When buying your first 3D printer for your office, lab, studio, or workshop, the first things you need to think about are the ease of use and customer support.

Your printer needs to contribute to your company’s overall productivity and speed to market. It needs to save you money and effort. You can’t afford to waste time with a slew of manual controls that require veteran expertise, prints that fail because of unreliable mechanics, or no one to call for help.

We’ve selected some of the easiest-to-use and dependable machines on the market that also have some of the best software and support backing them up. They have a complete ecosystem of hardware, software, materials, and expertise to help you get the most out of your 3D printer purchase.

As the low-price end of the market for 3D printers becomes more saturated with hobby machines of varying levels of quality, the mid-market machines are improving their technology and growing their feature sets to appeal to business users. Manufacturers in the $1,200 to $12,000 range focus on attracting a wide swath of professional customers with improved ecosystems of interoperable software, hardware, and materials, along with near-one-button-printing ability.

Whether you’re an architectural firm wanting to print better and faster models or a metal part fabricator looking to print useful tools, adding 3D printing to your workplace is a smart decision.

But before buying your first business 3D printer, check out our guide, “Business 3D Printers: How to Make a Purchasing Decision”, which covers establishing a business case for your 3D printer purchase, requesting a sample print, understanding hidden costs, and where to buy.

Now, let’s take a deeper look at our top picks (not in any particular order) for your company’s first 3D printer.

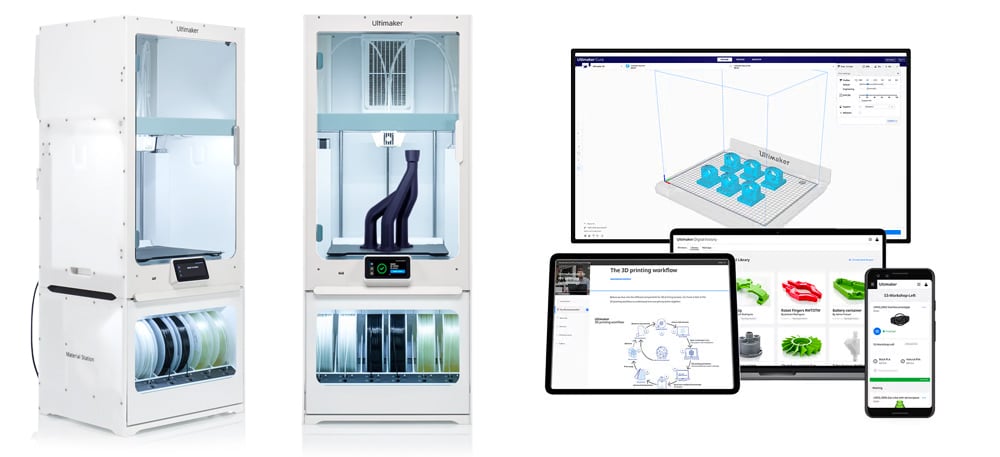

UltiMaker S7 or Factor 4

UltiMaker is one of your best bets for a business 3D printer because offers a comprehensive 3D printing solution, not just a machine. The company has 3D printing bundles that include the hardware, software, materials, and access to the company’s 3D Printing Academy and support, all at a convenient package price.

UltiMakers are truly simple-to-use dual extrusion machines ideal for prototyping, tooling, and replacement parts with an open filament system that lets you print with practically any filament, plus a new metal filament option for solid metal parts.

The company’s partnerships with material manufacturers ensure that UltiMaker machines have the idea settings preloaded to deliver optimal prints from a wide range of specialty filaments, including industrial-grade engineering plastics. They even recognize which material you have installed and automatically print with the corresponding settings.

Many companies new to 3D printing don’t realize how critical good software is to achieving good printed parts. UltiMaker invented the popular 3D printing software Cura that has countless settings to adjust to perfect surfaces, finer detail, and faster 3D prints. Alternatively, you can take the recommended setting and change nothing at all.

UltiMaker has also taken the guesswork out of how to keep your materials in optimal condition since exposure to moisture, heat, and cold can lead to failed prints. The S7 Pro and the Factor 4 feature filament humidity control and automatic material handling – if filament runs out or you start a new print that needs a different material, the material station automatically switches to the next spool.

