Artillery carved its place in the consumer 3D printer market when, in 2018, it released the Sidewinder X1 – a Creality-contending competitor that received our Best in Mid-Range ranking when we eventually got our hands on one last year. Now, the company is following up its breakout product with a new model: the Sidewinder X2.

Aside from more plastic trim to make it look more like the smaller Artillery Genius, the Sidewinder X2 doesn’t make any drastic changes – and that’s a good thing. The first release was a great experience with just a few minor flaws. To be expected of a newcomer’s first product.

The company continued releasing new iterations of the X1, acting on user feedback to improve. It seems to be continuing this trend with the X2. Most of the changes affect areas of the printer subject to mild criticisms from reviewers like us and the community.

We got our hands on the Sidewinder X2 just before its release on August 8th and have been testing it vigorously since. Here’s what we found.

The Verdict

Pros

- Capable of very high detail

- AC print-bed heats up fast

- Touch probe set an excellent first layer by default

Cons

- Poor stability and part cooling

- Touchscreen prone to phantom taps

- Price is all over the place

The Artillery Sidewinder X2 comes with nearly everything we want from a 3D printer. If you think the time has come for traditionally addon features like touch-probe bed leveling and a 32-bit mainboard to come standard, the X2 probably has you covered. It isn’t without its problems, but they’re largely addressable with some effort.

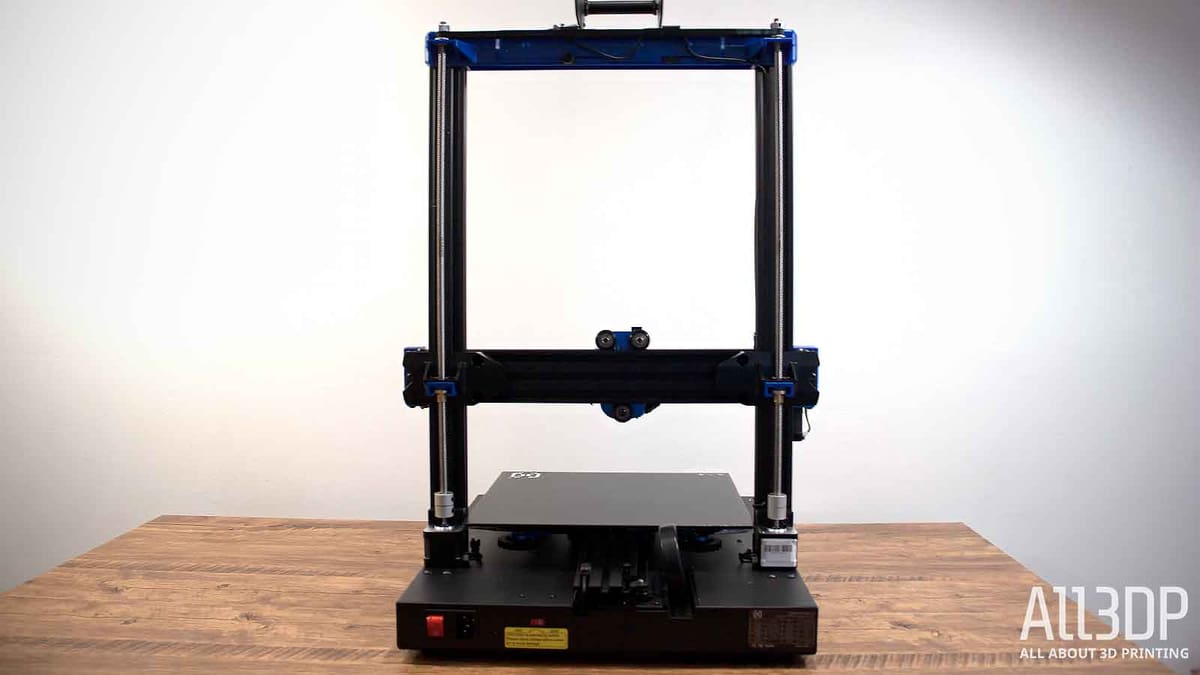

Ultimately, the Sidewinder X2 evolves from its predecessor, the X1 V4, in meaningful ways. Artillery clearly listened to community feedback and improved upon the most pressing issues. It can achieve impressive detail on smaller models but, unfortunately, is plagued by even heavier Z-wobble than we experienced on the X1 and poor part cooling. Both restrict full use of the generous 300 x 300 x 400 mm build volume. That said, if you’re willing to install gantry support and a new fan vent, the X2 is a system with good bones and desirable features for $489. Not a bad place to be.

