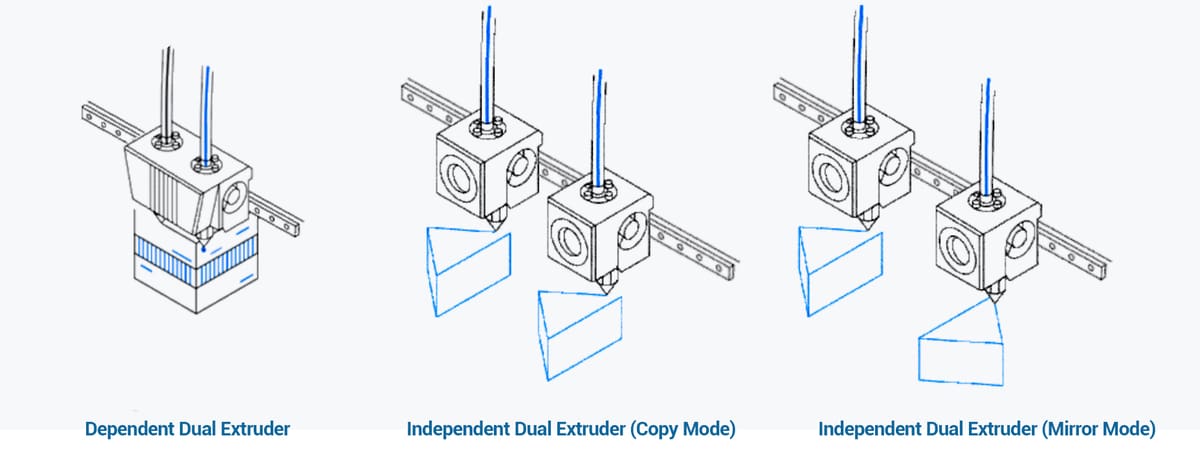

Dual nozzles on your extruder head (also called a dual extruder) are great for printing a support material alongside your part’s base material, but think what you could do with two separate extruders that could print two parts at the same time. 3D printers with these independent extruders are called, not surprisingly, independent dual extruders or IDEX or short.

