The hardest part about 3D printing isn’t actually the printing, it’s the designing. If you have a product idea to prototype or a broken part to replace — and you lack design skills — you’ll need a computer-aided design (CAD) professional to create the digital file required to print your part.

Designing products and parts for 3D printing is its own skill set. Unlike designing for other types of manufacturing or virtual environments, it’s important to work with a designer who understands the differences between the seven types of 3D printing technologies, the often unique materials available, and the requirements of 3D printing.

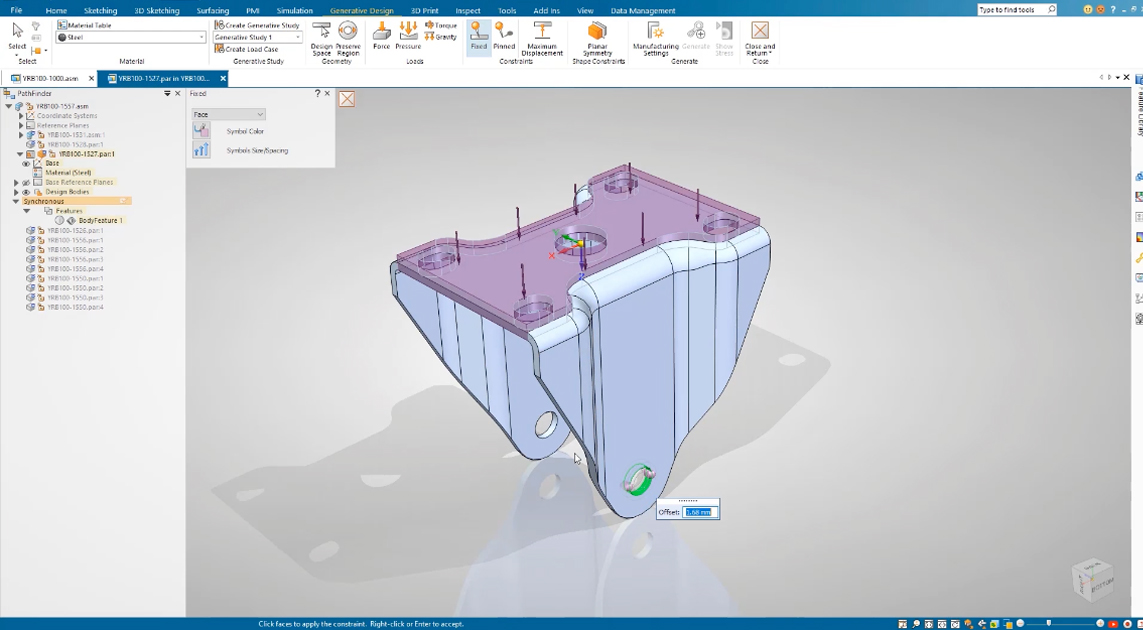

Even though CAD software programs used for creating 3D printable models, such as Fusion 360, SolidWorks, and Creo, are more accessible than ever, and many include tools and simulations specifically to aid in designing for 3D printing (also called Design for Additive Manufacturing or DfAM), 3D design is not a skill that’s easy or quick to pick up. In fact, there are many pitfalls even a skilled designer could encounter if they’re not familiar with 3D printing. Part walls that are too thin to print in the material you’ve chosen or features that are too small to 3D print in the 3D printing method selected are just two of the common ways a part fails to print properly.

Even if you turn to a professional to 3D print your design, they may determine that it isn’t 3D-printable. When uploading your digital design to a professional 3D printing service, many offer a “printability” check on your digital file before the printing starts. But if you fail that check, services typically don’t tell you how to fix your model.

More Reasons to Hire a Designer

For manufacturers turning to 3D printing, finding the right product designer is critical. One common problem is using the same digital part file used for traditional manufacturing (milling, molding, or casting) for 3D printing. Most of the time, for replacement parts or tools, it will 3D print just fine. However, 3D printing the exact part you once machined is missing the point and the benefits of 3D printing. With a bit of redesign, you could consolidate dozens of parts into one 3D printable part, use a lattice infill instead of solid material to make parts lighter, incorporate complex internal channels not manufacturable any other way, or incorporate topology optimization so your part can use less material overall.

There are many more reasons to turn to a professional 3D model designer specializing in 3D printing. Below we explore some of the top professional DfAM design firms and some budget design service options to get the best digital model that you can then 3D print.

Design Services at 3D Printing Service Providers

Many of the top 3D printing services offer some type of design service, from a basic “fixing” of your STL file to working with you to design a new product from scratch. Here we feature the latter, companies that can help you bring your idea to market or reveal how to apply the benefits of additive manufacturing to your existing products.

