From bike frames and car parts to figurines and prototypes, there’s no limit to what you can 3D print in pure aluminum and aluminum alloys. Even if you know nothing about metal 3D printing, you can have your parts 3D printed.

There’s a growing number of contract manufacturers with fleets of metal 3D printers ready to custom print your aluminum part, whether it’s a single spare or a production run of hundreds or thousands.

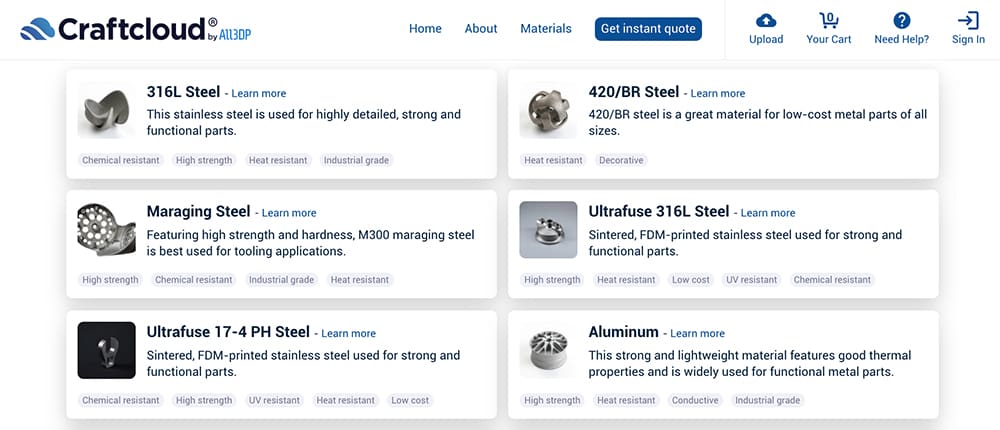

You could turn to Craftcloud, our 3D printing service marketplace, where you upload your 3D model and receive instant quotes from over 150 local and global manufacturers. Or, can check out these top 3D printing services below, offering a menu of extras, such as design advice and consulting, post-processing and polishing, and express 3D printing.

In this guide, we not only present our picks for the top companies offering aluminum 3D printing services, we also cover what you need to know about aluminum 3D printing technology to make the right choice for your needs. We took an in-depth look at a wide range of 3D printing services worldwide and came up with our picks based on:

- Services: Offering additional services, such as design, on top of printing demonstrates the company’s ability to serve various customer groups and guide you to the best solution for your needs.

- Service area: A company that can serve a wider area is a stronger contender.

- Range of materials: With more materials comes more expertise on which materials are best for your application. Even if you believe aluminum is the best choice, there could be a lower-cost polymer or a higher-strength titanium that’s a better fit.

- Quality inspection and certifications: If your aluminum part is destined to be a functional part, it should be tested for strength and compliance with manufacturing standards, where necessary.

- Range of technologies: There’s more than one way to print aluminum. Companies that offer a range of technologies can give you price, speed, and quality options, although laser powder bed fusion (LPBF) is likely your best option.

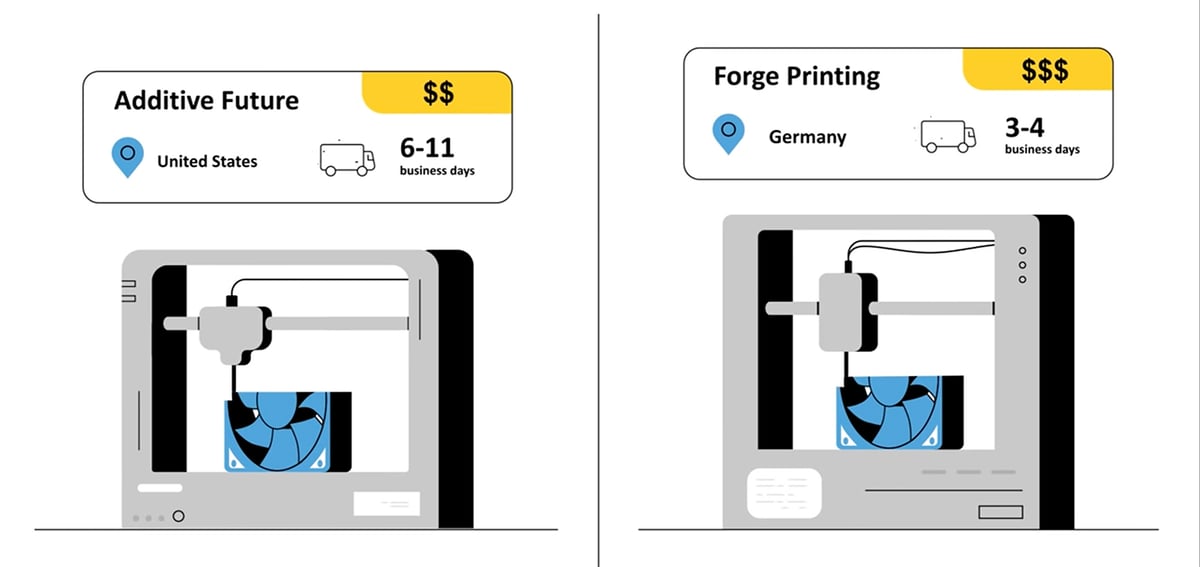

- Lead and quote response time: You can’t rush quality, but faster response and lead times are guaranteed to keep customers happy.