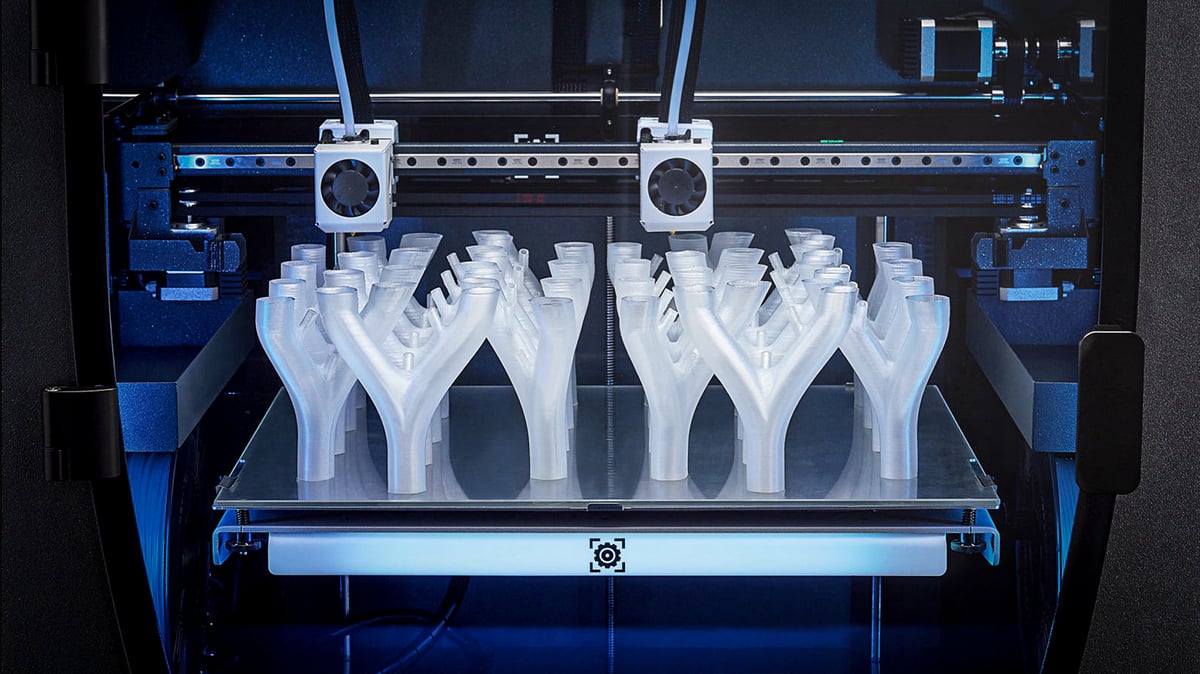

IDEX essentially doubles the capacity of your machine. It enables you to print two parts at once, side by side. There are even machines with quad-extruders capable of printing four parts at once. So if you’re considering buying two printers to manage your production volume fast, you could consider just buying one IDEX printer, but there are even more advantages to IDEX.

Let’s take a look at the different types of dual extruders and the features of the top machines.

| Printer | Build Volume in mm | Price | Max Extruder Temp |

|---|---|---|---|

| Craftbot Flow IDEX XL | 425 x 250 x 500 | $3,200 | 300ºC |

| Tumaker NX Pro Dual | 295 x 200 x 200 | $5,500 | 300°C |

| BCN3D Epsilon W50 | 420 x 300 x 400 | $8,500 | 300°C |

| Sindoh 3DWOX 7X | 370 x 390 x 450 | $10,000 | 180°C |

| Flashforge Creator 4 | 400 x 350 x 500 | $12,000 | 360℃ |

| Aon3D Hylo | 450 x 450 x 640 | $49,999 | 500°C |

| Essentium HSE 280i HT | 695 x 495 x 600 | ~$185,000 | 550°C |

IDEX Pros & Cons

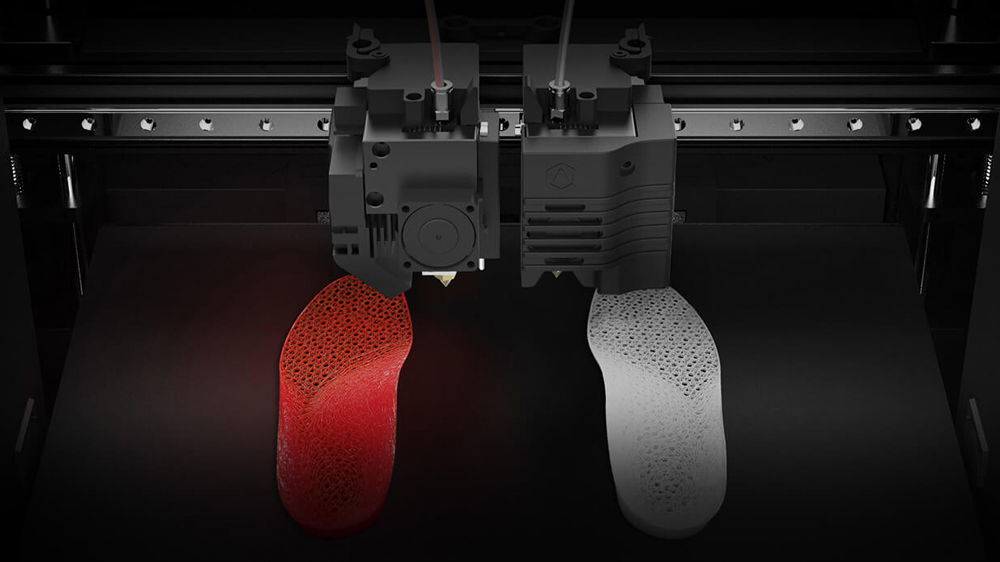

IDEX means a single printer can act like two smaller printers each printing the same thing at the same time (copy mode) or each extruder can be programmed to print different parts at the same time (mirror mode) with some limitations. For example, one extruder can print a left shoe sole model while the other prints a right shoe sole model. They can not print two completely different shapes where one extruder is waiting for the other extruder to finish a layer before moving up on the Z axis since that could cause previous laters to cool resulting in part defects.

