All 3D printing filament starts out in pellet form – small granules of plastic – so why not skip the long strands and print directly with the raw material?

Not only do you save money (an estimated 65% to 90% reduction in printing cost per kilo), but you can print faster, and, more significantly, you can directly print with your own chopped-up failed prints, supports, and other plastic waste. This process is available to consumers and huge manufacturers alike.

There can be trade-offs in part complexity and some other drawbacks to the practice that we detail below, but for a wide range of applications, 3D printing with pellets and shredded recycled plastic is a financial and environmental win-win.

Below, we take a look at how to print with pellets, the best pellet 3D printers available today, and the pellet extruder systems available for your robotic arm.

What is Pellet 3D Printing?

Also known as fused granulate modeling (FGM) or direct extrusion, printing with material in pellet form isn’t brand new, but it is experiencing a resurgence in popularity driven by the growing demand for larger 3D printers and interest in throwing less plastic waste into the environment. Not only can the printers we feature below print with economical industrial pellets but also almost any type of single-source plastic waste, once you chop it up.

You can even purchase plastic waste, or recycled plastic pellets and shreds, in addition to almost any other kind of manufacturing plastic. In fact, available pellets range from PLA all the way to high-temperature, engineering-grade thermoplastics, such as reinforced nylon and PEEK. Pellet printing doesn’t limit your material options, it broadens them since there are plastics only available in pellet form.

Pellets are cheaper than filament not only because one processing step is eliminated but also because pellet-form plastics are used in injection molding and other types of manufacturing already, so the market for pellets is huge, which keeps prices low.

Pellet Printing: Pros & Cons

Such a seemingly small change in material can deliver significant benefits in 3D printing along with some drawbacks. Pellet printers deliver much faster print speeds and much higher throughput, which are both significant advantages over traditional filament FDM when printing very large parts.

According to research by chemical company Convestro, which manufactures pellets for 3D printing, filament printers offer a typical throughput of 2.27 to 113 grams per hour. Pellet printers, on the other hand, have typical throughputs of 227 grams to 9 kilos per hour.

3D printing with materials in pellet form doesn’t generally impact the mechanical properties of the final parts. Evaluation tests have shown that pellet printing produces comparable results to FDM with filament. In some cases, it may even improve the mechanical characteristics, like tensile strength, because the plastic hasn’t been processed a second time into filament.

In the end, will the advantages of printing with pellets outweigh the drawbacks? Take a look at this list of pros and cons and decide for yourself.

Pros

- Cost Saving. Pellets can cost 65% to 90% less than filament of the same plastic, depending on the volume of your purchase.

- Faster Print Speeds. Because of the large heat zones in pellet extruders, nearly 100 times greater material throughput is possible compared to filament printers. This makes pellet extruders capable of up to 200 times faster print speeds.

