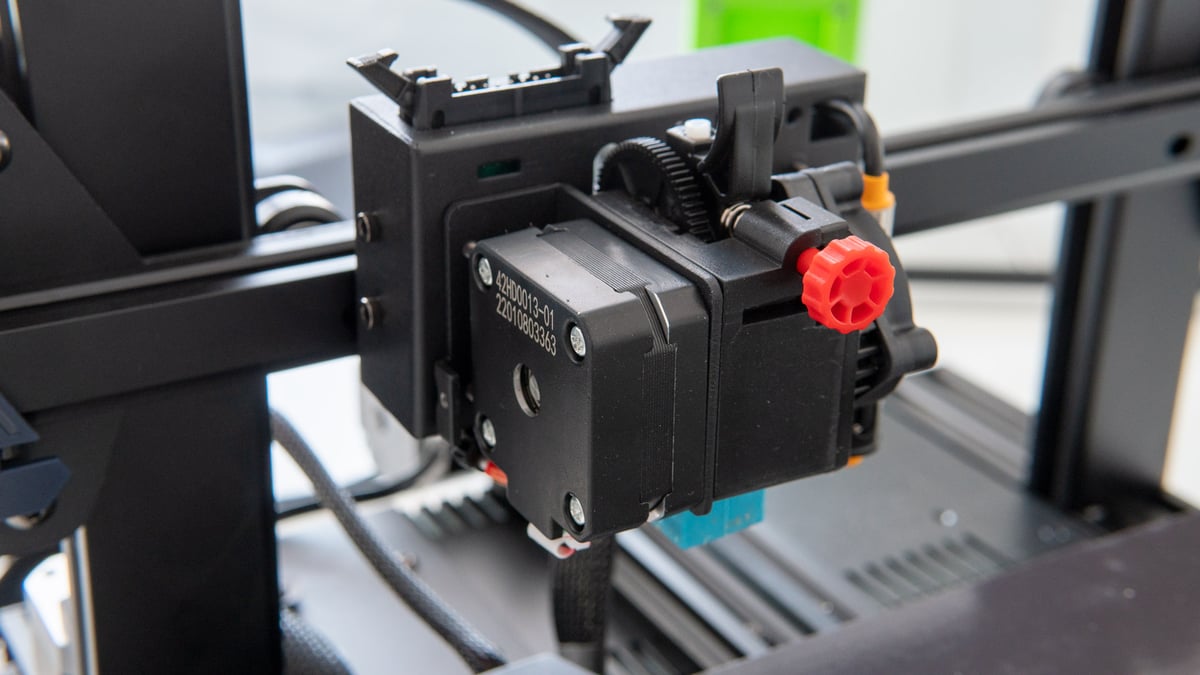

Direct Extruder

No Bowden here. The Kobra uses a geared direct extruder that’s vaguely reminiscent of the E3D Titan Aero. Some differences, though, include the drive gear that bites into the filament being a simple toothed drive gear rather than something more tailored to the job, such as a so-called “hobbed” gear.

Reduction gearing on the extruder means it’s strong, just not very subtle. Melting the filament is a basic PTFE-lined hot end that takes E3D V6-style nozzles.

Auto-Bed Leveling

There’s no manual bed leveling on the Kobra, meaning all first-layer fine-tuning happens using what Anycubic calls LeviQ – an inductive probe-based mesh-bed leveling routine. We detect nothing particularly unique about it. Anyone familiar with mesh-bed leveling on other printers will be familiar with the process here. Run the routine and it’ll map out 25 points across the bed and how much they deviate. This is then compensated into the early stages of a print for a smooth and even first layer.

Sensorless Homing

The Kobra comes with Stallguard enabled out-of-the-box, which is both unusual at this price point, and utterly welcome. It’s great.

In short, the Kobra doesn’t use physical, optical, or any other kind of endstop for homing its X- and Y- axes. Instead, it’ll throw the print head in those directions and register the resistance when they reach their physical limits, cutting the motion and acknowledging this origin.

