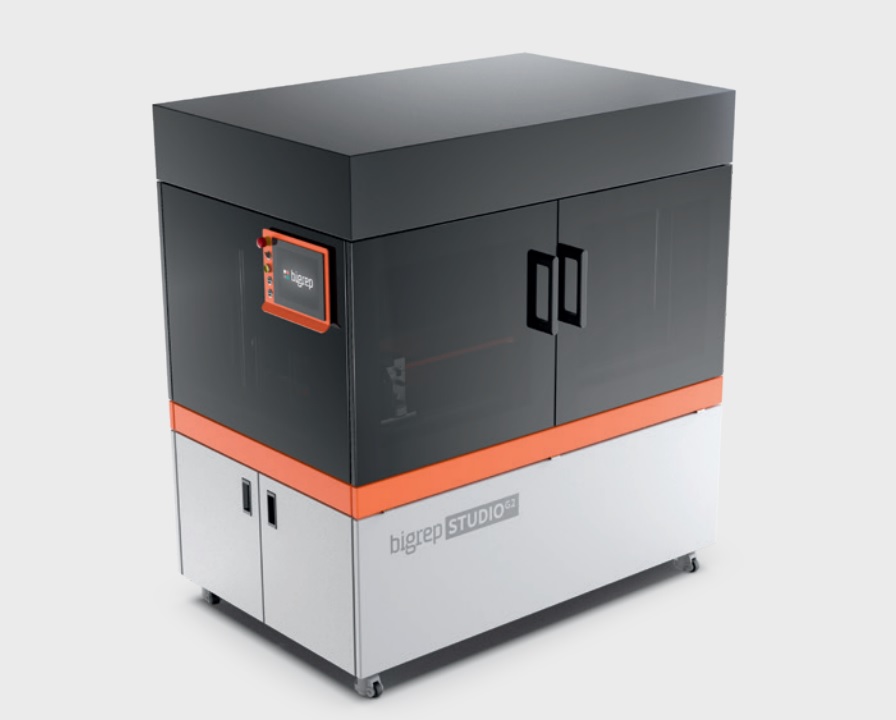

Large-scale 3D printer manufacturer BigRep revealed its latest 3D printer – the Studio G2 – at the RAPID+TCT 2019 trade show in Detroit, Michigan.

Since its beginning in 2014, BigRep has carved a niche for itself producing large-scale fused deposition modeling (FDM) 3D printers for use in the workshop or studio. Its first machine, the BigRep One, offers an enormous build volume of 1000 x 1000 x 1000 mm.

The smaller, more user- and workspace-friendly Studio 3D printer followed in 2016, shrinking the build volume but increasing the printer’s versatility with an office-friendly footprint.

As of 2019, the Studio line is now two strong, with the recent introduction of the Studio G2, which brings a raft of nips, tucks, and new features geared toward improving speed and versatility.

In this article, we review the features and specs that make the BigRep Studio G2 an option for professionals and small businesses.

Features

The Studio G2 is designed for industrial applications such as prototyping, tooling, casting, end-use parts and small-batch production on demand.

Standout features of the G2 are a print volume of 500 mm x 1000 mm x 500 mm, a fast-heating print bed that goes up to 100°C, dual extrusion capability, and a temperature-controlled filament chamber. Pair these with this high-resolution workhorse’s ability to print engineering-grade Polyamide (PA6/66).

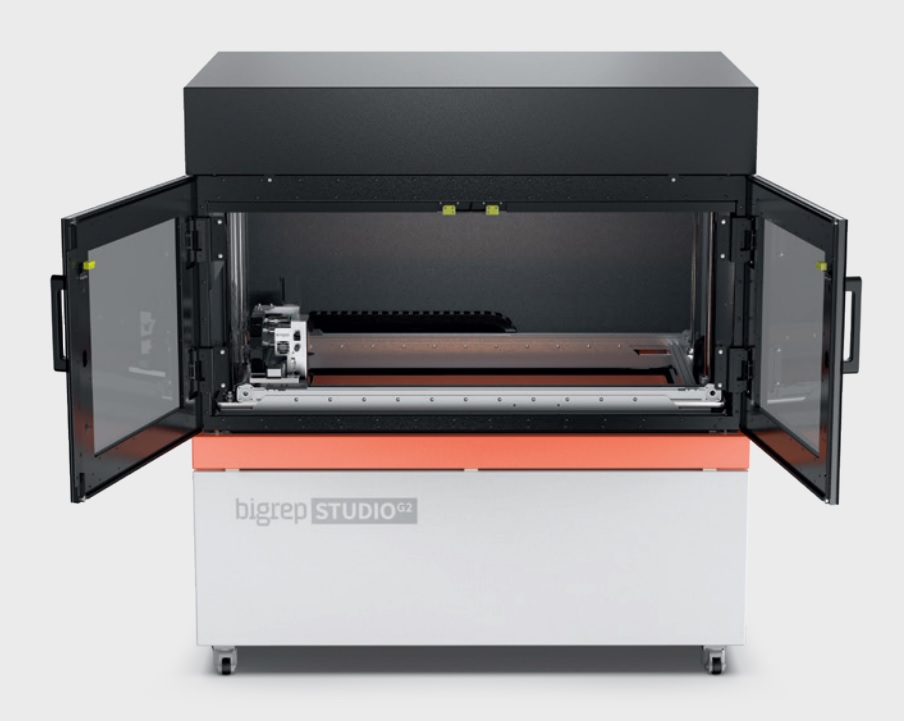

Bringing the Studio G2 to market, BigRep paid special attention to ergonomics. The build plate now located at a more accessible height, improving the overall usability of the system.

Of all of BigRep’s machines, the Studio line is the company’s most compact offering, allowing for non-disruptive delivery in small studio spaces – a factor worth taking into account, given the machine is delivered fully assembled.