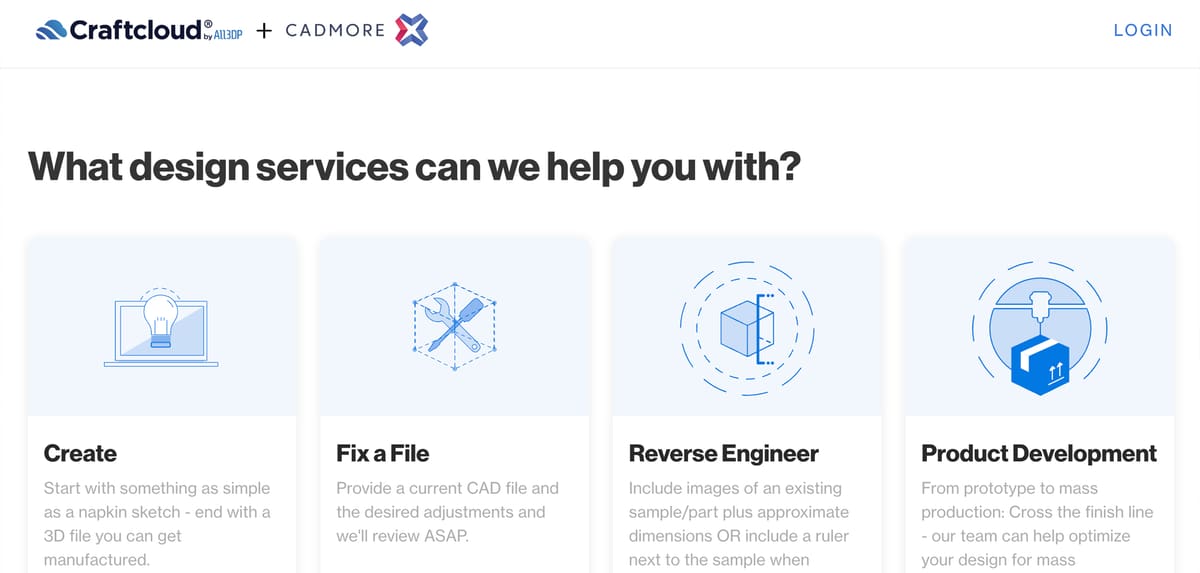

Craftcloud + CADmore

Craftcloud by All3DP, the global 3D printing marketplace, partners with CADmore, the US-based 3D design services company, to bring you a complete design and printing solution that can take your napkin sketch all the way through design and manufacturing to a marketable product.

CADmore sits upstream of prototyping and manufacturing, providing a real-time collaborative process solution for designers, product managers, engineers, and third-party partners to work together. The aim is to help companies simplify and accelerate the design-to-production process by offering a complete solution for on-demand digital manufacturing that includes leveraging our broad network of 3D printing partners.

In addition to creating digital part files from scratch, Craftcloud + CADmore, will also optimize and repair your CAD files, for example, if they’ve been rejected by a print service or have resulted in failed prints. It can also convert 2D drawings into 3D files, which is especially useful for companies that want to upgrade their legacy or spare parts catalogs.

Reverse engineering services include the ability to use photos and measurements (even a ruler sitting next to a part) to recreate the item digitally.

Craftcloud + CADmore boasts response times in minutes, quotes in hours, and models designed in less than a day and two free revisions are included for every project.

Models can then be uploaded to the Craftcloud 3D printing marketplace, where you’ll choose your materials and receive quotes from various 3D printing services.

If you’re worried about uploading your intellectual property, you’ll appreciate Craftcloud + CADmore’s mutual non-disclosure agreement.

Materialise

Materialise makes CAD and 3D printing software and offers a print-on-demand service, so it’s no surprise that they’d also offer 3D design services. In fact, companies have been turning to Materialise to help apply additive manufacturing to their businesses for decades.

Recently, Vuzix, a supplier of smart glasses and augmented reality technology, announced it was working with Materialise to accelerate the design and production of smart eyewear using 3D printing technology. By integrating 3D printing into the manufacturing process, Vuzix and Materialise aim to accelerate the development of new innovations for enterprise applications, from warehouses to operating rooms.

A 2023 survey by Materialise revealed that manufacturers are familiar with the unique benefits of 3D printing but face challenges in adopting and implementing it.

Guiding companies through the multiple phases, from concept through design to 3D printing as a service or establishing 3D printing in-house, is where Materialise shines through its consulting department Mindware.

Although they will redesign your part to benefit from additive manufacturing, Mindware is focused on helping companies spot opportunities for growth in 3D printing. They offer workshops to get your team on board as well as technology and material feasibility studies, along with identifying key applications for AM and deploying full-scale production lines.

Sculpteo Studio

Global 3D printing on-demand provider Sculpteo has industrial designers and engineers to support your AM projects at any stage of development through its Sculpteo Studio department.

