Classic Cartesian-XZ-head 3D printers are on the out-and-out in consumer circles, and CoreXY is the new hotness. Naturally Creality, with its dominant market share, doesn’t want recently launched brands eating its lunch with their shiny new, well-tuned systems. So, it’s responding to recent breakout market successes with its new “flagship” 3D printer: the Creality K1.

Creality already took a couple stabs at CoreXY machines with the Ender 6 and Ender 7, which we ultimately found “forgettable”. CoreXY 3D printers have evolved a lot since then, and breakout successes Bambu Lab have helped popularize the kinematics among hobbyists in a big way. The K1 is a clear answer to those new machines, with a shared look and even a name that seems set to confuse and conflate.

We first reviewed the Creality K1 in July, where it underwhelmed to the extreme with poor printing performance (outside of choice PLA), flawed software, and induced the perpetual eye roll of open source license infringement. We gave it a two out of five, which we stand by for the ultimately bungled release of a supposed flagship product.

Since then, Creality has been at work updating the K1 to improve or remedy some crucial complaints, and the printer is significantly better for it. As with any 3D printer we review that attracts sufficient interest, we continue testing long after we’ve hit “Publish.” As such, our updated impressions of the K1 are here. It wouldn’t be right to obliviate the original review from the web, particularly while some deficiencies remain. So, in the interest of keeping this as clean a reading experience as possible, we’ve forked the review. What you’ll read below is our current, up-to-date thoughts on the Creality K1 following further testing and, crucially, the installation of Creality’s redesigned hot end and extruder that are now standard on all new Creality K1 3D printers. Jump over to our archived K1 review to read our initial thoughts on the Creality K1.

The Verdict

Pros

- Fast printing that lives up to promises

- Consistent automatic leveling

- Excellent layer uniformity

Cons

- Shameful lack of open source acknowledgement

- Broken basic features and gutted firmware functionality

- Disjointed software experience

The Creality K1 is a decent machine that is capable of outperforming many 3D printers in its price range in terms of speed and part quality. Its enclosed design is an asset for the printing of higher-temperature materials, and we’ve seen great success printing with difficult materials like polycarbonate.

In our eyes, the K1 has had a rocky start to life, with hardware issues affecting some units’ printing performance and prompting a stealthy hot end redesign from Creality that’s now standard on all newer K1 machines (more on this in our update passage below). Many of the bugs with software and the UI have been addressed through firmware updates, but some frustrations remain.

Ultimately, Creality fails to offer the logical in-depth software options and controls that its competition does. There is certainly a strong sense that Creality could have differentiated itself with an open, largely untouched Klipper-based firmware more akin to its Sonic Pad, with useful elements of its base open-source firmware intact. But, even putting this thought aside, outside of the core printing performance – which is mostly excellent – the surrounding basic experience is decidedly mid. There are flashes of greatness, the ease of remotely printing from the slicer, for example, but currently, the software is a poor shadow of the platform it’s built on and doesn’t do enough to justify itself.

At A Glance

- Price: $599

- Build Volume: 220 x 220 x 250 mm

- Max. Hot End/Heated Bed Temperatures: 300 °C / 100 °C

- Print Bed Material: Magnetic PEI

- USP: Fast, networked printing & little Z-banding

- They say: “Stand firmly to the speed challenge”

