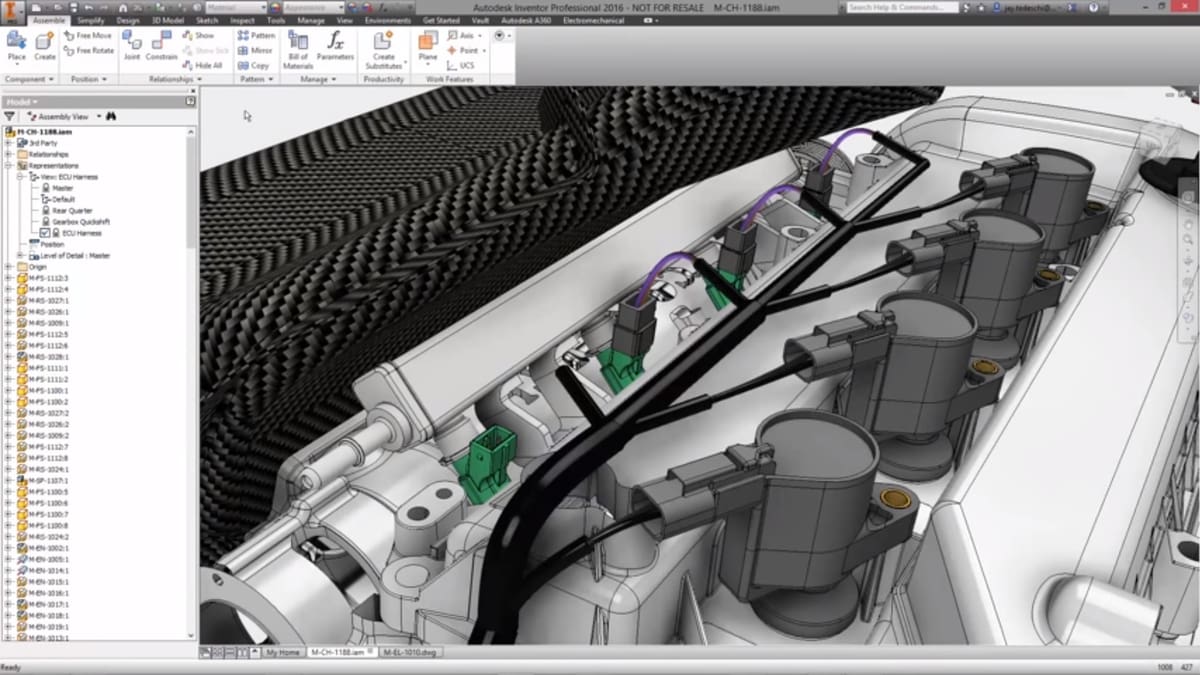

Main Features of Inventor

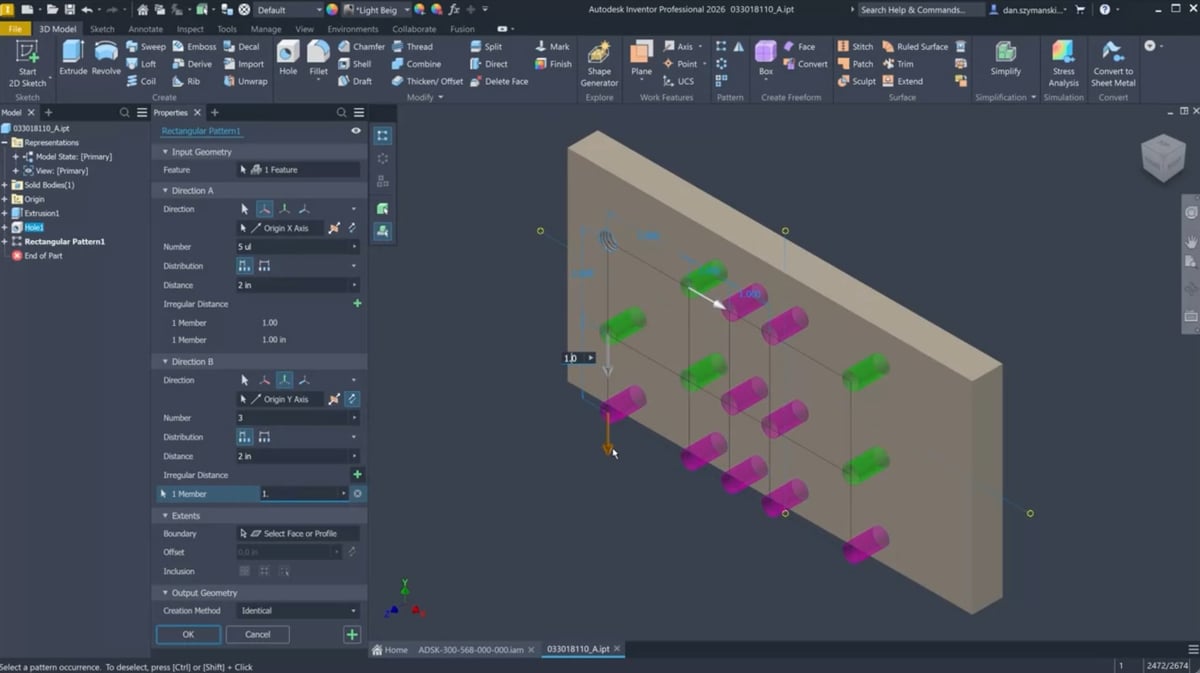

With Autodesk Inventor, you get a highly professional product development suite that offers a large array of tools for 3D mechanical design, simulation, 2D documentation, and manufacturing preparation. At its core, this CAD platform provides powerful parametric modeling tools, meaning that you define constraints and parameters for your design with values that can be modified later. When these values are changed, the software intelligently reshapes your entire model to adapt, preserving design intent and streamlining revisions.

Inventor’s capabilities go well beyond what most free or entry-level 3D modeling tools can offer. One standout feature is iLogic, a built-in programming language that enables users to automate design behavior by embedding logical rules into parts, assemblies, and drawings. With iLogic, complex assemblies can be automatically configured, reducing repetitive tasks and making designs more intelligent and customizable.

Another major strength is AnyCAD technology, which supports a highly collaborative workflow across different CAD platforms. Instead of requiring file conversions, AnyCAD establishes live associativity with non-Inventor parts, allowing changes made in the original files — even from software like Solidworks or CATIA — to update automatically inside Inventor projects. This greatly simplifies working in mixed CAD environments and keeps projects synchronized without losing fidelity.

