Note: This is an archived version of our initial Creality K1 review. Read the updated K1 review for our current thoughts on this machine.

Classic Cartesian-XZ-head 3D printers are on the out-and-out in consumer circles, and CoreXY is the new hotness. Naturally Creality, with its dominant market share, doesn’t want recently launched brands eating its lunch with their shiny new, well-tuned systems. So, it’s responding to recent breakout market successes with its new “flagship” 3D printer: the Creality K1.

Creality already took a couple of stabs at CoreXY machines with the Ender 6 and Ender 7, which we ultimately found “forgettable”. CoreXY 3D printers have evolved a lot since then, and breakout successes Bambu Lab have helped popularize the kinematics among hobbyists in a big way. The K1 is a clear answer to those new machines, with a shared look and name that seems to nod to Bambu Lab’s X1 3D printers.

The K1 is an interesting machine, coming at what seems to be a pivotal moment in the consumer 3D printing market. Creality could very well have a lot riding on whether it can still offer an enticing alternative to darlings in the space. Read on to hear how we think it stacks up.

The Verdict

Pros

- Fast printing that lives up to promises

- Consistent automatic leveling

- Excellent layer uniformity

Cons

- Shameful lack of open source acknowledgement

- Broken basic features and gutted firmware functionality

- Temperamental hot end

The Creality K1 is a decent machine that is capable of outperforming many 3D printers in its price range in terms of speed and part quality. Though it produces prints with admirable speed and clean layer uniformity, and the automatic bed-leveling system produces reasonably consistent results, the experience feels rushed to compete with Bambu Lab’s ultimately more polished product line and falls short of expectations.

Creality fails to offer the in-depth software options and control that its competition does and ships the K1 with some of the simplest features – file deletion and print speed adjustment – broken. Where Creality could have differentiated itself with an open Klipper-based firmware akin to its Sonic Pad, useful elements of its base open-source firmware (which receives no acknowledgment), like custom profiles, macros, and simply starting prints from a web interface, have been deleted or walled off – presumably to push users towards using Creality’s Cura-based slicer as it seems to be the only way to print over a network.

Moreover, we found the printer very hit or miss in terms of the material it would print with and were left with the impression that the hot end is rather temperamental.

Overall, the good results and ease of use that the K1 is certainly capable of are boxed in by bad software and a temperamental hot end that results in a frustratingly restrictive experience.

At A Glance

- Price: $599

- Build Volume: 220 x 220 x 250 mm

- Max. Hot End/Heated Bed Temperatures: 300 °C / 100 °C

- Print Bed Material: Magnetic PEI

- USP: Fast, networked printing & little Z-banding

- They say: “Stand firmly to the speed challenge”

