Jewelry Has Gone Digital

Traditional jewelry-making is a detailed and time-consuming process. Nobody can deny the skill and craftsmanship that goes into a handmade ring or pendant, and there will always be something unique about manually sculpted personal adornments. Still, the fact stands that it takes a lot of time and patience to make jewelry completely by hand.

Jewelers and goldsmiths have woken up to this reality and adopted 3D printing in droves to make jewelry production easier, faster, and far less costly.

Like so many other things, jewelry has gone digital enabling more companies, especially small one, to design and fabricate custom pieces quickly and economically.

| Product | Technology | Build Volume | Price |

|---|---|---|---|

| Phrozen Sonic Mini 8K | SLA | 165 x 72 x 180 mm | $450 |

| Elegoo Saturn 2 | LCD | 219 x 123 x 250 mm | $350 |

| Zortrax Inkspire 2 | LCD | 192 x 120 x 280 mm | $4,390 |

| Formlabs Form 3+ | SLA | 145 x 145 x 185 mm | $2,500 |

| DWS XFab 2500PD | SLA | 180 x 180 x 180 mm | $12,000 |

| 3DSystems Figure 4 Jewelry | DLP | 125 x 70 x 196 mm | $12,000 |

| AsigaPro 4K80 | DLP | 217 × 122 × 200 mm | $26,000 |

| RapidShape S30+ | DLP | 133 x 75 x 155 mm | ~$30,000 |

| ETEC Pro XL | DLP | 249.1 x 140.1 x 165.1 mm | ~$40,000 |

| Flashforge WaxJet 400 | Material Jetting | 289 x 218 x 150 mm | $52,000 |

| 3D Systems MJP 300W | Material Jetting | 294 x 211 x 144 mm | ~$75,000 – $90,000 |

The Advantages of Jewelry 3D Printing

It’s important to clarify upfront that when you hear about jewelry 3D printing, it mostly refers to 3D printing the wax (or other material) pattern or model like the blue rings shown above. Traditionally, jewelers carve these wax models by hand, dip them in a mold plaster, burn out the wax and pour molten metal into the mold. But 3D printers can simply fabricate the wax models from a digital design, sometimes dozens of individualized models at a time.

When consumers order custom 3D printed jewelry from a 3D printing service, such as Craftcloud, their submitted design is usually being made into a wax model first, then the process follows the traditional steps.

Yes, you can directly 3D print jewelry in precious metals, but most jewelers don’t use 3D printers this way because the technology is not quite accessible in terms of price for independent jewelers. This article covers the best 3D printers for wax models, but if your goal is to buy a 3D printer to directly print in precious metals, check out binder jetting 3D printers from Desktop Metal, HP, or Markforged. There are also more and more companies entering the jewelry market using powder bed fusion technology to directly turn precious metal powders into bespoke and customized designs.

As we mentioned, 3D printers replace the practice of carving a hard modeling wax into the desired shape. Using a computer and jewelry design software or any computer-aided design (CAD) program, a jeweler creates the design or alters an existing design and then 3D prints that piece of jewelry in a wax material, creating a pattern. From this point, it’s back to the traditional process of lost wax casting.

A 3D printer not only makes it possible to create a finely detailed master wax model, but also to customize your digital file of the jewelry in the software in a matter of minutes and print out another model, or 20 different models at once. This dramatically speeds up design development through fast iterations and enables mass customization.

Advantages of 3D Printing Wax Models

- Speed: Simply put, 3D printing is infinitely faster than carving wax by hand. Whereas the traditional method requires you to spend hours or even days painstakingly carving the wax model, the 3D printer will produce a detailed model in a matter of hours. Plus, changes are far easier since you can simply alter the digital file and print another version.

- Complexity: 3D printers can create far more complex and intricate geometries than hand-carved designs. You can print anything your CAD software can design so it makes great design more accessible to artists who may lack carving skills. Additionally, depending on the piece, you may even be able to produce geometries that are practically impossible through hand-carving.

