Developing new ideas was, according to economist John Maynard Keynes, not the issue. Escaping old ideas was the tricky part.

Perhaps there are a few too many old ideas baked into the fabric of desktop 3D printing. New ideas are out there, sure, but the old still retains a somewhat prohibiting grip on consumer 3D printing, and that’s now clearer than ever following our time with the new Bambu Lab X1 Carbon and its Automatic Material System (AMS).

Sometimes, a fresh perspective is required for progress to be made. The founders of Bambu Lab are made up of five highly-ranked ex-employees of DJI, a producer of high-performance drones, cameras, and gimbals. The fresh ideas, or perhaps the desire to escape the old, as well as the wider project goals of the firm’s X1 Carbon laid down by these five outsiders to 3D printing, are now shaking it up.

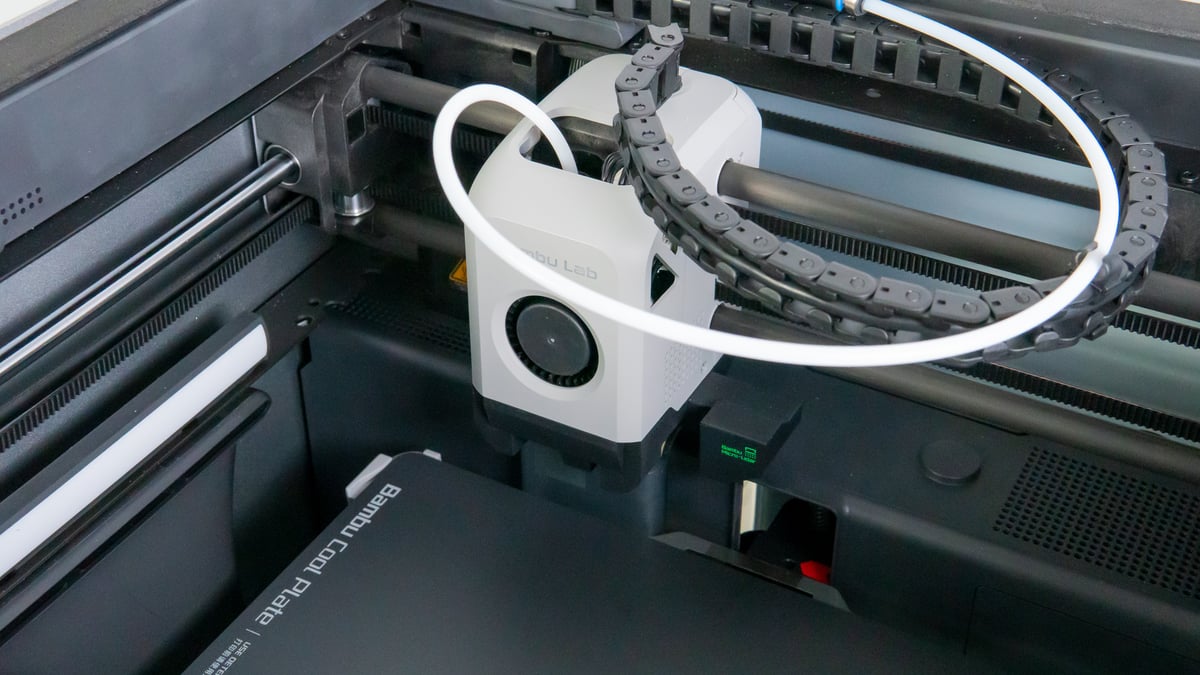

This gorgeously-designed, tech-laden CoreXY FDM 3D printer instantly stands out from the crowd. Features such as lidar-assisted bed leveling, vibration compensation, a 300 °C-capable hot end, and a material management system are not things you ordinarily come across everyday. Then again, as we’re about to find out, this isn’t an ordinary 3D printer.

Verdict

PROS

- Fabulous design and build quality

- High print speeds

- Simple, slick user-friendly experience

- AMS is an excellent optional extra

- Clear communication and connectivity options

CONS

- Material waste is high

- Default settings solid, but user experimentation needed to get the best print results

- Cardboard spools not officially compatible with AMS

Bambu Lab has burst onto the 3D printing scene, delivering a well-connected, beautifully-designed machine that makes printing easy and immensely enjoyable. Think of it as the 3D printing equivalent of Is This It? by The Strokes, in that it isn’t perfect, but as a debut, it’s an absolutely stunning piece of work, perfectly packaged, that leaves you wondering just how good the group could be in a few years with more experience under the belt.

