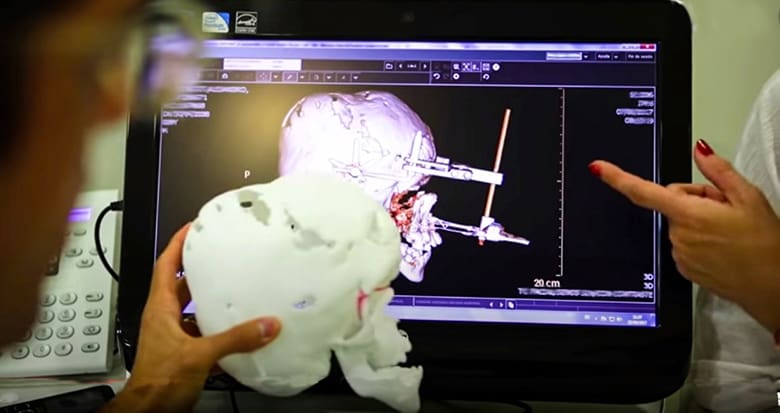

The Children’s Hospital Sant Joan de Déu in Barcelona first turned to 3D printing in 2013 to help plan a complex pediatric oncological procedure. Surgeons needed more information to prepare their approach.

Since that first planning case, teams within the hospital have found uses across six surgical specialties for 3D printing leading to the establishment of a 3D Printing Unit to better coordinate these needs.

The additive manufacturing specialist leading the way for this technology’s in-hospital use is a multidisciplinary team of individuals coordinated by Arnau Valls Esteve, a research and development engineer with a background in healthcare. Here he shares a look inside the hospital at how the use of a desktop 3D printer is leading to new ways of approaching treatment and contributing to better patient outcomes.

High Demand for In-Hospital 3D Printing

Case Study At A Glance

“Our first cases with 3D printing were in research and in pilot applications, mainly for surgical planning, for pediatric oncology and reconstructive surgery,” Valls says. “From 2013 to 2015, there was an increase in demand each year, from more and more surgeons, so we decided to create our own department staffed with personnel to create our own best model for implementation of this technology in the hospital.”

The hospital had, until the end of 2015, been working solely with external brokers to meet its 3D printing needs – and still works with some outsourced supply – but that marked increase in usage inspired the genesis of the 3D Printing Unit. Implementing the new in-house capabilities required significant research: which 3D printers would work best, and what would they be used to make? What would the 3D printer and its materials cost? What would be the clinical impact, and how would safety needs and regulations be met? Only after answering these big questions could the 3D Printing Unit take off – and take off it did.

“So many needs were things that can be done inside the hospital, such as simulation and training, where we can reduce costs by doing it inside,” Valls notes.

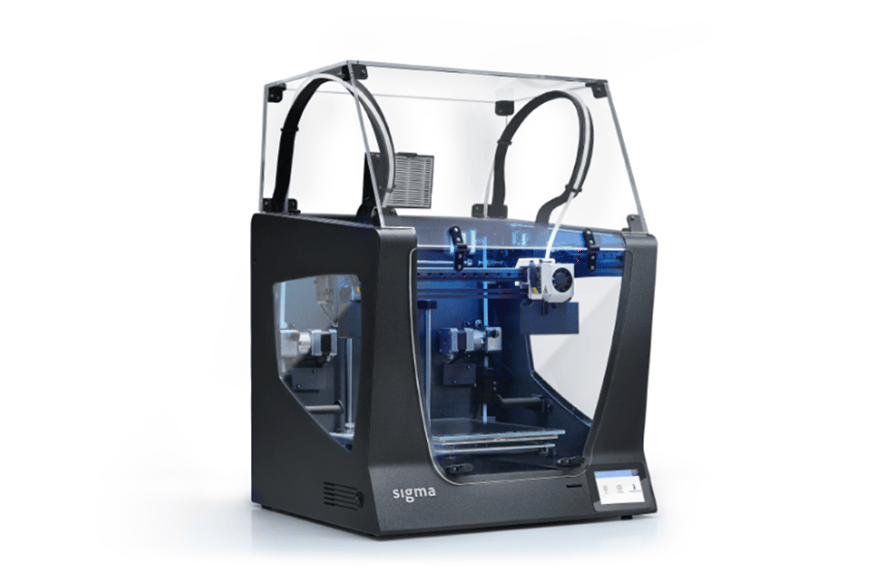

It was with this in mind that SJD Barcelona Children’s Hospital first brought a desktop 3D printer from Barcelona-based BCN3D on-site in 2015. Valls explains that the hospital has built a strong relationship with the local 3D printer producer, as well as the university – CIM-UPC, Technology Center of the UPC (Polytechnic University of Catalonia) – it was initially a division of, as the area’s technology centers are well connected.

