Adding to the mid-size FDM 3D printer market, with a build volume of 300 x 300 x 305 mm, is the Anycubic Mega X. A supersized Anycubic Mega S, if you will.

The market is already crammed with budget FDM printers, making it tricky to know which ones are worth your money and which ones are better removed from your shopping cart.

Ringing in at ~$399, it’s certainly not the cheapest machine in its category, but do the features justify the price?

We have put the newest iteration through the hoops in our review, and our expectations were mostly met and, on occasion, even surpassed. Read on for our take of the Anycubic Mega X and find out where it excels.

Verdict

Pros

- Sleek and sturdy design

- Fast heating Ultrabase bed

- Easy to use

Cons

- Medium-sized print bed

- Rather loud

- Resume print function not working

The Anycubic Mega X convinces with a decent out of box printing appearance and print quality.

The print volume of 300 x 300 x 305 mm gives a respectable print volume, or as the company puts it, enough space to print a full-size helmet in one piece.

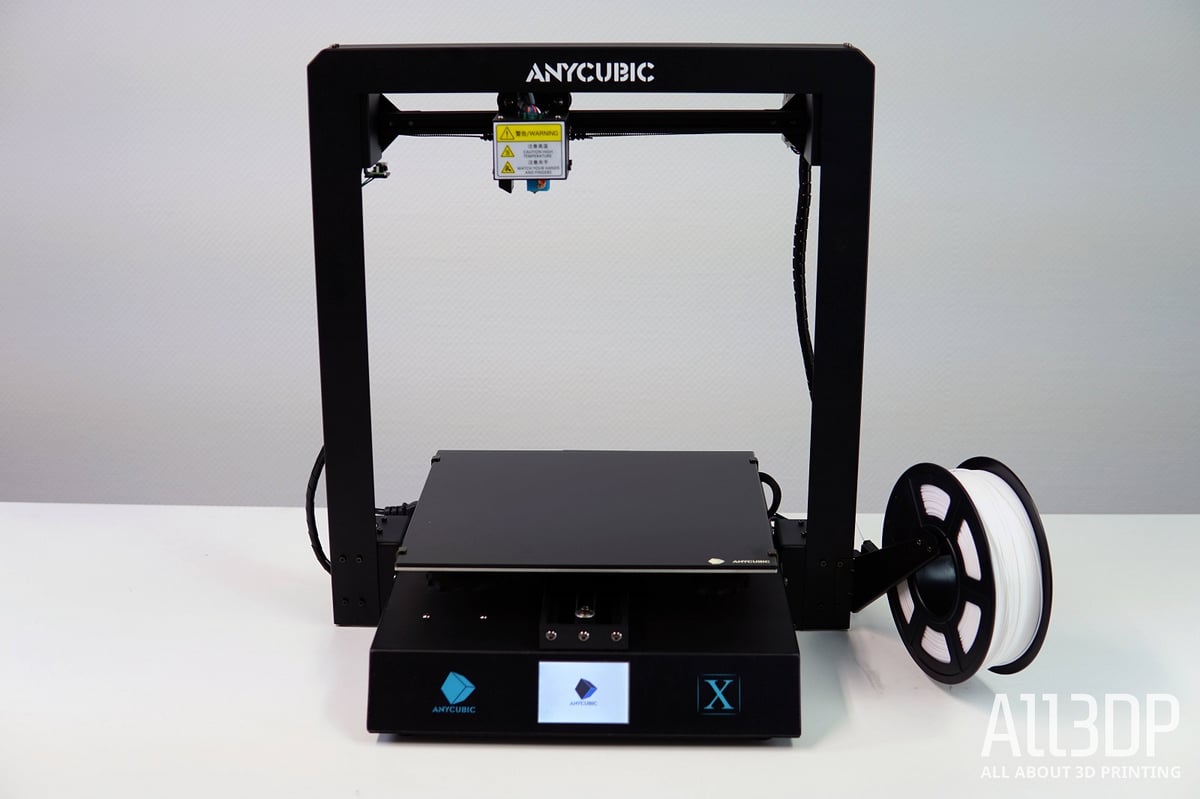

The all-metal frame and compact chassis not only make for a sleek look, but also ensure for little unwanted printer movement and overall build quality. Once this printer is set up, that’s it – no need to readjust every time you so much as touch it.