- Customization: Since the original master model is stored as a digital CAD file, you’ll be able to quickly modify it based on customer requirements.

- Mass Production: Depending on the capacity of your 3D printer, you may be able to print dozens of different wax models with one print run.

- Reproduction: 3D printing adds another level of convenience in that you can reproduce old or lost pieces of jewelry. With a 3D scanner, you can recreate an existing piece as a digital model that can then be cleaned up in CAD software and printed.

- Cost-Efficiency: Jewelry-scale 3D printing uses very little material. Although castable wax materials might be more pricey than regular resins, you’ll get a lot of mileage out of one batch of material, which helps you cut costs.

- Quick Prototypes: Fitting stones in a 3D printed model ensures a perfect fit and customer approval before casting the final piece. Clients can try on 3D printed models and get a truer sense of the final piece than a 2D image.

Models for lost-wax casting are not the only opportunity to make jewelry with 3D printers. As we mentioned, you can directly 3D print in precious metals, but there is also the possibility to print jewelry in polymers, ceramics, and non-precious metals.

What to Look For in a Jewelry 3D Printer

The first consideration when choosing a jewelry 3D printer is the technology. This, however, is an easy choice. Most jewelers opt for resin-based methods, including stereolithography (SLA), liquid crystal display (LCD) aka masked stereolithography (MSLA), or digital light processing (DLP) due to their high printing resolution and the availability of wax resins that will burn out cleanly during casting. If you’re not familiar with resin-based SLA or DLP 3D printing technology, check out our guide here:

Material jetting is another resin technology that’s generally faster than SLA and LCD especially for large-volume production. With material jetting, like 3D System’s MJP 300W 3D printer, layer thicknesses as thin as 9.5 microns make an extremely fine detail resolution possible.

There are some filament-based FDM printers that can print using wax filaments. However, as most FDM printers can’t create sufficiently fine details for intricate jewelry, it’s best to look for a resin printer.

Other considerations when picking your printer.

- Resolution: Pieces of jewelry are small, so the finer the detail your printer can produce, the better. You should aim for a machine that is able to create the finest possible details, ideally even as small as 8 microns. For reference, the average width of a human hair is 75 microns. If you want to get your level of detail down to layer thicknesses in the 2 to 5 microns level you’ll need to look into micro 3D printing.

- Print Speed: It’s hard to imagine a case where hand-carving wax would be faster than 3D printing it, so when it comes to speed, we’re talking about 3D printers. Ideally, look for a machine that lets you adjust the speed to get super-fast but less detailed prototypes, as well as extremely fine details which typically take a bit longer.

- Material Compatibility: Opt for a printer that is not limited to one manufacturer’s materials. It might just be that the best wax resin for your purposes is made by a third party. Proprietary materials are often more expensive than third-party ones, but then again some printers are tuned to print perfectly with their own resin, which cuts down on trial and error.

- Cost: When purchasing a printer, you need to not only consider the printer’s price, but also the cost of maintenance and materials. Although a jewelry 3D printer can return your investment in a few months, it’s good to pay attention to the budget.

- Exposure: If your designs have fine features and smooth surfaces, you’ll want to be careful with LCD technology. Some LCD machines produce models with a pixelated surface, and this could translate to the final piece when cast, unless you take time to do some post-processing.

- Volume: If you only plan to make one to six models at a time, the smaller volume machines will work, but if you think you’ll be mass-customizing hundreds of rings or pendants, look for larger volume machines.

- Accessories: Your model will not be good to go right from the printer. You’ll need some other equipment, such as washing and curing machines (although it’s possible to get by without them). So look for one company that offers the whole package.

No matter how good a printer sounds on paper, to evaluate a printer’s suitability for your workbench, you can ask the manufacturer for a sample print. Most will be happy to demonstrate the capabilities of their printers in practice.

Of course, you don’t need to own your own printer at all. You can order your lost wax casting models from a wide range of service providers, such as Craftcloud, just by uploading your digital file.

