With hundreds, of 3D printing services out there, how do you choose the right one? We aim to help by uncovering the top providers’ specialities, material menu, 3D printing technologies, and how their prices are calculated. Plus, we put their ordering system to the test by requesting plastic and metal parts.

Even if you know nothing about 3D printing, you can order parts 3D printed. Many services can either help you turn your napkin-sketch-idea into a physical object or shephard your project from digital file to final part by providing material and process advice. However, most of the services below assume a basic knowledge of the various 3D printing technologies and materials since you’ll need to select both from a list of options.

What You Need to Know Before Getting Started

If you’re already familiar with 3D printing technology, these online platforms require just a few clicks to deliver your finished parts in days (or less). If you don’t know FDM for SLS, or want to learn more about how services where and how to pick the right one from your project, check out these special sections below:

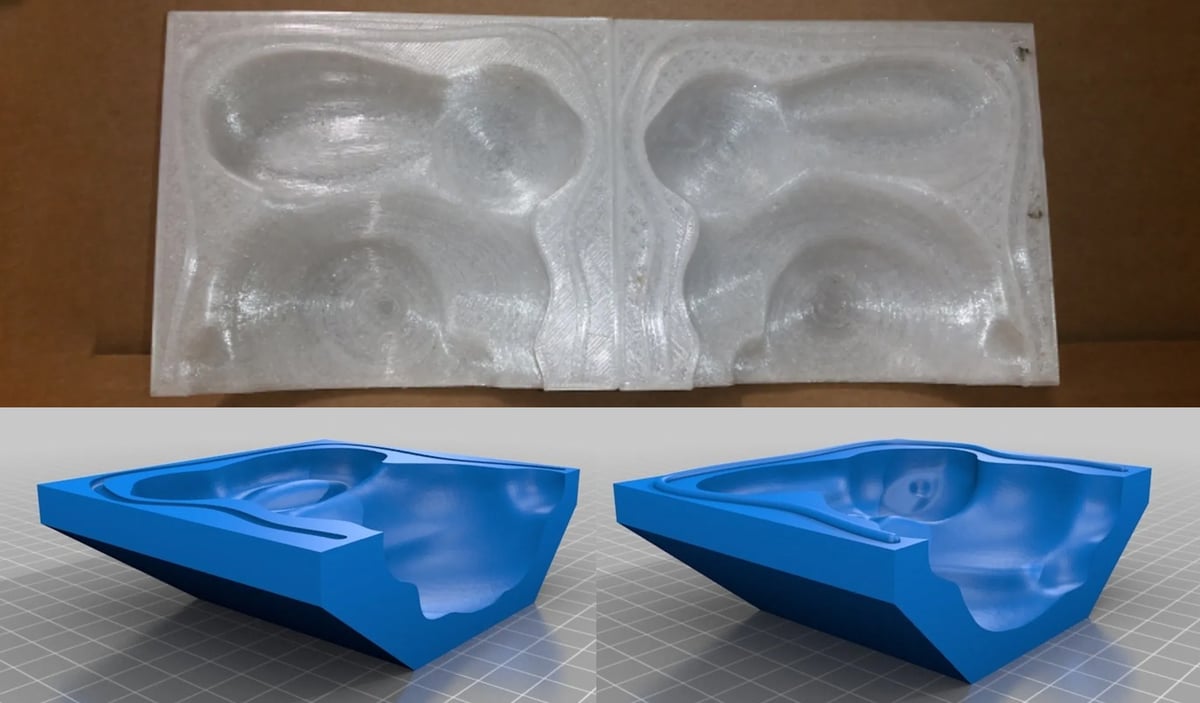

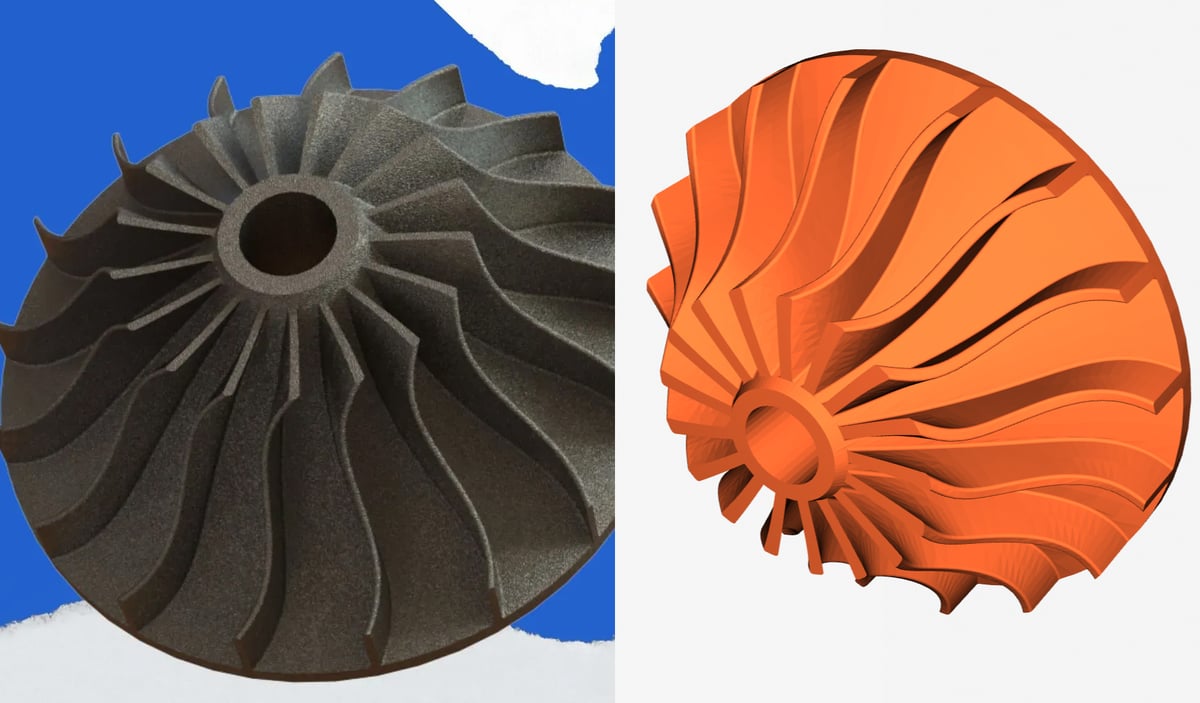

Put to the Test

To give you a sense of how these 3D printing services compare in terms of price we uploaded three parts to each one. We did not have all of these parts actually printed and delivered; that would have been highly wasteful, but going through the ordering process did reveal a lot about how these platforms function and the amount of knowledge you’ll need to have about 3D printing to get the part you need.

All prices were calculated on January 15, 2024 and do not include shipping.

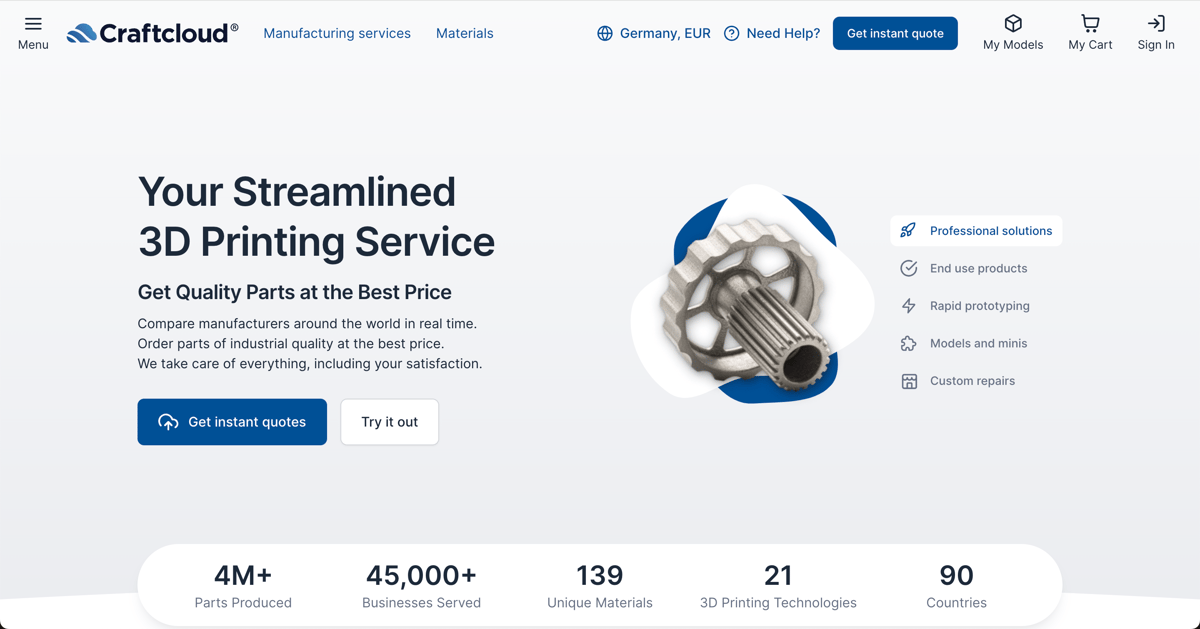

Craftcloud

Craftcloud is a 3D printing service that helps you find the best manufacturer to 3D print your parts and also handles the complete order for you. An instant comparison of the manufacturer’s offers makes it easy to get the best price. With a Trustpilot rating of “excellent” from over 1500 users, most customers are very satisfied.

