There’s misinformation, lack of regulation, and, perhaps, intentional fraud, by resin makers today that could negatively affect your health if you use resin 3D printers at home or in an office. This was the stark warning 3D printer manufacturer Formlabs issued alongside the marketing of their new, “safer” resin line, which is the company’s first offering of non-proprietary materials you can use on any resin 3D printer on the market.

Scare tactic or science? We reached out to Formlabs to talk about resin, chemicals, and why they made a line of resins for other resin 3D printers. We got an in-depth conversation with Alex Haring, Formlabs’ materials lead (and PhD in chemical engineering) and Jessica Bergau, Formlabs’ technical program manager. They shed light on why there is more to worry about today than you may have thought when it comes to many of the resins on the market, and what you should be doing to print safely.

How Toxic Is 3D Printing Resin

First, let’s look at the science behind resin and health. There have been a few studies lately that explore the chemicals in resin and the fumes created during the printing and post-processing processes.

In the American Chemical Society’s journal Chemical Health & Safety, a 2022 report on resin 3D printing found: “The emitted mixture of sensitizers, carcinogens, irritants, and flammable chemicals may present a hazard for indoor air quality and human health.” The resin 3D printer used in their testing was a Formlabs A2 and the resin was also a clear Formlabs resin.

Overall the study found that “personal exposure to total VOC and some specific VOCs of concern to human health, like formaldehyde and naphthalene, exceeded the recommended indoor levels … potentially causing irritation and other health impacts for 3D printer users.”

Sounds like bad news, yet, the study did not imply that resin 3D printing is inherently unhealthy, just that precautions, such as ventilation, gloves, and other handling steps should be followed. The estimated office exposure levels for the chemicals of concern, in fact, were below those indicated in regulations, the study found.

So if resin 3D printing emits unhealthy chemicals but the effects can be mitigated with proper safety precautions, what’s the new concern?

Beware Resins Without Safety & Ingredient Data

As sales of desktop resin 3D printers grow so does competition among 3D printer makers to deliver machines that are cheaper and faster. Resin plays an important role in both.

“To cut costs and boost printing speeds, manufacturers often use cheap, highly reactive chemicals,” says David Lakatos, chief product officer at Formlabs. “While some of these components are safe and well understood, others can pose significant risks when exposed to skin and are harmful when inhaled.”

All resin can be skin-irritating, which is why gloves are required, and adequate ventilation is always a recommendation, but what Laktos aims to spotlight is that new research on these chemicals show that’s more risk and reason to be concerned that previously thought.

One chemical in particular found in some resins, particularly the budget kind, is called ACMO (4-Acryloylmorpholine).

“There are worse things you could put in resin, but I think ACMO is the worst thing we see broadly put in resin, and pretty universally,” says Haring. ACMO is highly reactive and leads to fast printing times, but “things that are highly reactive also tend to be more hazardous and potentially cause organ damage over time. And that’s that’s really the trade off.”

ACMO contributes to the flexibility and toughness of cured resins and works to minimize shrinkage during polymerization among other benefits. This chemical got its start in the coatings industry, out of which resin 3D printing first evolved.

“ACMO is really commonly used in the coatings industry — although not in the US — because it’s fast, it’s low viscosity, and you can get pretty good mechanical properties out of it,” Harring says. 3D printing resins with ACMO cure fast and produce parts with good stability.

Yet, there’s a huge difference between having ACMO used in an industrial setting and putting it in consumer products.

