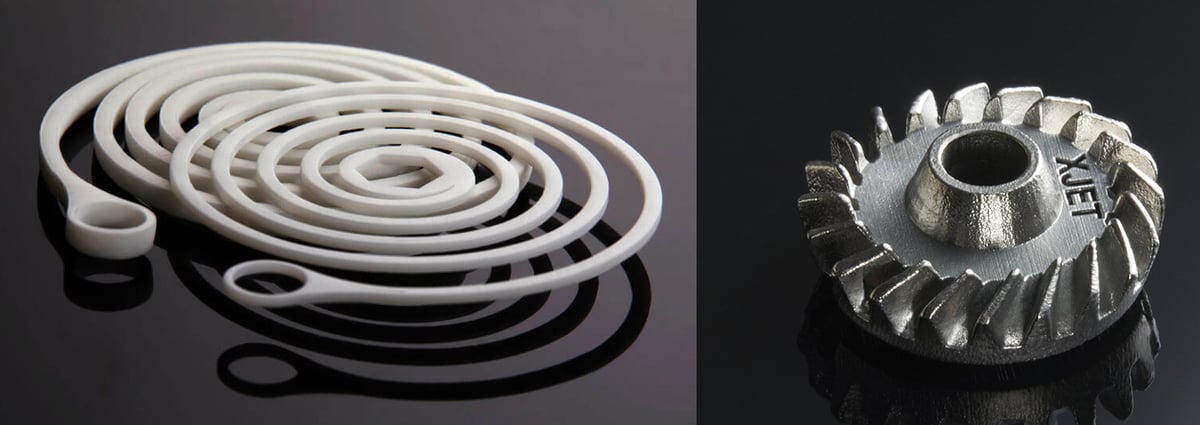

3D printing is an amazing technology and one of the most diverse in terms of methods, materials, and applications. You can spend just a few hundred dollars to take home a reliable 3D printer to make a huge variety of parts and models out of affordable plastic filament.

On the other end of the spectrum, you can spend millions of dollars to 3D print large, complex metal objects for aerospace and satellites, tiny biocompatible devices for advanced medical applications, or entire buildings from extrudable concrete material. Some of the most expensive 3D printers on the market today use multiple high-powered lasers to sinter metal powder, layer by layer, into 3D parts, or they harness the power of photons to cure liquid resin into micrometer-small objects, or they’re two stories tall printing the bulk of a house in a day.

As you will see, printer size isn’t a determination of how expensive a 3D printer will be. Today price is usually a matter of advanced – often proprietary or patented – technology and features that enable the printer to print better parts faster, and without a lot of specific technical expertise.

Some of the most expensive printers aren’t even for sale. They are custom made or modified for a particular application, such as rocket thrusters. Others are hired – with operators on hand – on a project bases, such as the Phoenix construction printer from home builder Icon 3D.

Features that boost a 3D printer’s price tag:

- Uniqueness of the technology

- How automated the processes are

- How large the capacity

- Quality assurance features

- Proprietary software

- Multiple controls and adjustments

- Carefully controlled environments (gas-filled chambers, consistent heat/cooldown)

Features that can add to the price of a printer include custom software that’s tuned to the printers specific technology, real-time print monitoring systems, and anything that automates processes that are sometimes done by hand with lower-cost systems (bed leveling, post-processing, or material filtration) or processes that require metallurgical or polymer expertise.

3D printing technology that requires a tightly sealed 3D printing build chamber filled with inert gas or printers that are cleanroom certified have these features reflected in the price tag.

Materials, likewise, play a huge role in the cost of 3D printing. Many 3D printers run only with proprietary materials developed by the manufacturer to run on their unique machines, which can range from custom metal powders where every tiny grain has a consistent diameter to specialty resins filled with carbon-fiber particles and unique polymer powders. You can 3D print in everything from pure gold to advanced plastics designed to withstand the harsh environment of space, provided you have the right budget.

Multi-material, multi-color printers are also on the higher range of the price spectrum, but many are surprisingly affordable.

If you’re looking for the best money can buy, check out these guides:

Most Expensive 3D Printers

No, There’s No Price Tag

As with anything extremely expensive, 3D printer makers are reluctant to publish exact prices. One reason is that they often customize these machines to your needs and offer optional features. It also makes a difference where in the world you live (taxes, import duties) and how far from the source the machine needs to be shipped. Also affecting price is your support package, installation, and training, among other factors.

With that in mind, though, below we detail some (but certainly not all) of the most expensive 3D printers available today – all above half a million dollars – and what they deliver.

Even though 3D printers are often a hefty capital expenditure, the ROI comes from the fact that no other manufacturing method can make the part complexity that’s possible with these machines, which leads to tremendous technological advancements in products, such as rocket engines, motors, and even medical implants.