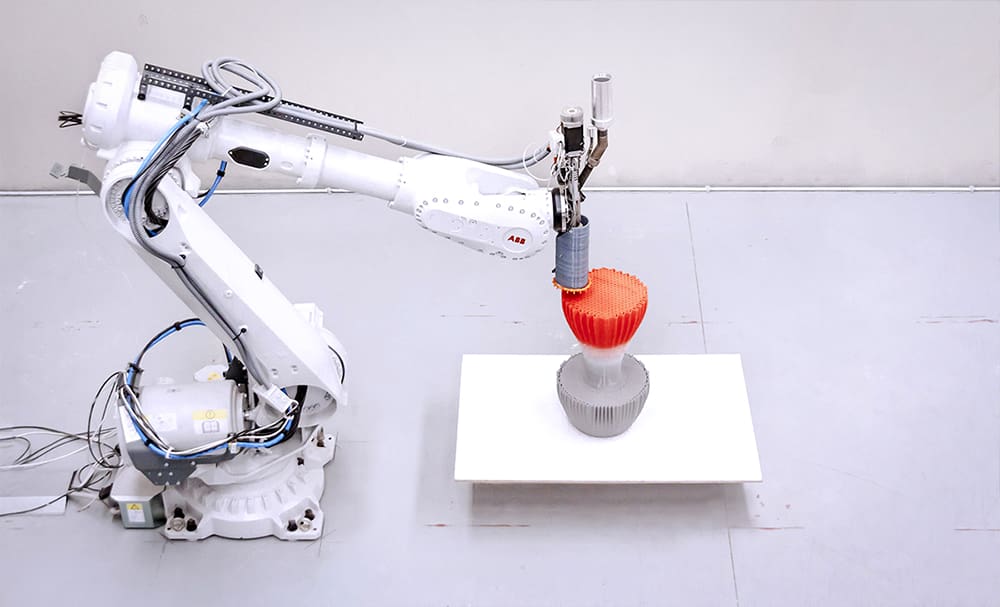

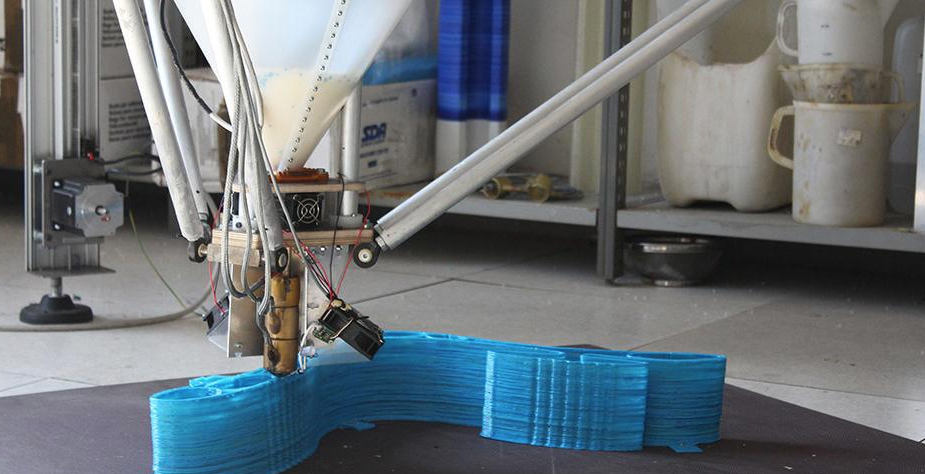

- Larger Print Sizes. 3D printed furniture and large objects are often only economically feasible with cheaper materials and faster print times. Robotic arm 3D printers coupled with pellet-fed extruders are what manufacturers typically use for very large prints, such as the furniture pictured below.

- Custom Composites. Create your own custom material blends by combining different pellets. You can easily add dyes, additives, and reinforcement fibers to the mix to create custom composite plastics. Reuse your waste plastic by tossing it in with your virgin pellets.

- Environmental Benefits. Someday, everyone will be chopping up their own household plastic waste to use in their 3D printer. Today, initiatives such as Print Your City are raising awareness by helping cities collect plastic waste to 3D print public park benches. Plastic makers, including Covestro, sell recycled plastic shreds.

Cons

- Limited Detail and Geometry. Due to the speed at which molten plastic is extruded, the practice isn’t generally used to produce fine details when coupled with a robotic-art style 3D printing. Desktop FDMs using pellets, however, can produce 40-micron layers heights.

- Print Defect Potential. Depending on the quality of your pellet extruder and original materials, you could experience print defects caused by inconsistent material intake and output. These could range from voids and air bubbles to warping and over- or under-extruding.

- Availability of Pellets. For industrial 3D printing, obtaining hundreds of kilos of pellets is easier than filament, but for consumers looking for just 5 – 10 kilos of pellets at a time, distributors are few.

- Lack of Retraction. Retraction in FDM printing prevents material from oozing from the print nozzle by reversing the direction of the filament-feeding gears. Pellet printers can’t do this because they rely on screws to push material to the nozzle. The only option to cut the flow of material is to stop or slow down the screw or block the nozzle. Only some industrial pellet 3D printers boast an integrated melt pump that is fully retraction-enabled.

How to Print with Pellets

You can’t process pellets through a regular FDM filament extruder-melter assembly. To print with pellets and shreds, you’ll need to purchase a pellet 3D printer (see printers below), use a pellet extruder system on a robotic arm, or convert your current FDM printer to a pellet printer with add-ons.

