When 3D printing went desktop-sized, a downright revolution in the small-scale manufacturing sector followed. Hobbyists, designers, and machine shops alike were suddenly offered a low-cost tool with which to produce prototypes and parts without lengthy lead times. But while 3D printing offers unprecedented speed and flexibility from concept to part as well as improved design complexity, most sub-$10k machines still struggle to compete with conventional manufacturing in terms of production volume, material properties, and price per part.

Desktop injection molding could now potentially fill this gap between small and large production scale by offering relatively cheap machines that find room on anyone’s desktop or workbench. APSX for example says that its small but mighty desktop injection molder can push out up to one million parts annually.

In this article, we take a look at all the relevant information regarding injection molding and answer questions about how you might benefit from investing in the technology on the desktop level. We’ll show you some successful applications and provide a selection of available desktop and benchtop machines to get you up and running in no time.

Just a few words of caution before we dive in – there are lots of small injection molding machines offered on various e-commerce platforms, however often with little to no information beyond the asking price. With buyer’s confidence in mind, the products we have included in this article all come with a solid web presence including homepages, manuals, technical documentation, and support channels.

| Model | Injection Type | Shot Size | Maximum Temperature | Injection Pressure | Market Price |

|---|---|---|---|---|---|

| LNS Technologies Model 150A | Manual | 1.1 in³/ 18 g | 500 °F/ 260 °C | - | $2,200 |

| Robot Factory Benchtop Injection Molding | Pneumatic | 32 cm³ | 660 °F/ 350 °C | 1870 N at 0.6 Mpa | $2,300 |

| HoliMaker HoliPress | Manual | 16 cm³ & 38 cm³ | 660 °F/ 350 °C | - | ~$3,500 |

| Galomb Model B-100 | Manual | 1.0 in³ / 16 g | 600 °F/ 315 °C | - | $4,500 |

| Manning Innovations Proto-Ject 150HP | Pneumatic | 1.5 oz/ ~42 g | 800 °F/ 427 °C | 9300 psi/ 641 bar | $6,000 |

| APSX - PIM | Electric | 1.83 in³/ 30 cm³ | 600 °F/ 315 °C | 5000 psi/ 345 bar | $13,500 |

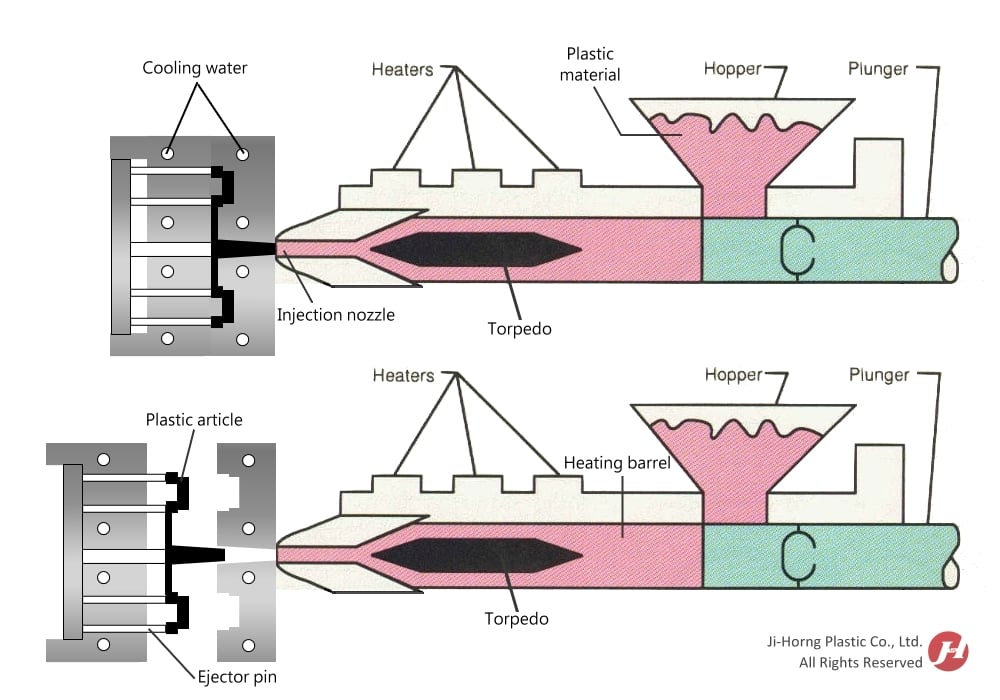

What is Injection Molding?