It’s a feature of the printer’s stepper motor drivers (while not explicitly stated anywhere, we assume they are Trinamic TMC2209s.) Most inexpensive printers won’t use these stepper motor drivers to their full potential, but this is a step in that direction.

Single Z-axis stepper motor

We’re a little torn on this. Direct extrusion means more mass on the print head, greater potential for resonance, and difficulty moving parts. It stands to reason a second motor to drive the Z-axis would help, but the Kobra skips this entirely. Printing to the machine’s limits in the Z, we detected no issues from only having a single motor, but this could be something that comes in time and the printer “wearing in.”

Other features

- Belt tensioners: You can manually tighten the Kobra’s belts. Good for long-term maintenance.

- Touchscreen display: The Kobra has a bright, responsive touchscreen display.

- MicroSD: You port prints to and from the printer using microSD cards. They’re fiddly and awkward.

- Thorough setup guide: Anycubic’s product documentation is becoming some of the best in its price bracket. The provided build guide is straightforward, and on the microSD card is a more detailed setup guide that will help new users get to grips with the machine.

Tech Specs

GENERAL SPECIFICATIONS

- Technology: Fused deposition modeling (FDM)

- Year: 2022

- Assembly: Semi-assembled

- Mechanical arrangement: Cartesian-XZ-head

- Manufacturer: Anycubic

3D PRINTER PROPERTIES

- Build volume: 222 x 222 x 252 mm

- Feeder system: Direct

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 ℃

- Max. heated bed temperature: 110 ℃

- Print bed material: PEI-coated spring steel sheet

- Frame: Aluminum

- Bed leveling: Automatic

- Display: 4.3-inch LCD touchscreen

- Connectivity: microSD, USB

- Print recovery: Yes

- Filament sensor: No

- Camera: No

MATERIALS

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, Flexibles)

SOFTWARE

- Recommended slicer: Cura 4.2.1 (provided)

- Operating system: Windows, Mac OSX, Linux

- File types: STL, OBJ, AMF

DIMENSIONS AND WEIGHT

- Frame dimensions: 486 x 430 x 486 mm

- Weight: 7 kg

Featured Prints

We wish we were as talented as the folks who designed the models we printed for this review. Links below to all the models featured in the photographs for this review. Full credit to them:

- Handsome Squidward Yarn Bowl by emily1713, via Thingiverse

- Mini Planetary Compartment Container by 3dprintingworld, via Thangs

- Low Poly T-Rex Skull by VittMaker, via Thingiverse

- Elden Ring Cracked Pot by cyanicman, via Thingiverse

- Vaporwave Bubblegum David by NotOnLand, via Thingiverse

- Autodesk x Kickstarter 3D Printer Assessment by Kickstarter, via GitHub

Similar Machines

There’s been a dizzying number of “upgraded” Ender 3-style machines hitting the market this last year. Here’s a handful that rubs shoulders with the Anycubic Kobra.

Mingda Magician-X

The Mingda Magician X might not offer the joy and wonder of pulling a rabbit out of a hat or sawing a glamorous assistant in half, but it does offer dual-geared direct extrusion, auto-bed leveling, and silent printing by way of TMC2209 stepper motor drivers.

Voxelab Aquila S2

The Voxelab Aquila S2 doesn’t quite follow the mold of the Kobra, ditching auto-bed leveling and offering higher-temp printing (up to 300 ℃) instead. Other specs read largely the same as the Kobra, but the allure of hotter filaments such as PC, or Nylon, gives the S2 an undeniable draw.

Creality Ender 3 S1

Creality’s fancy Ender 3 introduces direct extrusion, dual-Z stepper motors, and a whole host of other firsts for the series. It’s a premium-feeling machine – lots of metal and custom components – but with a price tag closer to $500 than $300, it’s a pricey alternative.

License: The text of "Anycubic Kobra Review: The Best 3D Printer Under $300" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.