- We say: Fast, but inflexible

The Tech

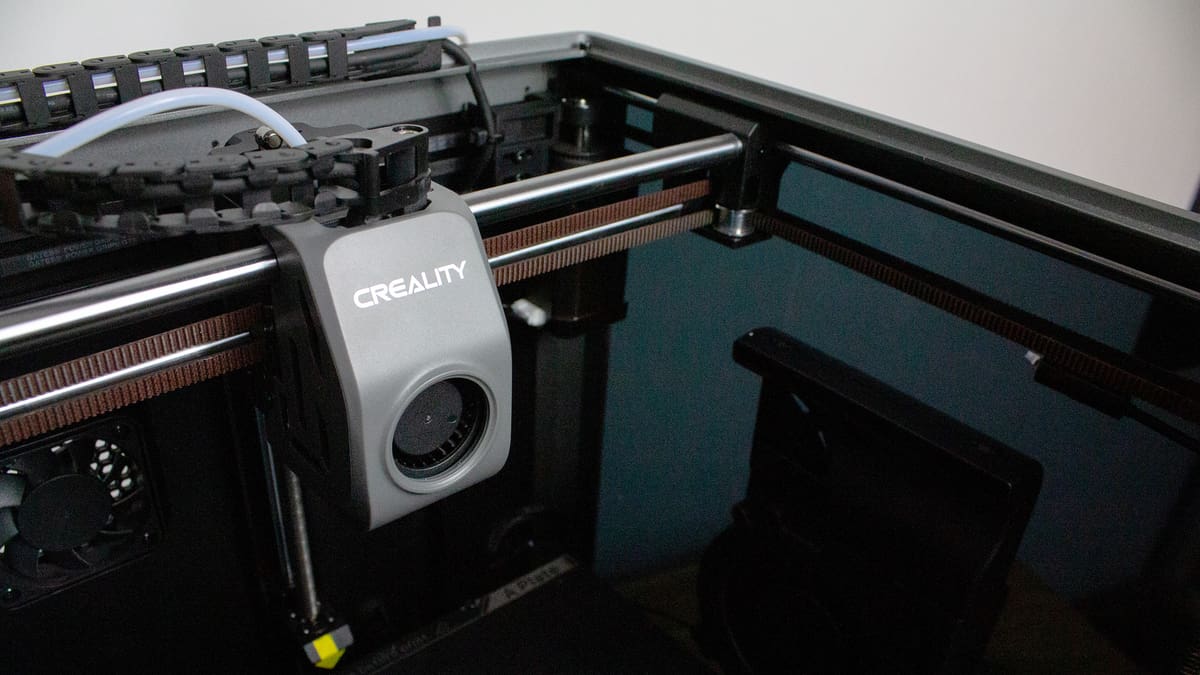

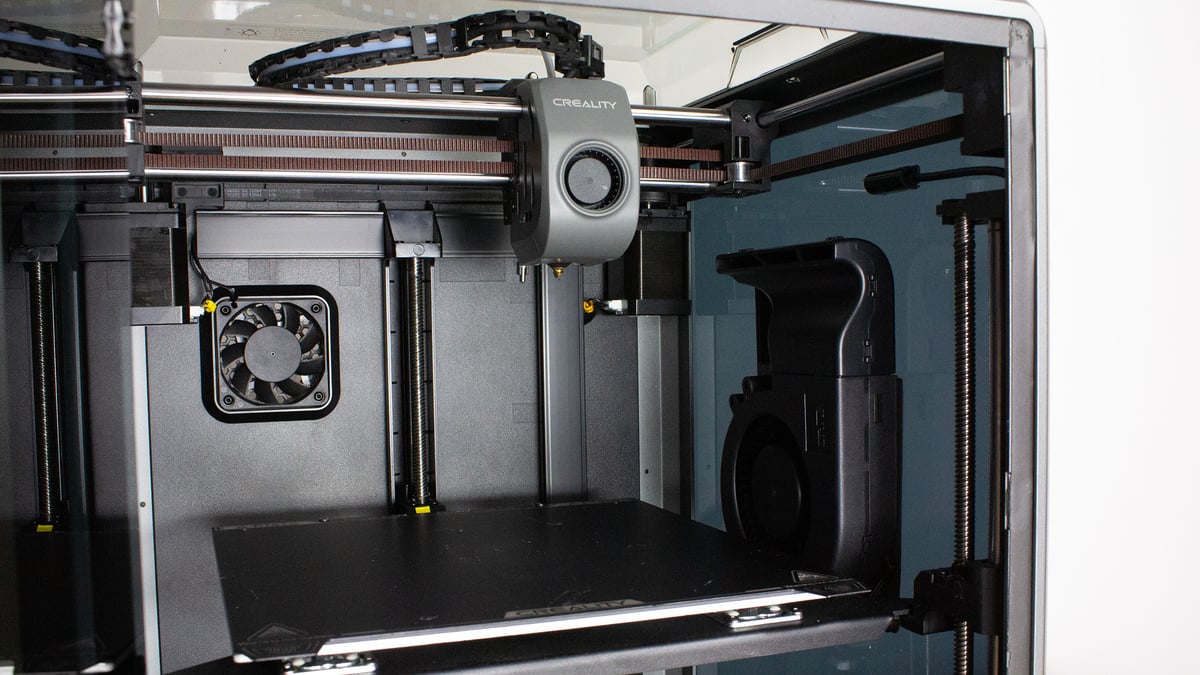

Creality’s new “flagship” 3D printer is a clear response to the massively successful Bambu Lab CoreXY machines. It’s a “hands-free auto-leveling” linear rod CoreXY system with an integrated accelerometer for resonance compensation (input shaping) and wireless network capabilities. The 3D printer is enclosed, with a case fan on its rear that we could see being a blessing to direct UFP-infused air away from users. There’s also an auxiliary fan on the printer’s right side for additional cooling power – a must-have for machines that want to compete at today’s high printing speeds.

It was clear that Creality needed fully automated bed leveling for this machine, and it provided it with an array of strain gauges integrated into the heat bed – rather than the nozzle probing manufacturers seem to favor lately. The system performed well throughout our time with it, but we did quickly notice mild damage to the flexible build plate where the nozzle probes.

The K1’s direct extruder is a new high-flow-rate design that Creality says can hit 32 mm3/s. The hot end is capable of printing at up to 300 °C and uses a circular ceramic heater that gets the volcano-style copper alloy nozzle up to temperature quickly.

We found the filament path less than ideal for loading filament and often had to remove the PTFE from the top of the direct extruder to feed the material to the gears within, caused by the severe angle the PTFE guide tube forces the filament into – straightening out the tube when loading material helps. You have the additional challenge of getting the material through a filament sensor, which also has hidden edges that can snag the filament as you try to feed it into the system. Overall, it’s not a particularly premium experience.

High Speed

It’s true that the Creality K1 prints fast. At its default profile speeds of 2-300 mm/s (from outer walls to infill), the K1 is capable of producing quality parts at about double the speed of recent Cartesian 3D printers fitted with Klipper firmware and accelerometers like last year’s Biqu Hurakan.