UltiMakers are easy to network and scale for print-farm production. The relatively new UltiMaker Essentials software-as-a-service enables companies to roll out 3D printing enterprise-wide with a central hub, heightened security, and biannual software updates. Their e-learning platform features issue- and topic-targeted videos covering the basics through to complex issues and even awards certificates for completion.

UltiMakers are ubiquitous across a range of industries, from automotive and art to healthcare and engineering, for good reason.

The S7 Pro bundled with the filament changer is a solid machine, yet UltiMaker launched the Factor 4 in 2024 for professionals looking for a, let’s say, more robust, shop floor-type 3D printer. The Factor 4 has the same build volume as the S7 but is designed for “light-industrial” tool production, short-run spare parts, and end-use components, the company says. Factor 4 gets a bit hotter and is more insulated than the S7 to produce parts from materials, such as PPS-Carbon Fiber and PEKK, and Ultrafuse metal filaments. On the software side the Factor 4 can deliver post-printing reports on any way that the part deviates from the model.

At $20,000 is could be a steep investment for your first 3D printer but, UltiMaker says, the modular design “future proofs” it to accommodate new technologies as they develop so you could have your Factor 4 for many years.

- Technology: FDM (fused deposition modeling), uses filament

- Price: $12,000(S7 Pro bundle), $20,000 (Factor 4)

- Ideal for: product designers (functional prototypes), manufacturing (fixtures, cases, molds), teachers (models, prototypes), automotive (prototypes, carbon fiber gigs and fixtures)

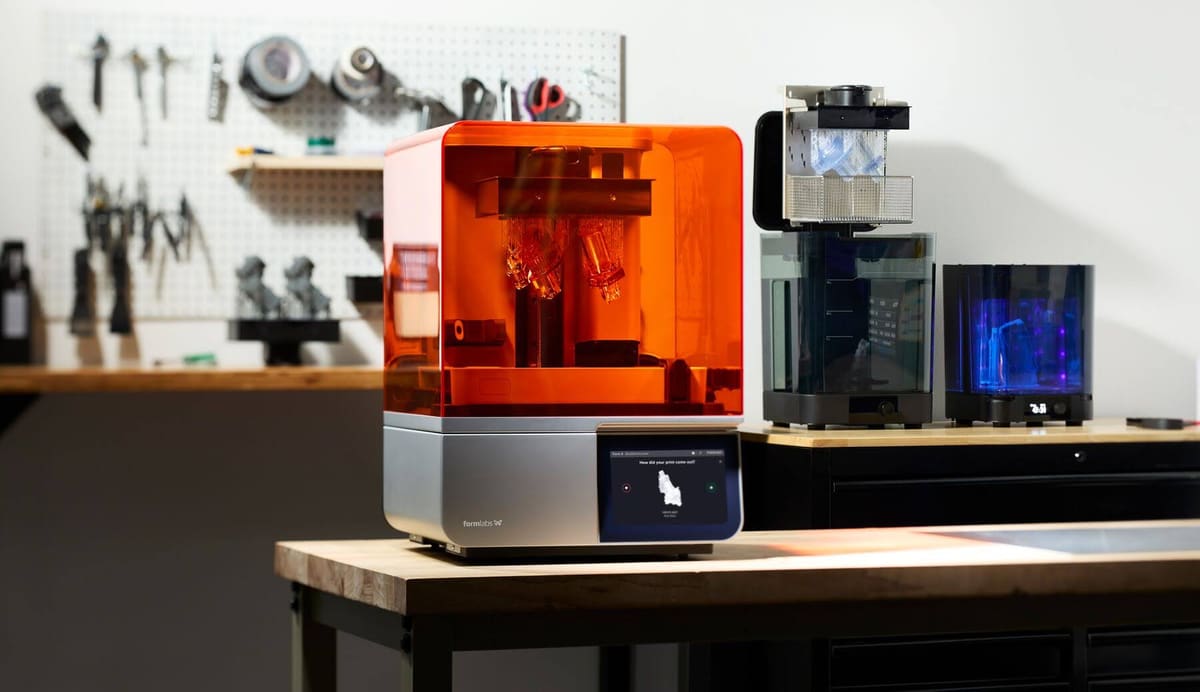

Formlabs Form 4

Resin 3D printers are not what most businesses start with unless they’re in an industry, such as dental, jewelry, entertainment, or art, that requires smoother surfaces and finer, injection molding-type detail than most FDM’s can produce. But there’s no reason not to jump into 3D printing with a resin machine like the Formlabs Form 4.