- We say: Fast, but inflexible

Learn more

The Tech

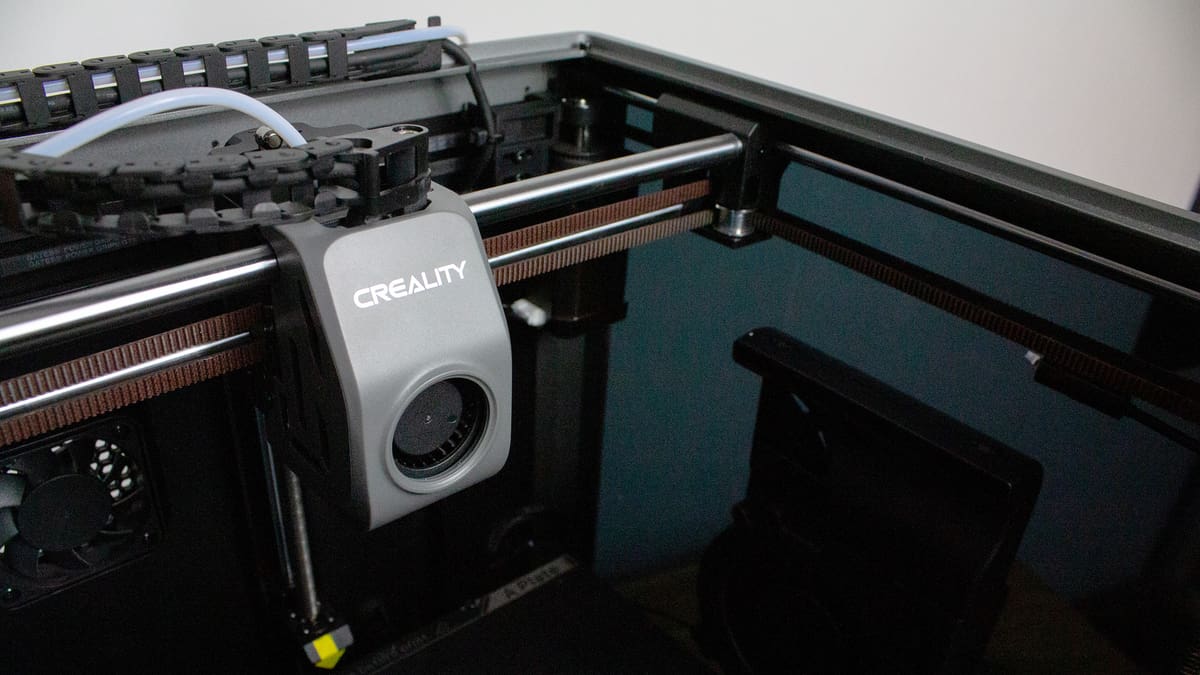

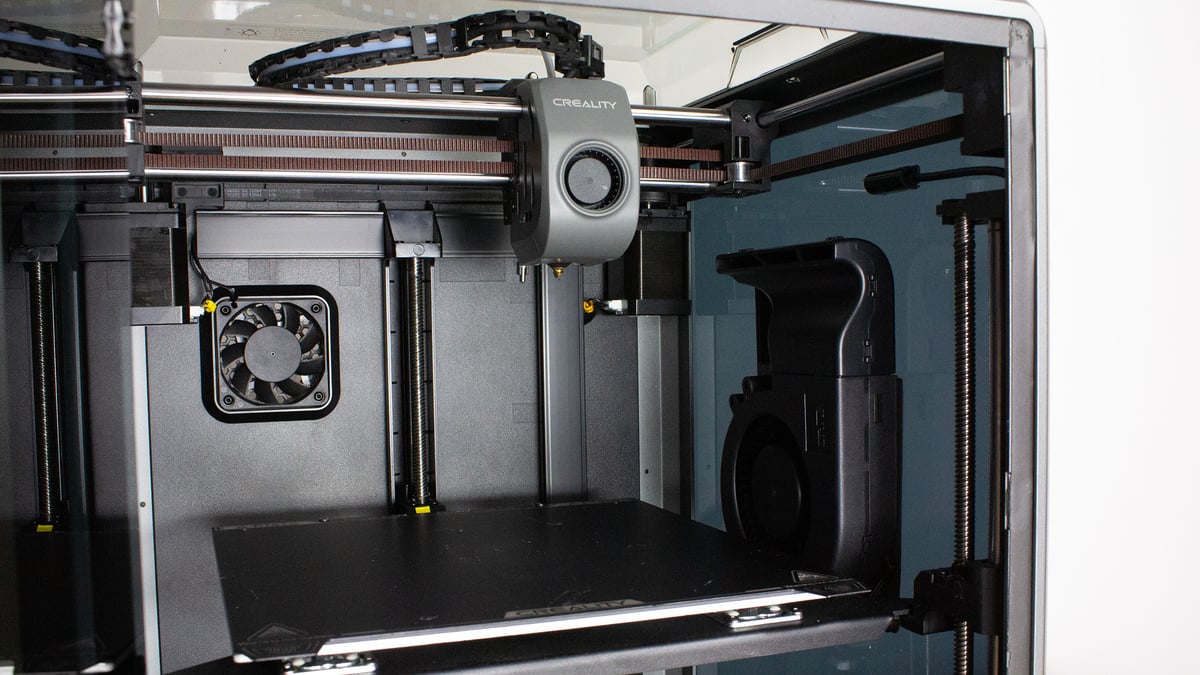

Creality’s new “flagship” 3D printer is a clear response to the massively successful Bambu Lab CoreXY machines. It’s a “hands-free auto-leveling” linear rod CoreXY system with an integrated accelerometer for resonance compensation (input shaping) and wireless network capabilities. The 3D printer is enclosed, with a case fan on its rear that we could see being a blessing to direct UFP-infused air away from users. There’s also