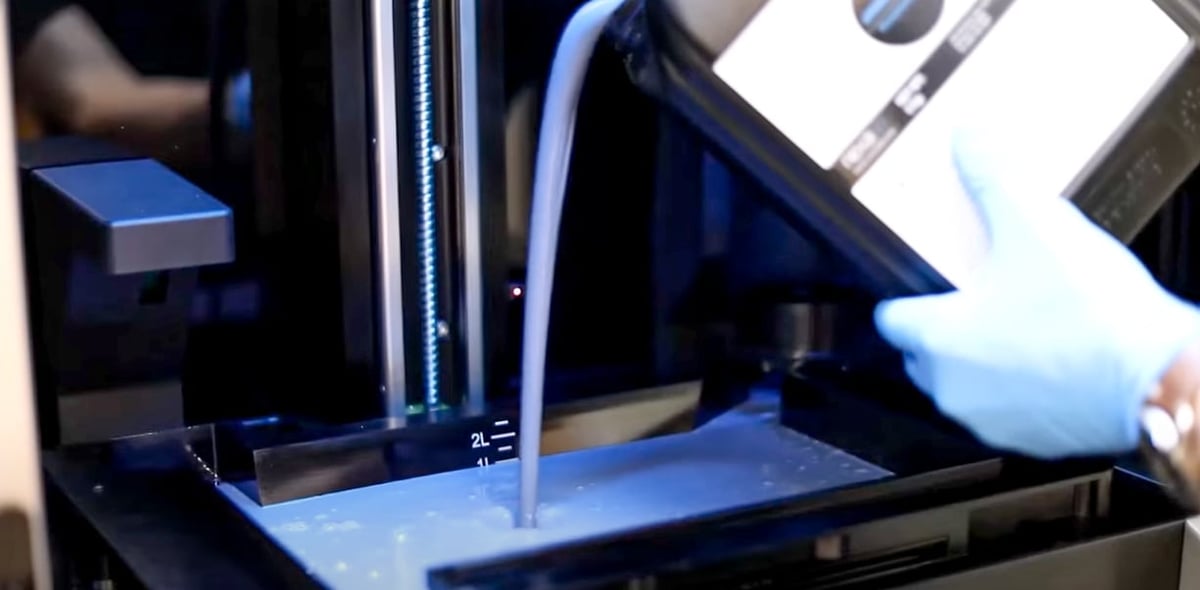

Formlabs says it has never used ACMO because it knows its customers are likely not working in an industrial setting (Formlabs printers are designed to be used in offices or small labs). Formlabs has always designed its 3D printer to contain pre-filled resin cartridges so that users never have to pour resin from a bottle and risk spills or other accidents.

“There are other sensitizing acrylic monomers and we try to avoid all of those as well, but I think that ACMO is the one that there’s the most data on, and it’s probably the most concerning,” says Haring. “It’s one that we’ve drawn a hard line on in our own resins.”

ACMO is not banned in consumer resins and Formlabs isn’t saying that they should be. “I think if people want to purchase them and use them, they have the right to do that,” says Haring. “I think that the real issue is that the hazards associated with it are not being communicated appropriately, in many cases.”

In 2024, the US Environmental Protection Agency (EPA) issued a Significant New Use Regulation (SNUR), for ACMO, which is registered under the US Toxic Substance Control Act, because of the dangerous effects of contacting skin and breathing in its vapors. The SNUR requires that certain warnings must accompany products containing ACMO, such as the fact that it may cause reproductive effects.

Another 2024 study in the journal Food and Chemical Toxicology found that AMCO could contribute to allergic reactions in the skin by promoting “keratinocyte activity,” a hallmark of immune system engagement.

Other manufacturers, including 3DRS have started to promote “ACMO-free” 3D printing resins.

But What About TPO?

Another chemical in resin that newer studies are showing is more toxic than previously thought, is TPO (trimethylbenzoylphosphine oxide), which is a “photoinitiator” or the chemical that kick-starts the hardening of the resin when it’s exposed to UV light. It’s a common industrial chemical but also widely used in most 3D printing resins, both hobbyist and industrial.

According to Haring, TPO has “increasingly had more and more data come out about its potential toxicity and reproductive hazards.” In the EU, it has recently (in 2023) been added to the list of the “substances of very high concern.”

A 2022 study looked at alternatives to both BAPO and TPO for dental resins because these two options’ cytotoxicity. It found another type of photoinitiator, TPO-L, had higher biocompatibility.

Formlabs opted not to use TPO in the Creator Series resins.

Instead of simply launching a line of resins that don’t have two of the most hazardous chemicals included, Formlabs went a step further: outing the resins that do.

Damage Control for Resin 3D Printing's Reputation

With the increased use of resin 3D printing at home and in offices there has been a proportional increase in the reports of harm or injury because of the, often improper, handling of liquid resin.