Combined with the Anycubic Ultrabase the Mega X produces consistently high-quality prints with your daily-driver filaments, making this printer not only a solid introduction to the world of 3D printing but also a trusty workhorse with the latitude to tackle some more advanced printing ideas.

The Tech

Anycubic gained a solid foothold in the low-end market with the release of the Anycubic i3 Mega back in 2017, followed by a buffed up version, the Anycubic Mega S.

Keeping the same design throughout, Anycubic’s Mega line has remained popular in part for the ease of use of the printers. To no surprise, Anycubic sticks to what it knows and scales things up for the Mega X. And why wouldn’t they.

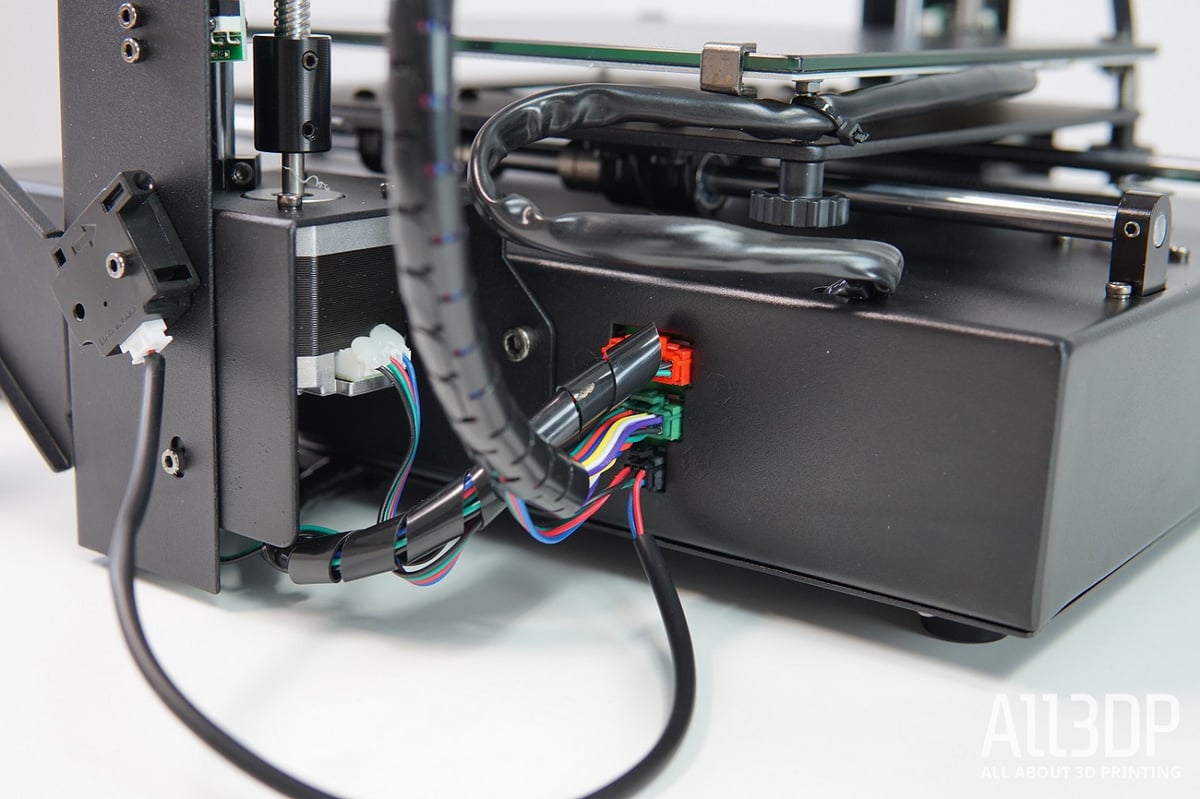

The power supply, mainboard, and touchscreen are snuggly packed in the base unit. Combined with the neat cable management – unlike a great number of budget desktop printers and the fistfuls of spaghetti-like cabling they come with – the Mega X puts out a svelte look.