IDEX Pros

- Enables multi-material

- Enables multi-color

- Enables two (or more) nozzle temperatures

- Enables two (or more) nozzle diameters

- Doubles the throughput of your 3D printer

- Enables 3D printing two different parts at once (as long as they are identical or mirrors of each other)

- Faster multi-material printing than with filament-changers

IDEX Cons

- Extra effort for manual calibration, extra time for auto-calibration

- Requires IDEX-compatible slicer software (there’s a plug-in for Cura)

You can also achieve 3D printing with two different nozzle sizes at once with some printers that have swappable nozzles inside their dual printhead, like the UltiMaker dual printhead pictured above.

IDEX 3D printer makers boast that their multi-material printing is more accurate than dual extruders and eliminates the stringing or accidental mixing of materials that can happen on some machines. This is sought after for more complex shapes that require internal soluble support material.

“True” IDEX

IDEX has variations. Another type of IDEX features extruders that are independent on both the X and Y axis. There is currently only one printer with this feature, the Essentium HSE (high-speed extrusion) 280i HT. On this machine, the independent extruders are not joined on the same gantry and can move separately along the X and Y axis (but not up and down on the Z axis). Essentium calls this “true” IDEX and it enables you to print two completely different parts with different materials on one platform, increasing your machine’s throughput. Of course, it can also print one part with multiple materials, or base materials and soluble supports.

Although there have been (and still are) some multi-extruder printers on the market featuring three or more extruders, it’s an attribute mostly used for different colors of filament that has yet to find a strong following.

IDEX Software

Most of the 3D printers below ship with their own slicers to manage the independent dual extrusion, but there’s also an IDEX plug-in for Cura. Simplify3D 5.0 just launched with a new support for IDEX motion systems.