CoreXY kinematics and 300 °C capable hot end allow for a diverse range of filaments to be printed at speeds that exceed the average 3D printer, with a Benchy by default taking just 17 minutes to complete to a solid standard. The next-gen tech integrated into the machine, such as lidar-guided bed leveling and first layer inspection, active vibration compensation, and error identification and communication, move the game on. We’re now able to know exactly what’s going on with the machine, and get notified directly on our phones if something has gone awry. Tinkering? Not necessary. Lengthy investigations into odd issues? A thing of the past.

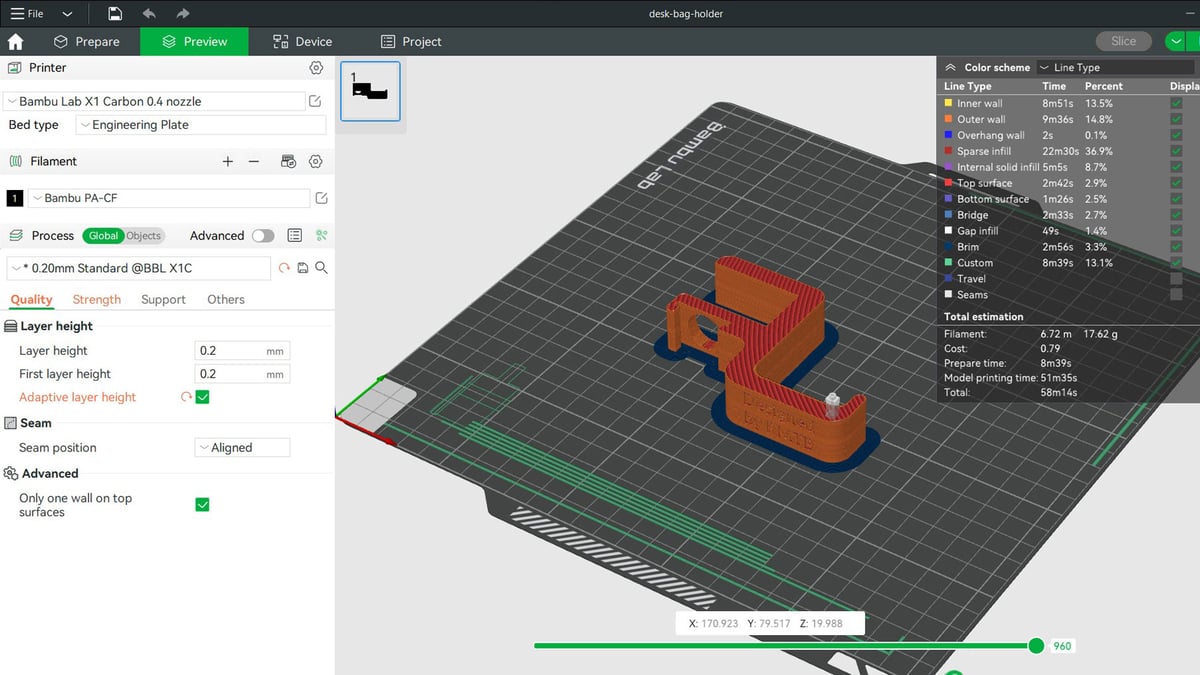

Print quality by default is very impressive, though users will need to dive into the settings of Bambu Studio, the firm’s Prusa Slicer-based slicing software, to really dial it in on a material-by-material basis. Though the Bambu Lab X1 Carbon and the AMS isn’t a perfect 3D printer at $1,449 (or $1,129 without the AMS), it’s difficult to ask for more. Drawbacks such as the unofficial compatibility of cardboard spools with the AMS, a high amount of filament waste on default multi-material, multicolor prints, and a claimed aversion to TPU are clear drawbacks.

Still, this is a technically superb, beautifully built and finished modern 3D printer with fresh ideas that has put the rest of the 3D printing industry on notice. Everyone else who designs and builds 3D printers will suddenly need to up their game because this machine is currently about as good as 3D printing can be for the average consumer. Suddenly, everyone else looks like they’re a few years behind.

The Tech

The Bambu Lab X1 Carbon is positively stuffed with tech. You can almost see it seeping out the sides of its boxy body. But before we get up to our armpits in that, a little background.

Bambu Lab is a new company, not just to 3D printing, but new full stop. The X1 Carbon here is its first product, launched in 2022 on Kickstarter alongside the X1, a lower-spec version of the Carbon we’re testing here. It costs $1,129, so it isn’t cheap, and its Automatic Material System is a $349 extra. As a “Combo” bundle, you can pick both of them up as well as a few 250 g samples of filament for $1,449.