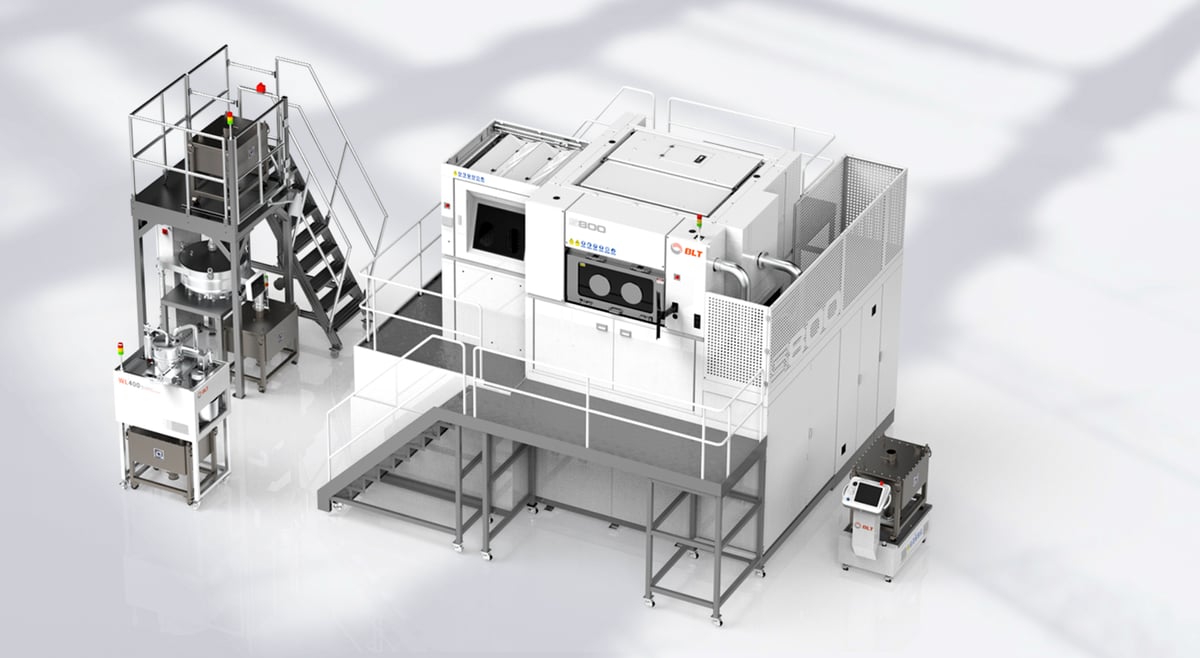

EPlus3D EP-M2050

China-based EPlus3D makes massive metal 3D printers for the country’s demanding manufacturing industry. The company’s models are used in aerospace, automotive, electronics, and tooling, to not only make huge parts, such as molds for heavy industry, but mass-produced parts.

The EP-M2050 metal 3D Printer is the company’s largest, with a 2,050 x 2,050 x 1,100 mm build volume in which it uses metal powder and up to 36 lasers to produce 99.9% dense metal parts in a wide range of materials at a rate of 1080 cm³ per hour. The company says it “pushes the boundaries of what’s possible in metal powder bed fusion,” and it would seem they’re right.

Others similar metal 3D printers with multiple lasers bound to cost in the same ballpark come from Bright Laser Technologies, Nikon SLM (see below), and Farsoon.

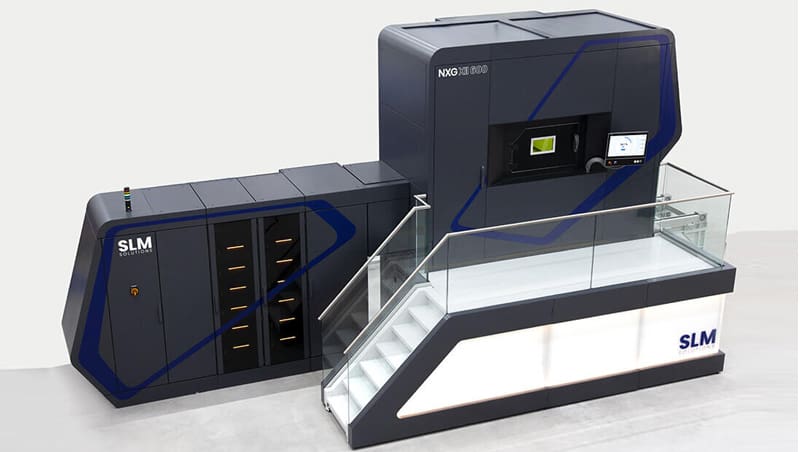

Nikon SLM Solutions NXG Xll 600

Nikon SLM Solutions is one of the leaders in metal 3D printing with a wide range of printers, but its NXG Xll 600 is what it says is a revolution in industrial manufacturing. The NXG XII 600 is designed for high-volume, serial productions and features an industry-first 12 lasers with 1,000 Watts each. The lasers enable speed and throughput not available elsewhere in a single machine.