Our Top Picks & Listing Criteria

For this list, we’ve considered the capabilities and cost of each printer and split them into three categories: budget, affordable (or mid-range), and professional. Although our process has been by no means scientifically rigorous, it will give you an idea of the printers’ features. Also, keep in mind that some of these top manufacturers offer both affordable and production printers.

Budget 3D Printers for Jewelers

We’ll start with the budget category, which lists great machines if you’re new to 3D printing and want to learn the ropes. You can get a really good resin printer, like the Elegoo Mars 2, for about $200 to get your feet wet in the technology, but it may not have the super fine resolution some jewelry makers are looking for.

There are hundreds of budget resin printers on the market, below are our top pics for quality machines that won’t disappoint.

Phrozen Sonic Mini 8K

The latest Phrozen Sonic Mini 8K 3D Printer is a package deal with incredible print detail, straightforward installation, and a competitive price. With one of the highest resolutions on the market at 7500 x 3240 on its LCD screen, the Mini 8K resin-based printer delivers intricate detail for a variety of print jobs for industry professionals and recreational enthusiasts alike.

At 8K resolution, this Phrozen printer allows users to print even larger build volumes at the same high-quality level of detail. Compatible with ChiTuBox and Lychee slicing software, the printer achieves an incredible pixel pitch of 22 microns across its build volume of 165 x 72 x 180 mm, enabling users to deliver exceptional intricacy in the details for an array of prototypes and consumer products.

This printer has a simple 3.5-inch color touchscreen with straightforward options for starting and stopping print jobs directly from a USB stick. While the company recommends its branded Phrozen 8K resins to accomplish high-quality print jobs, third-party consumer resins are also compatible though users may notice a comparative difference in the finer details. Despite the industry-leading higher resolution, the Phrozen may be limiting to some users interested in generating larger prints.

Newer features introduced since the previous version include a metal resin vat, a sturdier material trusted by the 3D printer community, and a buffed-up T-plate that can better withstand the internal forces that accompany each layer of printing. When it comes to accuracy, precision, and quality, the Phrozen Sonic Mini 8K exceeds expectations with resolution, self-intuitive operation, and compatibility with both Phrozen-made and third-party resins.

Elegoo Saturn 2

The Elegoo Saturn 2 is a resin-based MSLA (masked stereolithography) printer with a ten-inch LCD printing screen that offers larger-than-average build volumes and high resolution. Improved features from the previous version include an air purifier, a larger print plate, and a sleeker design.

The 3.5-inch LCD control screen gives the user direct control over system maintenance and print initiation, but also offers a visual preview of the print job during the different stages of a print job. Unlike FDM printers, the Elegoo Saturn 2 is resin-based and as a result releases a strong odor during and after print jobs, a feature that some critics may consider a drawback while supporters may consider it a bearable cost, given the printer’s quality and price.

The company provides a toolkit that includes items like protective face masks, scrapers, a snipping tool, disposable gloves, and an air purifier that plugs into a port behind the resin tank. Installation is self-intuitive, the one-page leveling card outlines all setup instructions, and once the resin is filled, jobs can be printed in minutes.

Affordable 3D Printers for Jewelers

This second category features mid-range printers that offer more advanced features, software, and automation while still coming through with a reasonable price tag (under $20K) for professional jewelers. As you move into this category, you’ll want to look for a printer company that offers an integrated workflow – something where the software, printer, and accessories like the washing and curing station all work together efficiently.

Zortrax Inkspire 2

Zortrax provides one of this list’s more affordable mid-range printers with the Inkspire 2. The printer’s UV LCD technology offers consistent print speeds no matter how much of the printing surface is used, making it a good option for printing multiple master or wax models at once.

The Inkspire 2 has a minimum layer height of 25 microns, which is on par with many other listed machines. The printer is easy to use thanks to its automatic calibration and Android-based operating system which can be fully controlled via Zortzrax inCloud for seamless printing farm management.