Sculpteo Studio’s team can help you identify the 3D printing opportunities at your company and partner with you to develop the designs.

Like Materialise, Sculpteo has years of experience helping companies bring their product ideas to life via 3D printing prototypes and final parts. They’ve worked with companies to lightweight and optimize their existing parts, reduce the number of parts in a component, and develop custom fit-for-purpose tools, jigs, and fixtures.

The company offers a free initial consultation.

WhiteClouds

In business since 2013, WhiteClouds is a print service and design service with a few unique specializations, one of which is very large 3D prints. “The vast amount of knowledge required for 3D design can take years to master,” the company says. “If you’re starting a small business or you’ve got other areas of focus, odds are, you’ll have bitten off more than you can chew.” WhiteClouds has worked for some very large companies, from the Chicago Bulls and Disney to Ford and Walmart, to create large 3D printed structures.

The company’s team of 3D designers, 3D print technicians, sculptors, artisans, painters, and engineers work together to bring to life your project, whether it’s a large display piece, signage, or end-use part. They can help you visualize the possibilities of the final design. They work with most modeling and CAD programs, including Maya, 3DS Max Design, ZBrush, AutoCAD, Revit, and SketchUp, and can work from your 2D blueprints or sketches to create a 3D file. “If all you have is an idea or a drawing on a napkin, we can start with that,” the company says.

When designing for large 3D printing structures, their team also checks for print integrity by creating reinforcement for thin geometries, making sure things aren’t top-heavy, and ensuring the bottom is flat and balanced enough to hold its own once the model is printed and assembled.

WhiteClouds also has a focus on 3D design for architectural models. They can take initial 2D designs from AutoCAD, blueprint drawings, imagery from Google, and many other sources to create the design of a printable 3D file. Another specialty is 3D raised relief maps.

Stratasys Direct

Whether you’re looking for help making small changes to your CAD file or need more robust design solutions for your application, on-demand 3D printing service provider Stratasys Direct has a range of design services to make your project successful.

The company’s design team can help optimize a CAD model for functionality, appearance, and value for use with the 3D printing technologies they offer. From ensuring seamless 3D designs all the way through to product manufacturing, the Stratasys Direct Design Services can help you wade through the technology adoption process.

Stratasys Direct has a few specializations, for example, in designing and 3D printing jigs and fixtures, that can be especially handy. They’ve worked with numerous automakers and manufacturers and have the industrial knowledge of the application to recommend not only the ideal part design but also the right materials for the job.

If they don’t have the specific experience you’re looking for, they say they’ll recommend several companies that can make your design ready for the real world.

Protiq Engineering Service

3D printing services company Protiq has design engineers to support you on your 3D printing journey. They can create a 3D model based on sample components or 2D drawings and make design adjustments according to your specifications.

Protiq engineering services include the design, simulation, and prototyping of 3D printed parts and assemblies for a variety of applications. The engineers can recommend the best materials for strength, hardness, ductility, and other mechanical properties and can also redesign your part using DfAM principles to reduce the number of components, lightweight, or optimize material usage.

If you have a part but no digital file of it, Protiq also offers reverse engineering.

3D-Alchemy

UK-based 3D-Alchemy is a great example of a local print service that has branched out to design. They offer a range of design types and the cost includes the original CAD file, all STL files, plus a 3D printed version of the design.

For speed, the company says it’s best to supply a basic electronic file of your project, which could be a 2D vector graphic illustration, such as something in Coral Draw or Adobe Illustrator.

Their clients include companies looking to develop prototype ideas into product designs. Recent projects include early-stage product design in conjunction with a University, 3D logo interpretations for a design agency, and scale model parts for a World War II aircraft project.

The company says a regular request is the recreation of CAD designs using one of the free CAD software options where clients can export their own high-quality STL files but also make changes.

Budget Options for Design Services

Fiverr, UpWork, Guru

There are a lot of talented CAD designers out there offering their services on freelance or gig platforms, such as Fiverr, Upwork, and Guru, costing anywhere from $10 to $100 or more, depending on the complexity of your part.

These platforms are a great budget choice. But not every CAD designer is familiar with CAD design for 3D printing.

To select the best option, ask the freelancer about their experience specifically with 3D printing (and which technologies) and ask what software they’ll be using to create the part. You’ll want someone who knows Solidworks, Fusion 360, Creo, or any of the programs we feature in our guide to CAD for engineers. Ask if the software they use has a simulation or build simulation feature that will help ensure that your part is printable and will function as expected.

Just because you’re provided with an electronic file that looks good doesn’t mean it will be printable. You sometimes have to pay on these platforms before you receive the work, so ensure there’s a way to come back to the designer if it turns out that the part is not printable.

UpWork offers a category under CAD Design for 3D Printing. Here you’ll find various designers who specialize in design for 3D printing and some who specialize in jewelry design as well.