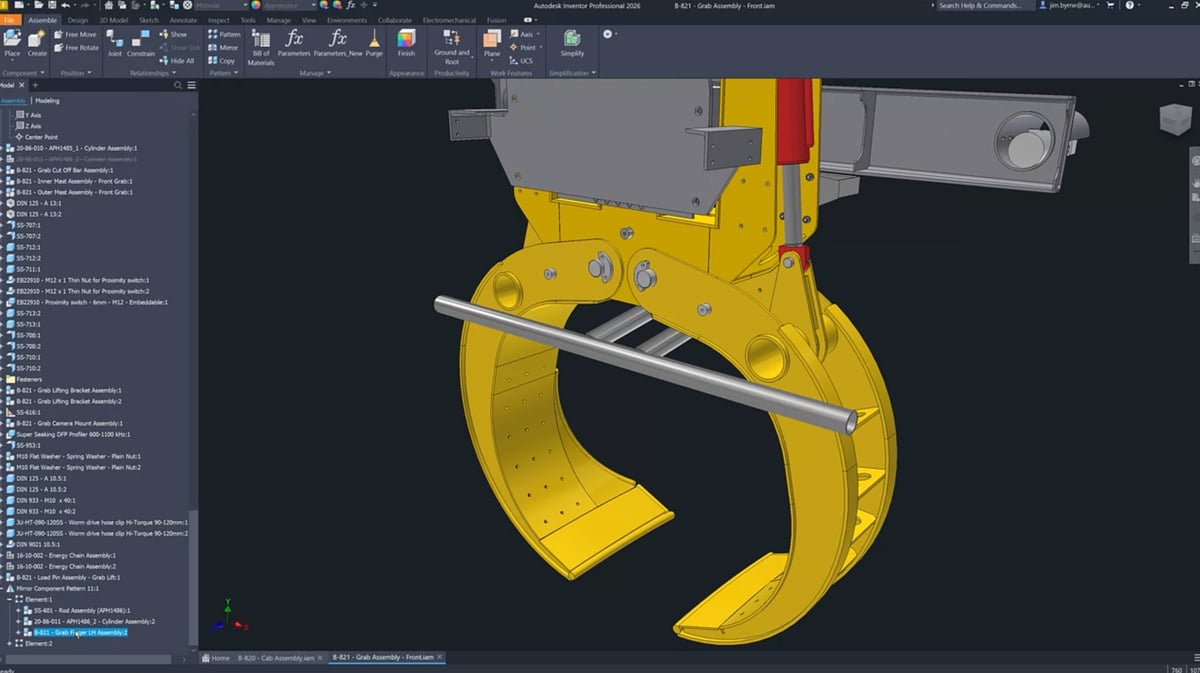

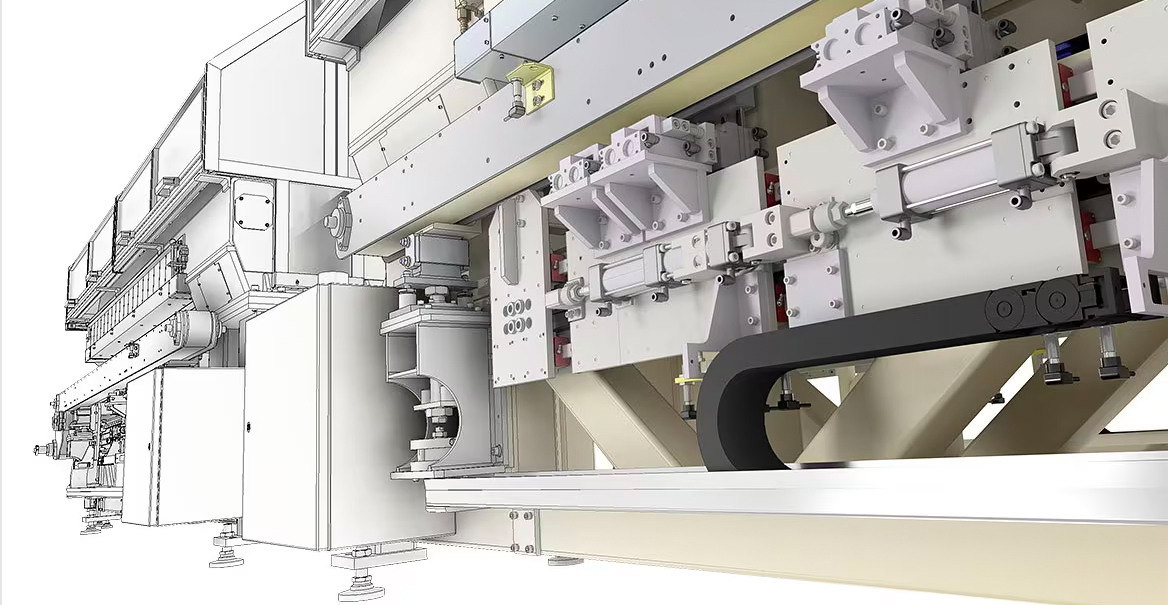

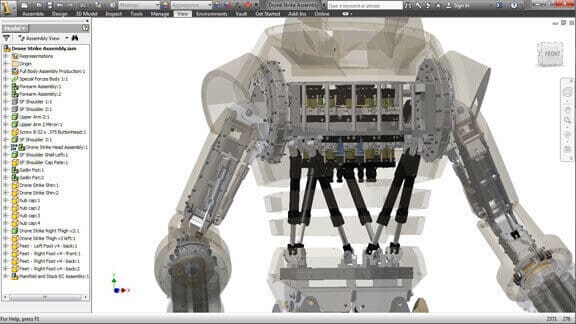

Inventor is especially geared toward engineering teams collaborating on large, complex projects, such as the development of entire vehicles, industrial machinery, and consumer products. For example, the integrated Shape Generator tool introduces a new way of designing parts: users can define the design space and the areas where forces will be applied, and Inventor automatically generates a lightweight, structurally optimized shape based on those parameters — bringing a form of generative design into traditional workflows.

