The telltale signs of 3D printed parts – the filament layer lines or the rough matte surface of powder bed fusion 3D printing – are less than impressive for final products. Even for prototypes, a smooth, shiny surface – typical of injection-molded parts – is more what consumers expect.

Fortunately, there are more options than ever to achieve a surface finish on your 3D printed parts that makes them virtually indistinguishable from injection-molded parts. Below we detail the most popular method called vapor smoothing. We’ll look at the process, the machines that make it easy, and the services that give your parts the polish they deserve.

But first, let’s look at what vapor smoothing is and how it works.

What is Vapor Smoothing

Vapor smoothing, also called chemical smoothing, is a post-processing technique that slightly metals the outer surface of 3D printed parts, commonly made of thermoplastic materials, such as ABS (acrylonitrile butadiene styrene), PLA (polylactic acid), and nylon. It involves exposing the printed object to a vapor of a solvent, typically acetone for ABS or ethyl acetate for PLA, in a controlled environment.

The vapor penetrates the surface of the object and softens the plastic, allowing it to reflow and blend together. As the vapor condenses on the surface, it dissolves a thin layer of plastic, effectively smoothing out any visible imperfections, layer lines, and roughness, resulting in a smoother surface finish.

Vapor smoothing improves the aesthetics of 3D printed objects, making them look more polished and professional, just like injection-molded parts, but it’s not all about appearance.

Some vapor smoothing methods can improve mechanical performance, create sealed water-tightness, and sterilizable surfaces.

However, this process can, in some instances, also slightly reduce the dimensional accuracy of the printed part, so it’s not suitable for all applications.

Vapor Smoothed Consumer Products

When bicycle component manufacturer Posedla (pictured above), chose to 3D print their innovative bicycle saddles with variable support areas tailored to the rider’s anatomy, they achieved the perfect form and function using HP’s Multi Jet Fusion 3D printers with BASF flexible TPU polymer, but something was missing. The saddles didn’t look or feel like other bicycle saddles on the market. Using a vapor smoothing machine from AMT PostPro became an essential step in appearance, but it also sealed the porous surface of the saddle, reinforcing its mechanical and structural properties. As a result, the saddle passed the required skin contact and irritation testing for this consumer product.

The Posedla saddles were also tested for mechanical damage and fatigue to meet and even exceed ISO standards for bicycle saddles.

In another recent example, Wilson, the sporting goods company, released its 3D printed basketball, the Wilson Airless Gen1, in 2024. As printed, it would not have had the surface grip and shine of a typical basketball. Vapor smoothing by DyeMansion along with coloring enables the product to rival traditional basket balls.

DIY Vapor Smoothing

For the occasional smoothing job, you could use the common, yet time-consuming and cumbersome technique of vapor smoothing by hand (gloved hand) with acetone, polyvinyl butyral, isopropyl alcohol, or another chemical. Follow our step-by-step guide linked below.

Yet, DIY vapor smoothing is a craft you’ll need to practice and experiment with to get the results you want. Not only is it important to match your vapor smoothing chemical with the type of polymer you print with, but each brand may have its own qualities.

What the vapor smoothing machine makers below offer is repeatability, ease of use, and the ability to set the exact amount of smoothing you want. The ability to smooth batches of prints is also a bonus for consumer products.

By the way, there are other methods to smooth your parts at home without chemical vapor. Check out our suggestions in “PLA Smoothing: How to Smooth 3D Prints.”

Vapor Smoothing Machines

Polymaker Polysher

The Polysher ($350) polisher from filament maker Polymaker is the smallest unit in our collection of vapor smoothing machines, and the simplest. Functioning a lot like a home humidifier, you fill the machine’s reservoir with isopropyl alcohol (IPA), place your printed part on the revolving platform, and press start. An IPA mist fills the chamber. You can control the color of the chamber lighting, which seems like a fun feature but doesn’t have any effect on the smoothing.

While the machine should be operated in a well-ventilated area, IPA is a more environmentally friendly and slightly less toxic material than acetone. Plus, it’s economical and widely available.