The Inkspire 2 offers four times more build volume compared to its predecessor at 192 x 120 x 280 mm. The UV LCD screen also received a powerful UV light engine upgrade that is 7 times more powerful at a 40% improved UV light distribution.

Nonetheless, the Inkspire is a capable machine that can produce repeatable, consistent prints with high surface quality. It can also expose supports to UV light for a longer time, hardening them and making them easier to remove. Other professional features include a built-in carbon filter to cut down on toxic fumes.

Zortrax offers its own BlueCast range of castable resins, but the Inkspire 2 also supports any light-curable resins, so you’re spoiled for materials options. The company also manufactures an ultrasonic cleaner unit as well as a curing station.

Formlabs Form 3+

Formlabs is one of the biggest names in reasonably priced SLA. Similarly, their Form series, including its latest reincarnation, the Form 3+, features some of the best-known printers on the market. Apart from their printers, Formlabs is dedicated to jewelry 3D printing with experts in jewelry you can call.

With the Form 3+, Formlabs introduced greater functionality and higher quality in a machine that requires less production time. Compared to its predecessors, the Form 2 and Form 3, the newly-improved Form 3+ achieves faster printing speeds with greater resin clarity and translucence. The Form 3+ also has more integrated sensors with the ability to detect dust, an enhanced Light Processing Unit (LPU) that can now be replaced in-house, an improved fail detection system during and after print jobs, and an easy post-job cleanup process.

Formlabs printers only work with Formlabs resins, but they offer two castable wax resins, which the company says are optimized for zero ash content and clean burnout. They also offer a resin strong enough to withstand the temperatures and pressures of medium-temperature vulcanized rubber molding. Formlabs also advertises its grey resin as an excellent material for jewelry prototyping and iteration for a total of four jewelry-specific resins on offer.

Although it doesn’t improve print speed, the new preheat feature speeds up the overall time it takes to produce parts. Previously, preheating the build chamber would only begin once a user confirmed a print on the touchscreen. But now, preheating will begin once the printer receives a job.

Formlabs also offers its own washing and curing stations. If you buy all three machines, you’ll have to dig deeper into your pockets, but you will also get a full 3D printing station with a proven track record.

DWS XFab 2500PD

DWS (which stands for Digital Wax Systems) is an Italian 3D printer maker with a strong focus on dental and manufacturing printers, however, it is still worth taking a look at for jewelry makers. The company makes ten printers, from smaller desktop versions all the way up to commercial production machines.

Here, we’ll focus on the company’s smallest; the XFab 2500PD. It’s aimed at professionals and able to produce models for direct casting as well as rubber molding. As an added plus for jewelry makers, DWS also produces a nanoceramic material, IRIX V which can reproduce realistic looking gemstones in any desired shape and size.

DWS not only makes the printers and the materials, but they make the software for a fully digital and automated workflow. The company’s Nauta XCluster software aids in the creation of already set-up trees for direct casting as well as the creation of already linked chains.

DWS printers are only compatible with DWS’ five castable resins. The smart cartridges for the XFab series have been designed to eliminate the often messy liquid resin issue, ensure safety, and provide a quick material change.

A plus with DWS is that if you outgrow your XFab 2500PD, you can scale up to larger machines and you already know the software and materials. One of the largest in the line, the XPro Q, can produce up to 3,200 models per day and is priced at $300,000.