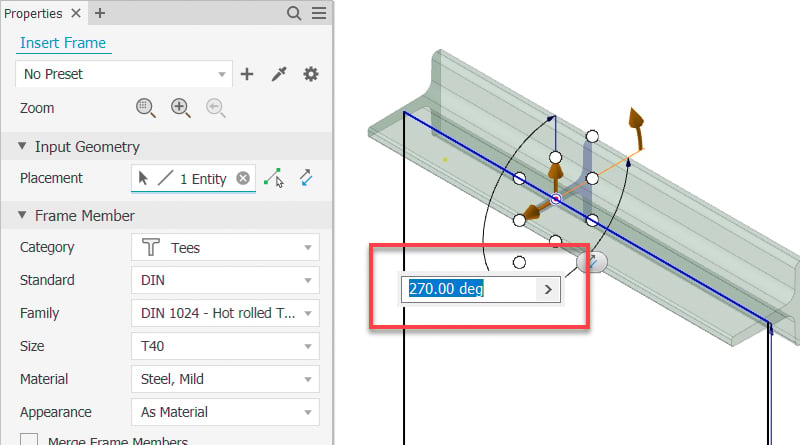

Beyond core modeling, Inventor includes specialized environments for sheet metal design, welded frames, and tube and pipe routing, which are essential in industries like manufacturing, aerospace, and construction. Its simulation tools allow for virtual testing of parts and assemblies under real-world conditions, including stress analysis, motion simulation, and frame analysis. This helps engineers verify performance early in the design process, minimizing costly physical prototyping.

Inventor also offers a 3D Print Environment that prepares models for additive manufacturing, with features for adjusting model orientation, breaking down parts to fit build volumes, and adding assembly features like guide pins. For more advanced additive manufacturing needs, Inventor integrates with Autodesk Netfabb for support structure generation, lattice design, and print simulations.

Finally, Inventor ties into cloud-based collaboration through Autodesk Fusion Team, allowing teams to review, share, and manage designs across distributed locations in real-time.

Like its competitors, Solidworks and CATIA, Inventor is a highly advanced piece of 3D modeling software. It demands both extensive training and a strong foundation in mechanical design principles to unlock its full potential, but in return, it delivers a comprehensive, scalable platform capable of tackling the most sophisticated design challenges.

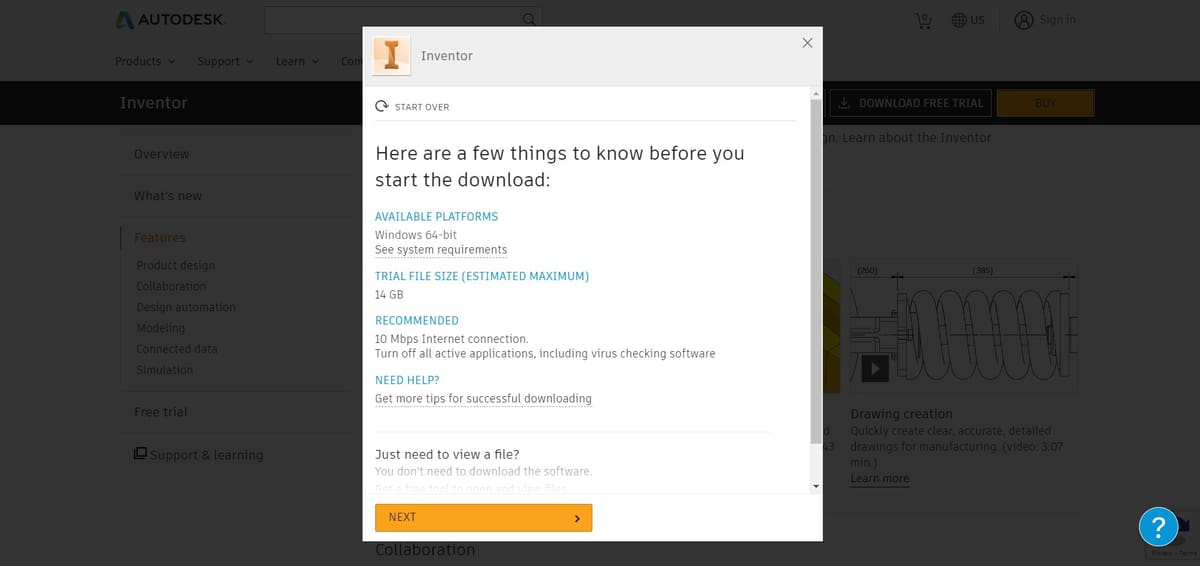

Autodesk Inventor System Requirements

- Operating System: Windows only. 64-bit Microsoft Windows 11 and Windows 10.

- CPU: Recommended is 3.0 GHz or greater, 4 or more cores. Minimum is 2.5 GHz or greater

- CPU for Complex and Large Assemblies: 3.30 GHz or greater, 4 or more cores

- Memory: Recommended is 32 GB RAM or more. Minimumis 16 GB RAM for less than 500-part assemblies

- Memory for Complex and Large Assemblies: 64 GB RAM or greater

- Disk Space: Installer plus full installation: 40 GB

- Graphics: Recommended is 8 GB GPU with 106 GB/S Bandwidth and DirectX 11 compliant. Minimum is 2 GB GPU with 29 GB/S Bandwidth and DirectX 11 compliant