The end product you should receive is an STL file, or if they’re more sophisticated, a 3MF. It’s unlikely that a designer will offer you the original CAD file (that you can then edit), but there’s no harm in asking or paying a bit more for it. The advantage of the original CAD file is that you can then take it to another design later on for changes or even make small changes yourself.

CGTrader

CGTrader is a popular online marketplace for downloading 3D models and assets, but you can also find designers for custom work.

The process is very similar to the freelance platforms above. You fill out an online form describing your needs, receive quotes from various designers, select one, then pay online when you receive work that you’re satisfied with.

One unique feature is that you can also search CGTrader’s designers based on skill, rating, or software preference and invite them to your freelance project. Since there are hundreds of thousands of models, you can also browse them and find something similar to your needs, then reach out to that designer specifically. Not all do custom work, but you can start the dialog right from the website.

CGTrader says it is home to 40,000 freelance 3D designers, including modelers, animators, riggers, and 3D print pros. Since some designers only do work for virtual environments, be sure to select one with experience in creating parts to be 3D printed.

Toptal

Toptal is another marketplace for top CAD designers, consultants, contractors, technicians, and drafters. Toptal says its in-depth screening and matching process ensures the design talent is matched to your precise project needs.

Setting it apart from some of the freelancing sites, Toptal provides more information about each CAD talent, including a photo and the specific CAD software they’re familiar with. Also, rather than scrolling through freelancers for hire, you can schedule a call with Toptal, where they present their capabilities and provide you with some matches to choose from.

Of the more than 200,000 people who apply to join the Toptal network each year, fewer than 3% make the cut, the company says.

Each engagement between you and your CAD designer begins with a trial period of up to two weeks, after which, if you’re not completely satisfied, you won’t be billed.

Independent 3D Printing Design Companies

Cad Crowd

Cad Crowd is a match-maker online platform to help you find the best CAD designer or design firm for your project. The designers on the platform offer a range of services for inventors, product developers, and engineers for CAD design for traditional manufacturing, 3D modeling for virtual environments, and, of course, DfAM.

From their homepage, you’ll want to click on services, then 3D Modeling Design, then 3D Printing Design. The available designers specialize in rapid manufacturing, the company says, and can ensure that your design is optimized for one of these types of 3D printing:

- PolyJet 3D Printing

- Fused Deposition Modeling

- Selective Laser Sintering

- Direct Metal Laser Sintering

Cad Crowd says its network of more than 65,000 design professionals are all vetted and qualified, which takes a bit of the risk out of hiring a freelancer. They even have a five-star Trustpilot rating.

Fill out the online form with your product description and Cad Crowd will get back to you with options. You’re not connected directly to a designer on the platform immediately. Alternatively, you can upload a project description for a confidential or launch a design contest on the platform and get multiple design submissions for your concept.

If you’re an inventor, Cad Crowd can also connect you with a qualified US patent attorney for patent searches, patent applications, and design patent services.

J-CAD

Designer Jason Vander Griendt started J-CAD as a side gig in 2006, with the help of 40 expert contractors, such as engineers, around the world. It has since grown into a business that works with some of the biggest companies in North America.

J-CAD aims to offer individuals and companies CAD design for use in 3D printing, prototyping, and mass production. Whether you want a simple model to print at home or in your office or a full product development partner for mass producing your new product, the engineers and designers and J-CAD can accommodate.

The start can be a simple sketch, an image of a similar product, or a 2D file of your desired product. Once they see what you need to do, they will quote your entire project in just a few minutes.

The company offers a free downloadable 3D viewer tool that allows you to see the design created for you. The company also offers nondisclosure agreements so your IP is safe.

The file you get can be sent to any 3D printing or manufacturing company but J-CAD can also manage that part of the process for you.

IRPD

Switzerland-based IRPD is not the type of company you’d turn to for an STL of a spare part. These industrial DfAM experts can take your existing part, whether it’s in an engine, a machine, or a building, and reimagine it for additive manufacturing.

Using CAD and simulation software, they can demonstrate whether your existing part could be smaller, stronger, lighter weight, more efficient, and cheaper to manufacture using additive manufacturing or not. Sometimes a part can not be optimized for 3D printing, which is also good to know before you go down that road.

They also have experience helping companies develop completely new business models around 3D printed parts that can be produced economically in small batch sizes or products made on-demand to customer-specific perimeters.

In addition to design, IRPD can conduct extensive simulation testing to offer you more data on how the new parts will resist stresses, deformations, and temperature fields, as well as reactions to velocity, pressure loss, turbulence, or heat transfer on complex components. The company will also oversee the production and distribution of additively manufactured products.

License: The text of "How to Find a Design Service for Your 3D Printing Project" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.