an auxiliary fan on the printer’s right side for additional cooling power – a must-have for machines that want to compete at high speeds today.

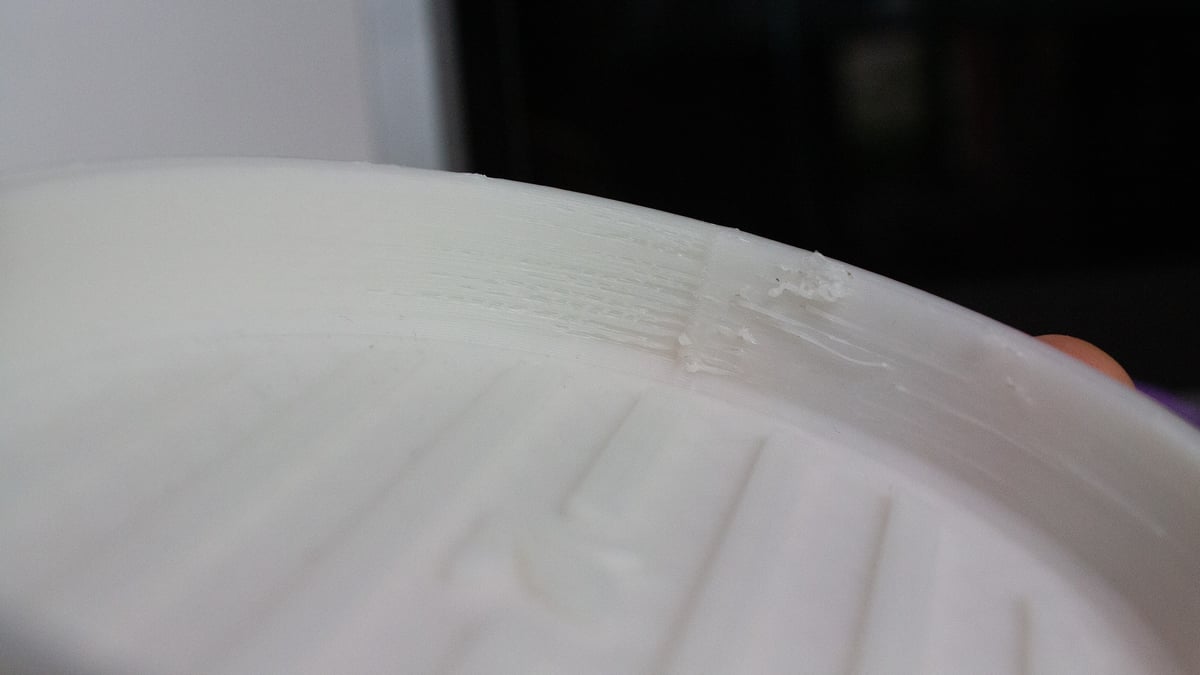

It was clear that Creality needed fully-automated bed leveling for this machine, and it provided it with an array of strain gauges integrated into the heat bed – rather than the nozzle probing manufacturers seem to favor lately. The system performed well throughout our time with it, but we did quickly notice mild damage to the flexible build plate where the nozzle probes.