The Tech

The Artillery Sidewinder X2 is a CR-10-like 3D printer offering a few extra quality-of-life features over the CR-10 V2 – but also missing some key components that would have helped where it struggled.

The Sidewinder X2 is really more of a “V5”, as Artillery’s Sidewinder X1 V4 shared almost all the same features. That’s not to say the upgrades aren’t significant, just that it’s a proper continuation of its predecessor.

If you take a look at Artillery’s Genius Pro, you’ll notice the two offer different build volumes for the same hardware – so you have more than one option if you like what you see.

What’s New?

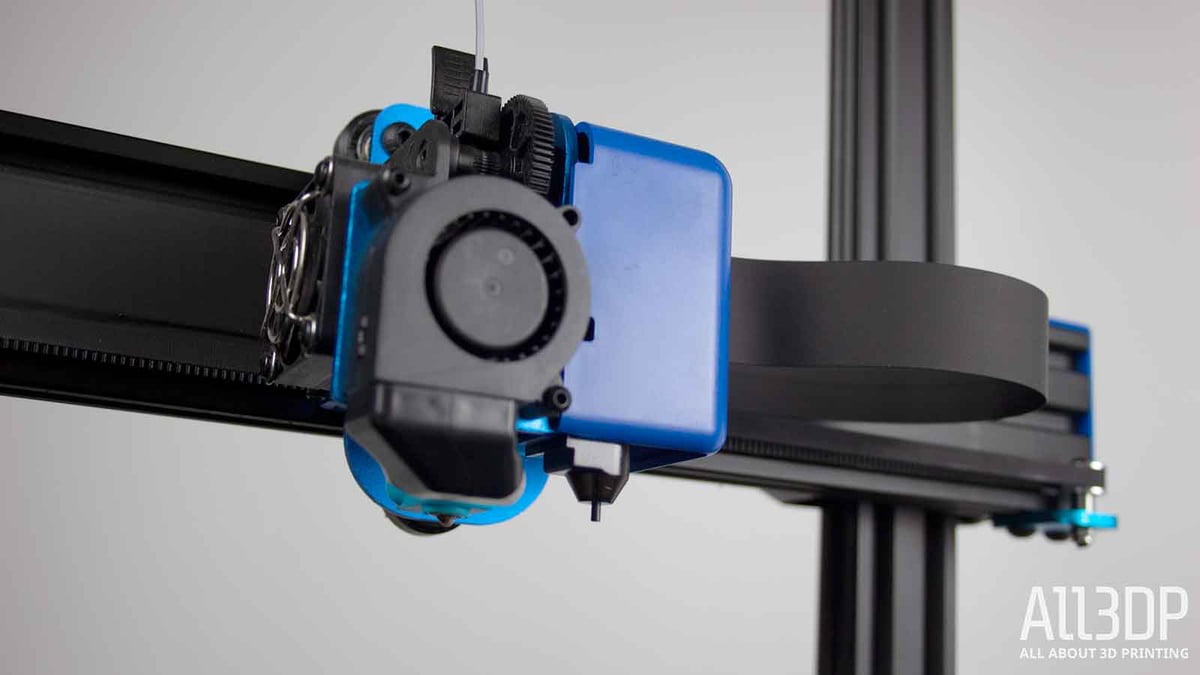

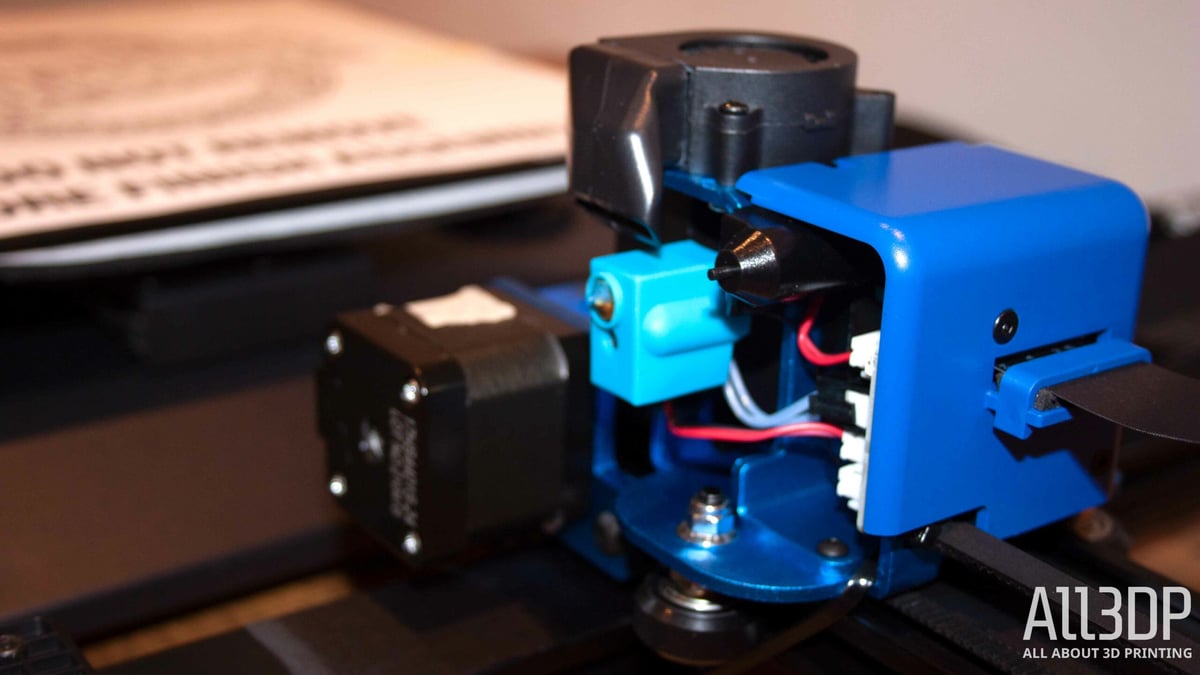

The Sidewinder X2 maintains the same generous 300 x 300 x 400 mm build volume, Titan-style direct drive extruder with Volcano-style hot end, filament and power loss detection, an AC fast-heating print bed, and clean flat cabling that were popular features of its predecessor.

Aside from a few manufacturing and aesthetic adjustments, what’s interesting about this new iteration is all the longevity and quality-of-life features included. Features that are quickly becoming a bare-minimum, like a BLTouch-style auto bed leveling touch probe and roomier 32-bit mainboard, have been added as have a few fixes to problems that plagued the otherwise impressive X1, like sturdier cable connections to reduce risks of thermal and electrical hazards and injection-molded aluminum Z-axis carriages attempting to limit wobble that caused banding. Oh, and let’s not forget the much better spool holder.

Safety First