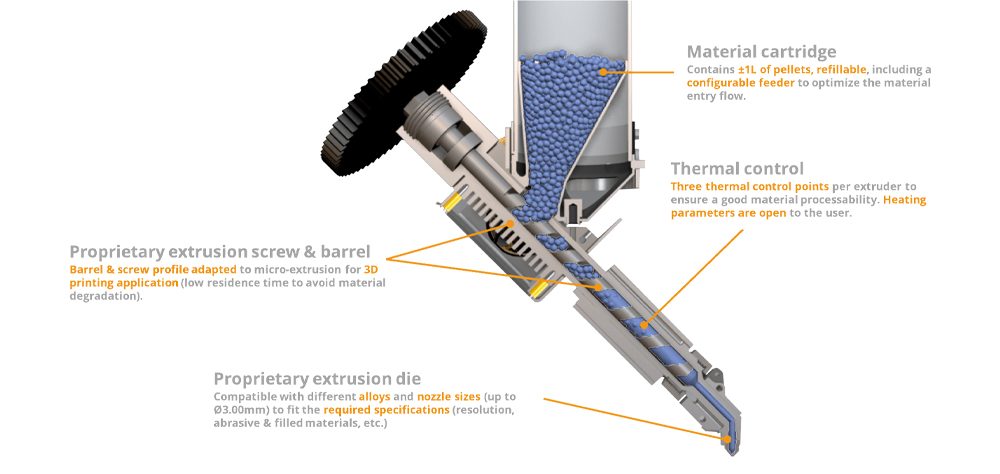

Pellet extruders are specialized print heads designed specifically for 3D printing with pellets or shreds. The heart of the extruder is an auger screw that transports pellets from the hopper outlet to the printing head. Along the way, the pellets pass through heaters that melt the plastic.

Most pellet extruders have several heat zones. The first one generally has a higher temperature to ensure uniform material melting. The other zones are lower in temperature, as their purpose is to maintain a consistent temperature and flow along the long screw. Note that these heaters are generally hotter than an FDM heater, and operators must ensure constant throughput to avoid burning the plastic.

The movement of the auger screw builds up the pressure at the end of the extruder, which forces the melted plastic through the printer nozzle.

The hopper in a pellet printer is just a large container to house the pellets or shreds. Some hoppers allow the pellets to fall down under their own gravity, while others use conveyors to move the pellets forward.

Some printers, such as from 3D Systems, Atlas, and WASP, have exchangeable extruder set-ups so you can print with pellets or filament; other pellet 3D printers are exclusive to loose material.

Desktop Pellet Printing

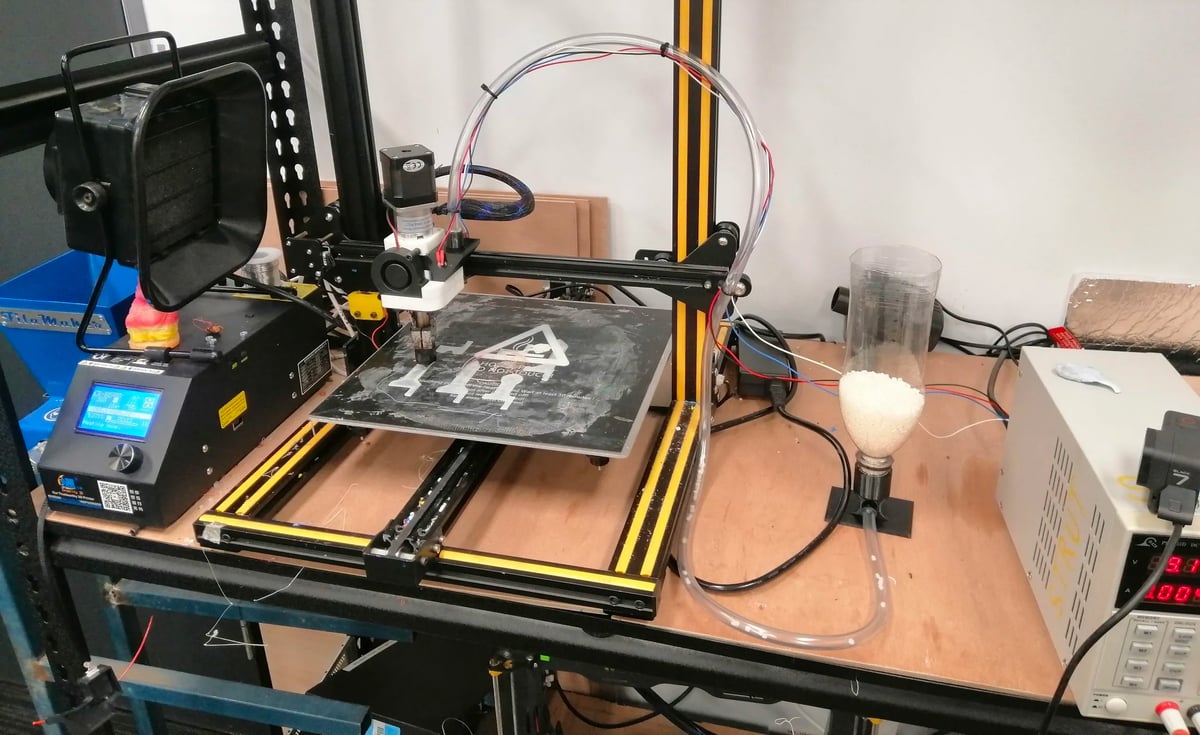

Converting your current FDM filament printer into a pellet printer is possible if you’re handy, but it comes with a new set of potential challenges, such as possibly needing to modify your printer’s firmware or redesign your printer’s X-carriage to work with automatic bed leveling. Running a pellet extruder also may consume more power than your printer’s original design.