Craftcloud partners with well-known manufacturers, such as Shapeways, Materialise, and Sculpteo, who have years of experience and serve many 3D printing networks, along with specialty manufacturers vetted for quality.

Once you have uploaded your 3D files, you can choose from countless materials, finishes, and colors. Unlike most other providers, you receive an instant quote without having to register first.

Their network includes over 150 select vetted contract manufacturers offering over 140 materials. You can choose the cheapest, the fastest, or the manufacturer with the best combination of these characteristics.

Unlike some other manufacturing networks, Craftcloud discloses the prices of each partner, and you choose the one that best fits your criteria. Still, Craftcloud takes care of the entire process from order to delivery to ensure your parts are printed and shipped to your satisfaction, all with no additional fees and no minimum order value.

New materials are added regularly, and Craftcloud recently expanded its services to CNC milling, sheet metal fabrication, and casting & molding services.

If you need help designing a 3D model, take advantage of Craftcloud’s CADmore partner offer, which is on-demand design services.

With Craftcloud, you can affordably get the full spectrum of services from design to doorstep delivery on a user-friendly platform with customer support.

Disclosure: Craftcloud and All3DP.com are different divisions of the same parent company.

What we like: Craftcloud is best for quality 3D prints at very competitive prices, combined with a user-friendly ordering process.