More than lasers, the NXG Xll 600 features all the bells and whistles that SLM Solutions’ manufacturing customers have demanded over the years, including automatic build start, a laser focus function, and a closed powder system among other developments.

Icon 3D Pheonix

Texas-based Icon 3D has been making house-building 3D printers since 2016 and launched its newest, Phoenix, in 2024, which is a concrete construction 3D printer for two story houses and other large concrete objects.

Technically, it’s an articulated arm on a rotating base. The major innovation, and key to its speed and accuracy, Icon says, is its stabilizing tool head that keeps the extruder nozzle exactly where it should be, compensating for wind, vibrations, and other forces. By increasing speed and size and decreasing setup time and the number of required operators, this advanced robotic system will reduce printing costs by half compared to its predecessor, the Icon Vulcan, the company says. But still, construction prices start at $25 per square foot for wall systems or $80 per square foot including foundation and roof, and that’s just the rental price.

Other construction 3D printers along these lines but available to purchase for a price tag will into the upper six-figures come from companies, such as COBOD, Apis Cor, Black Buffalo, and Twente Additive Manufacturing.

Voxeljet VX4000

Voxeljet offers one of the world’s largest and most powerful 3D sand printing machines for large components or large batches of small components. 3D sand printers are used to make molds, cores, and patterns used at metal foundries for traditional casting metal.

The company offers sand 3D printers in four sizes using binder jet 3D printing technology.

Voxeljet uses common foundry materials, including sand and binders, to ensure seamless integration into traditional production processes. In June 2023, the company launched its cold IOB (inorganic binding) technology so molds and cores no longer need a microwave post-printing treatment, which reduces costs. Voxeljet says this process reduces emissions and improves working conditions in foundries because only water vapor is produced during casting instead of harmful gases. The process is available now on the VX1000 and VX1000S printers.

UpNano NanoOne Bio

Austria-based UpNano has developed a 3D printer and a hydrogel-based bioink that enables direct printing of 3D structures containing living cells at both the meso- and microscale. The NanoOne Bio is a printer based on the company’s NanoOne range of laser-powered printers that are able to build structures across 12 orders of magnitude. The new hydrogel is the only commercially available resin that allows embedding living cells straight from a culture plate within 3D printed structures for biological applications.

UpNano says the combination of X Hydrobio INX U200 and the NanoOne Bio opens up new possibilities in biomedical R&D, both in industry and academia enabling pharmaceutical companies and research institutions to design cell models that mimic natural growth conditions in the human body.

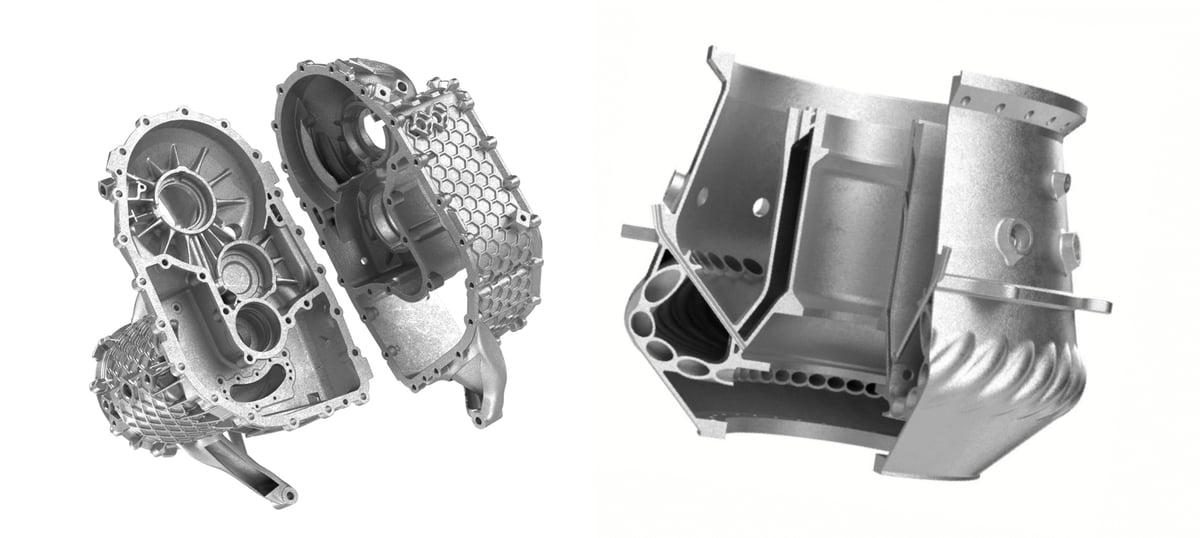

Velo3D Sapphire XC

The Velo3D Sapphire XC is a 3D printer that uses metal laser powder bed fusion technology, primarily for high-volume and large production, particularly in the aerospace and defense industries. It’s designed to print large parts and is popular with companies like SpaceX.

