From small manufacturers and product design firms to architects and artists, any small business looking to purchase a reliable, professional 3D printer has more options available today than ever before. There’s a wide range of highly capable options under $10,000 that offer the automation, sensors, and quality you need to make 3D printing an asset at your company, not a hassle.

As the 3D printer hobby market continues to be flooded with extremely cheap desktop machines, the better 3D printer makers are shifting their focus to offer high-quality, easy-to-operate machines with a multitude of features and better reliability.

Gone are the days when industrial-grade 3D printers filled an entire room (although some still do). Now, there are plenty of professional 3D printers that are desktop-sized and affordable but compatible with engineering-grade materials like carbon-fiber filled nylon, polypropylene, or biocompatible resins. We focus on those machines in this guide, and we have tested most of them ourselves in the All3DP lab.

Whether you want a 3D printer to prototype parts or produce end-use products, knowing what each has to offer will help you make an informed choice. Below we look at the best desktop-sized professional 3D printers on the market in the two most popular technologies: filament, also called fused deposition modeling or FDM, which uses spools of filament; and resin, which uses liquid polymers. Actually, we only have one pick in the resin category for this updated guide. The market for this technology has shifted and most professional machines under $10K now focus on the dental market.

| 3D Printer | Technology | Build Volume (mm) | Min layer resolution | Materials | Market Price (approx.) | Check Price |

|---|---|---|---|---|---|---|

| Prusa Core One | FDM | 250 x 220 x 270 | 0.05 mm | ASA, ABS, nylon, PLA, PETG, Flex, ABS, ASA, HIPS, PA, + | $1,500 | |

| Bambu Lab X1E | FDM | 256 × 256 × 256 | 50 microns | Carbon-fiber PAHT, ABS, PC, PLA, + | $3,000 | |

| Raise3D Pro3 Plus HS | FDM | 300 × 300 × 605 | 10 microns | PLA, ABS, PETG, nylon, carbon fiber, TPU/TPE, stainless steel, + third-party | $7,800 | |

| UltiMaker S7 | FDM | 330 x 240 x 300 | 20 microns | PLA, ABS, PETG, PVA, HIPS, stainless steel, carbon-fiber, + third-party | $8,300 | |

| Formlabs Form 4 | LCD | 200 x 125 x 210 | 25 microns | Formlabs resins, plus any 405nm photopolymer resin | $4,500 | |

| Markforged Onyx Pro (Gen 2) | FDM | 320 x 132 x 154 | 100 microns | Carbon-fiber-filled nylon, PLA, TPU | $9,600 | |

Consumer vs. Professional 3D Printers

What sets professional 3D printers apart from consumer ones? Aside from price, below are just some of the features you can expect on these next-level machines to ensure ease of use, efficiency, speed, and flexibility:

- Automatic bed leveling to save time and ensure accuracy

- Sensors to detect print failures, monitor print progress, and halt printing

- Enclosed chamber, not only for temperature control but also for safety and air quality

- Dual extruders (a plus, not a requirement) so you can print with an easily removable support material that saves time

- Hot end to at least 200ºC so you can print with a wide variety of engineering-grade materials

- Remote monitoring via Wifi connected software and in-chamber cameras

- Cloud-based software so you can start, stop, and monitor prints anywhere

- Ease of use with print profiles for multiple materials and near-one-button printing

The filament printers on our list offer you the widest range of materials to work with and require little to no post-processing. Your parts can be ready to go right off the print bed. The resin printers on our list enable you to create the finely detailed, smooth parts fast. Resin technology requires extra equipment to wash and cure the prints. We’ve added the price of those machines to each entry. Some resin 3D printer manufacturers focus on the dental or jewelry market, so check out our other guides specific to those needs.

If you have deeper pockets or are looking for faster speeds, higher volumes, and more bells and whistles, we also have you covered in our guides to industrial FDM 3D printers, professional resin 3D printers, industrial SLS 3D printers, and metal 3D printers (note that some of the FDM printers below will also process metal).

Prusa Core One

The new Prusa Core One ticks all the boxes of a professional 3D printing except for the typical price of one. We had it in our lab for just a few months now, putting it through its paces, and were impressed overall.