Website: craftcloud3d.com

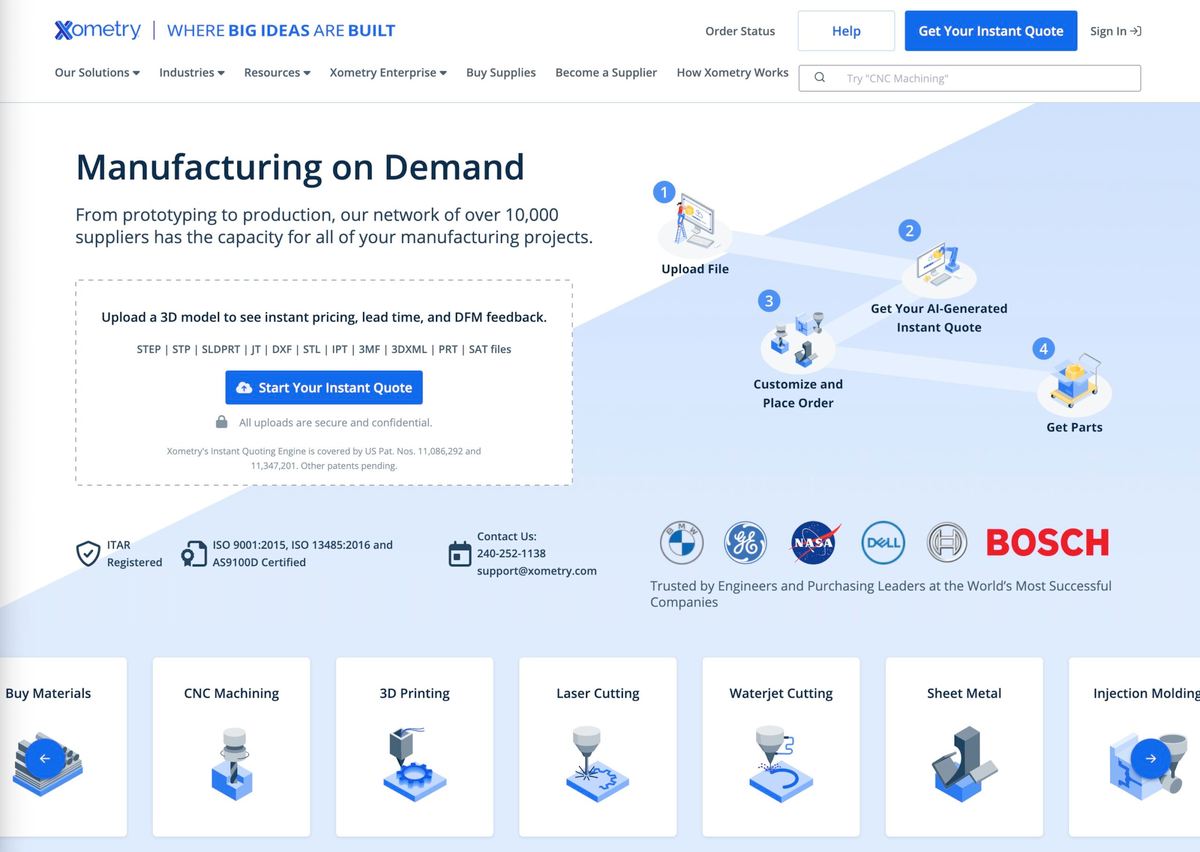

Xometry

Founded in 2013, Xometry has grown into the world’s largest online 3D printing service. Utilizing a nationwide network of manufacturing partners across the US, Xometry offers instant quotes that can be filtered by production method, material, and lead time. Serving clients that include Fortune 500 companies, Xometry efficiently connects those in need of custom parts with workshops seeking to streamline their inquiries and avoid unproductive leads.

Registration is mandatory if you want to use Xometry. Though it may be a bit overwhelming for regular consumers ordering a print, for business clients, Xometry’s features leave nothing to be desired. We think their Instant Quoting Engine is clearly geared towards industrial clients. It comes with a printability check and various part certifications. We found the order process to be straightforward.

In addition to 3D printing services, Xometry users can have CNC machined parts wrought from sheet metal or buy injection molded parts in bigger batches. They offer supply-chain solutions and high-volume production, too.

Xometry utilizes a vast network of manufacturing partners to offer instant quotes that can be filtered by production method, material, and lead time. This system effectively links companies needing custom parts with workshops seeking to streamline their operations and avoid unproductive inquiries.

What we like: Because Xometry is a manufacturing service that also offers 3D printing, it’s a great way to compare the price and turn-around time of 3D printing your part to, say, injection molding it.

Website: xometry.com

Protolabs (Network)

Protolabs Networks started out as Hubs, which was a 3D printing network facilitated by local enthusiasts and the occasional professional. Today, the company has its own production facilities and a network of partners offering additional services. The company offers a wide array of manufacturing processes ranging from 3D printing to CNC machining, injection molding, and sheet metal fabrication.

Prices are dynamically updated based on material and location and specified alongside turnaround times, filling you in on important variables in their purchase decisions. A minimum order value surcharge for smaller orders makes the service less interesting for consumers or single-item orders.

What we like: A broad array of local manufacturers, plus added services for professional clients is the main draw. There’s also a nice offering of post-printing surface finishes, like polishing, available.

Website: hubs.com

Sculpteo

Focusing on the professional manufacturer more so than consumers or small businesses, Sculpteo (owned by German chemical giant BASF) is a smart choice if you know exactly which technology and material your project requires.

Like other 3D printing service platforms, you can upload your 3D model and select your materials and quantity. Sculpteo offers a handy “printability” check to your digital files that we like since it can point out problems before your order goes to production. There’s also a “Solidity Check” to ensure fragile elements of your print won’t break during production.

When we put Sculpteo’s ordering engine to the test it turned out to be fast and robust.

Sculpteo’s suite of professional services positions it as a comprehensive partner for tasks such as batch production, prototyping, and design validation.

It’s also worth noting that Sculpteo’s 3D printing service can be accessed through Craftcloud.

What we like: Sculpteo’s strength is its materials. As part of BASF, you’re assured of BASF 3D printing materials including its popular carbon-fiber nylon and engineering-grade resins.

Website: Sculpteo.com

Materialise OnSite

Materialise is a Belgium-based company with offices and facilities in the US. Its services are broken out into a few different manufacturing arms, which makes it a bit difficult to navigate which one you might need. The likely reason behind this lack of ease-of-use is the massive range of what Materialise can print. From its healthcare wing, which prints human surgical guides and implants like jaw bone replacement, to its aerospace division that can fabricate certified-to-fly parts, to its quick self-service prototyping service called i.materialise, if Materialise can’t print it, no one can.

One of the strengths of Materialise is the design and consultancy services it provides to its business customers. If you’re not sure your product can or should be 3D printed, Materialise can help you analyze the real costs and potential savings.

Much like Shapeways, i.materialise also hosts designer-run shops, allowing creatives to sell their wares as physical items. The 3D printing service can be accessed via Craftcloud.

What we like: Wide range of technologies, materials, and applications; storefronts, plus educational discounts.

Website: materialise.com

Treatstock

Treatstock prioritizes enabling you to select from hundreds, if not thousands, of product files ready to be 3D printed, rather than uploading your own digital file – although it offers that service, too.