The K1’s direct extruder is a new high-flow-rate design that Creality says can hit 32 mm3/s. The hot end is capable of printing at up to 300 °C and uses a circular ceramic heater that gets the volcano-style copper alloy nozzle up to temperature quickly.

We found the filament path less than ideal for loading filament and had to remove the PTFE from the top of the direct extruder nearly every time we swapped it out to feed it through. When it worked, the K1 produced great results, but we found the extruder hit and miss on what materials worked with it. More on that later.

High Speed

It’s true that the Creality K1 prints fast. At its default profile speeds of 2-300 mm/s (from outer walls to infill), the K1 is capable of producing quality parts at about double the speed of recent Cartesian 3D printers fitted with Klipper firmware and accelerometers like last year’s Biqu Hurakan.

Creality was pleasantly transparent in its marketing about the K1’s speed, pushing its max speed of 600 mm/s and high flow rate potential readily but with a clearly visible asterisk noting its more typical speeds mentioned above. Getting 600 mm/s printing to produce a model of any strength would take some tweaking, but Creality does provide a speed test print to show the capability in action.

The company still fails in marketing honesty, though. Creality compares the 300 mm/s K1 to a “regular 3D printer” extruding at an antiquated 60 mm/s, ignoring more recent models like the aforementioned Biqu Hurakan that is capable of printing reliably at 150 mm/s, or, better yet, last year’s Flsun V400 that we found to reliably print at high speeds, including 400 mm/s. Or even Creality’s direct competition, the Bambu Lab P1P and X-series, both capable of printing at speeds matching the K1.

Klipper Firmware

We have a gripe with Creality’s poor (and unethical) implementation of the open-source Klipper firmware in the K1. Creality described the K1’s Creality OS firmware to All3DP as “quasi-Klipper”, but what we see is a version of the firmware that’s been gutted of user-friendly features and had its name stripped from the implementation. Instead, Creality only references Creality OS in the K1’s marketing.

Creality took its first stab at a Klipper implementation with the Sonic Pad. Klipper is mentioned readily in that product’s marketing, but here, it’s not in the slightest. Great timing on Creality’s part, as the community has been raising its voice recently about abuses of the GNU GPL license just like this.

Don’t think that just because the K1 uses a version of Klipper that it will have an experience as pleasant as the Sonic Pad, though – it’s completely different. In fact, limited software was an extremely frustrating part of our experience with the K1 by simply not working in simple ways – like deleting files from the touchscreen – and having useful features of the original open-source software cut out – like all Klipper’s customization features – for reasons we can’t fathom.