Bambu’s background is an interesting one, beginning as a team of just five people who felt the urge to break out and do their own thing. These five happened to be the people in charge of developing some mighty impressive camera drones over at DJI. The company’s blog post announcing its arrival appears pretty honest and open, as is the statement on the firm’s website that states quite plainly “We hated 3D printing as much as we loved it.” Does anybody familiar with 3D printing not relate to that? 3D printing, as brilliant as it is, can, and often is, intensely annoying.

Development to Unpacking

According to Bambu Lab, the X1 took 22 months to develop, going through seven different generations of prototyping before eventually getting to the unit we have sitting right here in our print lab today. Needless to say, nobody should be expecting to be a beta tester for this particular product. Expect it to handle as polished as it looks.

And boy, does it look. The X1 Carbon is a sleek and incredibly well-groomed-looking aluminum-trimmed box with a level of polish to it that just screams class. Looks are very much subjective, of course, but this could be one of the most handsome and refined-looking consumer 3D printers we’ve ever seen.

Upon unboxing the already-assembled X1 in the office, the All3DP team pretty much came to a standstill. Keep in mind that this is a team that deals with 3D printers every day, a team with the latest and greatest of 3D printing often at its fingertips. We are, admittedly, sometimes a bit numb to the coolness factor of 3D printing at times, but the Bambu Lab X1 Carbon stopped the team in its tracks and turned seasoned 3D printing editors into little children. “Is it ready yet, Jonny?” “No, it isn’t, and if you don’t stop asking me I’m pulling this office over and we’re all going home.” Five minutes later, what do you think the next question was?

Engineering a Thoroughbred

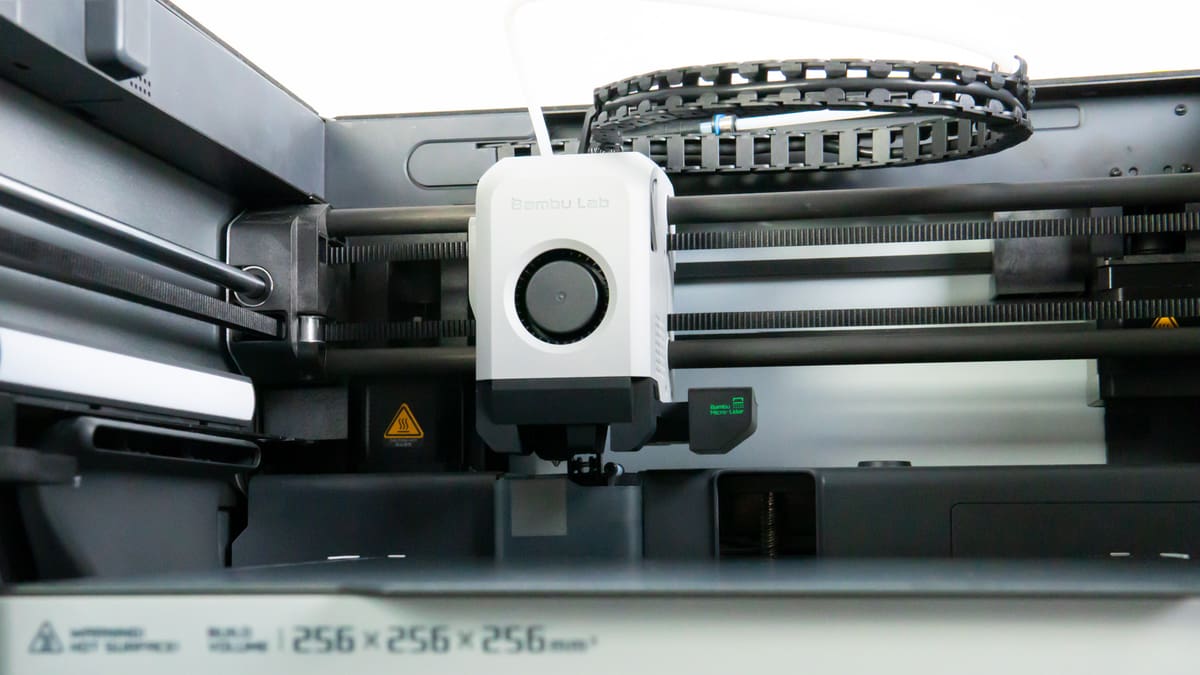

Alright then, onto the basic stuff. It has a 256 x 256 x 256 fully-enclosed build volume, which is what you want for printing more exotic materials, and at 389 x 389 x 457 mm (without the AMS mounted to its head), it’s a relatively compact machine too. It should fit fairly nicely into a lot of spaces around the home and workshop.