Treatstock invites artists to open storefronts and upload their designs for customers to purchase and order 3D prints. What’s more, Treatstock features a handful of apps on its website, enabling the creation of braille labels to make life easier for the visually impaired, plus relief 3D images based on photos.

If you need something 3D printed, you can access the instant quote system, which is is well-designed and customer-friendly, filtering out unsuitable providers as you select key criteria (such as international shipping, product application, and desired technology). Alternatively, you can select a service provider in your town, if that’s your priority.

The materials and the technologies are not very specific. For example, you can select nylon powder but you can’t select which type of nylon or the technology used, MJF or SLS. If the details of the material or the technology don’t matter to you, Treatstock is a simplified platform.

Treatstock’s 3D printing service can be accessed via Craftcloud.

What we like: A good instant-quote engine for customers, plus a storefront for 3D designers.

Website: treatstock.com

FacFox

FacFox is one of China’s most popular on-demand 3D print services, offering a broad selection of other manufacturing services, too. The company tailors its services to several industries, including architecture, medical, retail, and design.

After a somewhat lengthy registration process, there’s a simple online interface lets you quickly upload models, which are then checked for printability (and automatically repaired if not) before payment. Live tracking of the print’s progress is a nice touch, and competitive international delivery often makes it a cost-effective alternative to some of the perhaps better-known services on this list. The low prices come at the cost of site usability, which is not all that intuitive to navigate and some parts are still in Chinese despite the rest being in English. But if you know exactly what material you need and which technology, it should be a smooth, quick ordering process. A great option is you happen to be in Asia.

FacFox’s 3D printing service also can be accessed via Craftcloud.

What we like: Fast and low-cost printing, while offering a good range of materials.

Website: facfox.com

Quickparts

Seattle-based manufacturer Quickparts’ on-demand print service and global network of providers offers a wide range of plastics and metal printing along with design and engineering services. The company uses a lot of printers by 3D Systems because it used to be the on-demand service provider of that company before breaking off on its own.

The company has engineers stationed in several facilities around the globe and has decades of manufacturing experience.

Although it offers an instant quote service, our FDM prototype required a manual quote, meaning someone would respond via email, which didn’t happen, confirming out thoughts that Quickparts is focused on manufacturing and the small under $200 part may not garner that much attention from the firm.

What we like: Although we haven’t tested it out for ourselves, we like the idea behind Quickparts’ “Lifecycle Support.” The offering promises to provide you with a dedicated program manager to oversee your part from design to prototype and through to the final parts and even scaling up to full production.

Website: Quickparts.com

3DSPro

3DSPro, established in 2020, is a Hong Kong-based 3D printing service company offering a robust menu of materials and technologies through what it calls an AI-driven platform. We’re not sure how it’s AI-driven but it is certainly feature rich. It provides perhaps the most details on materials, processes, and finish options of any platform. You can also leave notes in various places to define your finishes and other requests. In this way, it’s the opposite of Treatstock.

There’s a long sign-up process before you can upload for a quick quote but once you do, the rest of the process is easy. The button to configure your part material and technology isn’t obvious and the default for parts is a white resin.

On the plus side, the platform provides the mechanical properties of material right in the quoting window. For example, the above-mentioned white resin offers a tensile strength of 52.3 MPa and an impact strength of 45 J/m. This can be handy as you scroll through materials to find the strength your part needs or at least determine which materials have higher strength that others.

What we like: Unique to 3DSPro is a handy feature that displays — without you having to configure it — the prices and delivery for your part in several other technologies and materials. For example, you can see that your part would cost $47 in nylon but $356 in stainless steel or $23 in basic resin.

Website: 3dspro.com

Reasons to Outsource Your 3D Printing

Using a 3D printing service opens up new avenues to make your business more agile, profitable, and sustainable. Here are the main points on how your business can profit:

- Enhance your production: Boost efficiency by creating complex parts without the need for multiple processes or tools (like molds), saving both time and resources. It also speeds up the prototyping process, reducing time and cost in developing new products, leading to faster market entry and higher ROI.

- Customization opportunities: Additive manufacturing can produce highly customized products with geometries that are only possible with this technology. Each item in a batch can be individually customized leading to better customer satisfaction.

- Reduce inventory and storage costs: On-demand manufacturing minimizes the need for large inventories, significantly slashing storage costs and waste.

- No hidden costs: Sure, it’s obvious, but by using a 3D printing service, you don’t have acquisition costs for the machine or materials, you don’t have to set up a 3D printing workflow, and you don’t have to think a second about the printing process itself. You simply get the final product shipped to you.