Probably the most important change, but also the easiest to graze over is the Sidewinder X2’s newly secure cable connections. The X1 introduced Artillery’s sleek flat cables but connected them with an incredibly flimsy port that members of the community reported breaking. The X2 fixed the problem with more robust cable support from the factory on all connections and replaced the fabric-sleeved heat plate cable – which some users reported to break and exposure the wiring – with a flat rubber sleeved alternative with a channel in the printer’s base. All gantry connections come preassembled, so Artillery seems to have taken an extra step to see cables done right this time.

Setting Up

The Sidewinder X2 comes in two pieces – the base and gantry. Everything else, from the extruder to the cables, comes pre-assembled. All you need to do is place the frame and screw it in with four easy bolts, double-check that the power switch is set to the correct voltage for your region and you’re ready to go.

Out of the box, the Sidewinder X2 screamed. Really screamed. Metal on glass and skipping steppers. While homing the extruder with its BLTouch-style auto bed-leveling probe to level the unfixed bed, the hot end slammed into the build plate before the probe could trigger. We suspected the build plate was just imperceptibly tilted — to be expected from an unfixed build plate — and higher towards the nozzle. Overcorrecting a tilt towards the probe allowed us to continue setup as normal, but when we tried to reproduce the issue much later we weren’t able to. We suspect a factory reset performed during our review cured the problem, but can’t say for certain.