The Bambu Lab X1 Carbon has its proprietary hot end design that, by Bambu Lab’s own admission, has both upsides and downsides. Bambu Lab’s initial idea in developing its own hot end was to ensure it remained light and compact, saving space for the lidar system and ensuring it could print at high speeds. The design has one significant downside: if the sort of nozzle clog not even a bottle of concentrated prune juice could cure should occur, a whole new hot end is required.

The hot end assembly isn’t horrendously expensive at $35, however, and you’d have to assume that sort of disaster isn’t something that’s going to be happening on a regular basis. By the way, a simple nozzle change will set you back about $15. This could all be a business model just as much as a packaging solution, however.

Speed is, of course, a big topic of conversation around 3D printers, print speeds are not everything, despite what marketers try to tell you, and fast printing often leads to hurried-looking results. Bambu Lab claims a maximum printing speed of 500 mm/s, which is lightning-fast. You won’t find many quicker, in fact. In order to achieve this sort of pace, the X1 Carbon makes use of a CoreXY motion system. To keep things brief here, a CoreXY system allows print speeds to be drastically increased. These machines are some of the fastest FDM guns in the West, and having seen it up close and personal firsthand, we can confirm the X1 Carbon here will have shot your hat off before your fingers have even had a glimpse of your trigger.

Automatic bed leveling is present on this machine, in a sophisticated flavor we haven’t had the chance to play with before. It functions by making use of two different sensors as well as an algorithm in order to deliver a perfect level seemingly every time. The two sensors in question are lidar, which plays a big role also in the detection of first layer issues and helps to calibrate filament flow, and an analog force sensor that probes the bed at every 60 x 60 mm point.

The lidar plays the key role here, scanning millions of points across the bed to an accuracy of 7 microns. Should you wish, it will also inspect the first layer of your print after it has been printed and notify you if it spots anything that it doesn’t think looks like a high-quality first layer. From there, you can abandon the print and begin again or continue.

Staying Connected

Notifications can be sent to you via a slick app known as Bambu Handy. Bambu Lab has delivered pretty impressive software and as its slicer (Bambu Studio) is based on PrusaSlicer and its offshoot, SuperSlicer, it should also feel pretty familiar to many. Even if it doesn’t, it is easy to navigate and explore options for what you might need for your printing. It’s a clean, concise, sensibly-arranged piece of slicing software. Bambu Lab also has a wiki to assist you with queries, should you need help.

Bambu Handy is your mobile accompaniment, the side dish to the beefy plate of slicer you’ve got there. You can’t slice from it, but you can control the printer’s main functions from more or less anywhere, monitor the status of prints, visually inspect the print chamber via the X1 Carbon’s in-built camera, and even trigger support requests. Everything is very straightforward once again, responsive, and well presented. It helps you stay in touch with your printer no matter where you are. One night, three cocktails deep at one of Munich’s local establishments, we wondered how our print was getting on. Not wanting to return to the office several train stops away, all we had to do was open our iPhone, check the camera, raise the Z-axis, and voila, we could get a full visual on our completed print, all while enjoying our Old Fashioned. We could get used to that.

Automatic Material System

Variety, you don’t really get much of it with 3D printing. For an additional $349 though, Bambu Lab’s automatic material system (AMS) can take four spools, and you can even link four AMS’ together via a hub for the option of 16 different materials for your prints.

It’s a clever little thing, the AMS. It can communicate with the printhead and detect tension on the spool and alter the feeding pace of the filament. Bambu Lab also claims that it is airtight and there are slots inside to store desiccant sachets to absorb excess moisture too.

Bambu Lab recommends that you only use its own filament with the system, saying that its filaments are thoroughly tested to work in tandem with the material manager, though you can, of course, use other spools of filaments. Not all of them, though.

TPU, for a start, is a no-go as far as Bambu Lab is concerned. Softer materials such as TPU and damp PVA can get stuck in the device, according to the company. So, that leaves you fresh out of luck there. You’ll have to use TPU on the lone spool holder at the back only, as you will any spool that doesn’t fit with the 50-68 mm width and <200 mm diameter requirements. Abrasives also aren’t recommended as they can rapidly wear out the AMS’ feeder funnel.