“The BCN3D Sigma is the best 3D printer at its price point; it works well, and we knew we had a connection with the company, so we decided to go for this printer and not for others. Other options on the market did not have its dual extruding, which we find quite useful. We use different materials, like ABS or PLA, with others and find that removing the support material easily is a very helpful feature. Also important for us was the fact of having the support in our city, something that most suppliers don’t have,” Valls says.

Wide Ranging Technologies to Meet Unique Needs

Starting with an earlier Sigma system in 2015, the hospital upgraded to the Sigma R19 when it became available – and they’re thinking of investing in a second unit. The fact that BCN3D is a local company with a young team and fast-growth mentality shows that they have “loads of motivation for everything to go well and be the best,” Valls notes.

The Sigma R19 is one among several more industrial 3D printers, including FDM, PolyJet, and SLA technologies, used to meet the 3D Printing Unit’s overall needs. The convenience of the BCN3D system, though, lends itself to significant use in creating patient-specific anatomical models, personalized tools for surgery like cutting guides and positioning guides, and prototype parts of medical devices.

In many ways, the 3D Printing Unit isn’t turning to this technology as a replacement for older workflows; it’s developing entirely new ways of operating.

“This is a new way of doing surgical planning; before, it was just using an image and the knowledge of the surgeon, radiologist, and physicians,” Valls explains. “Now that 3D printing and 3D imaging is part of it, that’s new: there was no alternative. We use 3D printing in more than 70 surgeries planned per year.”

Hospital data from 2018 shows that the 3D Printing Unit participated in:

- 70+ surgeries

- 4 European projects

- 1 medical device

- 1 university course

- 4 R&D projects

- 8 publications

In just a year of use, the BCN3D printer paid for itself; this certainly makes the prospect of obtaining a second system more appealing to the hospital’s administration. Valls explains that “we could see a return even before one year; it depends on the demand in the number of cases in a given year.” In 2018, SJD Barcelona Children’s Hospital reported seeing 350,000 patients per year, opening the door to more potential use than 70 surgeries annually putting the 3D Printing Unit’s capabilities to use.

3D Models Reduce Surgery Time

Although Valls declined to disclose the monetary cost savings to the hospital of in-house 3D printing, he was emphatic about the importance of the time savings that surgeons report: “We can have a 30% decrease in the time of a surgery, which necessarily means the reduction of costs is quite significant for the operating room. There are still costs associated with the 3D printing and materials use, but for the same cost overall you can have less time in surgery and more time spent in planning. This is better for patients, as they spend less time under anesthesia and can recover faster, seeing fewer consequences in the long term.”

The timeline for planning is, he clarified, lengthier – but that additional time spent pre-OR means less sedated time for the patient. The surgical team working on a patient can already have a hands-on understanding of the exact anatomy they’ll encounter, and can even have practiced ahead of the procedure to ensure a smooth operation.

“For the time and the price, it makes sense for us: that’s the key,” Valls says. “For the volume we have, having a 3D printer in a lab inside the hospital that is used throughout the year helps our patients. It also opens the door for participating in R&D projects, which is interesting for the hospital. We can really help European medicine to advance, as we are all operating in a base of medical additive manufacturing.”

For other hospitals considering adding 3D printing to their labs, Valls is confident that once medical personnel see and understand the benefits, “it grows quickly.” Not only is 3D printing technology itself growing quickly, but so too is physicians’ and surgeons’ comprehension of its practical applications in their practices. “In terms of investment, you need to take evolution of technology as well as regulations into account, as well as the demand,” he advises.

For SJD Barcelona Children’s Hospital, though, that demand is only rising as they continue to see the benefits in terms of patient care. With better simulation and training reducing complications, as well as efficiencies in the reduction of intervention time and improvement in results and quality of training, bringing 3D printing in-house has helped this hospital step forward as a leader in Spanish healthcare.

The hospital is planning to deepen its commitment to 3D printing in the future, with augmented reality (AR) navigation, patient and device tracking, and organ bioprinting on the horizon. For stages of early planning, Valls says, “3D printing may revolutionize the way surgeries are done” – and longer-term, “with bioprinting, we hope that one day we will see this too.”

Lead image source: (Source: BCN3D)

License: The text of "Case Study: Why Hospitals Need 3D Printers" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.