- More sustainable manufacturing: 3D printing can be more sustainable than traditional manufacturing processes. You reduce waste by using only the material necessary for the part itself and save resources by producing locally.

- Competitive prices: Only a handful of services (like Craftcloud) enable you to compare the prices of 3D printing services worldwide, so you pay the best price for the best quality from trusted service providers.

By leveraging these aspects, your business can streamline its operations and tap into new revenue opportunities and market segments. If you want to dig deeper, here is a perfect example of how to use a 3D printing service for your benefit.

What Sets Service Providers Apart

You’ve got a model you need printing. We’ve got the list of 3D printing services up for the task. It’s a simple case of clicking around and trying them out, right? Wrong.

Many services default to a preselected material and technology, which might not be the best for your part or the most affordable option. You can always change and configure these defaults to your needs, and usually should. For an overview of the processes, check out our guide to all the 3D printing processes.

Each of these services provides an array of materials and processes, various finishing option, such as polishing, assembly, or inserting threads for screws; plus a wide range delivery times. When it comes to price, that’s affected by a number of factors. Keep in mind that most larger 3D printing services (and the ones we feature below) are contract manufacturers, meaning that their bread-and-butter is volume orders. That doesn’t mean they won’t 3D print your single prototype or work of art, it’s just likely to cost more than if you went to a smaller or more local 3D printing shop, or used a 3D printing service marketplace, like Craftcloud.

There are a plethora of factors that we took into account in considering the print services and bureaus out there. Many providers didn’t make the cut when we looked at the depth of their services. Here, to help you hone in on what matters, are the primary considerations to keep in mind when choosing which 3D printing service to use.

Material Choice

A surprisingly diverse array of materials is available for 3D printing technologies, making even the most discerningly specific of jobs a possibility. From difficult gold parts created using 3D printed molds for investment wax casting to flame-retardant casings printed in impossible shapes – the limitations become less by the day.

This means the onus is on you to know your materials. Functional prototypes must stand up to testing that reflects their end use, while engineering jigs and fixtures must be durable enough to survive on the shop floor without distortion or wear over time. All crucial considerations – made simpler by many print services allowing you to select a material from a drop-down menu.

The more specific the provider can be on materials the better. There are high-grade nylon materials and then there are economical-grade materials. Those with professional use and stringent mechanical and chemical requirements for their part in mind would do best to consider the larger print services that have highly visible partnerships with material makers. Chances are their material offerings and support will be better than those of smaller operators.

Not to diminish the little guy, though, they have their own value which is usually apparent in customer service; the economy of scale, however, means the big organizations may have more options.

Those less interested in having a part perform in a specific way, needing just a design prototype, have the luxury of choice. Any print service can physically realize a model – with material considerations gone, it’s down to cost, scale, time, and (possibly) certifications and confidentiality.

Scalability/Batch Production Volume

Another factor that will limit the number of useful 3D print services you can turn to is their ability to handle batch production. Finding a print service with the right material is good, but if it can’t handle 1,000 pieces of that thing you need by next week, then this is moot.

Some services specialize in batch production. Using a scalable farm of printers to complete large jobs quickly, the steps necessary to accomplish this are greater than the straightforward click+upload pipeline you commonly find for on-demand print services. Replaced instead with direct feedback and quotation, this will be a necessary step no matter the service you use to ensure all considerations and demands are met.

When using a 3D printing service for low-volume batch runs, be sure to check that the service you have in mind is equipped to deal with the number of prints you need. Some print technologies a service lists can be indicative of this, with selective laser sintering one particular printing tech suited to batch optimizations.

Cost

The factors affecting the final cost of a 3D printed part are many but you have some power to influence the cost of the parts you order, be it through using a 3D print service that is local to where you need the printed piece to be and being flexible with the materials you use.

Another valid strategy to scope out the best price for 3D printing is to create quotes with many print services, comparing and adjusting parameters until you achieve an acceptable price. However, this comes at a high cost in time and frustration. Who wants to acquaint themselves with the intricacies of a dozen file upload systems, material selections, and checkout pipelines? Not us.

Where cost is a factor, 3D printing price comparison services and those that operate as hubs come into their own. For example, you could spend half an hour configuring quotes from the top three print services for a given material or turn to a service such as All3DP’s own Craftcloud, upload the model once, select the material once, and see prices and shipping estimates for multiple services in one step.

Time

Fortunately, some 3D printing service providers offer rush jobs should you not be too picky about the material your parts is printed in.