Smart Design

But, it’s not all looks. The all-metal frame and robust chassis of the Mega X leave little to be desired, coalescing with dual Z-axis lead screws and a bed-steadying Y-axis carriage running dual rails. The result is a solid printer with the foundation for consistent printing.

Complementing this solid setup is something seldom found in the Mega X’s price segment – dual Z-axis end stops. A measure that addresses any unevenness that may creep in across the X-axis, this inclusion means that the Mega X effectively relevels the X-axis every time it homes.

Unlike the mechanical end stops on the X-axis, Anycubic used a contactless sensor for the print bed (Y-axis) end stop. The sensor strikes when the mechanical slider comes close.

All in all, the Mega X design puts out a distinct workhorse-like vibe. Once this tank-like machine is up and running, there is little reason for you to fiddle around with it.

The Bed

Encompassed by all this sturdiness is the heart of the 3D printer – the roomy, 300 x 300 mm Anycubic Ultrabase print bed, perched atop four spring screws for manual bed leveling.

Cutting to the chase – having a massive print bed is awesome, more so when it’s an Ultrabase print bed. This once novel (but now widely imitated) glass bed is coated with a porous microstructure that, in our experience, is second to none for print adhesion. Especially when printing PLA.

The bed can heat up to 60°C in two minutes, has a maximum temperature of 90°C, and – most importantly – does carry that heat across the whole print surface.

This is essential for successful large surface prints, as objects will warp due to potential temperature differences – a problem the Mega X faces nonetheless when printing ABS. With the bed capped at 90 °C, we suspect this to be the reason. Were it to tick up a little hotter to 100 °C or more we might have had better results.

The spacious print bed, in combination with 305 mm travel through the Z-axis, makes up to a bulky 27.5 cubic liters of print volume. There are printers in a similar price range – like the Artillery Sidewinder X1 – that offer roughly 10 cm more on the vertical axis, nonetheless the Mega X’s print volume is not one to be shimmied at.