- Temperature: The temperature range determines which materials can be used on your machine. Quite simply, if your chosen material stays below its melting point because your machine won’t get hot enough, it won’t inject. If you are using a temperature that is too high, it will lead to quality defects and degradation of the plastic.

- Injection pressure: As the molten plastic travels through the mold, it cools down and solidifies. The higher the injection pressure, the higher the chances that plastic will be pushed to even those hard-to-reach cavities like channels and thin walls. This is where benchtop machines are quite limited compared to their industrial counterparts and molding success depends highly on the size and complexity of the mold. The available clamping force is another metric to consider, as larger parts need higher pressure to stay together.

- Shot Size: The main size limitation for molds is defined by shot size, the amount of plastic that can be held in the heating element. For desktop machines, this typically doesn’t exceed 50 grams, so any geometry larger than that is simply not possible. Additionally, the shot size should be at least 1.5 times the part size since most benchtop machines use a plunger for injection. Some plastic will travel up through the unmelted pellets in the chamber to heat up the next material and let air escape. In theory, shooting the entire volume of the heating element is possible, but severely impacts cycle times and subsequent part quality.

- Usability: This is a more general area of concern, but can greatly impact your experience with the process. Leaking, molten plastic can be a cleaning chore at best and a dangerous projectile at worst, so make sure you take built quality and safety features into consideration. As is often the case, the price is a good indicator of what sort of machine you can expect. Also, if you plan to get as close to a continuous production process as possible, features like automatic part ejection are a must but will come at an extra cost.

Additionally, injection molding is considered the gold standard when it comes to plastics manufacturing, offering a wide range of cheap stock materials with great physical properties that your printer might not be able to match. Even cheap desktop injection molding machines are generally capable of processing polypropylene, polystyrene, TPU, PET, ABS, and yes, even your failed PLA prints.

Because injection-molded parts don’t face the same layer-adhesion challenges, they are generally stronger than 3D printed parts made from the same material, keeping in mind that we’re talking about sub-$10K machines, both 3D printers and injection molders. Still, injection molding is not set out to replace 3D printers – on the contrary, its success is partly explained as a direct consequence of 3D printing’s success.

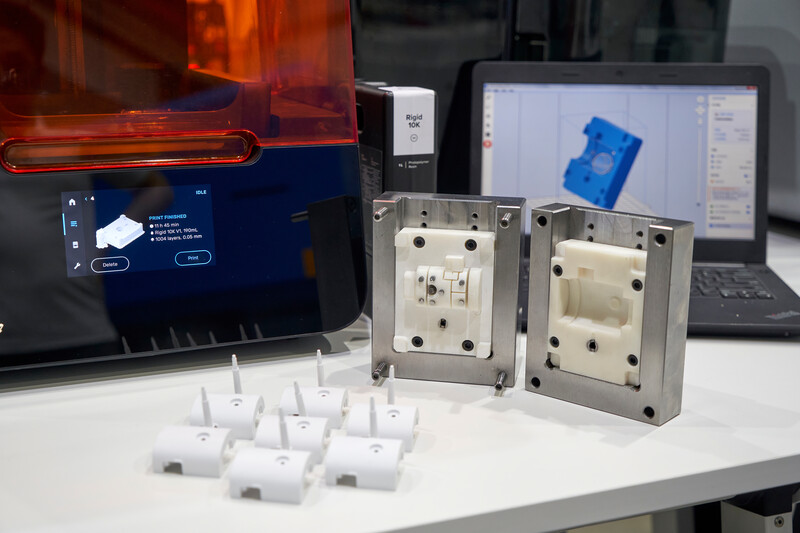

With the material qualities of resins constantly improving, people started 3D printing injection molds that would withstand anywhere from a couple to a couple of hundred shot cycles. Injection mold production therefore no longer necessitates CNC machining knowledge and expensive equipment but can be done with a much cheaper and easier-to-handle resin 3D printer.

Therefore, where the technology really shifts into a higher gear is when combined with 3D printing. Many companies like Formlabs offer temperature-resistant materials like the High Temp, Grey Pro, or Rigid 10K resins that can temporarily withstand the high heat and pressure of low-volume injection molding.

A 3D printed injection mold comes with its own design considerations and will not replace machined aluminum or steel in terms of surface finish and longevity, so having a CNC machine on hand will still greatly improve your experience. Luckily, the CNC world is witnessing a similar miniaturization trend with affordable unit prices for any maker or small engineering shop.