Formlabs on its blog pointed to a few Reddit posts where consumers received skin burns from handling resin without gloves and inhalation injuries, but these can also be found across social media. There’s no clear connection between injury report and lower resin 3D printer sales, but there is confusion about how safe or not safe resin 3D printing really is, especially for children.

“I think that people were seeing what was happening; these scary posts on Reddit about people becoming sensitized and having severe exposure reactions to the chemicals in the product they’re using,” says Haring. “I think people are getting nervous. That’s a reasonable response.”

Formlabs, too, was getting nervous. Although its main market is professional resin 3D printing, if consumers continue to get injured, it’s bad for the entire market. So they set out to investigate.

Although many reported injuries were the result of not following recommended safety guidelines when working with resin, others were not clear. Could there be something different about the resin?

Formlabs collected resins from nearly 30 companies and independently analyzed them. Not only did many contain ACMO, including Elegoo, Anycubic, Sunlu, Phrozen, Siraya Tech, and Creality, of the 28 ACMO resins, 13 did not have the correct health hazard statements on the SDS, 11 did not list ACMO as a component, and five did not have a SDS at all. (Download the list from Formlabs here.)

Not only did the technical data sheet not list all the ingredients, but resins were sold, often via Amazon and Walmart, either without a safety data sheet or one that didn’t communicate the health hazards.

There were no industrial 3D printing resins on Formlabs ACMO list. Does this mean professional reasons are ACMO-free? Not at all. Formlabs focused on consumer resins because professionals who 3D print are far more likely to have government- or industry-mandated employee safety measures in place, such as proper ventilation and required personal protective equipment.

Can Resin 3D Printers Make Resin Printing Safer?

The desktop filament (or FDM) 3D printer market, especially enclosed heated chamber units, have started lately to include activated charcoal and HEPA filters to capture more VOCs and improve indoor air quality.

Resin 3D printers are all already enclosed and more manufacturers are adopting the resin cartridge model, but Haring says there’s some potential to do more.

“We see more and more of these plug-in filters that some companies are offering, but I haven’t seen any convincing data that they do much to help you,” he says, “but I could see printer manufacturers moving toward easier ways to vent printers out a window.”

Haring says the problems is less about controlling what’s happening on the printer and more about the liquid resin materials and the overall environment. “You’re always going to have a hard time containing everything in the printer and we’re not going to seal these units up because that’s not realistic, either.”

“Ventilation is really just part of it,” says Bergau, “and contact with skin is another part of it. We can try and optimize the printer and the system to be as resin- or sticky-free as possible, but part of the onus is ultimately going to be on the manufacturer to tell the consumer how to use and operate this resin, and then ultimately on the consumer themselves to handle them properly.”

Wear Gloves! & More

At Formlabs, the effort to make resin safer is a continuous project and a growing focus of the company.

“We’re always looking at the new reports that come out and the new studies and thinking what might we be able to tweak or take out of the resin in order to make sure we’re having the properties and material performance people want without exposing them to unnecessary risk,” says Haring.

Bergau adds that Formlabs has been in contact with Amazon to alert them that some resin products it sells are not accompanied by the required safety documentation. The company has also been in contact with the Photopolymer Additive Manufacturing Alliance to find a way to get the resin safety message out to the public more broadly.

“I think sometimes people can look at Formlabs and say, you know, you’re trying to sell a product here, so why should I believe you?” says Bergau. “So we want to bring in people from the industry in general who have their own opinions on things to be able to come out and speak to this as well.”

Formlabs is just getting started on its resin safety initiative and there’s more to come, not only in new resin but also in education.

“We’ve been asking ourselves what’s the most addressable thing that we can actually do now,” says Bergau. “The thing we all agree on is we need to be pushing the wearing gloves mandate, as far and wide as possible. You absolutely should be wearing gloves anytime you’re interacting with the printer, with a green part, even when I’m holding a bottle of resin that may have any resin on it.”

If you want to learn more about the safe handling of resin, check out All3DP’s guides below:

License: The text of "Are Formlabs’ New Resins Really Safer?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.