The Extruder

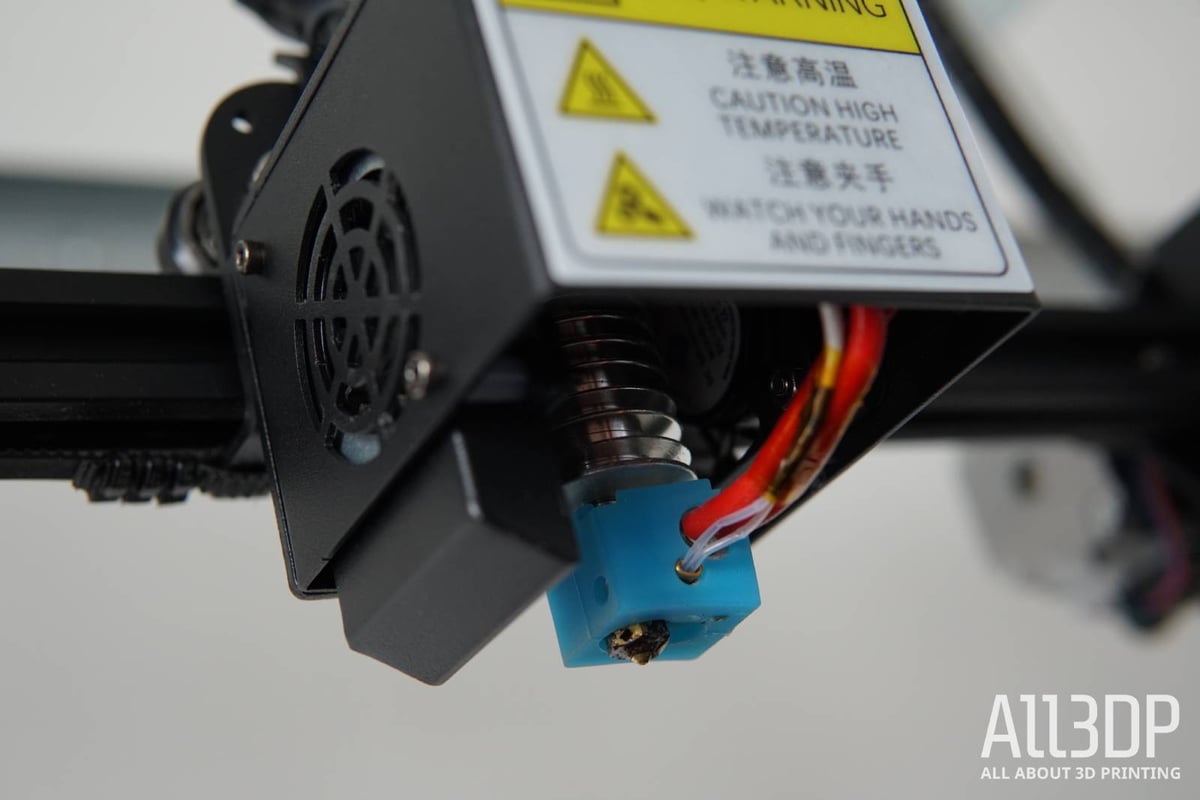

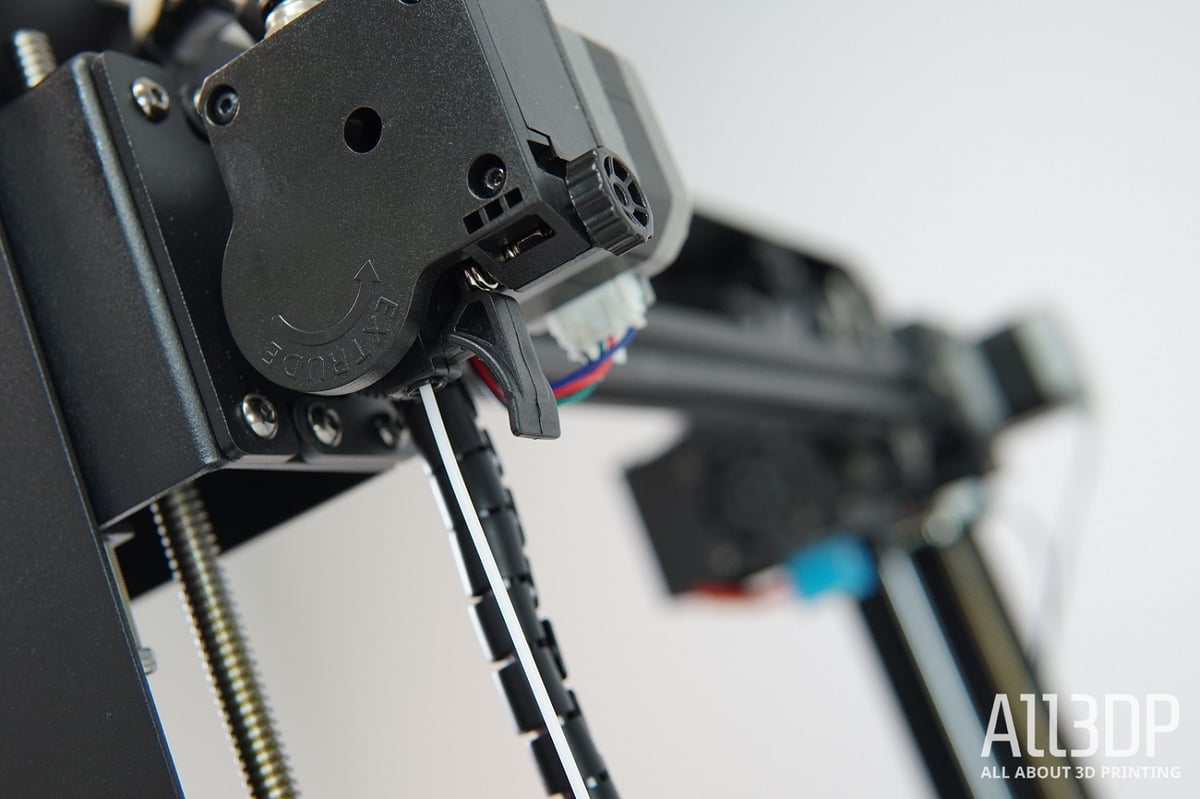

Filling that print volume one layer at a time is a Titan extruder, paired to a hotend capable of reaching 250°C.

Hotends such as the Mega X’s use PTFE tubing to funnel filament to the meltzone. Print hotter than 250°C for long and you get off-gassing of the PTFE, with the hotend end melting and releasing toxic gases. The Mega X is limited to 250°C, which suffices more than enough for the range of consumer materials. We had no problem with printing PETG at 245°C, a high-temperature material usually extruded at a slightly higher temperature.