What You Need To Know Before Ordering Aluminum Parts

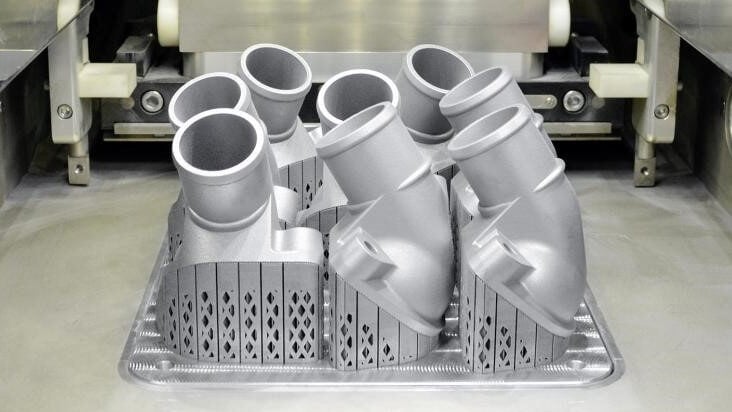

Metal 3D Printing Technology

Although there are about six distinct types of 3D printing that will produce aluminum parts, including fused deposition modeling (FDM), binder jetting, and wire arc additive manufacturing (WAAM), the most common method is laser powder bed fusion (LPBF) also called DMLS or SLM or simply metal laser sintering. Be sure to inquire which 3D printing method your service provider uses. FDM, for example, is quick and cheap for prototypes, but it may not have the mechanical strength you would need for an end-use car part, for example.

Your metal service provider is able to guide you through the technologies and explain your options, but take a look at our overview of metal 3D printing methods for a grounding in the various methods. Consider the mechanical and aesthetic qualities that your final parts must have. These will inform which printing process and post-process finishing you’ll need. Functional parts are typically printed using laser sintering, metal prototypes are made very affordable with FDM, and large parts or induction molds can be produced with WAAM.

Your 3D printed aluminum parts will behave just like cast or injection molded aluminum parts. They’re not only weldable, but can be machined and polished.

Variety of Aluminum

There has been considerable R&D effort in aluminum alloys for additive manufacturing recently. In the early days of AM, engineers had challenges working with aluminum, but things have changed. New high-performance aluminums and alloys have been crafted specifically for 3D printing processes that exhibit the traditional characteristics that manufacturers today require. These materials are particularly tuned to take advantage of the unique melting processes of laser and electron beam additive manufacturing.

Many of the current aluminum alloys for 3D printing are simple casting alloys, such as AlSi10Mg. These aluminum alloys are not particularly strong, nor can they manage high temperatures. Still, their mechanical properties are suitable for a wide range of applications and the material is “weldable” and, therefore, can be used in 3D printing without cracking. The properties of these materials may be all some companies are looking for in metal 3D printing, but others, especially aerospace and advanced manufacturing, need more.

Specialty aluminum alloys, such as scalmalloy, A20X, and CustAlloy, provide final part characteristics unheard of in traditional manufacturing. You’ll find these at services such as Oerlikon AM or FIT AG detailed below.

New on the scene is sustainable aluminum, such as the new EOS Aluminium AlSi10Mg that incorporates a minimum of 30% recycled feedstock, reportedly achieving a 25% CO2e reduction compared to the prior formulation.

How to Order Aluminum Parts

Metal 3D printing services have various business models. Some will work with you to design or redesign your part and hold your hand through the entire process. This is ideal if you’re new to metal 3D printing. For instance, if you have one broken but essential machine part you need to be recreated faster and cheaper than by machining or casting, but you don’t have a digital file, look for a full-service provider.

If you’ve 3D printed metal before or your in-house metal 3D printers are at capacity and you have a digital file, you may want a service that enables you to simply upload your digital model, select a few parameters and get your part in the mail in a few days.

In general, almost all metal printing services offer an online quoting platform or they will provide a quote after their metal printing experts evaluate your project. The more complex your project, the more personalized consulting you may need.

The workflow generally follows these steps:

- Create an account and sign in.