The Prusa Core One is a fully enclosed high-speed machine speed designed to handle a wide range of materials, from PLA to engineering options like ASA and nylon. Built for speed without sacrificing quality, the Prusa CORE One utilizes CoreXY kinematics and a high-flow nozzle, ensuring rapid yet precise prints. Factory-tuned profiles for over 200 filaments take the guesswork out of printing. The Nextruder with 360° cooling enhances dimensional accuracy, the company says, allowing for intricate designs and steep overhangs without compromising material efficiency.

It features active temperature control, a rugged steel exoskeleton and a compact footprint. It supports multi-material printing through the MMU3, enabling vibrant, multi-color models with minimal filament waste.

Prusa works hard to make the 3D printing process intuitive. It integrates with PrusaSlicer, Prusa Connect, and the Prusa App for streamlined workflow management. With smart automation features, including fully automatic first-layer calibration and proactive monitoring, the printer is ready to use within minutes, requiring only a one-time calibration to get started.

An advanced filtration system makes its office friendly and machines are easily networked for scaling and print farm setups.

Another bonus with Prusa is the reputation of upgradeability, so you’re investing into a platform that will continue to grow over time.

Bambu Lab X1E

Bambu Lab’s professional offering, the X1E, is specifically designed for professionals with extra features, the company says, such as air filtration, secure LAN connection, and an actively heated chamber to prevent material warping.

One of our favorite features is the first layer LiDAR sensor that notifies you via a smartphone app if the first layer doesn’t look perfect so you have the option to restart the print. There’s also a failure detection, called spaghetti detection, that can sense if a print has gone wrong and automatically stops it so you don’t waste time, materials, and potentially damage your printer.

The heated chamber is great for 3D printing with nylon and other engineering grade materials and for PLA and other basic prototype materials you can simply remove the lid so the temperature doesn’t get too hot — you loose the air filtration feature, however, when you do this so this printer isn’t as office-friendly as it could be.

An optional add-on is a four material changer enabling you to print with four materials on one print, a unique feature on this list.

We took this for an extensive test drive late last year and while you can read more in the review linked below, it’s a favorite for ease of use, speed, and print quality.

Common applications for this professional 3D printer? Functional prototyping, jigs and fixtures, cases and housings, engineering assemblies, replacement parts, tools, automotive prototypes, etc.