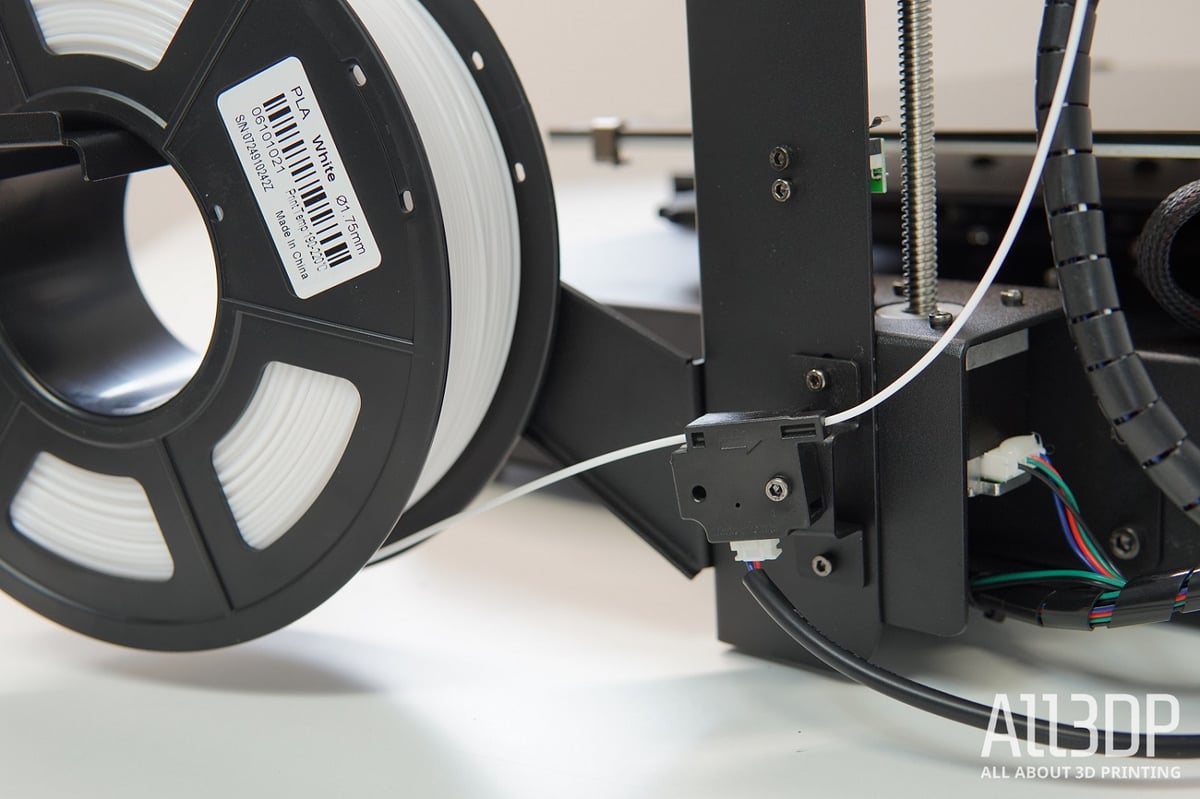

As with past Anycubic 3D printers, the filament holder sticks out sideways at the bottom, which does take some load off the frame, where holders tend to be installed – but results in the upside-down feeding of filament. Combined with the filament runout sensor – mounted on the side of the gantry – the filament is always a bit strained.

While it isn’t dual geared like a Bondtech extruder, the feeding mechanism does work surprisingly well and ensures continuous feeding. It just takes a bit of fiddling when changing filament, inserting it upside down. Handily, Anycubic has a little plastic funnel mounted to the extruder feeding hole. This helps you to guide filaments into the gear mechanism more easily. Unfortunately, Anycubic does not ship a spare one with the included extras.

Rigid filaments such as PLA, PETG, and ABS pose no problem to the extruder, but it does reach its limits – as notorious for Bowden-style extruders – when trying to funnel through flexibles.

Connectivity & UI

To oversee the whole printing process, the Mega X features a 3.5-inch color touchscreen. Aside from the somewhat convoluted menu, the software provides you with all info and options you will need. Connectivity options are SD Card or USB cable.

The above mentioned are all nice-to-have features, but setting them aside, the Mega X does not have a lot of new stuff going on compared to its predecessor the Mega S. Considering the previous model was released a couple of years ago, there’s been time to innovate and add new features. However, things like WiFi connectivity, auto bed-leveling, or quieter printing are conspicuous by their absence on the Mega X.

The Xperience

The Setup

Putting the printer together is a breeze. The Mega X comes neatly packed and pre-assembled with proper instructions on both the USB stick or the manual provided.

Aside from the usual spatula and clippers, Anycubic also ships a 1 kg spool of PLA, and spare parts including as hot end and PTFE tubing. The assembly consists mainly of the task of mounting the gantry to the base unit with a couple of screws. Followed up by connecting some cables, the whole procedure can be done in mere minutes. Take care to set the MeanWell PSU switch to the correct voltage, though.

Leveling the bed needs to be done manually. With the printer’s large adjustment knobs, though, this necessity of printing is trivial.

Just auto-home the print head and get to leveling with a sheet of paper, adjusting each knob as needed. Compared to the tiny levers some budget competitors install, the large knobs make this dull but necessary job endurable – no need to twist and contort your hand to reach them (why yes, we have been traumatized by past printers and their stupidly small bed adjustment knobs.)