You’ll need to just eyeball the amount of smoothing happening in the chamber and take out your print when it gets to the level of smoothness you require. Note that Polymaker says that the Polysher only works with printed parts made from its PolySmooth and PolyCast materials, which are designed for post-processing with isopropyl alcohol or ethanol. For most common 3D printing materials, like PLA, IPA isn’t strong enough to smooth the surface and instead if often used to clean the surface. Soaking a PLA part in IPA for long periods of time doesn’t work either, it simply warps and degrades the part.

The Polysher can handle a maximum part diameter of 150 mm (5.9 in) and a height of 180 mm (7.1 in).

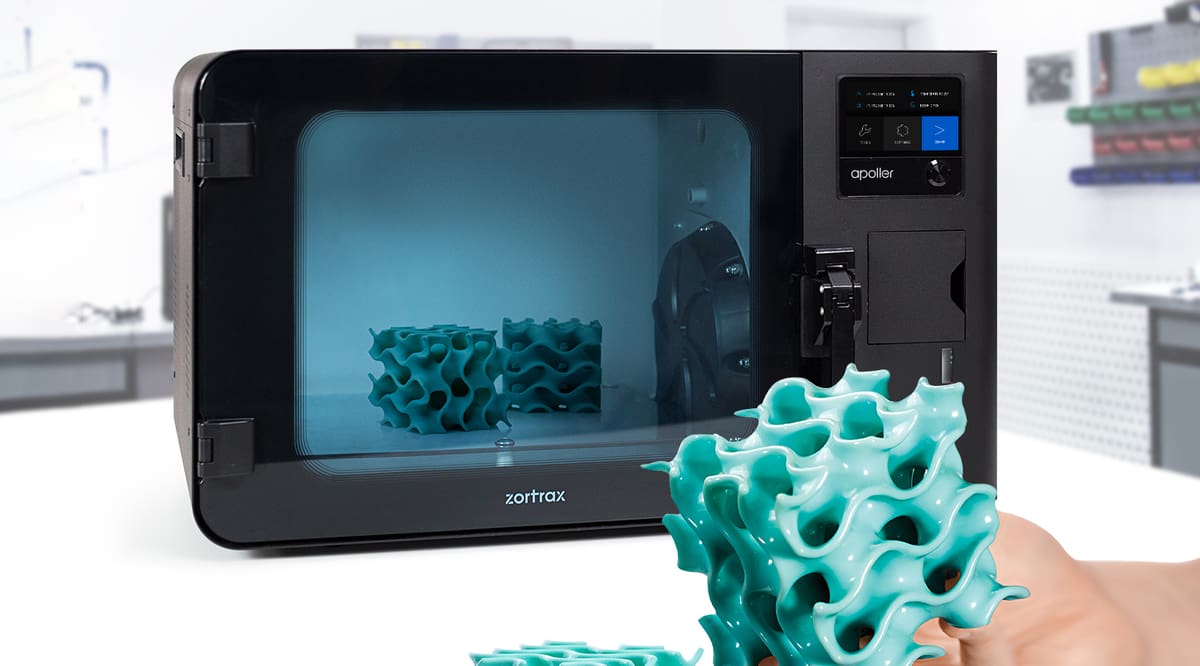

Zortrax Apoller

Zortrax Apoller ($6,300) is a desktop vapor smoothing device from 3D printer and material maker Zortrax. It takes your FDM printed parts and gives them a look on par with injection molded parts, the company says.

Looking a bit like a microwave oven, the Apoller can smooth models printed on all FDM 3D printers using any ABS, HIPS, and ASA material, regardless of the manufacturer.

The Apoller works using MEK (methyl ethyl ketone), also known as butanone or acetone, essentially, by evaporating the solvent, which condenses on the surface of prints, the Apoller superficially melts the outer shell, smoothing away the layer lines before a heating procedure dries the print and re-condenses the remaining solvent vapor back into the tank for reuse.

A number of systems are in place to protect the user from the solvent, including a double seal that separates the active smoothing environment from the user, plus electromagnetic redundancy locks that activate in such a situation as a power cut.

In addition to the above safety measures, the Apoller features an intuitive touch interface and an advanced vacuum system for locking in vaporized solvents. WiFi and Ethernet connectivity round the device out as a capable machine for the office environment.

The vapor chamber can hold a volume of 300 x 250 x 250 mm parts.

AMT PostPro

AMT PostPro is a UK-based manufacturer of post-processing machines for a wide range of 3D printing technologies.