Learn more

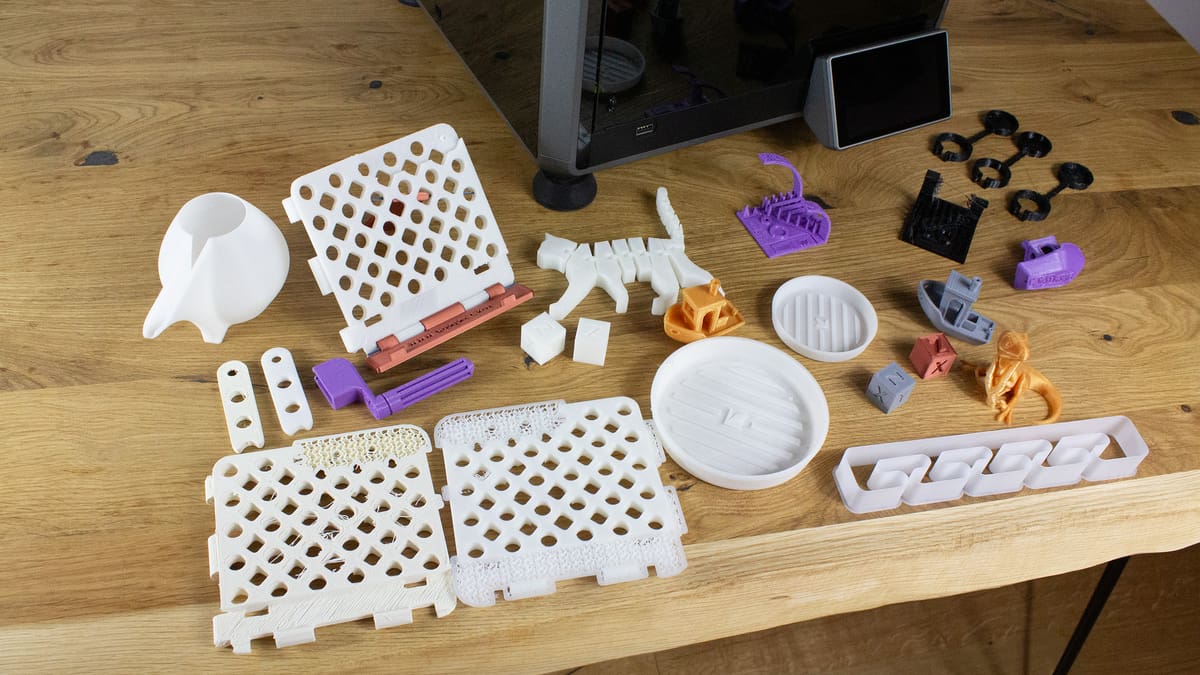

Printing

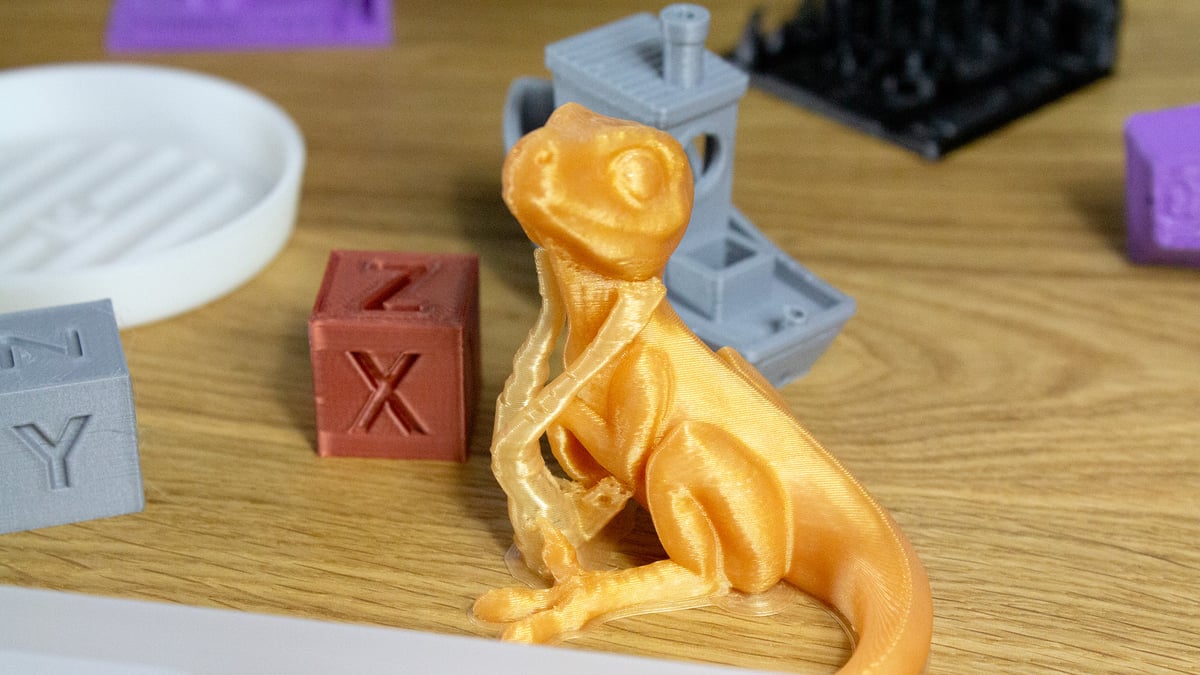

Out of the box, the Creality K1 produces impressive parts. The company made a point to highlight an “upgraded Z axis” that it claims reduces Z banding, and it seems to be right. On all our successful prints, the K1 produced parts with admirable layer uniformity. They look great and – with materials that play nice – print consistently.