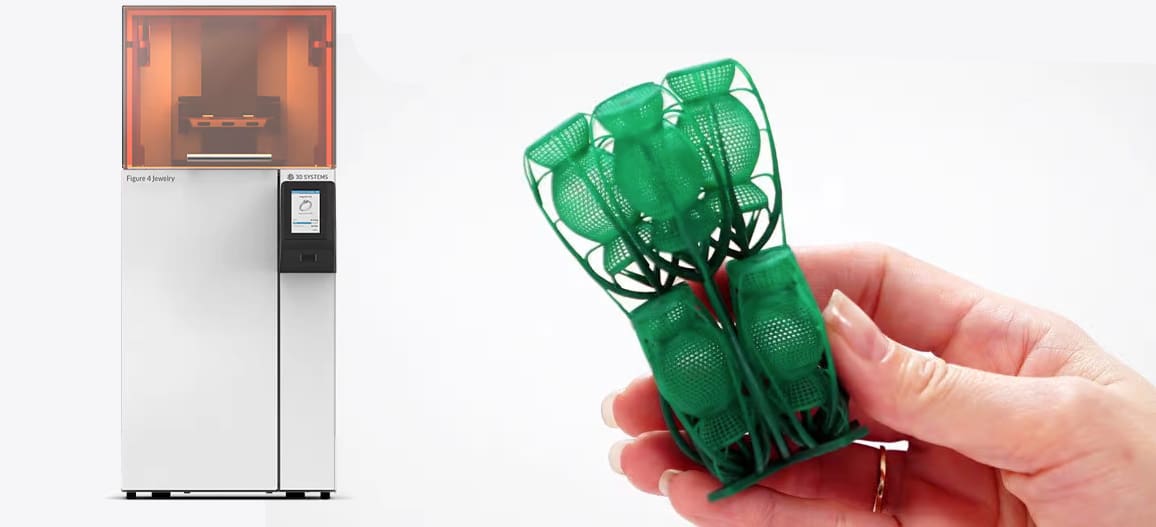

3DSystems Figure 4 Jewelry

3D Systems produces a range of 3D printers for jewelry casting, including the MJP 300W, ProJet2500W Plus, ProJet 3600W series, and the ProJet 6000 HD. The Figure 4 Jewelry is geared toward printing both casting and master models.

It can achieve high print speeds of up to 15 mm per hour when printing at a resolution of 30 microns. 3D Systems has a proprietary casting pattern material available, in addition to a material made specifically for printing master patterns for molding.

The Figure 4 Jewelry uses non-contact membrane technology, which works together with the company’s exclusive MicroPoint supports to keep part-to-support contact to a minimum. The technology produces smooth walls and high-detail patterns that require little post-processing.

The printer brings fast production speeds for casting and master patterns to the table, alongside prototypes and fit-check models. 3D Systems also offers a UV post-curing unit (required for finishing prints) and a materials mixer. Looking for something larger? 3D Systems offers the ProJet MJP 3600W and 3600W Max for higher productivity.

Commercial 3D Printers for Jewelers

If you’re looking to scale-up jewelry production, automation, and capacity in addition to excellent quality, check out these top picks below. Just like in the world of budget resin printers, there are great resin printers in the professional and industrial categories that don’t necessarily focus on jewelry but may still fit your needs. In this category, you’re looking for ease of use, reliability, and consistency.

AsigaPro 4K80

The Pro 4K80 from Australia-based Asiga combines 4K imaging technology with an open material system boasting hundreds of compatible materials, including wax and castable resins. Using pixel shifting technology, Asiga’s 4K mode reduces the pixel size to increase part accuracy and resolution without impacting build area or printing time. The printer’s higher power 3D printing UV wavelengths (385nm) reduce XY scattering and over-cure, the company says, resulting in sharper detail definition, accuracy, production reliability, and the option to process water-clear materials.

In 2011, Asiga launched the world’s first LED-based DLP 3D printer and started the affordable desktop stereolithography revolution, which significantly changed digital manufacturing.

The Asiga Pro 4K80 has Wifi connectivity, wireless direct and ethernet connection, automatic support generation with the included Asiga Composer software, and a touchscreen interface.

RapidShape S30+

Popular among jewelry manufacturers, the RapidShape S30+ features an intuitive user interface and extras that focus on simplifying the jewelry mold production workflow without the need for professional knowledge.