Desktop & Benchtop Injection Molding Machines

Hydraulic injection is the standard for industrial machines as it generates by far the highest forces but is only found in the most expensive desktop models like the Babyplast 6/12. These pricey machines are more suitable for labs or medical device manufacturing plants producing specialty applications.

If the machines on this list are blowing the budget or you’re up for the challenge of building an injection molding system yourself, make sure to also check out our guide on the Best DIY Desktop Injection Molding Machines.

LNS Technologies Model 150A

LNS Technologies offers a great, no-frills injection molding machine. Based on a simple manual press, this machine has a relatively small shot size of 1.1 in³. While that’s not a huge amount, 1 cubic inch is fairly standard when it comes to hobby-level injection molding. With a simple vice to hold your aluminum mold, the machine can accommodate a maximum mold size of 8″ x 5″ x 5″. The machine is also compatible with resin-printed molds, as well as epoxy molds.

LNS Technologies also sells a number of pre-machined molds for items like keychains and fishing lures. In terms of plastics, they stock PP, LDPE, ABS, and TPE in various colors.

- Injection type: Manual

- Shot size: 1.1 in³ / 18 g

- Maximum temperature: 500°F/ 260°C

- Injection Pressure: –

- Cost: $2,200

- Where to find it: LNS Technologies

Robot Factory Benchtop Injection Molding

Robot Factory is all about small-scale serial production with its own selection of conveyor belt-type 3D printers and modification kits as well as thermoforming machines. Their latest addition to the portfolio, the “Benchtop Injection Molding”, further expands the company’s plastics processing technology offering.

While a manual version is available upon request, the standard machine comes with a Ø63 mm pneumatic piston that has an optimal operating range between 0.6 and 0.8 Mpa. The base model will set you back roughly $1,600. Depending on the chosen vice (manual, mechanical, pneumatic), that price can go up by an additional $540.

Be aware that a compressed air generator is needed to operate the machine. The company recommends a 50-liter compressor that reaches at least 6 bars of pressure.

Consumables, like a large selection of plastic pellets and raw aluminum molds, are also offered by the Italian company, with custom aluminum mold production possible upon request.

- Injection type: Pneumatic

- Shot size: 32 cm³

- Maximum temperature: 660 °F/ 350 °C

- Injection Pressure: 0.8 Mpa

- Cost: ~$1,600

- Where to find it: Robot Factory

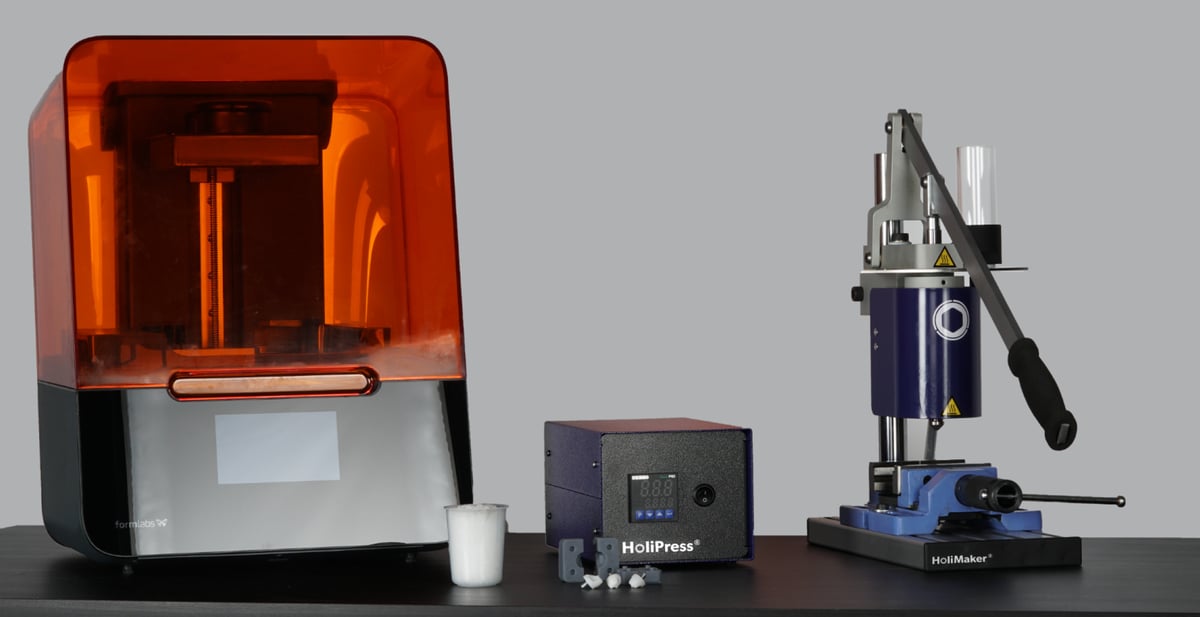

HoliMaker HoliPress

French company HoliMaker claims that their manually operated system, the HoliPress, is up to 20 times faster than FDM 3D printing “with your manual strength,” which clearly depends on how fast you can hustle. Maximum output is 1 piece every 3-5 minutes, the company says.