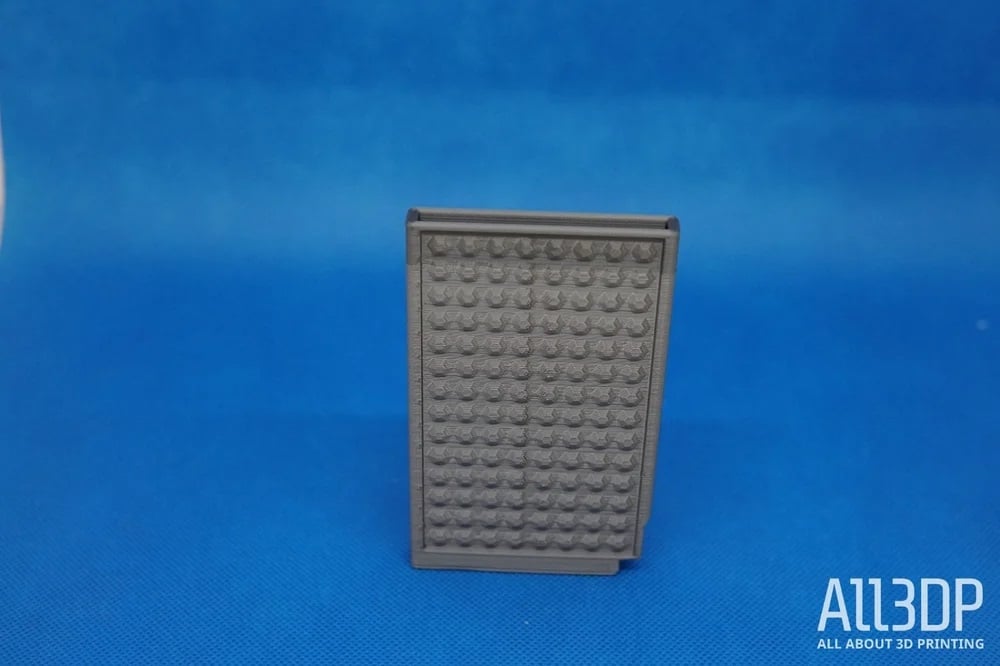

The Prints

With sprain free hands, we started our first prints. Off the bat, the Mega X produces satisfactory results. In fairness, we expected nothing less based on our experience with the previous iterations of Anycubic’s Mega line, so to see this confirmed is comforting. Especially in the budget sector, it’s not uncommon that one must make some adjustments here and there to get the machine to function correctly.

As mentioned above, the Ultrabase bed is a desirable feature, and this rings true here. Prints adhere nicely and pop off the plate afterward with ease. And the best thing about it is that using it is a glue-less affair. Not only does that leave the print bed with a constant fresh-out-of-the-box look, but more importantly, it leads to smoother first layer finishes, resulting in more aesthetically pleasing prints overall.

We did already touch on the Mega X’s capabilities of handling different materials based on the printer’s technical prerequisites. Not to go over it all again, but as always, the proof of the pudding is the eating. We experimented with a couple of flexible filaments, and it comes down to a bit of a gamble in our experience. Some flexibles will tangle up helplessly in the gear mechanism (Fillamentum TPU), others – with an identical shore hardness of 98A (Kodak TPU) – work flawlessly. In any case, it is essential to dial down the print and feed speeds to keep a manageable flow without the filament backing up and coiling out of the extruder.

The ever occurring warping problem midway through our ABS prints, however, we could not find a workaround, despite all the fiddling with temperature and fan settings and even applying (with a heavy heart) some adhesive.

The print bed being capable of only reaching 90°C indeed is a downside and basically takes ABS prints off the table. Still, on the upside, the Mega X’s printed multiple PETG materials pretty well, so you are not limited in your tensile-strength choice of filaments. The same goes for your run-at-the-mill prints with PLA. No hiccups here, just smooth printing all the way.

In reviews past we’ve touted the Anycubic Mega printers as one-trick PLA ponies. The Mega X breaks free from this and stands up well to filament-founded scrutiny.

The Usability

Prints can be sliced for the Mega X with most of today’s popular slicers. We used Cura, as recommended for the machine, and the provided printer profile that ships on the included USB stick. The default PLA settings worked fine for our first test prints, except for the Z-axis support-to-print-distance, which was too close, resulting in support structures fusing to some of our early prints.

Generally, the Anycubic Mega X convinces with its ease of use, even though the UI is somewhat convoluted. The menu items are large and easy to read for easy handling; it’s just sometimes unclear which submenu contains particular tools and options. We would advise muting the obnoxious button press sound it makes every time you touch it, though.

While we are on the subject of being loud. The Mega X is sturdy as a tank, but unfortunately, it also makes the noise of one. Especially the Z-axis lead screws are earsplitting. Luckily the Z-axis really only moves a lot when homing the printer at the beginning of a print.

The rest of the printer is not particularly quiet. The Trinamic drivers and cooling fans within lead to an operating noise level of around 70 dB.