You’re also not supposed to use any filaments that come on a cardboard spool, as the rollers within the AMS that spin the spool are not really compatible with the “minimal friction” the cardboard spools provide. As the majority of the world is currently pushing for more eco-friendly solutions, this is a bit of a shame. A lot of top filaments come attached to cardboard spools nowadays.

Bambu’s own filament utilizes RFID technology, which the AMS reads and automatically knows which filament you have loaded into it. It’s a nice touch, and certainly adds to this machine’s overall slick usability, though it’s far from a hassle to just tell the slicer which filament you’ve just loaded into it.

All said and done, the AMS is a hugely useful luxury item to have with this machine that allows for mid-print switching between different colors and materials, though it comes with some restrictions that prevent it from looking like a perfect solution to multicolor, multi-material 3D printing.

While we’re on the topic of filaments, we ought to mention another fancy little feature of the X1 Carbon. You can print a spool holder from Bambu Lab’s site, and attach filament to it and dry it. How? Just tell the printer which filament you want to dry, and the printer will run a routine according to that filament profile, heating the print bed and thereby drying out the filament. A useful trick with some of the more vulnerable engineering filaments out there.

Printing and Usability

Usability begins from the box. If you’ve ordered an X1 Carbon with one, the AMS comes very neatly packed, safely attached inside the X1’s print chamber via a plastic brace. Four spools of filament are also provided with an AMS, each offering 250 g of plastic to begin experimenting with. Ours featured nylon with carbon fiber, two lots of PLA, and Support W (Bambu Lab’s name for its white support structure filament suitable for use with PLA).

Getting the X1 Carbon from the box to printing shouldn’t take long. The screen and the spool holder to the rear of the machine need attaching, and the AMS needs plugging in too. Instructions vary between what you’re provided in the box and what’s hosted by Bambu online. The company says to follow what’s in the box, as instructions have been simplified since launch. It shouldn’t take you long before you’re running through the initial calibrations.

Solid Shake

This is where things can get a little bit noisy. The X1 features something called active vibration compensation. During initial calibration procedures, it will shake the printer to calibrate the vibrations and compensate for them to deliver a smoother, faster printing process. This is something Bambu Lab’s chief engineer has brought over from his time developing drones, and it should ensure prints with fewer artifacts and a cleaner finish, even when printing at the high speeds the X1 is capable of.

In practice, it seems to be working. The prints we’ve had coming off the X1’s print bed are about as clean as you can get from an FDM 3D printer running at high speeds. Better still, the vibration compensation gets quieter over time, as the printer beds in the frequencies and doesn’t need to run such severe calibration shakes. So, if things are a little rowdy at first, try not to be alarmed. Things should settle down after a few prints.

Setting up a print couldn’t be simpler. The X1 has Wi-Fi connectivity, and once you’re locked and loaded with filament and connected, you can slice and print directly from Bambu Studio. It’s effortless. Of course, you still have the option of sliding in an SD card should you wish to, but unless you’re off the grid or put your print room in some sort of signal-impervious cave, why would you?

The default print plate provided is a dual-sided affair, with one side dubbed “Cool” and one side “Engineering”. Different materials are intended for each side of the plate, with the Cool side handling PLA, PETG, the basic consumer filaments, and the Engineering side handling carbon fiber, polycarbonate, and those sorts of more advanced materials. Regardless of what you’re printing and why, you’ll need to make use of a glue stick. Bambu Lab is very keen to make sure you do, stating that printing on either side without the stickiest assistant in the lab could lead to very, very stuck completed prints. Your print plate can therefore become a bit mucky, but it’s nothing a trip to the sink and some soap shouldn’t solve, though you’ll want the X1 to have its own special brush.

In practice, the system works. The print plate is flexible and magnetic, meaning it’s easy to remove prints with a bit of flexing, and thanks to the clever lidar-assisted leveling and first-layer inspections, we’ve encountered zero issues with first layers and bed adhesion. Not one.

In fact, problems in general have been very few and far between. We’ve had just a couple of notifications to our phones informing us of issues, one of which being that the filament chute became blocked at one point. This happened during a print involving a large PLA part and Support W filaments. The Bambu Lab X1 Carbon produces an enormous amount of filament waste in multi-material or multicolor printing, dispatching purged filaments through a little pipe and ejecting the lumps of filament out. There’s something very, well, biological about it.

Having It All

As much as we human beings desire it in almost every aspect of our short, silly lives, it isn’t actually possible to have everything.