This is further highlighted by Creality’s speed test print – a pre-loaded test print that produces a ribbon-like shell in vase mode at the machine’s top 600 mm/s speed. It wasn’t just vase mode that made the test print seamless; layers are practically non-existent on the part.

It’s interesting to note that the K1 shakes like crazy printing at these speeds – it’s impressive that it still manages to produce high-quality results with the amount the machine moves. Clearly input shaping is doing some heavy lifting here, and it shows the value of integrated accelerometers to achieve high speeds.

Prints do seem to rely heavily on the K1’s auxiliary fan to achieve good results even at its default 300 mm/s printing speed, and that makes sense – 3D printers touting fast speeds are increasingly implementing these side-mounted fans. Unfortunately, prints that block the airflow from the auxiliary fan can struggle. You’ll need to slow it down if you notice the far side of your prints suffering.

Material Madness

So, the Creality K1 can perform very well in the right conditions, but its weak spot seems to be how limited the machine is in changing conditions.

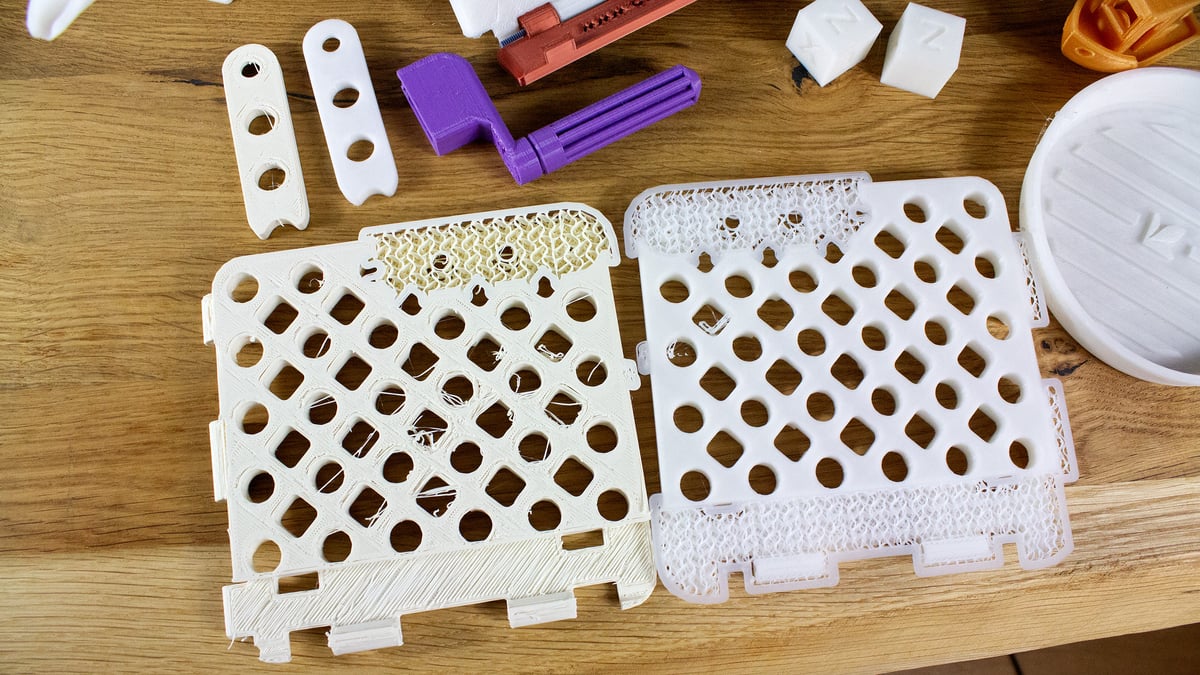

While materials like Creality’s Hyper PLA work wonderfully – and so do many third-party materials – the K1 is a lot more finicky about the filament it can print with than most 3D printers. Several of our usual testing materials produced terrible, heavily under-extruded parts if they produced something you could even call a part at all. Where other machines continue to produce fine results with these same materials, the K1 seems simply incapable, no matter how we played with the print settings: hot, cold, fast, or slow. It’s rather confusing, considering the volcano-sized melt-zone, honestly.