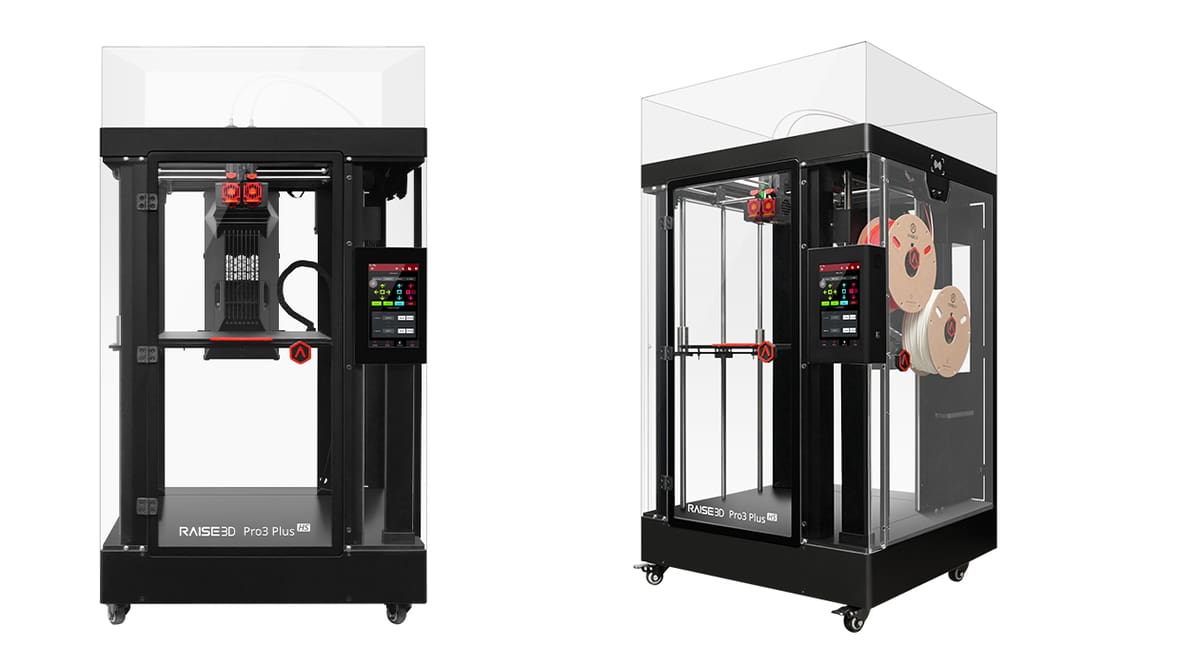

Raise3D Pro3 Plus HS

What makes this a professional 3D printer? Raise3D’s Pro3 Plus HS dual-extruder FDM 3D printer packs an impressive number of industrial-level features into a unit priced under $10k, especially with the recent upgrade that makes it much faster.

Previously an upgrade kit but now fully integrated, the Hyper FFF feature is a hardware, software, and filament combo for high-speed printing. Raise3D says professional FDMs average 50 to 80 mm per second print speed, while the new Hyper FFF can push the print speed on the Pro3 Series to 350 mm/s. The speed is attributable to new dual extruders with vibration cancellation technology along with special high-speed filaments. The company promises that speed does not come at the cost of quality and says the Pro3 keeps the same quality of layer adhesion and surface finish as before.

We especially like the Pro3 Plus HS for its size. It is the larger version of the Pro3 ($5,600) and was selected here for its impressive build volume for tall prints. It features interchangeable modular hot ends that can be swapped out with a quick click-and-lock mechanism. The hot ends can reach 300ºC, so they’re compatible with a wide range of engineering-grade materials from nylon to metal-filled filament.

Other features that make professional printing hassle-free include automatic bed leveling and a smart assistant called Eve that helps you to locate and resolve print job issues. Eve also analyses printer usage and sends reminders of scheduled interventions to ensure you don’t forget essential printer maintenance.

Because you can 3D print larger parts on this machine, you’ll need more filament. To reduce the frequent manual filament replacement, the Pro3 HS printers dual-extruder can now print from two external 2.5 kg material boxes sold separately for about $. It can print continuously for up to 120 hours (assuming 1 kg /24 h).

Common applications of this professional 3D printer? Functional prototyping, jigs and fixtures, cases and housings, engineering assemblies, automotive, electronics, etc.