Bambu Lab has provided users with a lightning-fast 3D printer capable of producing impressive prints, but results are also not perfect. Print speeds, as ever, can be a hindrance to print quality, and it can take some adjustments and plenty of tweaking in order to obtain the level of quality that a user may find satisfying. That, of course, varies person-to-person, but we’ve had Benchys printed in just 17 minutes that are of very high quality, but they’re 8/10s, not 10/10s.

PETG, meanwhile, prints far better on the X1 than it does on many budget 3D printers, which is what you’d expect. Stringing is kept to a minimum and bed adhesion has been no trouble at all, with this and every other filament we’ve tested here. The way the X1 handles filaments, switches between them, and lays them onto the print surface is nearly flawless. The issue of overall print quality only really comes into play when sticking to standard print settings and reaching for the higher speeds. What we’re saying is that no matter how good the hardware is and no matter what materials are being used, a balance is often needed to be struck for things to be harmonious. To bring this back in a loop, that’s very much an aspect of our short, silly lives, isn’t it?

Material switching will be handled by the X1 Carbon’s AMS, of course. This accessory is orderable with the machine and included in the full $1,449 price tag, but can also be ordered separately for $349. This unit holds four spools and seamlessly switches between filaments during printing, if you need to make use of multiples for whatever reason, be that material or color. With just one toolhead, naturally, this can lead to a drastic rise in print times, as the need to purge filaments through the hot end between each switch takes time, but it also produces waste, a lot of waste. Users have experimented with the slicer settings in order to try and reduce that, but the fact of the matter is that Bambu’s default setup for filament purging is enormously wasteful. It’s a shame.

Multicolor printing functions just fine, and the community has put together some truly cool multicolor prints, but it can take time to find the settings that work for you, balancing quality with reducing the huge filament wastage. Practice makes perfect, and knowing your filament also helps a great deal, of course.

So, what we’re left with here is a machine that doesn’t give you perfect, fast prints in a variety of materials every time but does give you one of the best platforms with which to do just that from the get-go. As a starting point, you can’t honestly ask or expect for much more in and around this price region. PA-CF and other more advanced materials are always going to be challenging to print, but at least issues like bed adhesion are unlikely to crop up, thanks to the refined system the X1 Carbon is, to begin with.

Understanding and dealing with 3D printing is made all the easier by a gorgeous UI, a clear, well-presented touchscreen that’s responsive and easy to navigate. You actually won’t need to use it all that much, given the advanced controls offered via the slicer and application, and the communication the X1 is capable of helps you to understand exactly what’s going on and what’s causing an issue. Once you’ve used an intelligent 3D printer, you’re unlikely to ever want to go back to staring at a cheap bed slinger that provides no feedback on what’s gone wrong.

Is It Worth It?

At $1,149, the X1 Carbon isn’t a cheap 3D printer, but it also isn’t expensive. In combo form with the AMS you’ll be $1,449 all in, and own one of the most advanced consumer FDM 3D printers to date, assembled and packed with some of the most useful, user-friendly technology around.

The Bambu Lab X1 Carbon is a significant step forward in 3D printing. It’s not only stylishly designed, but engineered to a high standard too, and about as easy and as enjoyable to use as a 3D printer can be. But perhaps the biggest thing that this printer does is how it makes the competition look.

Bambu Lab’s fresh thinking, new approach to FDM 3D printing has made almost every other FDM printer look like relics from the last decade. The X1 Carbon looks, feels, and prints like the future, albeit with users still needing to spend time dialing in material fineries. That particular aspect of 3D printing is likely to always be there, no matter what machine is in question.

Could established 3D printing juggernauts have produced something like this sooner? You certainly have to assume so. Like so many major 3D printing brands, Bambu Lab is based out of Shenzhen, yet the company has not fallen into the trap of producing watered-down riffs of an old design, or a half-baked experiment that would struggle to break out of R&D labs. Instead, it has brought genuine innovation and a fresh-thinking approach in order to create something that drives the industry forward.

The point is, that with a little more effort, a fresh approach, and a genuine desire to produce something impressive rather than something that will deliver good margins, great things can be achieved.

So, is it worth it? Keep in mind that this package tested here won’t offer you leave you much change for your $1,500. Still, we, for the time being, can’t think of a better machine to splash that cash on. This is a highly refined, technologically advanced 3D printer that provides one of the very best foundations to build a printing experience upon. The hardware and software combine brilliantly to provide users with a compelling, premium 3D printing experience that is actually pretty good value for money for what you get.

Features

Basics and Background

According to its manufacturer, the Bambu Lab X1 Carbon is the result of 22 months of development and seven generations of prototyping.