Currently, you won’t find many major desktop printer brands, such as Ultimaker or Raise3D, offering pellet printers or printing conversion kits. (Creality is a recent exception.) What you will find are a few companies — such as Polylab or Extrudinaire — that make add-on pellet extruders that can be used to transform most existing desktop filament printers into pellet printers, they say. These extruder units are designed to enable consumers and small businesses to start recycling plastic and realize the other benefits of pellet printing.

Industrial Pellet Printing

For business and industrial users, 3D printing with pellets can save tens of thousands of dollars a year in materials, especially if you print with the more expensive engineering-grade polymers. The professional 3D printers we detail below have largely perfected printing with pellets to get the highest print quality from the technology without the defects you may experience in converted desktop printers.

Of course, you don’t even need a 3D printer to print with pellets. All you need is a pellet extruder head and a pellet hopper hooked up to a robotic arm or CNC machine with the appropriate software. This type of set-up is known as robotic arm 3D printing and it almost exclusively uses pellets as material. These, however, are not the type of printer we’re featuring here since robotic arm is really a different technology and we go deep into the details of the extruders, robotic arms, software, and applications in the separate guide linked below.

Here, we focus on 3D printers, both desktop and industrial, that are not robotic arm systems, but rather all-in-one gantry- or delta-base 3D printing systems.

Pellet 3D Printer Manufacturers

Many of the 3D printers below were launched in just the past few years showing that printing with pellets is gaining attention. You’ll also find a wide selection of pellet printers that use a delta configuration that speeds up the printing process even more.

IT3D Tumaker NX Pro Pellet

Tumaker’s NX Pro Pellet ($7,000) features the company’s own extrusion system that makes printing with pellets as easy as filament. You can pour small amounts of pellets directly in the hopper or use the optional Automatic Pellet Feeder that independently and directly feeds the head hopper. This mechanism frees the user and allows him to ignore the routine of manually feeding the extruder. At the base of the feeder, a temperature and humidity sensor manages this data to keep it in optimal conditions. The NX pro for pellets comes as a single or dual extruder system or you can select one pellet extruder paired with a filament extruder.

The NX Pro has a print volume of 295 x 185 x 200, a heated bed to 100ºC, automatic bed leveling, and a 300ºC extruder that can handle everything from PLA to PEEK as well as carbon fiber nylon. There are six available nozzle diameters.

The company offers nine pellet-enabled printers to choose from, spanning desktop to completely custom and configurable large-format 3D printers. You can opt for single, dual, or quad print heads and select filament, pellet, or both in a range of build volumes.

Among the pellet printers on the market, these units stand out for their detail quality boasting a layer resolution of 10 microns.

Piocreat G5 Pro

Well-known desktop 3D printer maker Creality has another brand called Piocreat that’s been working on desktop and industrial pellet material extrusion machines since about 2021. It launched its G5 Pro in 2022.

The G5 Pro ($5,000) has a very large volume (500 x 500 x 500 mm) for a desktop printer, a heated bed, and a nozzle temp up to 450ºC so it can handle just about any material, including pellets and recycled plastics, but it does not come enclosed, so that may limit your material options a bit.

The hopper is relatively small and material is fed to the extruder by gravity, but there’s a zippy (100 mm/s) print speed and a decent minimum layer height of 0.2 mm, and it can achieve a 3-mm layer height with the 2.4 mm nozzle for rapid printing. If your material runs out, there’s a pellet run-out detection and print resume after a power outage.

The printer comes with both automatic leveling and auxiliary leveling modes, runs on Creality Print slicing software, and has a magnetic spring steel build platform for easy part removal.