This did give us a chance to see the failsafe kick in on the Sidewinder, which detects it’s been “moving” for too long and stops to prevent damage to the steppers or build plate. Having dealt with that odd early issue, we’d suggest tilting the plate a little upwards on the probe side before you home the print head for the first time. That will ensure you don’t run into this at all.

It’s worth mentioning that, initially, we had a difficult time setting the first layer height. Before performing the aforementioned factory reset using the accessible button next to the touchscreen interface, the probe was a bit high and needed its offset adjusted. But while adjusting the offset through Artillery’s custom Marlin UI it wasn’t, at first, accurate. For example, we would set an offset in slicer and get a great print, but setting that offset in Marlin would return different results.

After a bunch of testing we performed our quick reset and the probe defaulted to a perfect setting. We tried adjusting the offset again and finally got reliable results. Offsets between the slicer and Marlin matched just fine. It’s not clear what caused that issue, or whether it was related to our earlier problem while homing the extruder, but if you’re having trouble leveling then a quick reset might be all you need.

Printing & Usability

After spending some time with Artillery’s Sidewinder X2, we think it’s a great 3D printer – but with a couple of major weak points. That it comes loaded with all our favorite features, gets to work fast, and is capable of producing highly detailed results in the right conditions is great, but we see some poor performance in fundamental things that should have been addressed before the extra features were tacked on. There are some very simple mods users could do to try correcting these issues, but Artillery should really address them.

The Prints

The Sidewinder X2 pushed out some prints that were really quite impressive. High detail, no zits, really fast. Our Benchy printed nearly perfect in both PLA and PETG.

Smaller models, especially, really detailed ones like The Bearded Yell by Ben Dansie (this model a supportless remix by iczfirz) show just how much detail the Sidewinder X2 can capture .

Still, the back of The Bearded Yell shows one of the Sidewinder X2’s biggest shortcomings: its overhangs.