Formlabs has sold more than 130,000 3D printers since it launched the Form 1 in 2012, making it one of the best selling professional 3D printer makers. Widely adopted by product design firms for prototypes, Formlabs’ machines have successfully expanded to the medical and dental market as well as low-volume production of end-use parts for automotive, light-manufacturing, and consumer products.

Formlabs printers are as near to one-click printing as you’ll get in a professional desktop resin machine. Its ecosystem of business software, materials, printers, post-processing accessories, and printing resources is a full bundle that goes a long way toward ensuring easy and predictable printing. Plus, Formlabs offers material cartridges (instead of the mess of pouring resin material into the machine from a bottle), which makes office 3D printing and cleanup easier and safer for employees. The Form 4 is also an open material machine so you can print with a wide range of materials.

Form 4 features validated print settings for more than 20 resin types including engineering, biocompatible, and flame-retardant. The machine’s hardware is more robust than the company’s previous machines. The company says its LCD screen will last for “a million layers” of printing (or between 2,800 and 5,000 prints) and there’s also a longer-lasting resin tank.

A plus for businesses, Formlabs software offers a dashboard so employees can queue print jobs and monitor printer activity from anywhere. The printers, whether you have two or 20, network together to easily scale print production. Unique on this list is the Formlab Form Auto, which is a piece of hardware that attaches to the printer and automatically removes prints, pours them into a holding bin, and readies the printer for the next print job. The Form Auto, however, it not compatible with the Form 4, but instead the Form 3 series.

Unlike FDM, resin 3D printing requires two additional pieces of equipment that boost your investment: a washing ($700) and a curing ($750) machine. Parts are not useable right from the 3D printer.

Support is another Formlabs strength. On their website, you’ll find a library of in-depth guides, step-by-step tutorials, and webinars. You can also upgrade the basic warranty to a Pro Service Plan or an Enterprise Service Plan that includes priority email support, expedited troubleshooting, live training sessions, and remote printer health monitoring.

The Form 4 comes in special editions for the dental and medical industries.

- Technology: Resin, Masked Stereolithography (also called LCD)

- Price: $4,500 (Bundle with printer, wash, cure, accessories, service plan, $6,500)

- Ideal for: architects (models), manufacturing (tools, molds), jewelry designers (wax casts), product designers (detailed prototypes), dentists (dental models)