Interestingly, one material that does work with the K1 (although is rather stringy with default settings), Eryone PETG, seems to fall off harder with age than with other machines. Running some of the PETG that’s a bit past its prime, we had a hard failure – the K1 couldn’t get more than stringing blobs down. But, the older material still worked well with other 3D printers on hand. The K1 has a hard hot end to please.

Certain materials having a hard time with particular machines isn’t exactly unheard of, but we were surprised to find failures quite so absolute with materials that worked perfectly well on older machines like the Ender 3 V2 – even when the K1 was slowed down to their much more pedestrian speeds.

Software Woes

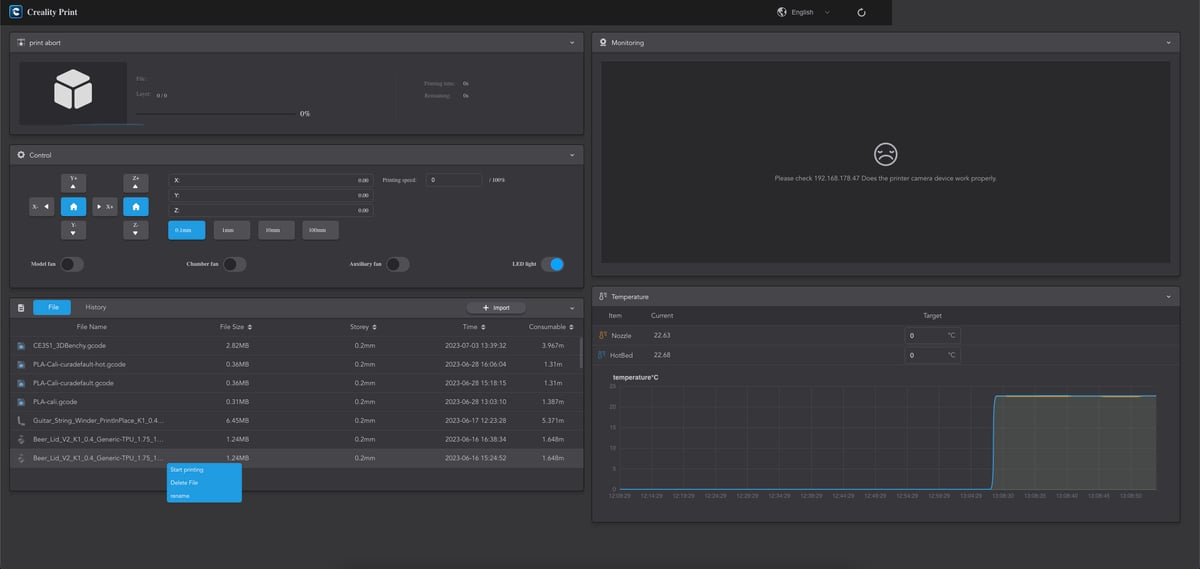

As we mentioned before, the Creality K1 runs on a modified version of Klipper that Creality calls Creality OS. Unfortunately, it doesn’t work like other Creality implementations of Klipper that we’ve seen.

In the K1’s Creality OS, a web interface that appears to be based on Fluidd (we can’t say for sure) is accessible – but its functionality in comparison to a full Klipper UI is entirely butchered. For one, the customizability features are gone, leaving only the interface home screen. No profiles, no custom macros – nothing. You can still upload G-code through the web interface, thankfully, but you can’t start a print from it. Instead, it prompts you to start the print from the machine. This all seems to be a way to push users to Creality’s slicer and app, which appear to be the only methods to start a print on the K1 over Wi-Fi.