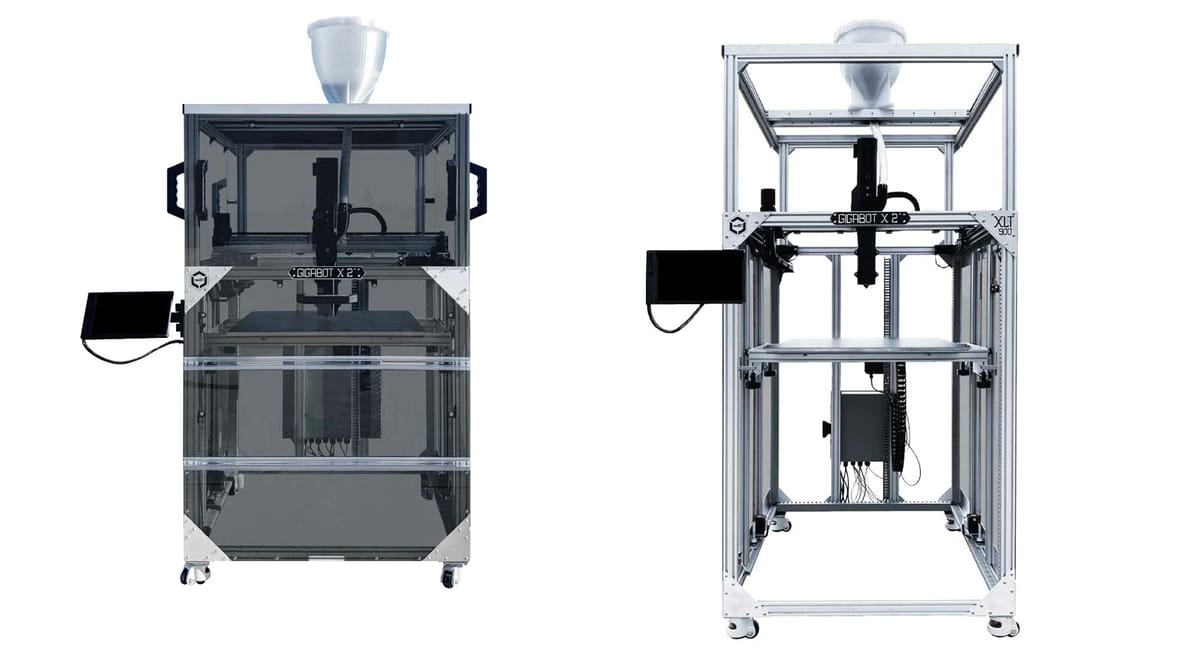

Re3D Gigabot X2

Re3D produces some of the best-known pellet 3D printers with its Gigabot X line. Including both Gigabot X2 ($20,800) and Gigabot X XLT, the printers are compatible with recycled and virgin plastic PLA, PC, and PET pellets, flakes, and shreds, alongside customized specialty composites.

Gigabot X2 has a build volume of 570 x 595 x 470 mm, while the Gigabot X XLT bumps that up to 570 x 745 x 770 mm. Able to handle pellet sizes up to 5mm and materials that melt at or below 270°C, the Gigabots support a wide range of material options. The optional enclosure goes for about $900.

Re3D says they’re able to provide customized hardware for their machines, which makes them a great choice for highly specialized applications.

In late 2022 the Re3D printer line got a few upgrades, including a front-mounted 10-inch full-color LCD touchscreen, an overhauled electrical system and control board. Also new is a webcam viewer for remote monitoring and an integrated USB port for loading Gcode files directly onto your printer. The company transitioned from Marlin firmware to Klipper because it says it enables higher precision stepper movement, smooth pressure advance, and input shaping, and also an API server that enables the opportunity for custom development.

The GigabotX 2 features a feeding and extrusion system engineered for processing pelletized and granular thermoplastics. Material is manually fed into the 24-hour capacity hopper, which rides on an independent hopper gantry system, to allow a full and smooth range of motion and consistent feeding into the extruder.

Filament Innovations

Despite the name, US-based Filament Innovations is perhaps better know for its innovative pellet 3D printers. There are three on the menu and the massive (1,060 x 1,080 x 1,050 mm) Poseidon is the only one on this list that can switch seamlessly between pellets and filament. The machine is also designed to be customizable so you can shoose dual filament extrusion or only a pellet system. The hybrid version includes the entire ecosystem including a pellet system, high-flow filament system, 25kg pellet dryer, and the Odin slicing system for about $125,000.

The smaller Icarus ($50,000) gives you the choose from either a pellet extrusion system or a high-flow filament system, and while the slightly larger Ares ($79,000) is a dedicated pellet printer.

Each machine features pellet feeding systems and extruders from Dyze Design with tool steel nozzles available in six diameters from 1 to 5 mm. There are two LCD screens included with the system. The 7-inch PanelDue from Duet3D, and a 15-inch touchscreen enable you to visualize your height-map, write custom macros on the fly, and monitor your system. File transfer and connecivity options include USB jump-drive, WiFi, and hardwired Ethernet.

3D Systems Ext 1070 Titan Pellet

3D Systems, offers two pellet-enabled printers with large-scale build volumes – from 1,066.8 x 1,066.8 x 1,219.2 mm on the 1070 Titan Pellet to 1,270 x 1,270 x 1,828 mm on 1270 Titan Pellet. The pellet extruder and the filament extruder can both reach 400°C. Couple this with the heated bed to 140°C and enclosure to 80°C and a wide range of engineering grade materials are possible, including PEEK. In fact, Titan printers can use hundreds of grades of pellet materials and dozens of filament materials from any supplier.