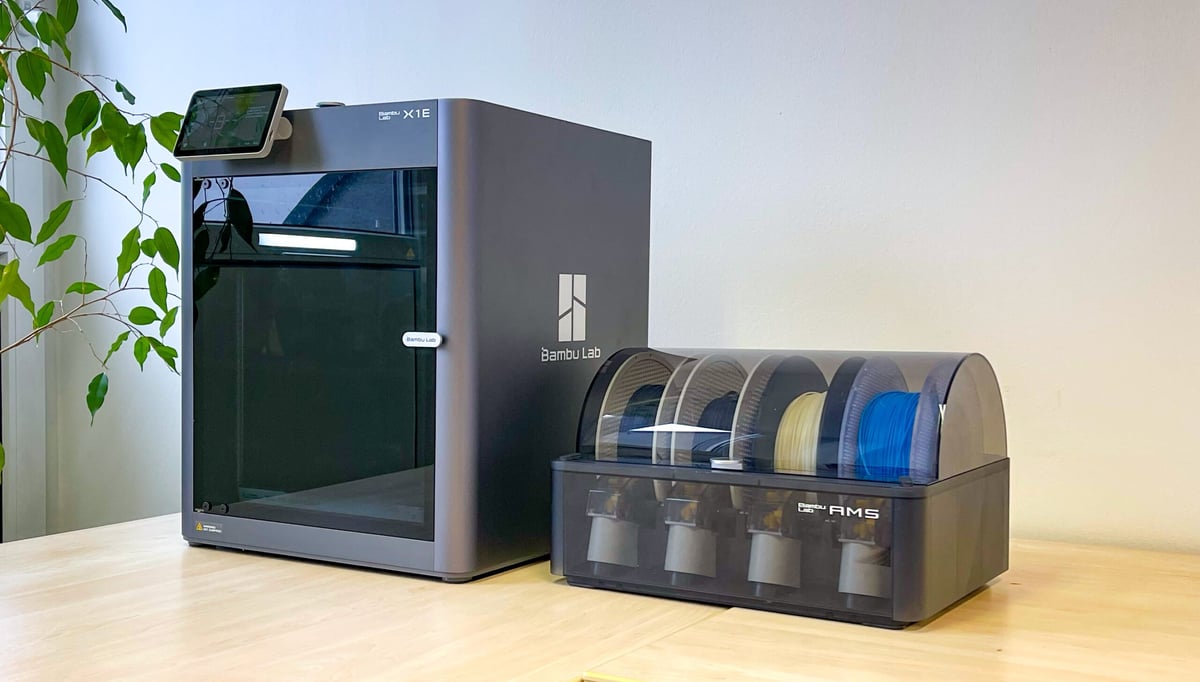

Bambu Lab X1C or X1E Combo

The Bambu Lab 3D printers have quickly become a favorite at businesses around the world and in the All3DP offices, so they may also be right for yours. Granted, we have more experience with various 3D printers than, well, anyone, but we think you’ll also find it easy to jump right in to using a Bambu Lab.

Bambu Lab burst onto the 3D printing scene in 2022, delivering a well-connected, beautifully designed machine that makes printing easy and enjoyable. Although the other companies on our list have been churning out 3D printers for decades, Bambu Lab is new-ish, and their printer isn’t perfect, but it has far more pros than cons. Plus, it’s the only “multicolor” (max. four colors) printer on our list and the second-most affordable at only about $1,400.

Although it’s completely open material, we’ve found that Bambu Lab’s own filaments work best with its Automatic Material System, meaning you’ll mostly have to buy from them, but their prices are around average to affordable and the menu of materials is long.

There are a trove of features that make is easy to use, including the lidar-assisted bed leveling and print failure detection, and a well-presented touchscreen that’s responsive and easy to navigate. There’s also all the specs you need in terms of temperature and settings for printing both basic PLA and some more industrial materials, such as carbon-fiber reinforced materials.

We’re recommending the machine combined with the four-material station that enables you to print four-color parts, although there may not be a lot of business applications for a four-color part, it’s a nice option to have.

The X1E came out in 2023 and is aimed at professionals offices with features, such as a heavy-duty air filtration system, a higher level of network security, and the new hotter 320ºC nozzle temp and active chamber heating so it can handle more engineering-grade materials without warping. We took it for a spin and were pretty impressed with its performance on single-filament parts.

Bambu Lab printer lack some of the connectivity of Ultimaker, Prusa, or Formlabs and are not inherently designed to scale. The software options to manage multiple machines, set up prints queues, track jobs and materials are underdeveloped at the moment, yet something the company says it is working on.

You also won’t find the robust support like other printers on this list, but Bambu Lab would argue that their machines are designed so you don’t need it.

- Technology:FDM (fused deposition modeling), uses filament

- Price: $1,450 (X1C Combo), $2,850 (X1E Combo)

- Ideal for: product designers (multi-color prototypes), manufacturing (fixtures, cases, molds), teachers (models, prototypes), automotive (prototypes, carbon fiber gigs and fixtures)

Learn more

Markforged Mark Two

The great appeal of the Markforged Mark Two, the company’s flagship 3D printer, is its ability to deliver metal-strong parts without metal. Especially prized by engineers in automotive and machine design, its carbon- or Kevlar-fiber-infused prints can stand in for traditionally machined aluminum tools, fixtures, and functional prototypes at a fraction of cost and time.

The Mark Two is easy enough to use that businesses of all kinds can skip the machine shop and print from their desktop.