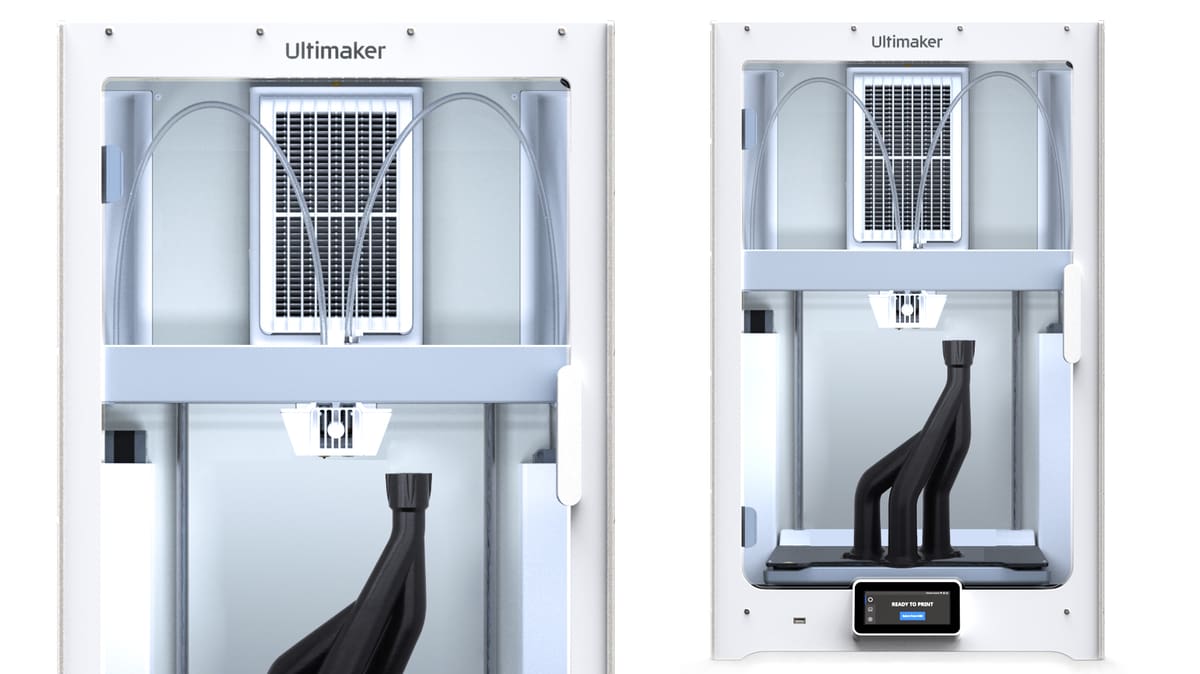

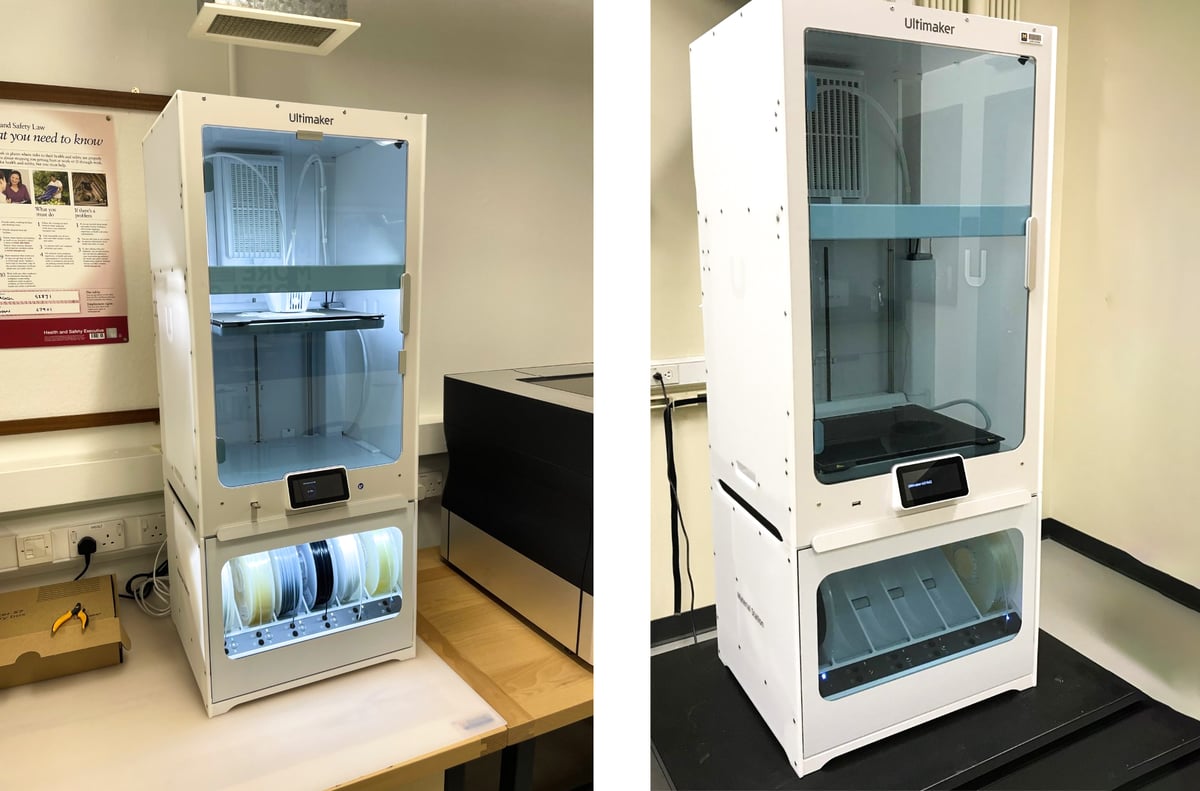

UltiMaker S7

What makes this a professional 3D printer? UltiMaker’s S7 builds on the already impressive S5 and offers robust dual-extrusion 3D printing with a large library of materials (300), including the Metal Expansion Kit that enables users to switch between printing plastics and metals on one machine.

The S7 includes upgrades from the S5 aimed at professional users, such as an upgraded heating system for more consistent heat over the entirety of the bed and throughout the chamber, which is designed to prevent part warping, plus a more precise bed leveling system. The redesigned print head features a sensor to detect potential print errors.