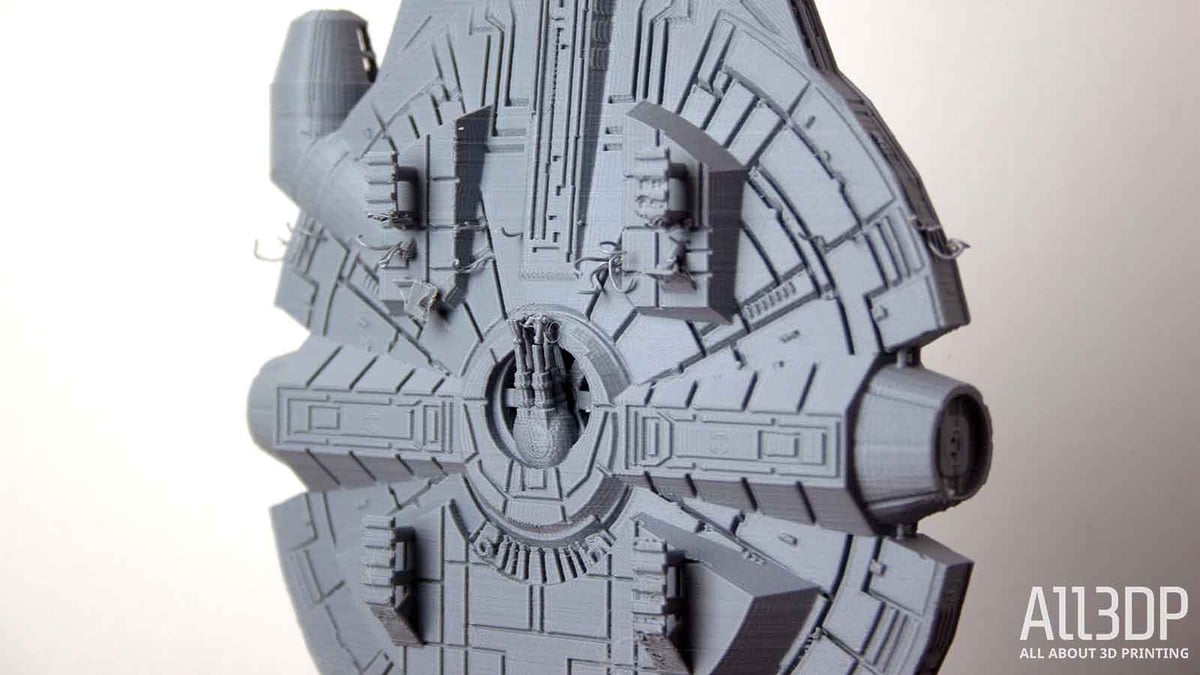

Overhangs were consistently weak from the X2, indicating poor part cooling. On some models it managed to get away with a slightly frayed look, but it was seriously detrimental on others – like the classic Fillenium Malcon by Andrew Askedall. The small, detailed overhangs on features like its landing gears and satellite just didn’t hold up despite being an angle you’d expect to print fine. At least for the Fillenium Malcon, this may have in part been due to the Sidewinder X2’s other major issue: Z-wobble.

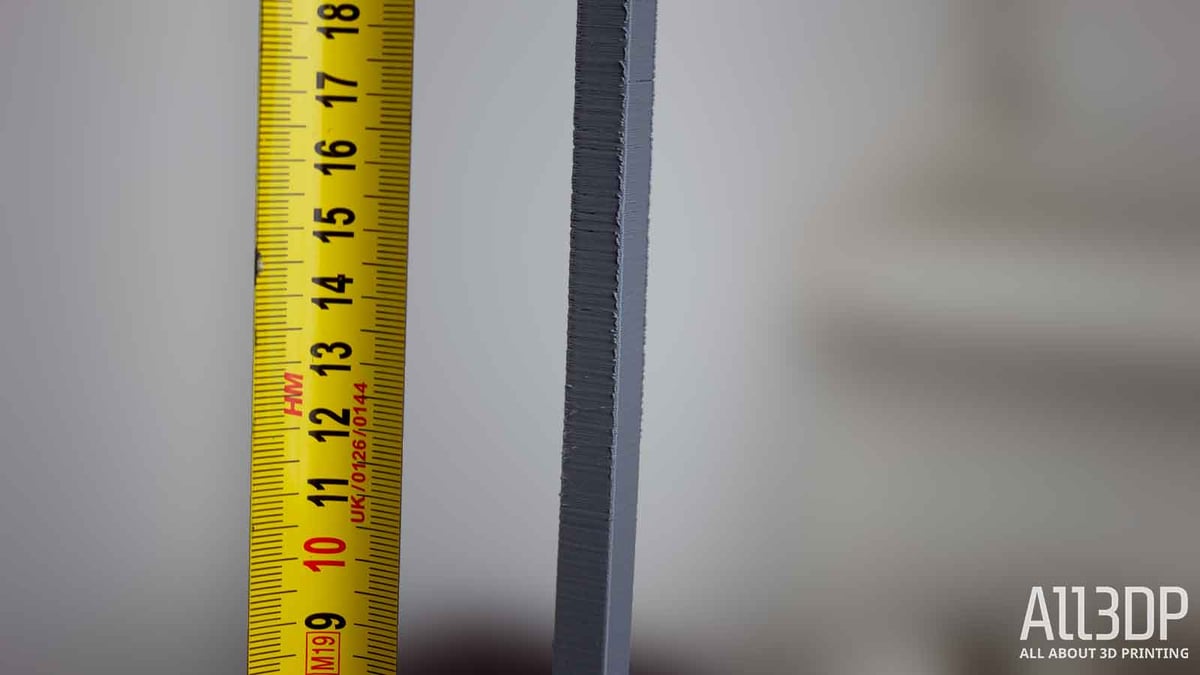

At 400 mm, the Sidewinder X2 is very tall. Unfortunately, the new injection molded aluminum Z-carriages don’t seem to have improved much in the way of Z-wobble. We were pretty stunned by the poor performance of our Z-resonance test and eliminated any exterior factors that could have caused undue vibrations to try again and get the best demonstrable results. Still, they were severely lacking.

The simple fact is that Artillery’s 40 mm wide extrusions might be enough for shorter printers, but going as tall as the Sidewinder X2 demands more than the four horizontally-aligned screws holding such a high gantry in place. The frame is simply too easy to shake, and it’s showing in the prints. After just 100 mm we start seeing noticeable Z-banding that gets progressively worse.