With a 256 x 256 x 256 mm build volume and overall dimensions of 389 x 389 x 457 mm (without its automatic material system), it’s a relatively compact machine. Its build volume is slightly bigger than the average Ender 3 clone, but the amount of space it needs to work is a little less, as it isn’t a bed-slinging 3D printer. Instead, it uses a CoreXY motion system and direct extruder that offers bags of speed and a hot end that can hit 300 °C. That means users should get plenty of opportunity to print with more exotic filaments, as well as the standard consumer batch of PLA, ABS, PETG, and TPU.

Bambu Lab offers an X1 and an X1 Carbon edition, a more upgraded machine. You can seemingly take your pick between them, but the good news is that Bambu Lab has designed the X1 to be upgradable into a Carbon edition, so the path is there should you wish to take it.

Artificial Intelligence

Yes, you read that right, the Bambu Lab X1 comes complete with AI. Using some of the tech listed below, the AI checks out the current print and informs the user when something has gone pear-shaped. It features “spaghetti detection” (only on the Carbon edition), which looks out for a totally wild and out-of-control print getting, well, wild and out of control, and it also inspects your first layer. If it’s too high or too low, the X1’s brain should notice and inform you via a notification.

In practice this works really well. We had one instance of the AI detecting a possible print disaster waiting to happen, and it let us know via our iPhone app, asking us to inspect it. We did, and it looked fine, so we told the print to continue, and low and behold, everything turned out great. The fact that it was looking out for us was a welcome treat – a bit like having a friend standing by your printer while you’re off carrying on with your life.

Lidar, Bed Leveling

The X1 uses a sophisticated dual-bed leveling system that makes use of two different sensors as well as an algorithm in order to nail the bed leveling. The first sensor is a lidar. According to Bambu Lab, it probes the nozzle height, assists with the first layer, and calibrates the flow of filament too. It will scan the bed before printing and has an accuracy of 7 microns.

Following this, the scan is crosschecked with information obtained from the probing of the bed carried out by the nozzle. Working together, the two sensors deliver an effortless, accurate bed leveling system and, in combination with the AI, detect any errors happening early on in the first layer. It’s super.

Automatic Material System

Bambu Lab’s automatic material system is an airtight box that sits on top of the X1 printer and has room for up to four different filaments or materials.

In tandem with the direct extruder, this allows for multi-material and multi-color prints. The box itself comes equipped with sensors to monitor the humidity and the amount of filament left, as well as a sensor to detect what that filament actually is – if it’s a Bambu Lab filament.

A setup like this should provide plenty of opportunity to experiment, and with one slot in the box occupied with a filament such as PVA for soluble supports, the ability to print more complex objects too.

Fully-Enclosed

A fully-enclosed 3D printer has certain benefits, particularly when it comes to the printing of finickier filaments. ABS is a filament that loves an enclosure, and the X1’s can hit an ambient temperature of 60 °C, providing a suitable environment for the material to print.

Once fully calibrated, the X1 Carbon is also a pretty quiet but far from silent 3D printer, certainly not bothersome at all in terms of audio bombardments, at least. During initial calibrations for the vibration compensation system though, expect loud noises and a fair bit of shake.

CoreXY Motion System

A CoreXY motion system has a number of benefits, despite being a more complex (and potentially more troublesome) system. A CoreXY motion system involves a build plate connected to the Z-axis gantry that moves up and down to reach the nozzle on the printhead. That printhead moves across the X- and Y-axes through a configuration of two long belts that run along the printer’s top gantries and frame.

The primary benefit of this system is that it can hit some very high printing speeds. Bambu Lab is claiming a maximum of 500 mm/s. We certainly saw some very fast print speeds during our time using the X1 Carbon, it was mesmeric to watch at work. However, experienced makers will know print speed isn’t everything, and how fast you can go and still maintain a decent level of print quality is dependent on a number of other factors. That being said, this machine is considerably faster than a Cartesian 3D printer, if you’ve gone from a bed slinger to this, it’s immediately noticable.

Bambu Lab says its high print speeds result from more than just the CoreXY system, with lightweight carbon rails, the heating and cooling system, and the chassis all playing their parts.

Bambu Handy & Studio

Bambu Lab is offering a mobile app to work alongside the X1 that helps you stay in touch with your printer and receive notifications when things have gone bad. It’s named “Handy,” and that’s perfectly descriptive too. Remote control of the printer, checking its temperatures, filament loading and unloading, camera operation, and more is all possible to control from your app. Even if you’re in a bar in Munich at 11pm on a Wednesday night.