With cloud-based operability coming from UltiMaker’s Cura slicing software and the another software called Digital Factory, which is UltiMaker’s printer fleet and organization management platform, the Ultimaker S7 is a good choice for designers, engineers, and small-to-medium-sized businesses.

Fully networked and with UltiMaker’s software offering leveraged properly, we can see the S7 slipping almost seamlessly into product design and in-house production workflows. To get more of a flavor of working with Ultimaker, read our own exhaustive review of the S5, we found it offers a nearly flawless printing experience.

If your budget allows you to go a touch over $10k, the optional Material Station holds up to six spools of filament and automatically detects which UltiMaker materials are loaded and sets the correct print profile.

UltiMaker just launched a major update to its S series, the S8 that’s significantly faster and has higher accuracy. Without the material station, which you would really want to have, the machine is $9,000. Check out more in the article below.

Common applications for this professional 3D printer? Functional prototyping, jigs and fixtures, cases and housings, engineering assemblies, medical, automotive, electronics, etc.

Formlabs Form 4

What makes this a professional 3D printer? Undeniably one of the most reliable and affordable makers of professional-level resin 3D printers for prototypes and production parts, Formlabs new machine is a significant shift in technology, boosting speed and overall productivity.

US-based Formlabs’ fourth-generation desktop resin 3D printer, Form 4, offers vastly improved print time over previous Form version, which the company says is up to five times faster than Form 3+ depending on the material.

Considered by many to be the champion of desktop resin 3D printing, Formlabs has positioned itself as one of the most popular professional 3D printers on the market. The resin-based process allows for higher resolution and more precise prints than FDM, offering a layer thickness of between 25 and 100 microns.

Unlike consumer printers, Formlabs has features that enable you to better fine tune your results. The Adaptive Layer Thickness is a tool that analyzes the geometry of digital parts and assigns layer heights throughout the sliced model for the best detail at the fastest speed.

Another benefit of Formlabs is that it’s very materials focused. Form 4, like all Formlabs’ printers, features a mess-free, easy to use, material cartridge system, not bottles. In addition to validated materials and detailed print profiles, you can purchase a license to “open” the material settings and use any resin you wish. But the big news in materials is that they are cheaper, Formlabs says, starting at around $99 per liter instead of $150 for Form 3+ materials. Not only cheaper, but several have been enhanced to deliver better mechanical properties, the company says.

The Form 4 is compatible with 23 resins in all with more in the pipeline. Six new resins enable the Form 4 to print two- to five-times faster than the Form 3+. The Form 4B for healthcare can accommodate 15 additional biocompatible materials.

If you want all for these features and more in a larger printer, the Formlabs Form 4L (335 × 200 × 300 mm) is $10,000

Post Processing Machines

- Formlabs Form Wash: $700

- Formlabs Form Cure: $750

Common applications for this professional 3D printer? Automotive, dental, figurines, jewelry, product development, engineering assemblies, etc.

Markforged Onyx Pro (Gen 2)

What makes this a professional 3D printer? The Markforged Onyx Pro is in a class by itself on our list as the only “composite” 3D printer, meaning it combines two materials as it prints: a base material and a reinforcing fiber. This union produces parts that are incredibly strong and ideal for tooling, manufacturing guides, jigs and fixtures, and any number of tough, durable parts.

Compact and easy to operate, the Onyx Pro features one nozzle that forms the walls and infill using a proprietary material called Markforged Onyx, a micro carbon fiber-filled nylon material, while the second nozzle inlays continuous fiberglass fiber in user-specified space. The continuous fiber is bonded (reinforced) due to the nozzle heating and compressing the materials during the extrusion process.

Popular with small manufacturers and machine shops, Markforged knows its audience and has developed software that takes the usability of this machine to another level. Eiger, Markforged’s secure browser-based software, has a cloud-based storage system that enables you and anyone in your company to print parts on demand from your digital library with a single click.

Digital Forge is Markforged’s subscription platform. It enhances Eiger software with part simulation, enabling you to validate part performance before you hit print.

Common applications for this professional 3D printer? Functional prototyping, jigs and fixtures, cases and housings, engineering assemblies, automotive, electronics, etc.

License: The text of "Top 6 Professional 3D Printers Under $10,000" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.