The Titan printers aren’t just pellet printers, the base unit includes a single pellet extruder but can be equipped with up to three toolheads including a second pellet extruder, a filament extruder, and a 3-axis CNC spindle. For large parts that need to be printed quickly, select pellet extrusion for high-deposition rates. For parts that require high surface resolution and fine details, filament extrusion is the preferred method.

Even with the filament extruder, the machines offer high flow rates of up to 1lb/hour, and the pellet extruder works even faster. The printers support a wide materials range, from soft rubber plastics to carbon-filled high-performance composites.

The Industry Magnum

Swedish manufacturer The Industry (aka The Industry Sweden AB, formerly known as BLB Industries) offers a large-format 3D printer aptly called Magnum ($160,000). It’s capable of printing with pellet materials and recycled plastics in a range of formats. This new industrial printer can print with composite materials containing wood, hemp, flax, and other biomaterials to become “the most sustainable 3D printer on the planet,” the company boasts. Not only are pellet materials less than half the price of filament, but printing with pellets is typically faster.

Magnum’s large print volume (2.16 cubic meters) enables really large prints but is compact enough to be transported in standard containers. The printer also features an air-cooled nozzle to remove heat from the object to prevent the collapse that can happen with really large prints. Depending on the material, this can enable it to print even faster. The top print speed is an impressive 600 mm/s.

The patented heated vacuum table enables more efficient and cheaper production, the company says, because you can remove the print on the printing sheets and then immediately start another print.

WASP Delta 3MT HDP

WASP 3MT HDP is a hybrid filament and pellet 3D printer that comes with two extruders. Its XL extruder, along with its pneumatic loading, is capable of extruding standard, technical, and recycled thermoplastics starting from pellet form.

The printer has a sizeable 1,000 x 1,000 x 1,000 mm heated print chamber, which makes it suitable for large prints. WASP says the max speed is 3.8 kg per hour using ABS and a 5 mm nozzle. The minimum layer height is a fine 0.5mm (with 2 mm nozzle) to 2.5 mm (with 5 mm nozzle).

The 3MT HDP comes with the features you’d expect from an industrial 3D printer, including onboard camera monitoring, Wi-Fi support, open-door safety sensors, a resurrection system to restart printing in case of a power outage, and a printer self-diagnosis system.

Also pellet-enabled is WASP’s slightly smaller 4070 HDP ($23,000) large format 3D printer with a 5-liter pellet tank. The 4070 HDP has a build volume of 400 x 400 x 600 mm.

Epeire 3D T-600

Epeire 3D’s Epeire T-600 is hot stuff, at least if its printing temperatures are anything to go by. With a maximum printing head temperature of 600 °C the printer also features “Hot Bubble” technology, which creates a targeted 350°C hot area around the nozzle, removing the need to heat the entire build enclosure and thus reducing energy consumption and heat loss, the company says. As a result, the T-600 can print with practically any thermoplastic material, including glass- or carbon-reinforced PEI and PEEK.

With an accuracy of 30 microns, the T-600 can reproduce details at the same level as FDM filament printers (although that level of accuracy comes at the cost of decreased throughput). It also has a well-sized print volume of 500 x 540 x 500 mm, which makes it a very attractive small to medium-scale manufacturing option.

The company’s other pellet 3D printers focus on metals and ceramics. The Epeire T-MIM is not a metal injection molding machine as the name might suggest, but instead is a metal and ceramic 3D printer. Its reinforced stainless steel extrusion system (300 °C) supports highly abrasive printing feeds. The company also features a metal pellet extrusion machine especially for titanium.

In 2023, the company launched a desktop version of the T-600 called the E-300, which is also pellet feed. Not quite on the market yet, it will have a 250 x 250 x 250 build volume.

Pollen AM P Series

French 3D printer maker Pollen AM offers plenty of options when it comes to which type of pellet printing you’d like to do, from standard thermoplastics to high-temperature polymers to metal and ceramic.

The company’s PAM (Pellet Additive Manufacturing) series of printers include “P” machines tailored specifically for thermoplastics with engineering that fixes many of the common drawbacks of pellet printing. For example, the P printer ($65,000) has six nozzle sizes available, so it can achieve layer heights down to 40 microns. The printer’s print head has four extruders.

The company’s P-HT (high temperature) performance material printer has two extruders that can reach 450 ºC, a heated chamber up to 80 ºC, and a heated bed up to 250 ºC.