Other users clearly continue experiencing this issue as well, as the earliest Sidewinder X2 mods to pop up on repositories like Thingiverse have been to better stabilize the large frame with CR-10-style and other braces.

Despite these issues, the quality of shorter models – where things are most stable – is impressive. Even pushing the Sidewinder X2’s to its limit and printing a detailed miniature, Dwarf #01 by Christian (@free-minis), turned out with stronger results than we’d expect from this large FDM machine. Credit where credit is due, the X2 can really print when it isn’t shaking around.

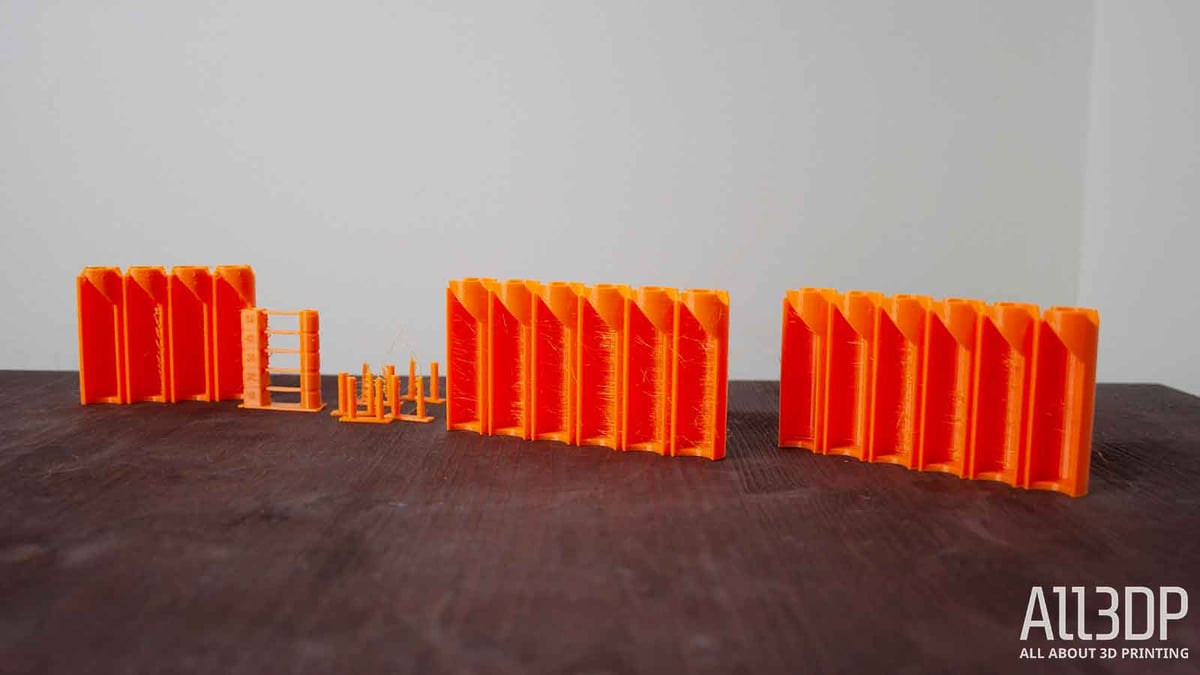

PETG also printed well. Stringing was under control with most prints, like Benchy, but some challenging prints, including these AA battery holders by @mistertech, were a bit tougher to reign in.

We managed to minimize stringing on many, but it’s definitely a balancing act. Whenever stringing was under control in our tests more zits began popping up. Both sides were within reasonable limits, though, and should prove easy to clean up with some mild post-processing.

The Experience

The Sidewinder X2 gets G-code shuttled over by our favorite peripheral means, USB, or MicroSD. It’s a shame there’s no Wi-Fi module built into what otherwise feels like a premium feature set, but the USB-B port should allow OctoPrint to be set up easily.

Artillery’s touchscreen UI gets the job done. We did initially have an egregious number of phantom taps on the lower-left corner of the touchscreen interface that made our early interactions with the printer frustrating, but these inexplicably went away, eventually.

Still, if this isn’t isolated it is yet another issue Artillery should fix – and users should mind. A system susceptible to unintended commands while left on is a potential hazard, not to mention the simple potential for prints to be interrupted should the phantom taps be in the wrong position.