Like the others in this collection of ideal entry-level business printers, Markforged backs up solid technology with robust software. The company’s Digital Forge 3D printing cloud-based software encompasses a digital part library, print prep, and printer fleet remote management into one platform. You can control who has access to the printer based on their role in your organization and even connect your 3D printers with your inspection equipment to ensure every part is produced as designed. There more to the company’s software than we can cover here but

Delivering better resolution than your typical desktop filament printers, the Mark Two is optimized for the company’s proprietary materials that produce parts with verifiable strength and flexibility. If your business just needs to print robust manufacturing tools and parts, like props for the movie industry, this printer is hard to beat.

Although ease of use is its strong point, to get the most out of your Markforged investment, staff can attend a multi-day Markforged University in person or online.

- Technology: FDM (fused deposition modeling), uses filament infused with continuous carbon or kevlar stands

- Price: $16,000

- Ideal for: manufacturing (fixtures, cases, molds, factory tooling), product designers (functional prototypes), teachers (models, prototypes), automotive (spare parts, prototypes)

Original Prusa MK4S

There’s no doubt that the Original Prusa is a favorite among 3D printing hobbyists with over half a million Prusa printers in the wild, but its invariably excellent results elevate it as a solid choice for any business looking for small part prints and prototypes. In fact, it rivals the print quality and reliability of machines that cost ten times as much while being the lowest-cost option on this list at $1,100.

The simple software makes it easy to use and as your first step into 3D printing at your office, it won’t disappoint.

Although you won’t find a sophisticated learning platform, what you will find are countless videos and support posted online by throngs of loyal users. This should be support enough. Every Prusa 3D printer receives long-term support and upgrades for years after launch so you don’t have to worry about it becoming obsolete.

The MK4S, which launched in August 2024, is the latest version of the Original Prusa and with it, the company introduced some exciting upgrades. Not only is the MK4S twice as fast as the MK3S+ “while preserving accuracy and print quality,” the company says, but it features a new native Prusa app. The app enables you to control and monitor the machine from anywhere, scheduled print start, and a connectivity feature that enables you to simply tap your phone against the MK4S to connect.

It’s not officially on our list, but we’re very excited about the new Prusa Core One (pictured above) that just launched and should start shipping late January 2025. Compared to the MK4S, Prusa says is 50% smaller than the MK4S with an enclosure yet has a slightly larger print volume, plus produces results 20% faster (up to 27% faster in some cases).

- Technology: FDM (fused deposition modeling), uses filament

- Price: $1,100

- Ideal for: product designers (prototypes), teachers (models, prototypes),

Raise3D Pro3 Plus HS

The Pro3 series fine-detail, high-speed 3D filament printers from Raise3D are mini-factories from the start with quality construction and reliable output print after print. Not exactly plug-and-play, but considering the sophistication of its output, relatively little onboarding is needed for great results.

Raise3D calls its printers “industrial grade,” which fits this manufacturing tool well, considering its strong focus on durability, repeatability, and volume production. The dual-extruder Pro3 Plus’ large format is a favorite among artists and engineers alike for large (605 mm tall) prints.

The Pro3 Plus connects with Raise3D’s 3D printing software ecosystem that includes a 3D slicing program, ideaMaker, an open-software template called IdeaMaker Library, and the cloud-based 3D printing software RaiseCloud. This networkability creates a companywide seamless workflow enabling staff in various departments to easily design 3D printing files and produce accurate results. The RaiseCloud 3D printing management software remotely monitors the entire printing production across one or multiple 3D printers.

A wide range of materials – from carbon fiber to wood fill – make almost any type of print possible on the Pro3. And for a large printer, it’s incredibly fast.

The Raise3D Pro3 HS Series is a powerful professional-grade 3D printer that builds upon the Pro3 Series with integrated “Hyper FFF” technology. Available as a kit for older Raise3D machines, but build into the Pro3 HS, it enables 200% faster prototyping and print times reduced by 75%.

The upgraded motion control system with a closed-loop stepper motor further improves the precision and accuracy of high-speed printing, making it ideal for printing demanding industrial applications with minimal manual intervention.

- Technology: FDM (fused deposition modeling), uses filament

- Price: $7,600 plus accessories and materials

- Ideal for: product designers (rapid prototypes, functional prototypes), manufacturing (fixtures, cases, molds), teachers (models, prototypes), automotive (spare parts, prototypes)

License: The text of "The Best 3D Printers for Small Businesses in 2025" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.