The MC metal and ceramic pellet printer prints with most of the existing metal injection molding feedstocks. Using these standard industrial metal feedstocks with the MC makes sense for industries already using them. Existing grades can be printed as-is just like in injection molding. The MC is also compatible with thermoplastics.

All Pollen printers use the same PAM series frame with a cylindrical platform 300 mm in diameter and height. The variety of different extruder configurations and material options make Pollen’s machines suitable for practically any application, from prototyping to the production of high-grade parts for aerospace and other demanding industries.

Arburg Freeformer 300-3X

Arburg brings serious accuracy to the table with their Freeformer Series, including the 300-3X, the larger 750-3X, and the smaller 200-3X, which offer pellet printing with a minimum layer thickness of 0.2 mm.

The Freeformers achieve this high level of detail thanks to their unique printing technology, which the manufacturer calls Arburg Plastic Freeforming. Unlike the other listed printers, the Freeformers deposit melted plastic as individual droplets instead of a continuous string, so it’s a material jetting technology rather than an extrusion technology.

The printers feature an open platform, making them compatible with any plastic material that can melt, from ABS and PLA to medical-grade PLA and PC thermoplastics. This is what you’d expect from a company that makes injection molding machines. The 300-3X can print with three materials at once and also a material drying system.

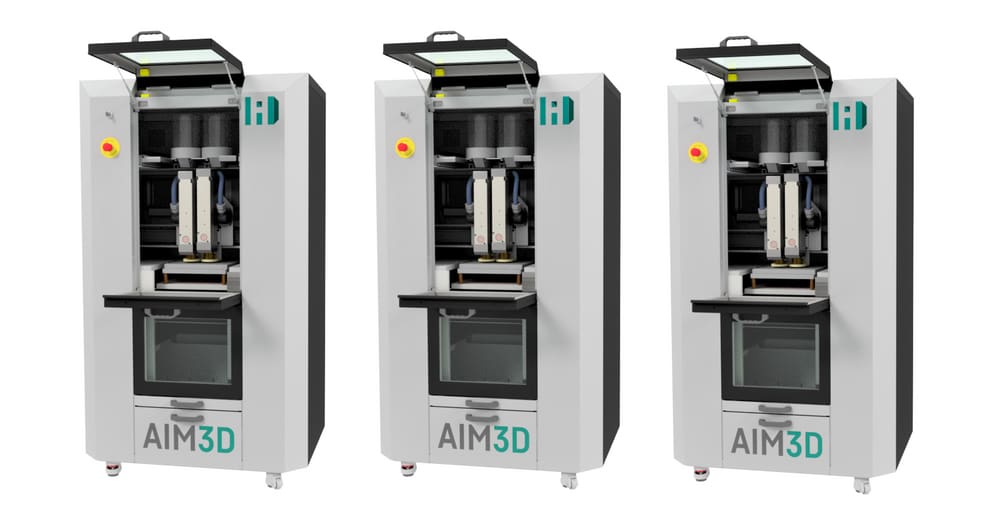

AIM3D ExAM 255

German start-up AIM3D has printers still in beta testing but they’re on our list for the shear promise of their technology. (We’re rooting for you AIM3D!)

First off, the company offers two multi-material pellet printers. And when we say multi, we’re not talking about just different kinds of plastic. You can print with plastics, metals, and ceramics. And not some special proprietary materials, the same conventional plastic, metal, or ceramic pellets used in injection molding, plus recycled shredded material.

The company said it developed this printer to overcome the material challenges in the 3D printer market, such as filament and expensive proprietary materials. The idea is that these machines will become “the 21st century’s machine tool” seamlessly integrated into any shop floor.

Each extruder can hold up to one liter of material and the material hopper can be refilled during the printing process. The build space is generous and the company says layer heights can go as low as 25-microns, depending on the material. The ExAM 510 is larger and faster.

Weber Additive DX 025

The additive manufacturing arm of German manufacturer Hans Weber, called Weber Additive, launched a pellet-fed large gantry 3D printer in 2020 that’s about the size of a freight elevator.

The DX 025, with a print volume of 2.5 square meters, is based on a CNC-controlled portal system and comes with your choice of proprietary Weber extruders specially developed for 3D printing. The DX 025 comes standard with a pellet conveyor system and material dryer.

The DX 025 is configured for your needs and can include a number of options based on your application. It can be fully or partially enclosed, there’s a fume extraction option, a chamber heater option, melting pumps that ensure a consistent material output at high speeds, and various print beds.

The DX 025 has a handy feature that analyzes your digital model’s G-code generated from popular slicers like Cura and Simplify3D, and converts the estimated amount of filament to the estimated amount of pellet material.