Let’s see what the BigRep Studio G2 brings to the table:

Massive Build Volume

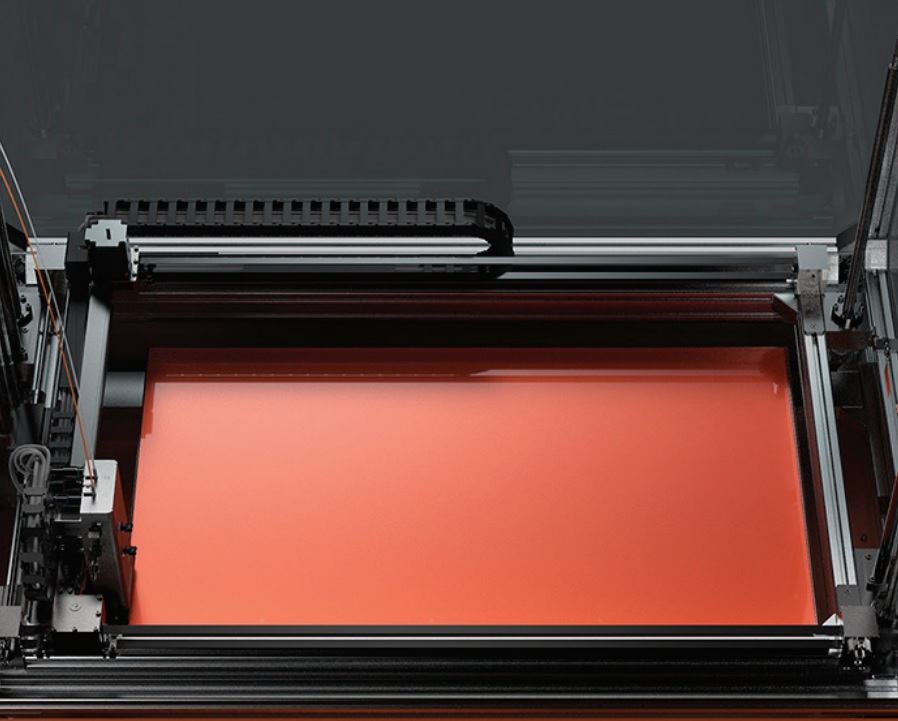

Just like its predecessor, the Studio G2 boasts a large print volume of 500 x 1000 x 500 mm. One of the few industrial FDM machines to offer such a build space within a svelte frame, it presents an office-friendly footprint that is sure to win some admirers.

Combined with the G2’s ability to fabricate high detail models from tough materials, this potent combination should prove a more than capable system for producing high-quality prototypes, tooling, and end-use parts.

Dual Ruby Extruder

The Studio G2 is made for printing with abrasive, engineering-grade materials – such as PA6/66 – at maximum speed and high resolution. This is possible due to the G2’s new dual 0.6 mm ruby nozzles. Housed within a specially designed extruder said to achieve a high level of detail, it is possible to print at layer heights as fine as 0.1 mm with a maximum throughput of 19 mm³/s on parts up to a meter long.

Following the reveal of the BigRep G2, the company has alluded to further engineering-grade materials to come, including carbon/glass fiber composites and ASA.

Professional Temperature Management

The Studio G2’s enclosed, temperature-controlled build envelope facilitates the printing of injection-molding-grade Polyamide. Users can monitor the printing process using the G2’s built-in camera. Environmental features like auto-pause upon opening ensure a smooth and safe printing process.

Another newly added feature is the heated filament chamber, ensuring that materials remain dry in a consistently controlled environment for the best printing quality.

Where previous BigRep systems did not feature a heatable filament chamber, the Studio G2 adds this, along with independent temperature control to tailor the environment needed for the respective materials used.

Improved Heated Bed

Another major update to the predecessor is the faster heating print bed.

Where the Studio G1’s print bed could only heat to 60°C in approximately 10 minutes, the G2 reduces the time and increases the temperature, reaching 100°C for reliable material-bed-adhesion.

Furthermore, a new inductive sensor on the print head enables semi-automatic leveling to ensure a simpler time of calibration.

New Slicer Software

The Studio G2 makes use of BigRep’s proprietary BLADE slicer software. Allowing for greater control of printing parameters while providing presets for all BigRep-compatible materials, a key feature of the program is its new estimation engine. Giving accurate predictions of printing time and material use it is intended to aid engineers in making better-informed designs and decisions.

Technical Specification

GENERAL SPECIFICATIONS

- Technology: FDM

- Year: 2019

- Mechanical arrangement: Cartesian

- Manufacturer: BigRep

3D PRINTING PROPERTIES

- Build volume: 500 × 1000 × 500 mm

- Layer height: 100 – 500 microns

- Feeder system: Direct Drive

- Extruder: Dual extruder

- Nozzle size: 0.6 mm

- Max. Extruder temperature: –

- Max. heated bed temperature: 100 °C

- Print chamber: Enclosed

- Bed leveling: Semi-automatic

- Connectivity: USB, Ethernet

MATERIALS:

- Third-party filament: Yes

- Filament materials: PLA, PETG, Pro HT, TPU, PA6/66 (More engineered materials in development)

SOFTWARE REQUIREMENTS:

- Operating system: Windows, Mac

- Recommended Slicer: BigRep BLADE

DIMENSIONS AND WEIGHT:

- Power: 208 V – 240 V, 16 A, 50/60 Hz

- Assembled dimensions: 1715 x 1170 x 1765 mm

- Weight: 500 kg

Where to Buy

The BigRep Studio G2 starts from $62,700. It can only be ordered via BigRep directly following consultation. To request a quote from the manufacturer directly click on the link below.

License: The text of "BigRep Studio G2: Review the Specs" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.