If you’re looking for high-volume printing results with consistent quality for design offices and jewelry manufacturers, this printer should be on your list. The automatic separation module (ASM) enables you to produce multiple print jobs one after the other without having to remove the build platform from the printer. Combined with an open system for print materials and remote access, the S30+ offers more flexibility for fast, high-quality, high-quantity printing. The resin temperature control allows the S30+ to control and adjust the temperature of resins as needed.

Naturally, a printer of this size (and price) comes with a worldwide service team to assist you, as well as all the necessary software and accessory machines (the clean and cure units) in a tidy bundle.

ETEC Pro XL

The Pro XL is the latest professional-grade desktop 3D printer from Etec, a division of Desktop Metal. This printer boasts high speeds, a 4K ultra HD projector, great precision and one of the largest build volumes of the printers on this list. The Pro XL is compatible with a range of Etec and third party materials, including the Easy Cast 2.0 – the photopolymer with the highest wax content available – perfect for jewelry makers.

Although one of the newest printers out on the market, the Pro XL is designed using the same chassis as its Envision TEC Perfactory, a system that has proven its ability since DLP printers were first introduced in the early 2000s.

Flashforge WaxJet 400

The Flashforge WaxJet 400 uses a material jetting technology called Multijet Printing, which is faster than most SLA printers. This technology allows the WaxJet 400 to print with Flashforge’s 100% pure wax material at a minimum layer height of 16 microns, resulting in highly detailed ready-to-cast wax models.

This industrial-level printer is optimized for fast mass production. With its large print chamber, the manufacturer claims WaxJet 400 can produce up to 350 ring-sized models per day.

The printer also uses a dissolvable wax support material that makes post-processing faster and easier. If the WaxJet 400 seems like overkill for your purposes, Flashforge also offers the resin-based Hunter printer, along with its proprietary castable resin materials.

But the most important aspect of production printers is efficiency, and that’s where the WaxJet 400 shines. Flashforge delivers a jewelry-optimized, high-precision printer that every professional jeweler should consider.

3D Systems MJP 300W

Printer maker 3D Systems, a pioneer in jewelry model 3D printing has launched a new, high-volume 3D printer aimed at the largest players in the $8B 3D printed jewelry market.

The new MJP 300W uses 3D Systems MultiJet Printing (MJP) technology, which is a type of material jetting, to 3D print highly detailed jewelry patterns at a max speed of 240 cm3 per hour. The goal is to deliver more patterns faster without sacrificing quality to help jewelry producers keep up with their metal casting workflow.

3D Systems already has four other large wax 3D printing platforms. But with the introduction of the MJP 300W, the company unveils two new print modes that give users more flexibility in their production processes.The QHD mode enables more than 50% improved resolution compared to the older ProJet MJP 2500W Plus and an impressive 9.5-micron layer thickness. The other mode, UHD, offers twice the print speed of the ProJet MJP 2500W Plus, significantly increased throughput, and reduces the labor required for finishing and polishing.

Along with the new printer, 3D Systems is launching a new wax model material that’s stronger and less prone to warping and melting. VisiJet Wax Jewel Ruby is the company’s “most advanced material”, it says, creating models with better durability and higher thermal stability

Get Your Jewelry 3D Printed

If you’re not ready to dive into purchasing your own printer for jewelry molds, there are plenty of third-party printing services where you can upload your digital file, choose your materials, and receive your model in the mail. Some will also do the metal casting step for you – along with polishing and finishing – so you receive your final jewelry piece in the mail in precious metals, including gold, silver, and platinum. As we mentioned above, if you want a piece of jewelry directly 3D printed in precious metal – which isn’t common – be sure to ask the providers below if they offer that service.

Craftcloud. The ideal place to start is on this 3D printing service marketplace where you simply upload your 3D file and receive instant quotes from other major 3D printing services worldwide, so you’re sure to get the right price.

- Castable Wax

- Gold

- Sterling Silver

- Platinum

- Bronze

- Copper

Lead image source: Formlabs

License: The text of "The Best 3D Printers for Jewelry" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.