The Weber Additive robotic arm 3D printer and the stand-alone extruders are covered in our guide to robotic arm 3D printers.

JuggerBot 3D

Founded about 10 years ago in Youngstown, Ohio, large-format 3D printer manufacturer JuggerBot 3D offers industrial pellet-fed 3D printers called the Tradesman Series. At one time the company offered large-format 3D printers that used filament but has since completely moved over to pellet material machines.

The P3-44, which comes in variations, thus the “series,” is a fully enclosed 3D printer capable of printing at a speed of 13.6 kg of material an hour. The bed can be heated to 120°C and the chamber to 95°C, so you can print with a wide range of materials, including glass- or carbon-fiber-reinforced polymers, PEEK, PEKK, Ultem, and more.

Rather than a touch-screen, the Tradesman is built with an integrated workstation that includes a monitor, slicing software (ORNL Slicer 2), and machine control programs with a library of processing information. Also, included are third-party material profiles streamlined production workflows called Material Cards.

Your Tradesman includes a pellet material hopper and feeding systems with a mobile drying unity to remove moisture.

JuggerBot 3D says its industrial machines include “robust integrated motion controllers” coupled with closed-loop servo motors and absolute encoders to ensure “reliable and repeatable movement.”

JuggerBot 3D’s machines range in price from $275,000 to $325,000.

Up-And-Coming Pellet Printers

3D printing with granules is evolving at a rapid pace and manufacturer and consumers look to save money while printing big. Below are some interesting new printers that have debuted but are not yet commercially available or have just launched.

Roboze Argo 1000 HyperMelt

Roboze launched it’s huge industrial 3D printer Argo 1000 in 2022 as an FDM printer using massive rolls of filament but announced in late 2023 that it was converting the machine to run on pellets instead. The company is calling its new pellet system Hypermelt. And although it won’t be an open material systems, Roboze says you’ll have a wide range of engineering-grade polymers and high-performance composite materials to choose from, including PEKK, Ultem, and carbon PEEK.

Roboze says the Argo 1000 is the “world’s largest pellet-based 3D printer,” but it actually isn’t. There are at least three other 3D printers that are larger; the WASP 3MT HDP, the Industry Magnum, and the JuggerBot 3D P3-44.

Fused Form P1000

If your business is located in South or Central America, shipping a large-format 3D printer from Europe or the US is likely cost-prohibitive. But that’s certainly not the only reason to consider the P1000 large-format pellet 3D printer from Colombia-based manufacturer Fused Form.

“Our machines are designed to be durable, robust and 24/7-hardworking,” the company says. The P1000 has an impressive 1,100 x 1,100 x 1,300 mm enclosed volume, a 300 mm/s maximum printing speed, a super-hot extruder (450°C), and a heated bed to 120°C.

Q.BIG 3D Queen 1

German couple Katja and Dennis Herrmann founded Q.Big 3D in 2019 to make large-scale 3D printing economically viable, they say. The company’s first machine, the Queen 1, debuted in 2023, and it sports some innovations that may catch on quickly in the large-format 3D printing space.

First is its print head with variable nozzle diameters that can switch from a 1.5 mm diameter to a 3 mm diameter, which enables it to print fine detail in parts that need it and less detail in parts that don’t, resulting in faster print times. Maximum print speed is 500 mm/s.

The Queen 1 only prints with material in pellet form with a maximum output of 2.0 kg/h. It’s a fully enclosed machine with a build volume of 1,700 x 1,050 s 1,050 mm, a heated chamber to 80°C, and a heated bed to 120°C. Q.Big 3D says its machine is particularly designed to “accelerate development and early-stage manufacturing of large parts.”

Where to Buy Pellets & Source Shreds

As we mentioned above, companies and industrial manufacturers should have no problem sourcing 50-kilo bags of pellets from commercial polymer makers and plastics distributors around the globe. Smaller quantities for prototype labs and non-professionals are a little harder to find but not impossible.

Just like shopping at Costco, it only makes sense to buy in bulk if you plan to use it. As with plastic filament, pellets should be stored in a moisture-free environment and may need to be dried before use.

Recycling your own plastic is another story. Corporations are beginning to look seriously at the amount of plastic waste they produce and how to address the issue. Carmaker Audi, for example, launched a program this year to shred industrial packaging and feed it into a filament maker to use in its 3D printers and produce factory tools.

Industrial shredders can consume your plastic waste and produce an abundance of material to feed your hungry 3D printers. For smaller-scale shred production and more on how to chop up your failed prints and scraps, see our article below:

Pellet & Shred Resellers

License: The text of "The Best Pellet 3D Printers & Extruders" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.