HoliPress comes in two sizes; an injection volume of 16 cm³ and an injection volume of 38 cm³ and has enough room for molds as tall as 190 mm. Compatible polymers include PP, PEDH, LDPE, PLA, PS, PA, TPU, PUM, ABS, and PMMA.

The HoliMaker also offers the HoliShred ($850) for manual plastics pellet production from plastic waste like water bottles and caps. Since PLA and ABS are also listed as processable with the HoliPress, the same goes for old or failed 3D prints that can then be turned into new products rather than landfill waste.

- Injection type: Manual

- Shot size: 16 cm³

- Maximum temperature: 660 °F/ 350 °C

- Injection Pressure: –

- Cost: ~$3,500

- Where to find it: HoliMaker

Galomb Model B-100

For those who are looking for a sturdy manual injection molding machine, the made-in-America Galomb B-100 is a solid choice. Although the design is relatively similar to the LNS 150A, the Galomb B-100 is made using a solid cast iron frame that you bolt to your benchtop. There’s also a non-stick coating on the injection plunger and an included cleaning kit.

This machine is capable of reaching temperatures of up to 315°C, which opens up the possibility to work with more demanding materials such as nylon and PET.

Galomb has a variety of resources for the DIY injection molding enthusiast on their website, with several pre-made molds available.

Galomb also offers the S-100 model, which is exactly the same as the B-100 except for larger capacity tube sized.

- Injection type: Manual

- Shot size: 1.0 in³ / 16 g

- Maximum temperature: 600 °F (~315 °C)

- Injection Pressure: –

- Cost: $4,200

- Where to find it: Galomb

Manning Innovations Proto-Ject 150HP

The Proto-Ject 150HP (High Pressure) by Manning Innovations is a considerable step up when it comes to injection pressure. At 9300 psi and a maximum operating temperature of 800 °F, the machine is well-suited for higher molecular weight materials and thus offers a wide material selection for processing. Depending on the material, clamping pressure needs to be considered, as the machine comes in a 10, 15, 25, or 40-ton configuration. This metric also defines achievable maximum dimensions of a part, as mold surface area is limited to available clamping pressure.

Prices for Proto-Ject machines start at $6,000, but add-ons and specialty configurations can pile up to reach $10,000 and higher, so at this price tag you should have a clear idea of what you want to manufacture. Keep in mind also that this unit is not fully automatable.

For the Proto-Ject 150, Manning Innovations recommends an air compressor of at least 15 gallons capacity with a maximum tank pressure of 175 psi or higher.

- Injection type: Pneumatic

- Shot size: 1.5 oz/ ~42 g

- Maximum temperature: 800 °F/ ~ 427 °C

- Injection Pressure: 9300 psi/ 641 bar

- Cost: $6,000

- Where to find it: Manning Innovations

APSX - PIM

The illustrious-sounding APSX-PIM is an industrial-grade automatic unit that offers a massive number of configurable options to optimize your production line.

Capable of both full-cycle production as well as manual operation, the APSX-PIM works entirely through electric motors, eliminating the need for additional air compressors. On the downside, this means that generated forces are not as high as pneumatic or hydraulic systems but are still impressive at 5,000 psi injection pressure and a 5-ton clamping force.

Coming in at $13,500, this heavy-duty machine is far from cheap, but it’s the best tool for 24/7 continuous parts manufacturing and offers the highest degree of parameter controls for process optimization. Molds that include ejector mechanisms are more challenging to build though, so smaller production runs might still make more sense to be done via manual part ejection. APSX has sold thousands of these little powerhouses worldwide.

- Injection type: Electric

- Shot size: 1.83 in³/ 30 cm³

- Maximum temperature: 600 °F/ 315 °C

- Injection Pressure: 5000 psi/ 345 bar

- Cost: $13,500

- Where to find it: APSX

License: The text of "The Best Desktop Injection Molding Machines" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.