When Julian Jauk was pursuing his degree in architecture at Graz University of Technology in Austria, his professor Milena Stavric invited him to join a research project on 3D printed clay. From then on, he was hooked on the marriage of material, method, and advanced computational design that enables truly innovative creations from one of the world’s oldest building materials.

Now, after 11 published research studies and papers on experimental clay shaping techniques, reinforced clay, and multi-material printing, among other topics, plus speaking at international symposiums and teaching at the university — he even developed a software plugin specifically designed for 3D printing of clay called Termite* — Jauk is now a post-doc researcher and teacher at the university’s Institute of Architecture and Media, after completing his thesis on advanced methods of 3D printing with clay

All3DP caught up with this innovative young researcher to talk about the cutting-edge of clay 3D printing today, including the breakthrough applications, advances in the materials, and the appeal of clay for sustainability in architecture.

Is 3D printed clay in architecture just decorative or can it be structural?

“I envision numerous applications for 3D printed clay in architecture, including load-bearing structural components resembling bricks, columns, façade elements, and intricate details such as handrails or purely decorative features. While these applications focus on utilizing 3D-printed elements as fired ceramic components, there is also extensive research into printing monolithic structures from unfired clay. However, my research is specifically focused on fired ceramic modules. In my opinion, 3D-printed clay is unlikely to replace mass-produced bricks entirely. Instead, it will contribute to a hybrid system, where mass-produced bricks are used for the majority of the structure, and 3D-printed elements are employed in technically challenging areas, such as corner connections, window joints, and other complex structural details.”

What are some advantages of clay over concrete or currently used materials?

“I’d say the environmental advantages of choosing clay over concrete or polymers for large-scale 3D printing are quite obvious. In my daily work as a researcher, clay is particularly useful because it can be reused after printing, making it ideal for design-driven research methodologies and rapid prototyping1. Additionally, the natural qualities of clay, including its colors and haptics, have a positive psychological effect on people, as this material has been part of human history since as early as 7,500 B.C.”

[1Printed clay, and even completely dried clay, can be rehydrated by adding water and kneading it to restore its workability.]

What are the challenges of clay as a material in 3D printing? How can it be improved?

“When it comes to 3D printing with clay, the primary limitation is its viscosity, which directly affects the types of designs that can be achieved, particularly with overhanging structures. While the overall shrinkage can be calculated quite precisely, this is contingent upon well-designed objects. Specifically, the mass should be evenly distributed within an object to prevent cracking during the drying process.

From my experience in 3D printing, I’ve developed an intuition for what is possible and what techniques can be employed to push the boundaries of the material’s limitations. Techniques such as fiber reinforcement, filament reinforcement, and the strategic use of heat guns during printing are valuable. Additionally, designing printing paths intelligently—using non-planar printing beds to support specific geometries—can also be effective in achieving more complex forms.”

What breakthrough application do you think could accelerate the adoption of clay 3D printing?

“3D printing of ceramics has begun to gain traction over the past few decades. However, digital fabrication of clay is not yet as technologically advanced or standardized as the concrete, wood, or steel construction industries.

I believe that progress in this area can be divided into three stages: art, research, and industry. Currently, 3D printing of clay is well-established among artists but is still in the early research phases at universities. I propose that once larger companies begin to engage with 3D printing of clay in the near future, the market will adapt accordingly.

In my PhD thesis, I identified five key areas that need to be advanced to further develop 3D printing of clay:

- Development of novel material mixtures and composite materials.

- Fundamental research in the field of mechanical properties of 3D printed clay.

- Enhanced accessibility of software to enable a broader adoption of 3D clay printing.

- Further development of existing 3D printing methods to enhance object surface quality and structural integrity.

- Representative showcase projects that underline the distinct potentials of 3D printed clay”

What do your students learn from designing and 3D printing with clay?