The lack of features present in the K1’s firmware doesn’t stop at Klipper. Basic controls that we’ve come to expect any 3D printer to have are missing, making the K1 a severely limiting device to work with. There are no extruder controls beyond those pre-packaged for material changes and no opportunity to change the printer’s Z-offset. While auto-bed leveling performed consistently well for us, we would have liked to adjust the offset at times. As it is, if you’d like to change your Z offset, you’re going to have to do it through your slicer.

Even standard features that do exist often just don’t function. Adjusting print speed – something you might consider important on a 3D printer touting how it pushes speeds – simply doesn’t work. Any time we tried to change the print speed from its default 100%, it just changed back. This, of course, made testing all those filament failures a lot more tedious than it had to be. “Does this filament just need to print a little slower? Guess I’ll reslice it to find out.”

Learn more

Should You Buy One?

The Creality K1 is a hard sell compared to Bambu Lab’s budget offering, the P1P, which retains many of the impressive X1’s features like a convenient setup and software experience. On top of that, you get compatibility with Bambu Lab’s advanced addons like the AMS multi-filament system – something Creality lacks a comparable offering of. While the larger K1 Max appears to bridge features between the K1 and X1 somewhat, with lidar and an “AI camera”, but we can’t speak to the effectiveness of those systems (it’s not shipping yet). The standard K1’s poor software doesn’t give us high hopes.

And, of course, since the P1P recently received a substantial $100 price drop, it now matches the K1. For $599, there’s no contest; the K1 falls short.

Learn more

Alternatives

If you’re planning to pass on the K1, your next port of call is probably the Bambu Lab P1P. It costs the same but has some really impressive features, fantastic user-friendly software, and hasn’t stonewalled us while using materials that otherwise perform perfectly fine. It’s also possible to use Bambu Lab’s AMS to print with up to four different materials through the P1P’s single extruder. Creality doesn’t have a similar offering and actually directs customers to Bambu Lab in an FAQ if that’s something they’re looking for.

If you’re not necessarily keen on CoreXY 3D printers but find the K1’s feature set appealing, you can take a gander at Klipper systems touting similar hardware that came out last year. The Biqu Hurakan is much more affordable at ~$380, but you’ll sacrifice some speed. On the other hand, the FLsun V400 is a Delta 3D printer that’s more expensive than the K1 at ~$850, but we found it to produce quality parts at higher speeds. Both are capable of input shaping and use regular Klipper firmware, so you can add macros and print wirelessly to your heart’s content.

Learn more

Featured Prints

Shout out to the talented folks who designed the models featured in this review’s photos:

- Cute Baby Velociraptor by Marcoglossum, via Printables

- Sheet Music Stand by Hobbyman, via Thingiverse

- Plant Pot Dish/Saucer by PRSPR, via Printables

- Print In Place Guitar String Winder by DavVvE, via Thingiverse

- Handleless Watering Can by Mav3r1ck, via Thingiverse

- Beer Guard, Beer Lid by Ambifox, via Thingiverse

Tech Specs

- Technology: Fused deposition modeling (FDM)

- Year: 2023

- Assembly: Fully-assembled, plug and play

- Mechanical arrangement: CoreXY

- Build volume: 220 x 220 x 250 mm

- Feeder system: Direct

- Nozzle: 0.4 mm copper alloy

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 100 °C

- Print bed material: Magnetic, Flexible

- Bed leveling: Build plate strain gauge array with auto-bed leveling

- Connectivity: Wi-Fi, USB

- Filament sensor: Yes

- Filament diameter: 1.75 mm

- Frame dimensions: 355 x 355 x 480 mm

License: The text of "Creality K1 Review: Boxed In" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.