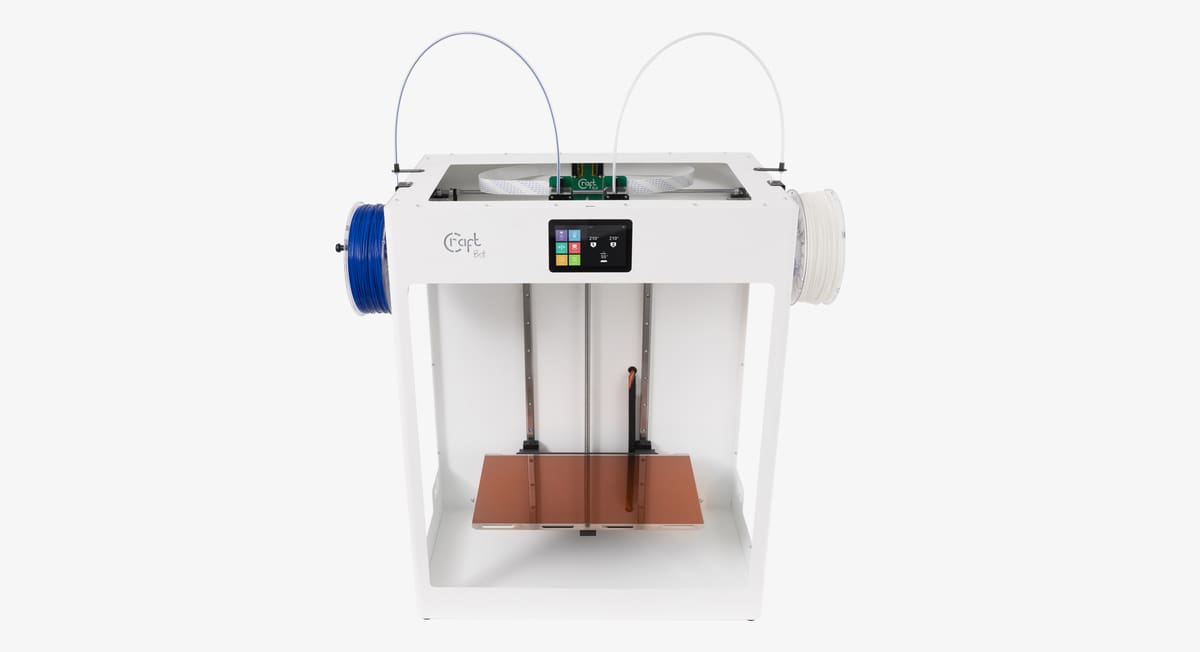

Craftbot Flow IDEX XL

The Craftbot’s Flow IDEX XL is the company’s largest dual extruder and features a heated bed (up to 110°C) made of either metal, tempered glass, or Kapton for easy part removal. You can print with multiple materials and soluble supports, or print two objects at the same time in mirror or parallel mode.

The two direct-drive all-metal hotends – capable of heating up to 300°C – can handle industrial-grade materials, including nylon and carbon fiber-reinforced composites, allowing the printer to be used in a wide range of applications.

Although not included with the base model, Craftbot sells acrylic enclosures for the Flow IDEX XL separately. In case you plan on using temperature-sensitive materials, an enclosed printing chamber can provide ambient conditions that will greatly enhance the printer’s performance with said materials.

The Cratfbot Flow IDEX XL 3D printers come integrated with the proprietary slicing software, CraftWare. It works on Windows, Mac OS, and Linux operating systems. The built-in camera and filament monitoring sensor keep failed print waste to a minimum.

Craftbot also offers a slightly smaller version called the Craftbot FLOW IDEX that sells for about $1,000 less.

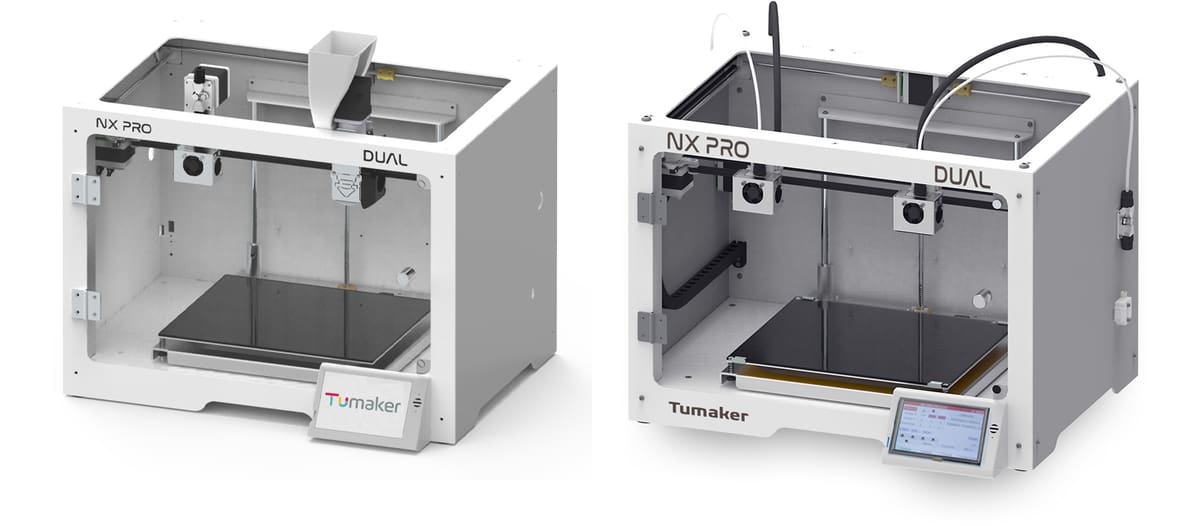

Tumaker NX Pro Dual

Tumaker has a long track record of developing specific printheads for specific needs. Its Pro Dual range of IDEX 3D printers enables you to choose the printheads you want on your printer to customize it for the types of materials you’ll be using, even mixing filament with pellet materials.