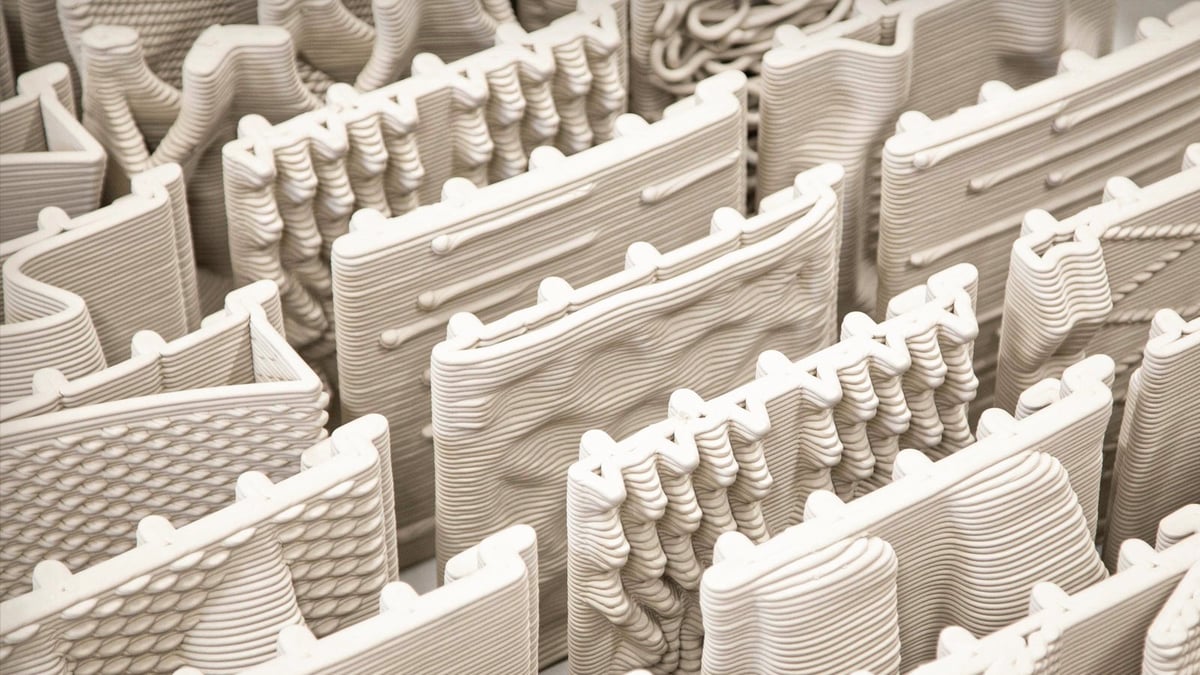

“For most students, working hands-on with clay was a completely new experience. Additionally, for many, this course represented their first encounter with digital fabrication. As a result, there is a significant amount for them to learn within just one course. Although many students are familiar with 3D printing plastics using nozzle diameters around 0.4 mm, they are often surprised to discover that, due to the size of an individual printing path or layer, the design of the printing paths—rather than simply creating a closed 3D object on the computer — is crucial for the structural and aesthetic qualities of the printed elements.”

Which type of clay 3D printer do you use at Graz?

“We initially began with a Delta WASP 40100 clay printer and later integrated the WASP Continuous Feeding System as soon as it became available. To prepare the printable clay, we also utilize a 40-liter industrial kneading machine. Last year, we modded the WASP printer by replacing the electronics, including the motherboard, with open-source components to allow for a more experimental workflow. Currently, we are developing a clay 3D printer with a printing volume of several meters.”

____________________________________

* Termite, version 1.0 released in 2023, is a plugin for Rhinoceros 3D that addresses the unique requirements of clay printing, such as the need for larger nozzles and precise control over printing paths, in order to make the material more accessible to a wider audience, including companies, artists, and educators.

____________________________________

Julian Jauk’s work was funded by the Austrian Science Fund (FWF), project no. F77.

You May Also Like:

License: The text of "An Expert’s Perspective on Clay 3D Printing for Architecture – New Applications & Challenges" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.