The company offers three vapor smoothing machines ranging from a desktop unit to an industrial version.

AMT’s vapor smoothing systems use proprietary “environmentally friendly” solvents designed to be safer for operators and end users to handle, the company says. The desktop PostPro SFX machine ($17,000) is compatible with polymer powder bed fusion 3D printed parts in nylon 12. Other material compatibility is in development.

The larger, PostPro SF Pure, is compatible with polymer extrusion and powder technologies (including SLS, MJF, and HSS) made with more than 150 thermoplastic polymers, including nylons and flexible materials. Cycle times range from 90 to 120 minutes.

AMT’s third machine, the PostPro SF PP, is exclusive to polypropylene from a range of manufacturers, including Ricoh, BASF, HP, and AM Polymers, printed with filament, granule, and powder technologies.

AMT says its machines reduce surface roughness by 420% and improve mechanical properties three times better than without vapor smoothing.

- PostPro SF Pure: Chamber size of 400 x 300 x 400 mm or 400 x 600 x 400 mm. Volume 48 or 100 liters.

- PostPro SF PP: Chamber size of 400 x 300 x 400 mm or 400 x 600 x 400 mm. Volume 48 or 100 liters.

- Post Pro SFX: Chamber size 190 x 320 x 190 mm. Volume 11.5 liters.

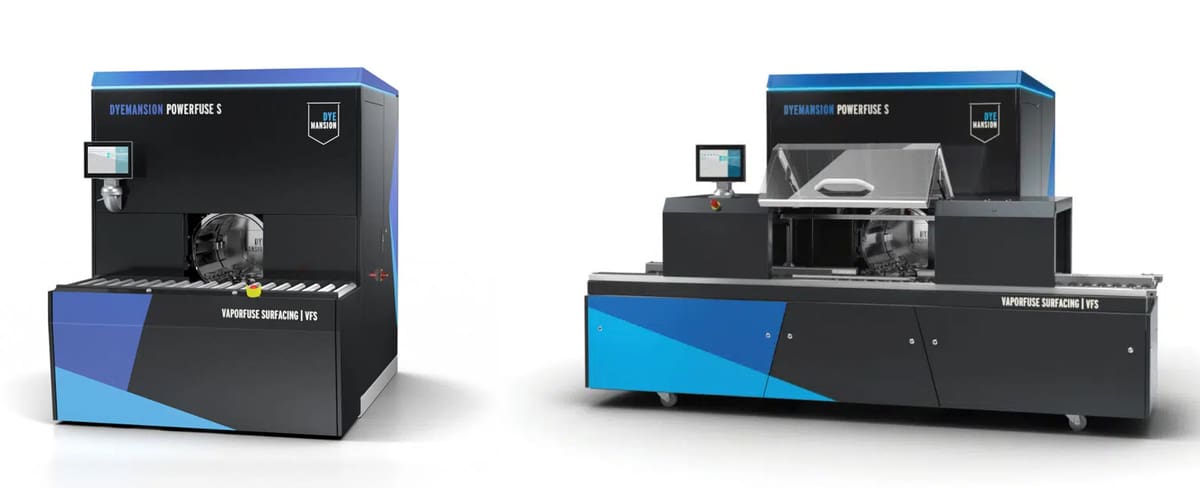

DyeMansion PowerfuseS

3D printing post-processing machine maker DyeMansion offers the Powerfuse S in four varieties aimed at the industrial market.

The Powerfuse S has an 85-liter capacity and a cycle time of 45 to 180 minutes. There’s a version for rigid materials like PA11 or PA12, and semi-rigid materials, including nylon and TPU, and then a version just for polypropylene. Each version has a manual loading and an automatic loading edition.

The Powerfuse runs on a proprietary halogen-free “VF44 EcoFluid” that is 100% bio-based and readily biodegradable as well as non-toxic. The machine features a closed-loop circulation with integrated solvent recovery.

DyeMansion says its smoothed parts have reduced roughness by up to 70%. With vapor smoothing, part surfaces are sealed, water-repellent, and washable to inhibit bacteria growth. Parts can achieve an elongation at break increase by up to 200% depending on your material, according to DyeMansion.

Powerfuse S machines are Industry 4.0 ready, meaning that they run fully automated 24/7, offering traceability and connectivity.