Bambu Lab is also launching its own slicer alongside the X1, known as Bambu Studio. The software is shipped with the machines and is also available to download from the Bambu Lab website. It’s based on Prusa Slicer, so you know what you’re in for. It’s slick, easy to use, and pretty fast.

Promising project-based workflows and “systematically optimized slicing algorithms,” Bambu Studio initially had a few hurdles to overcome, as some users have reported issues with the software. During our time, however, we had so such problems. The machine also supports Cura though, which is presumably something to fall back on should you find any issues with Studio.

The software natively supports the 3MF file format as default, with Bambu Lab saying that printing in other file formats may cause some of the more advanced features to be unavailable.

Further Features

Additional features include:

- Touchscreen UI: A 5-inch color touchscreen is provided for users to poke. It’s gorgeous, responsive, and easily navigated.

- Pre-calibrated, pre-assembled: The X1 and X1 Carbon come calibrated and pre-assembled from the factory, meaning users can get up and printing very quickly.

- Optional air filter: A standard piece of kit on the X1 Carbon and an optional extra for the standard X1 is an activated carbon air filter for the print chamber.

- Optional camera: Again, an option only on the X1, but standard on the X1 Carbon. This accessory is quite important if you want to make the most of the AI and monitor your prints remotely.

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2022

- Assembly: Assembled

- Mechanical arrangement: CoreXY

- Manufacturer: Bambu Lab

3D Printer Properties

- Build volume: 256 x 256 x 256 mm

- Feeder system: Direct

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 300 ℃

- Max. heated bed temperature: 110 ℃

- Print bed material: Steel

- Frame: Plastic, Aluminum

- Bed leveling: Automatic

- Display: 5-inch color touchscreen

- Connectivity: Wi-Fi, microSD

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No (X1, though optional), Yes (X1 Carbon)

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, Flexibles), engineering-grade materials (PC, PA, ASA, carbon fiber reinforced polymers)

Software

- Recommended slicer: Bambu Studio, Cura

- Operating system: Windows, Mac OSX

- File types: 3MF, STL

Dimensions and Weight

- Frame dimensions: 389 x 389 x 457 mm (without automatic material system)

- Weight: 13.2 kg (X1) 14.15 kg (X1 Carbon)

Featured Prints

3D printer reviews: we couldn’t do them without you, generous model designers and sharers. We look through the top sites for cool models that catch our eye to conduct these reviews. To those who design and share them with the 3D printing community, we salute you. If you like what you see, here’s a list of who designed them and where you can find them to 3D print yourself.

- Pen and Pencil Holder by Beeverycreative, via Cults

- Chainmail – 3D Printable Fabric by Agustin “Flowalistik” Arroyo, via Printables

- Just In Case – Pun Box by Andrew Geltz, via Printables

- Headset Hanger 2.0 by RMTB, via Printables

- Porsche 718 Cayman GoPro Mount by Rasmussen, via Printables

- Minimal Surface Fruit Bowl by DaveMakesStuff, via Thingiverse

- Dual Color Dutch Cow by rossero, via Thingiverse

- Spiral Chess Set (Queen Model) by BigBadBison, via Thingiverse

Similar Printers

Finding 3D printers similar in some way to the Bambu Lab X1 is a wee bit tricky, but if you’re not interested in similar and just want the best, head on over to our Best 3D Printers Guide. Otherwise, carry on scrolling.

Ultimaker 2+ Connect

Ultimaker has a very good reputation among businesses for its prosumer 3D printers. Its 2+ Connect model has an enclosed printing area, a 223 x 220 x 205 mm, and Wi-Fi connectivity. The problem is, it’ll set you back close to $2,500 to purchase, and that’s before you’ve thrown in any extras. Gulp.

To be fair, this machine is intended for businesses and educational facilities though, not the everyday consumer.

Flashforge Adventurer 4

Priced around $800, the Adventurer 4 is one of the latest generations of fully-enclosed, connected FDM machines that Flashforge has a penchant for. It can’t reach the same temperatures as the Bambu Lab X1, has a smaller build volume, and weighs twice as much. It also only works with its own proprietary slicer.

Original Prusa MK3S+

The Original Prusa MK3S+ is a proven winner of a 3D printer that comes with the terrific customer backing of the company. The print quality is great, it’s easy to use, and it is a well-thought-out machine overall. It doesn’t come with an enclosure (though you can get one) or a CoreXY motion system, and its build volume is far smaller than the X1 and X1 Carbon.

License: The text of "Bambu Lab X1 Carbon (AMS) Review: Fresh Thinking, No Tinkerin’" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.