Although lacking a heated chamber, the nozzle temps peak at 300°C and the bed gets to 120°C so it can handle some engineering-grade materials. Where it shines is the pellet compatibility. With some add-ons, you can print with material in economical pellet form and mix your pellets in the feed hopper.

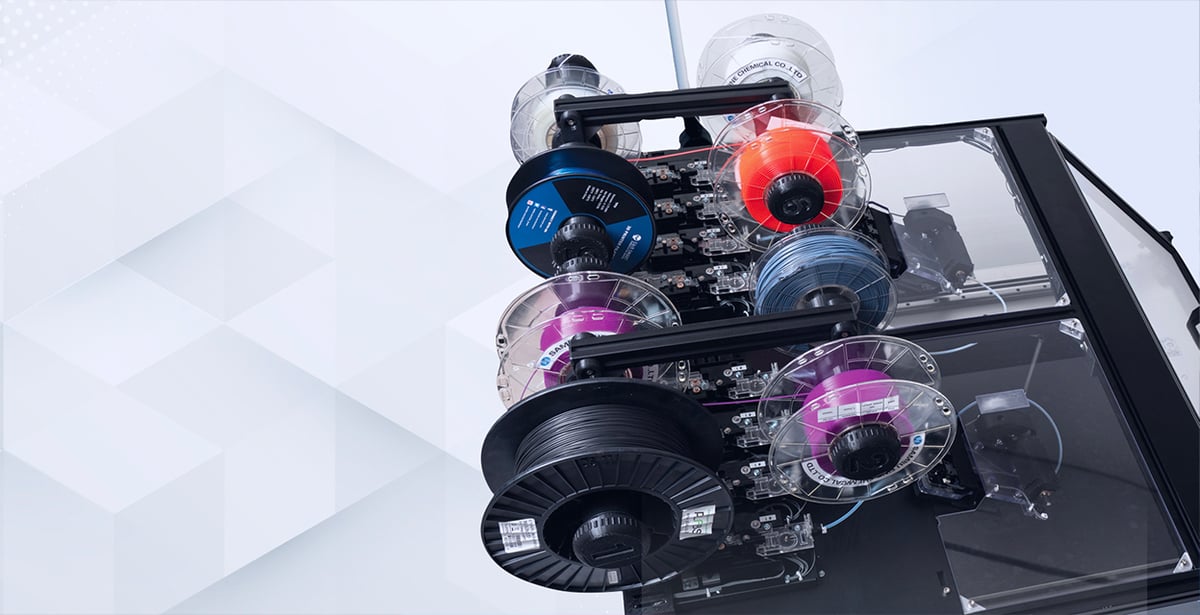

Definitely unique among the dual extrusion 3D printers on the market is Tumaker’s Pro 4 Extruders. The 4-head machine makes it possible to 3D print with up to 4 pellet extruders, 4 filaments, or a combination of both at the same time. Create parts with four materials or print four unique parts simultaneously.

Every extruder combination comes available with Wi-Fi connectivity, a five-inch touchscreen, a filament runout sensor, and a 32-bit processor. Tumaker comes with proprietary slicing software to configure printing with dual or quad extruders.

BCN3D Epsilon W50

BCN3D only makes IDEX printers, which currently come in three models: Epsilon W50, Epsilon W27, and the new Omega 160 for industrial high-temperature 3D printing.

The BCN3D Epsilon W50 is designed to deliver large-scale parts with materials ranging from PLA and TPU to PP and nylon. It features a passively heated chamber (up to 60°C) and a heated bed reaching up to 120°C. However two upgrade kits, the Fiber Kit and the Metal Kit, include specially designed hotends and accessories that enable printing with fiber-filled and metal-filled filaments such as PP glass fiber 30, PAHT carbon fiber 15, 316L stainless steel, and 17-4 PH stainless steel.

Built like a tank and featuring a pleasant to use UI, calibration setup, and customized flavor of Cura for easy-to-manage dual extrusion prints, it’s perhaps one of the more user-friendly dual extrusion 3D printers to make this list.