Some providers focus on rapid prototyping with a history of next-day shipping. Such services are, of course, bound by physical limitations such as geography, so pay attention to the location of the service you use if time is of the essence.

As much as the location of the company printing your part can negatively impact the shipping cost, it can also increase the time it takes to reach you.

Those in a hurry would do best to opt for services that guarantee quick turnarounds and fast shipping. Otherwise, try to stay as local as possible.

As with the cost factor, a 3D printing service price comparison can come into its own here, helping you pick the service that offers the quickest turnaround when the cost matters less than having it in hand, like, now.

Privacy/Certifications

One less obvious factor to consider when choosing a 3D printing service is the company’s privacy policy, terms, conditions, and any certifications they may have.

It’s a natural assumption that most 3D printing services operate with the intent to foster trust with their users – who are uploading potentially sensitive and IP-protected prototypes, after all. Most are quick to declare that in uploading your file for manufacture, you are granting a non-exclusive license, allowing the company to fabricate your model. However, there are occasions when you, as the user, need airtight confidentiality regarding the files you are uploading. To that end, a print service willing to sign a non-disclosure agreement is your friend. Few print services are upfront about their readiness to sign such documents, but digging around a given service’s FAQ page or user forum usually yields an official stance on the matter.

Another factor, albeit a less tangible one for you as the end-user, is ISO:9001 certification. An increasing number of 3D printing companies adhere to the stringent checks and auditing that come with ISO 9001. This means little for the actual production of your part; instead, think of it more as an indication that the company is committed to ensuring a high level of standards across the breadth of its organization.

One natural benefit to think of here would be, for example, if a 3D printing service also offered CNC milling at its second location on another continent. Maintaining ISO:9001 means that the management, service, customer care, and manufacturing quality of parts coming from both sites are on par with one another. Leading to greater interoperability between different entities, it’s an assurance of commitment to excellence. Better-organized companies will inevitably lead to a better experience for you, the customer.

There are other more niche requirements that few 3D print services offer. One such example would be International Traffic in Arms Regulations (ITAR) compliance, a requisite for any step in the supply chain of “defense articles” as specified on the United States Munitions List.

One-Off Prototypes vs. Production Volumes

When All3DP set out to find the best 3D printing services in San Diego, we found a local shop called 037 Designs. We uploaded a single prototype model and the resulting cost was about $5. The same model at a larger service, like Sculpteo, was closer to $20. The price disparity between large 3D printing companies and more local ones reflects the growing competition in the services marketplace where companies are deciding if they want to focus on volume or other specialities, like design or prototyping. Local shops are more likely to take smaller orders whereas the larger companies are establishing minimum order sizes and getting rid of prototyping technologies, like FDM, altogether.

As we mentioned, one place where big and small services mingle is at the 3D printing service marketplaces. You upload your digital file, select the materials and technology, and multiple services offer you a price, which typically results in more affordable small orders.

How Service Providers Calculate Their Prices

When you upload your 3D file to a 3D printing service, you’ll get a quote instantly or later by email. However, not all these services are transparent as to how a 3D printing service calculates its prices.

Below, we have compiled a list of the most important factors determining how 3D printing services calculate prices. Some of them are obvious to anyone with a 3D printer at home, while the operational processes of a given 3D printing service provider can also affect the price.

Material Cost

It’s no leap to say that an item printed in PLA will cost significantly less than the same item in sterling silver. Ideally, 3D printing services publish a list that reveals how much a certain amount of the available materials cost. Your price, or rather, the price of material required for your job, is calculated by multiplying the material cost by the volume of the 3D file.