- Upload your 3D model to the manufacturer’s online system or reach out to their sales staff.

- Choose your desired material and finishing details, in addition to the number of parts.

- Review the pricing quote that’s generated either instantly or after expert evaluation.

- Place the order and the item goes into manufacturing.

Now, let’s have a look at our top performers.

Top Aluminum 3D Printing Services

Craftcloud

Craftcloud isn’t just a 3D printing service. It’s a marketplace of 3D printing services that enables manufacturers and engineers to compare prices and services from different service providers and find the right custom manufacturer at the right price.

With partners around the world, Craftcloud presents you with the best services in terms of price and lead time, with no additional fees. Quotes are generated in real time based on your uploaded models and location. Using the platform is as simple as any other 3D printing service but with many more options available. You can choose from common metals like aluminum with custom finishes.

Technical specifications

- Material: AlSi10Mg

- Method: Laser Powder Bed Fusion

- Maximum part dimensions: 800 x 398 x 500 mm

- Minimum Feature Size: 0.381mm

- Finishing: Raw Matte, Deburred, Sandblasted, Glassblasted

Materialise

Based in Belgium with a facility in Michigan, Materialise, known for its 3D printing software, offers both a rapid prototyping service and on-demand additive manufacturing for volume production. Both options offer metal.

Materialise offers a range of services, including part development and optimization and several business integration solutions, like manufacturing partnerships and white-label integration. This makes it easy for your firm to partner with Materialise to provide parts and services for your customers under your own name, such as for spare parts.

Materialise offers one aluminum option, AlSi10Mg, which is common in automotive, aerospace, and automation. The company’s design guidelines for aluminum parts is a must-read if you’re not experienced in designing parts for 3D printing.

Technical specifications

- Material: AlSi10Mg

- Method: Laser Powder Bed Fusion

- Maximum part dimensions: 500 x 280 x 325 mm

- Layer thickness: Standard: 0.09 mm, Performance: 0.06 mm

- Minimum wall thickness: Standard: 1 mm, Performance: 0.5 mm

- Finishing: Supports removed, corundum blasted (matte), glass bead blasted (satin), matte + post-machined

Protolabs Network

Minnesota-headquartered Protolabs makes their claim to fame with speed. The company promises very short lead times. They also have a digital quoting platform, which provides not only instant quotes but also design analysis. Back in 2021, Protolabs joined forces with the online manufacturing platform Hubs, which has greatly enhanced its production capabilities.

Although Protolabs doesn’t provide 3D modeling services, they offer an automated design for manufacturability analysis. If you have questions after the online quotation process, Protolabs’ expert engineers will walk you through your material and design choices and help you determine the optimal part orientation for printing.

In addition to 3D printing, the company offers CNC machining and sheet metal fabrication services. They also offer mechanical testing (Tensile, Rockwell Hardness) for your metal parts.

One of the reasons to pick Protolabs is its wide range of post-processing and finishing services. You can have your aluminum part machined to add a range of features and you have have full traceability of the process from the powder through to the final part.

Technical specifications

- Material: AlSi10Mg

- Method: Laser Powder Bed Fusion

- Maximum part dimensions: 800 x 400 x 500 mm

- Minimum Feature Size: 0.381mm

- Finishing: Brushed surfaces in a range of grits and polished mirror finishes.

- Certifications: ISO 9001:2015, AA9100D, ITAR

FIT AG

FIT is a German additive manufacturer that’s been delivering custom metal parts and components globally for more than 20 years. They have facilities in the US, Japan, Russia, and Europe.

When it comes to aluminum, FIT offers three technologies. Together with their development expertise for 3D printed components and their extensive post-processing possibilities, they offer metal additive manufacturing for everything from medical implants and aerospace parts to spare auto parts and sculpture.

FIT shines when it comes to expertise and has 250 employees on the job. They boast that they make the entire value chain of 3D printing available to customers – from product design through to engineering, production, and post-processing. As a development and implementation partner, they’re not an upload-and-order shop like Protolabs. They’re more of a guide for additive manufacturing and can show you the best path to reach your project goal.

They provide individual consultation and training services on the topic of additive manufacturing. And, because they know additive manufacturing is not always the best solution in every single case, they also have numerous conventional technologies, such as CNC milling, injection molding, vacuum casting, or elastomer manufacturing.

Technical specifications

- Material: AlSi10Mg, Aluminum Alloys 3.3206, 6063, Al6061

- Method: Laser Powder Bed Fusion, Wire Arc Additive Manufacturing, Cold Spray

- Finishing: Supports removed, polishing, heat treatment

- Certifications: ISO 9001, ISO 13485, FDA,TISAX

GKN Additive Forecast 3D

Every day at manufacturing locations around the world, GNK Additive Forecast 3D combines powder metals with innovative production technologies to create unique metal products and they want to be your production partner.