Something Artillery continues to handle exceptionally well on all its printers is the quiet stepper drivers. Like other Artillery systems we’ve reviewed, the Sidewinder X2 lived in a small office next to our workstation printing away for months and was not a disruptive noise. The fans are almost always more audible than the stepper drivers themselves.

Is It Worth It?

Despite egregious issues with Z-wobble and sub-par part cooling, the Artillery Sidewinder X2 can print in pretty impressive detail. Unfortunately, those fundamental problems still severely restrict users who want to create high-quality models with the full build volume out of the box. If you’re not sure you need the extra space the Sidewinder X2’s large build volume offers, we would suggest seriously considering the printer’s little sibling – the Artillery Genius Pro. We’ve yet to review that system but, build volume aside, they’re identical. The Genius Pro’s preceding model, the Artillery Genius, also had issues with Z-wobble, but it’s possible the metal carriages with a shorter gantry than the X1 are enough to tame it. You’d also be paying $140 less for the Genius Pro, at just $349 to the X2’s $489.

Despite its difficulty making use of it, it is fortunate for the Sidewinder X2 that it falls into a strange size category. If you need the volume but not especially high detail capabilities, the X2 is for you out of the box. If you’re on a tight budget but set on the features and a larger build volume than the Genius Pro (or even taller than the Ender 3 Max), the Sidewinder X2 is a great choice.

Day-to-day it’s been a largely hands-off machine and we’re impressed with the quality of prints from the lower-end of the Sidewinder X2’s build volume. We wouldn’t recommend it for tall models that require a high surface finish, lest they suffer the same fate as our Fillenium Malcon, but with some simple mods to stabilize the gantry and improve the part fan’s vent we expect results could be enviable there too.

However, something to consider is Artillery’s rapidly changing price for the Sidewinder X2. The company uses the common (but frustrating) tactic of listing products “on sale” from higher prices than they’ve ever sold for — making it sometimes difficult to pin down what they’re really worth. When the X2 launched it was on a genuine release sale for $409, listed as marked down from $469. We reached out to confirm the price and were told it would sell for just $449 on Artillery’s website. But now? The Sidewinder X2 is listed at $489 and remains “on sale” from $519. Given the global chip shortage, it’s not all that shocking the price went up by $40, but it would be a lot easier to swallow if Artillery cleaned up its store pricing and dropped the fake sale prices.

For price comparison’s sake, the Creality CR-10 Smart is just $10 more than Artillery’s current price for the Sidewinder X2 and includes gantry supports, Wi-Fi connectivity, and a fixed bed. We haven’t reviewed the machine, but it provides a fair comparison for what all these features are worth – and how much more Artillery could do for the increased price. Even the feature-sharing Genius Pro, as noted above, is a significant $140 less.

Features

Automatic Bed Leveling

The most practical upgrade added to the Sidewinder X2 is its automatic bed leveling. Missing from Artillery’s products until now, the BLTouch-style physical probe included on this new printer is a welcome addition. It doesn’t do away with spinning springy knobs completely, since the bed remains unfixed, but will manage to reduce the amount of leveling maintenance required. Out of the box, we found the touch probe applied the perfect height for our first layer.

Fast-Heating Print Bed

Continuing with an attractive feature of many Artillery printers, the Sidewinder X2 is equipped with a fast-heating AC-powered tempered glass print bed. It’s a winning combination compared to the more common DC-heated print surfaces. We found it the Sidewinder X2 met Artillery’s claims, heating its larger-than-average print volume of 300 x 300 x 400 mm to 110 °C in just about three minutes. However, the tempered glass print surface is, like all Artillery’s printers, adhered to the metal heat plate, making any future repairs or replacements difficult and probably more expensive than they’d otherwise need to be.

New Brains

Last year, Artillery released an in-house 32-bit Ruby mainboard with its budget system, the Artillery Hornet. That upgrade has carried over to the Sidewinder X2, improving on the X1’s 8-bit board.

The ample wiggle room provided by the new Ruby board should ensure the Sidewinder X2 has enough processing power for any future updates, or if you want to dig around in Marlin yourself (maybe to add WiFi to the mainboard).