Both Sapphire XC and XC 1MZ use eight 1-kW lasers for fast printing at scale. A proprietary non-contact recoater eliminates the risk of part collision, protecting both the build and the recoater while enabling thinner walls and more accurate builds.

Standardized and controlled parameter sets, along with automated calibrations, ensure consistent geometric accuracy, surface finish, and validated material properties.

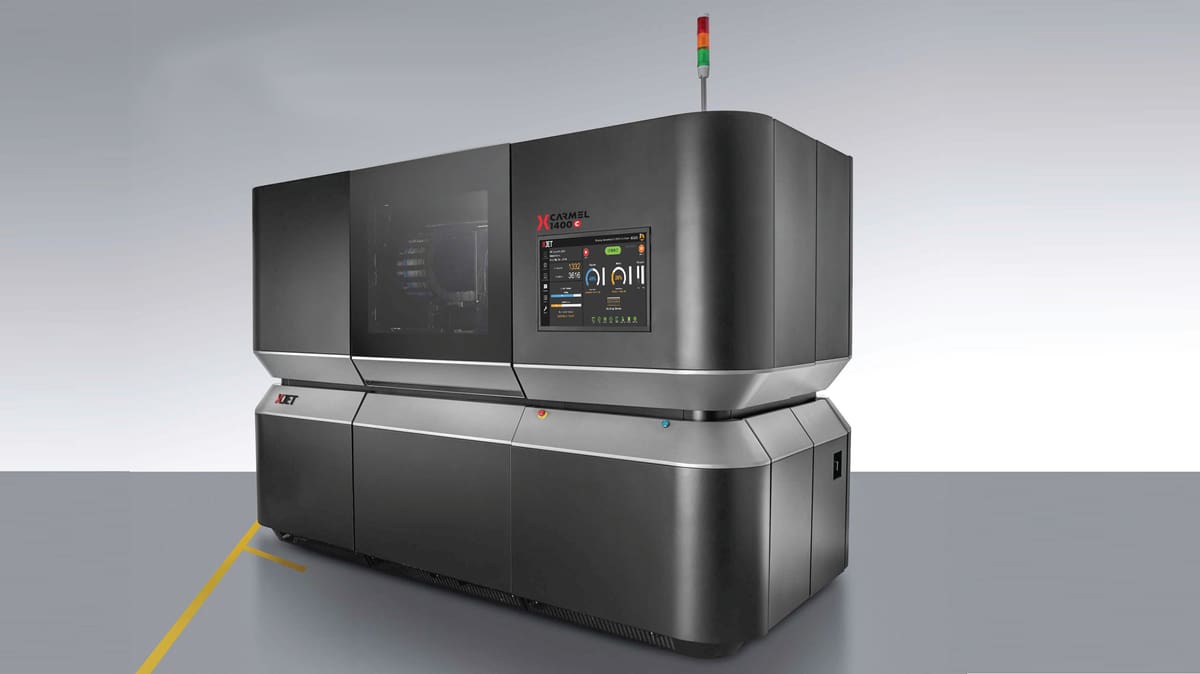

XJet Carmel 1400C

Israel-based XJet developed a unique technology for ceramic 3D printing that demands a high price. NanoParticle Jetting (NPJ) technology enables the production of metal and ceramic parts featuring high levels of detail, finish, and accuracy. It’s not just the technology and the proprietary materials that make this printer a serious investment, but the advanced automation in the printer itself that makes it easy to use.

Featuring a 1,400 cm² build tray – one of the industry’s largest – the Carmel 1400C enables the simultaneous production of multiple ceramic parts.

Caracol Heron

Robotic-arm style 3D printers, which are used for all types of large-scale 3D printing, typically with plastics, but also ceramics and cement-like materials, are another high-price category.

Large-format 3D printing service Caracol launched a printer package for sale, called Heron, that includes a Kuka robotic arm, an extruder head, a material feeding system, software and more so that companies can achieve large-scale thermoplastic 3D printing in-house.

The company launched a metal robotic arm 3D printer in 2024 that we suspect is even more pricey. The Vipra XP (Extreme Productivity) uses a technology called CMT (Cold Metal Transfer) for large-scale metal manufacturing. With high deposition rates in materials like aluminum and nickel, it’s used for fast production of complex automotive, marine, and architectural components.

You May Also Like:

Lead image source: EPlus3D's EP-M450H SLM 3D printer.

License: The text of "The World’s Most Expensive 3D Printers in 2025" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.