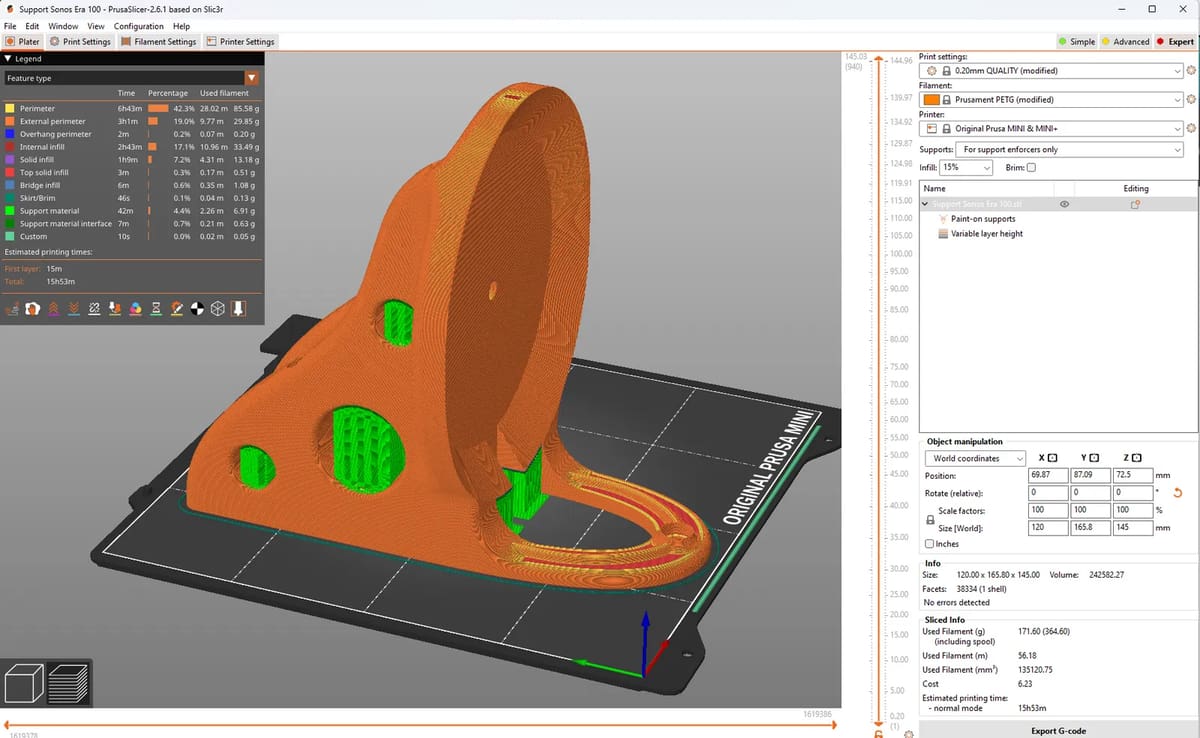

However, other factors must be considered to understand how 3D printing service providers calculate their prices. For one, usually, parts are not printed as solid pieces. Instead, in FDM parts, a certain infill percentage is used to balance strength and cost.

What’s more, many 3D files with overhanging parts require support structures to be also printed. The material spent on these supports must also be factored in to calculate 3D printing service prices.

Manual Labor

Although 3D printing services are highly automated and use sophisticated software to facilitate every production stage, there is still a lot of manual labor involved. For instance, after printing, the parts are cleaned and post-processed according to your order, supports are removed, and then they’re packaged. The final cost of a printed item reflects this labor, a part of the “service fee” that is charged per item or order.

Another factor that must be considered to understand how 3D printing services calculate prices is finishing: the sanding, dying, polishing, and other post-processes that help get the most out of your 3D prints. However, since they are often done manually, they will increase the final cost. Some are optional add-ons, but others are a required part of the fabrication process.

Maintenance Cost

What 3D printing services also include in their calculations of 3D printing service prices are costs involved with maintenance. This includes initial printer investment, electricity, depreciation, repairs, and failed prints. Aside from labor, these costs are also wrapped up into a “service fee.” These costs can also be covered by 3D printing services charging a minimum price for orders that would otherwise be below a certain value.

Layer Height / Resolution

When setting up the print, it is sometimes possible to tweak the printing speed by adjusting the layer height. Parts with bigger layer heights will cost the printing service less time and can save you a lot of money. So, by tweaking the resolution of your part, you can determine how 3D printing service prices are calculated.

The same applies to the amount of infill. Printing solid parts does not only increase the material cost but also the time needed for printing.

Machine Space / Time

In processes like SLS and MJF, the biggest driver of 3D printing cost is neither material nor labor, but machine space. 3D printing services stack or “nest” different size parts from various orders together in order to print as many parts as possible at once. This process makes 3D printing more cost-effective for 3D printing services. In turn, they pass on the part of the money they saved. So, the shape of your 3D file can directly influence how 3D printing service prices are calculated and it may be why the larger services with a lot of volume can print your part cheaper.

Shipping Costs

Of course, it takes someone to deliver the finished piece to you. Companies like Shapeways, Sculpteo, and Materialise usually work with local subcontractors. The 3D printing file gets transferred to them to be 3D printed. Then, after successful completion, it is shipped.

It makes sense to take a look at shipping costs, as they can greatly differ. Some 3D printing services charge up to 100 percent more than others for handling and shipping.

Lead image source: Voodoo Manufacturing

License: The text of "Parts On Demand: Top Online 3D Printing Services 2025" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.