- Powerfuse S Manual: Chamber size, 1,700 x 1,700 x 2,070 mm. Volume 85 liters.

- Powerfuse S Automatic: Chamber size, 1,700 x 1,700 x 2,070 mm. Volume 85 liters.

- Powerfuse S PP Manual: Chamber size, 1,700 x 1,700 x 2,070 mm. Volume 85 liters.

- Powerfuse S PP Automatic: Chamber size, 1,700 x 1,700 x 2,070 mm. Volume 85 liters.

C2 Liquid Color Smoothing

The new C2 chemical smoothing machine from Germany-based AM Solutions, released in Nov. 2023 and still in beta testing, is a 2-in-1 system that enables both chemical smoothing and color dyeing of 3D printed polymer parts in a single process.

The entire process is fully automated and continuous without manual intervention, the company says. Like the other industrial machines in this guide, the C2 is a closed-loop system with continuous cleaning and recycling of the process liquid.

AM Solutions hasn’t released many details on the machine, but more should be revealed as the beta testing at various partners wraps up in 2024.

- C2: Chamber size, 400 x 400 x 250 mm. Volume 70 liters.

Vapor Smoothing Services

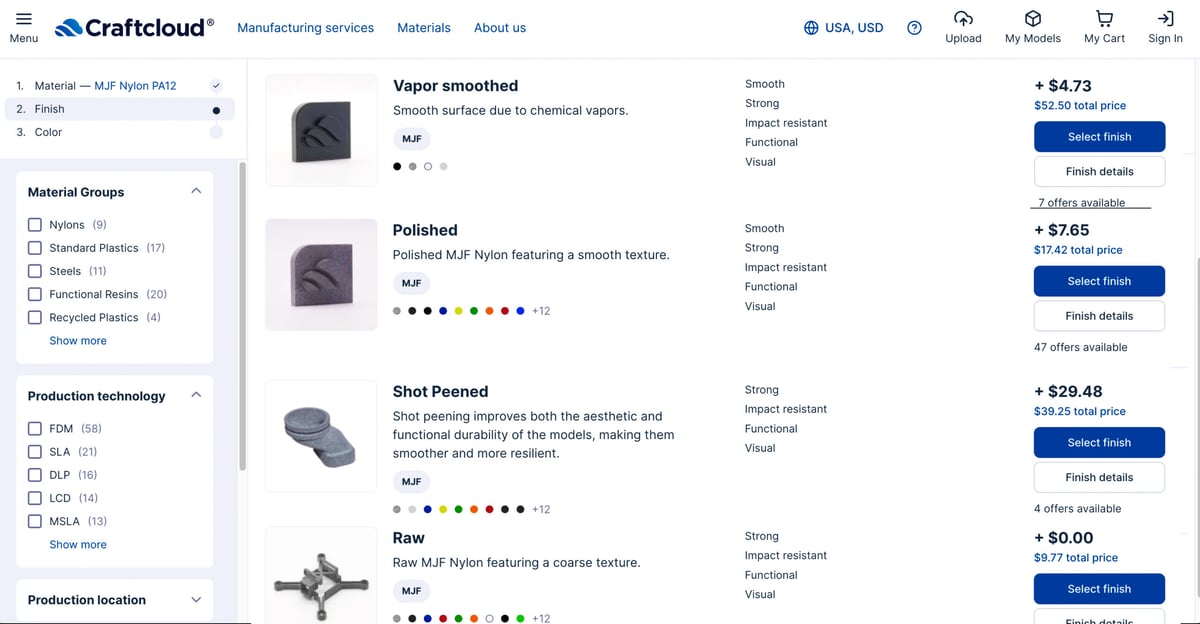

You don’t have to own a vapor-smoothing machine to get vapor-smoothed parts. Most 3D printing service providers today, such as Craftcloud by All3DP, offer vapor smoothing as a finishing option.

It’s not common to send your 3D printed part to a service provider just to have it vapor smoothed, rather the service provider would print and smooth the part.

Not all service providers offer vapor smoothing on all materials so check to see if the terms “vapor smoothing” or “chemical smoothing” are offered as finishes once you select your material.

For a list of our top 3D printing services worldwide, check out the article linked below.

License: The text of "Boost the Beauty & Strength of 3D Prints with Vapor Smoothing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.