Injection Molded Z-Carriage

The Sidewinder X2’s dual Z-lead screws come equipped with injection-molded aluminum Z-axis carriages “for maximum stability and durability.” The carriages extend further than the brackets included on previous systems but it’s not the right fix for the Sidewinder X2’s stability problem, which we found to wobble more than the X1 before it. The tall gantry needs its high top supported, or at least to have a stronger base connection than four horizontally aligned screws.

Clean Cabling

A sleek, clean look is something that Artillery’s printers are identifiable for, and the tidy cabling they all feature is a large part of that. The Sidewinder X2 continues this with ribbon cabling that lends the printer a professional look and enough aesthetic to fit into visible settings more comfortably than some messier-looking budget printers (sorry, not sorry). You won’t have to deal with strands of cabling falling all over like a spilled bowl of noodles here.

Artillery clearly listened to user feedback here, too. The previous Sidewinder had weak cables and connections that were prone to hazards, but that’s been effectively remedied on the X2. Cables are pre-installed and very well supported.

Further Features

Additional features on the Artillery Sidewinder X2 include:

- Titan direct drive extruder — Like its predecessor, the Sidewinder X2 features a Titan direct drive extruder with a volcano nozzle. It’s capable of pushing a lot of material out fast, making the Sidewinder a prime candidate for a wider nozzle.

- 110/220 V Switch — Artillery has simplified its manufacturing somewhat by adding a voltage switch to the Sidewinder X2. While this was never much of an issue at the consumer end when the company produced two models for each voltage, it does eliminate any risk of ordering (or being mistakenly sent) a unit with the wrong voltage.

- Power interruption and filament runout detection — Also like the X1, the Sidewinder X2 will pause should a power outage occur or you’ve run out of filament and pick up where it left off when corrected.

- Touch Screen UI — We like Artillery’s touch screen UI, finding it pleasantly colorful, suitably intuitive, and responsive. Aside from some concerning issues with phantom taps early in our testing, the company has managed to be successful with this small feature that can make or break a system’s user experience.

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2021

- Assembly: Pre-assembled

- Mechanical Arrangement: Cartesian-XY-Head

- Manufacturer: Artillery

3D Printer Properties

- Build Volume: 300 x 300 x 400 mm

- Feeder System: Direct drive

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 240 °C

- Max. heated bed temperature: 130 °C

- Print bed material: Coated tempered glass

- Frame: Aluminum

- Bed leveling: Automatic

- Connectivity: USB, microSD

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: PLA, ABS, Flexible Materials, Wood, PVA, HIPS

Software

- Recommended slicer: Cura, Simplify3D, Slic3r

- Operating system: Windows, Mac OSX, Linux

- File types: STL, OBJ, AMF

Dimensions and weight

- Frame dimensions: 550 x 405 x 640 mm

- Weight: 12.9 kg

Similar Printers

You may also be interested in the following printers:

Artillery Genius Pro

The Artillery Genius Pro was released alongside the Sidewinder X2 and shares all of its features with a reduced build volume. We haven’t gotten our hands on one just yet, but if you’re concerned about the Sidewinder X2’s Z-wobble the Genius Pro is worth considering. Bear in mind that the original Artillery Genius wasn’t void of Z-wobble either.

Creality CR-10 Smart

The Sidewinder X2 takes the Creality CR-10 style, so the original is worth considering. Though the CR-10 V2 lacks the extra features of the Sidewinder X2, the more recent CR-10 Smart has all and more – including a fixed print bed and Wi-Fi out of the box. It also has the standard CR-10 gantry braces, which the Sidewinder X2 should really take note of itself.

Ender 3 Max

Coming close to the Sidewinder X2’s size — with just 60 mm shaved off the top — the Creality Ender 3 Max is a standby mid-sized printer. Though the Ender 3 Max lacks some of the bells and whistles present out-of-the-box on the Sidewinder X2 — like that handy auto bed-leveling probe — they’re easy to upgrade. Since Creality (and especially the Ender series) has one of the largest and most enthusiastic 3D printer communities, there’s plenty of guides, tips, and tricks online to help you get set up with any of the addons you might desire.

License: The text of "Artillery Sidewinder X2 Review: Improvements, But Better?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.