The HEPA and carbon filters on the unit shield your environment from any potentially harmful fumes produced by the materials used. The Epsilon W50 and Epsilon W27 can be paired with the new Hotend X, designed to print seamlessly with fiber-filled materials. This enables printing sturdier parts for the most demanding applications.

The connectivity of the BCN3D Cloud lets you directly send print jobs from anywhere and monitor a group of printers even if they are placed in different locations, and easily share your printer with other teammates. Managing the IDEX printing is the company’s Stratos software.

Sindoh 3DWOX 7X

Sindoh offers a range of 3D printers spanning three technologies. For extrusion printing, the 3DWOX 7X is a professional IDEX 3D printer that enables you to mix two colors or two materials for a wide variety of applications. As an open material platform, you can print with nearly any third-party filament in the extruders’ temperature range.

The 3DWOX 7X features automatic bed leveling, HEPA filters, and a newly-designed removable bedplate. Additional features include Ethernet and Wi-Fi connectivity, a voice-based user guide, and filament print cartridges. With an integrated camera and LED light, monitor your print from an app on your phone or tablet. The 7X runs on the 3DWOX desktop slicer.

However, the larger 3DWOX 30X (740 x 490 x 150 mm) combines IDEX printing with a material changer that holds 8 spools.

Flashforge Creator 4

Flashforge made a leap into professional machines with the launch of the high-temperature IDEX Creator 4.

Designed with three extruder options, the Creator 4 can print with flexible filaments, engineering filaments, and carbon fiber composite filaments. With a generous build size, the Creator 4 features a thermal-control chamber that stays at 65°C, a temperature that reduces product shrinkage and ensures better printout quality, the company says. The printer’s software offers users greater flexibility to configure internal temperature controls, to further customize filament specifications, and to pause print jobs in the event of power outages. Ideal applications for the Creator 4 include customized prints of tools, jigs, fixtures, and production parts and equipment.

The extruder temperate peeks at 360℃ to handle nylon, carbon fiber infused, and PC. There’s a built-in camera with remote control and an optional filament dryer.

Aon3D Hylo

Just launched in Nov. 2023, Aon3D launched its new flagship IDEX FDM, Hylo powered by new “machine learning-driven software” called Basis that enables you to slice, simulate, optimize, then print.

Hylo, which replaces the company’s M2 and M2+ machines, is designed for a range of applications including tooling, jigs and fixtures, end-use parts, and rapid prototyping using high-performance thermoplastics. It features an open-material environment, so it’s compatible with a wide range of material brands, including Solvay, Sabic, DSM, Infinite Material Solutions, and others, and comes with validated print profiles for them.

In addition to open materials, there’s open parameters so you can fine tune various processes, temperatures, and motion settings.

The Hylo has more than 25 integrated sensors for automated calibration, process control, and monitoring the print process to validate parts as they print. After printing, you can review the various data points of your as-printed part with its digital twin.

Basis also manages and monitors all of your Aon3D printers, projects, users, revisions, optimizations, and as-printed part data in one user interface.

Aon3D says its software replaces trial and error printing with AI-driven process simulation and digital file optimization. Basis can simulate the Hylo printing process, enabling you to identify and correct issues before ever hitting print.

Essentium HSE 280i HT

The industrial-grade, high-temperature HSE (high-speed extrusion) 280i HT from US-based Essentium is aimed at high-volume factory customers. In fact, Essentium CEO Blake Teipel told All3DP that the machine is “designed to be a true manufacturing system” with innovations that will underpin most of the company’s future growth.

The printer’s independent dual extruders are actually independent on both the Y and X-axis. This “true” IDEX, as the company calls it, enables the printer to create different parts at once, not just mirror or duplicate parts.

As an open-material printer, the HSE 280i HT offers application flexibility and can print with materials including PEEK, TPU, and nylon, and materials from other companies.

Essentium’s slightly smaller dual extruder is the HSE 240 HT, which features a dependent dual extrusion print head.

Lead image source: The Tumaker Pro 4 Extruders

License: The text of "The Best Independent Dual Extruder (IDEX) 3D Printers" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.