We deliberately let the filament run out on one of our prints and prompted the runout sensor into action. A swift filament change later, it picked up the job without problems. Keep in mind this is a mechanical sensor. Compared to the costly alternative of an optical sensor, which could also detect filament blockages, the mechanical sensor only trips when there is a lack of filament. It is a budget solution, but a welcome and necessary one nevertheless.

The advertised resume print function we could not utilize, though. After – in this case intentionally – yanking out the power cable, you are presented with the option to resume printing. Selecting this did nothin, leaving us no choice but to start over from scratch.

Is it Worth it?

Reviewing a printer leads inevitably to picking up the nitty-gritty, but all in all, the Mega-X met our expectations and, on occasion, exceeded them.

The printer’s sturdy appearance is directly reflected in its build quality. No janky parts, but stamped steel panels mean once this printer is set up, it’s set up – no need to relevel or readjust every time you so much as touch it.

It’s 300 x 300 x 305 mm build volume leaves you with enough space to tackle ambitiously large prints. Granted, some printers in the same price category offer 100 mm more on the Z-axis. But, the neat features, good design, and ease of use make your printing experience as smooth as possible and make it worth overlooking its slightly smaller build volume.

At the end of the day, though, the Anycubic Mega-X does not differ very much from the former Mega S, except in build volume. It would have been nice to see new features such as WiFi connectivity, auto bed leveling, and quieter fans, but perhaps there is only so much you can expect at this price range and size of the machine.

As a large new budget 3D printer with a decent out of the box printing experience and print quality, the Anycubic Mega X convinces.

Tech Specs

Here’s an extensive look at the Mega X’s tech specs:

General Specifications

- Technology: FDM

- Year: 2020

- Assembly: Semi-assembled

- Mechanical arrangement: Cartesian-XZ-Head

- Manufacturer: Anycubic

3D Printing Properties

- Build volume: 300 x 300 x 305 mm

- Layer resolution: 0.05 – 0.3 mm

- Feeder system: Bowden drive

- Extruder type: Single

- Nozzle size: 0.4 mm

- Max. extruder temperature: 250°C

- Max. heated bed temperature: 90 °C

- Print chamber: Open, not enclosed

- Frame: Metal

- Bed leveling: Manual

- Print bed: Heated bed with Anycubic Ultrabase

- Display: Color touchscreen

- Connectivity: SD card, USB

- Built-in camera for monitoring: No

- Filament sensor: Yes

Materials

- Filameter diameter: 1.75 mm

- Third party filaments: Yes

- Materials: ABS, PLA, HIPS, wood, etc.

Software Requirements

- Recommended Slicer: Cura

- Operating systems: Windows, Mac OSX, Linux

Dimensions and Weight

- Outer dimensions: 500 x 500 x 553 mm

- Weight: 14 kg

Similar Printers

You may also be interested in the following printers:

For further information, feel free to check out our Best 3D Printers Guide.

Anycubic Mega S

The Mega S is Anycubic’s previous iteration of the Mega line. Sporting the same sturdy build and identical features, it provides a build volume of 210 x 210 x 205 mm, which is roughly two-thirds that of the Mega X. Priced around $270 it is a budget alternative if you don’t want to miss out on all the goods parts of the Mega series and don’t mind the smaller print volume.

Artillery Sidewinder X1

The Sidewinder X1 is Artillery’s flagship 3D printer. Priced around $450, the Sidewinder puts out a similar sleek look but features a bigger build volume of 300 x 300 x 400 mm as well as a direct drive system. The print quality out of the box falls a bit short compared to the Mega X, but with some fine-tuning it can be great.

Original Prusa i3 MK3S

At just shy of $1,000, the Original Prusa i3 MK3S has it all. From excellent print quality out-of-the-box, a fast heating flexible metal build plate, a direct drive system, and automatic bed-leveling. The MK3S truly is the best bang for buck printer around and our pick for the “Best 3D Printer of Spring 2020”

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.