GKN offers a range of polymer 3D printing solutions, but its heart is in metal since they are a division of GKN Hoeganaes, a global metal powder manufacturer and metal powder developer for a range of industries founded in 1953. GKN Additive, as a metal manufacturing solution, serves the automotive, industrial, aerospace, electronics, and consumer industries.

Technical specifications

- Material: AlSi10Mg, AlSi7Mg0.5

- Method: Laser Powder Bed Fusion

- Certifications: ISO 14001:2015, ISO 50001:2018, ISO 45001:2018, IATF 16949:2016

Oerlikon AM

Oerlikon AM is a division of the Swiss technology giant OC Oerlikon that was set up in 2016. They have production centers in Europe, the U.S., and China. From these three centers, Oerlikon is able to serve customers on all continents.

In materials, Oerlikon relies entirely on its alloy powders, developed in-house, including aluminums. The on-site material production allows them to even create customized materials for their customers. They’re also able to provide in-depth engineering and design consulting from concepts to production, in addition to post-processing and testing services.

With their extensive experience in additive manufacturing and focus on demanding industries – like aerospace and automotive – Oerlikon has a narrower service scope than some other providers. That’s not a bad thing, though – they know exactly what they’re good at and are making the most out of it.

Oerlikon prints on Concept Laser, EOS, Renishaw, and Trumpf LPBF 3D printers.

Technical specifications

- Material: AlSi9Cu3(EU), AlSi7Mg(EU), AlSi10Mg, AlMgSc (Scalmalloy), 6061 RAM 2(US), A205(US)

- Method: Laser Powder Bed Fusion

- Maximum part dimensions: 400 x 400 x 380 mm

- Certifications: ISO 9001, ITAR

Burloak Technologies

Focusing more on part development than most on our list, US-based Burloak boasts a team of engineers that not only designs for additive manufacturing but also has expertise in aerospace manufacturing, propulsion, thermal management, tooling, and molding. In fact, Burloak, a division of Samuel, Son & Co., works with Boeing to additively manufacture aluminum alloy components to the Boeing BAC 5673 specification. Samuel is one of the largest processors and distributors of aluminum products in North America.

The company’s approach is to deliver an engineering team that can work alongside yours, helping you understand the intricacies of AM as it may apply to your specific project and, in some cases, completely manage the product development.

From rapid prototyping in plastic to full-scale production in metal, Burloak Technologies also provides materials development, high-precision CNC machining, post-processing, and metrology.

Technical specifications

- Material: Aluminum A205

- Method: Laser Powder Bed Fusion

- Certifications: ISO 9011, ISO 17025, AS 9100, ITAR

Addman

A relative newcomer to 3D printing as a service, Addman, founded in 2020, seems to have jumped in with both feet, acquiring a stable of existing additive and traditional contract manufacturing companies to quickly build up its machine inventory and service menu. The Florida-based company offers metal and polymer 3D printing, CNC machining, and other post-processing at six facilities across the US.

When it comes to applications and industries served, Addman says it covers aerospace, medical, energy, and industrial and produces everything from rocket thrusters to tooling to mission-critical hinges. They’ll even send you a free part sample.

The company’s metal 3D printing is carried out on an enviable collection of the industry’s top laser powder bed fusion printers, including a Velo3D Sapphire, a collection of EOSs, and machines from 3D Systems, GE Additive, and Renishaw. Engineers on staff can guide you to the right machine, materials, and post-processing for your application. In fact, the engineering consultancy can start with your part requirements and develop your part’s application-specific design, material, and manufacturing process.

Technical specifications

- Material: AlSi10Mg

- Method: Laser Powder Bed Fusion

- Certifications: ISO 9001:2015, AS9100D, ITAR, ISO 13485:2016, ISO 14001:2015, SEP: ISO 50001

RapidObject

When Germany-based RapidObject launched in 2006, it was the first online shop to offer 3D printing to a global customer base. The service was ahead of its time nearly 15 years ago and is still doing strong.

RapidObject has a fascinating material range. In addition to polymers and PolyJet, the company offers a range of metals, including aluminum. It even offers a express service for its aluminum parts promising a two-day turnaround in the EU for small parts.

RapidObject shines in particular with its additional services. The company offers CAD design, 3D modeling and scanning, component consolidation and optimization, consulting, and education services.

Technical specifications

- Material: AlSi10Mg

- Method: Laser Powder Bed Fusion

- Maximum part dimensions: 360 x 280 x 280 mm

- Layer height: 0.02 mm

Lead Photo Alumium 3D printed Parts: Top left: In3DTech, right: Desktop Metal, bottom left: Materialise, center two small objects: RapidObject.

Lead image source: Shapeways

License: The text of "9 Aluminum 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.