Creality was pleasantly transparent in its marketing about the K1’s speed, pushing its max speed of 600 mm/s and high flow rate potential readily but with a clearly visible asterisk noting its more typical speeds mentioned above. Getting 600 mm/s printing to produce a model of any strength would take some tweaking, but Creality does provide a speed test print to show the capability in action.

The company still fails in marketing honesty, though. Creality compares the 300 mm/s K1 to a “regular 3D printer” extruding at an antiquated 60 mm/s, ignoring more recent models like the aforementioned Biqu Hurakan that is capable of printing reliably at 150 mm/s, or, better yet, last year’s Flsun V400 that we found to reliably print at high speeds, including 400 mm/s. Or even Creality’s direct competition, the Bambu Lab P- and X-series, both capable of printing at speeds matching the K1.

Klipper Firmware

We have a gripe with Creality’s poor (and unethical) implementation of the open-source Klipper firmware in the K1. Creality described the K1’s Creality OS firmware to All3DP as “quasi-Klipper”, but what we see is a version of the firmware that’s been gutted of user-friendly features and had its name stripped from the implementation. Instead, Creality only references Creality OS in the K1’s marketing.

Creality took its first stab at a Klipper implementation with the Sonic Pad, where Klipper is mentioned readily in the product’s marketing (the source code for its implementation was released piecemeal on GitHub, after the Sonic Pad’s launch), but here, it’s not in the slightest. Great timing on Creality’s part, as the community has been raising its voice recently about abuses of the GNU GPL license just like this.

Since our initial review was published, Creality has stated it will open source the K1, but we’ve yet to see when and how exactly this will look.

It’s a dramatically different experience to the relatively clean version of Klipper the company presents with the Sonic Pad. Instead, you have useful features removed and a locked-down experience that, while leaner and arguably more beginner-friendly, is also messier. For example, while you can still log in to the printer via a web browser, control over the speed of the printer (presumably a core feature, given the K1’s primary selling point is speed) is present but broken. This is nothing that can’t be fixed with future updates, of course, but from day one through to today – several months later – it seems like Creality is still playing catchup stomping on bugs and smoothing the experience out.

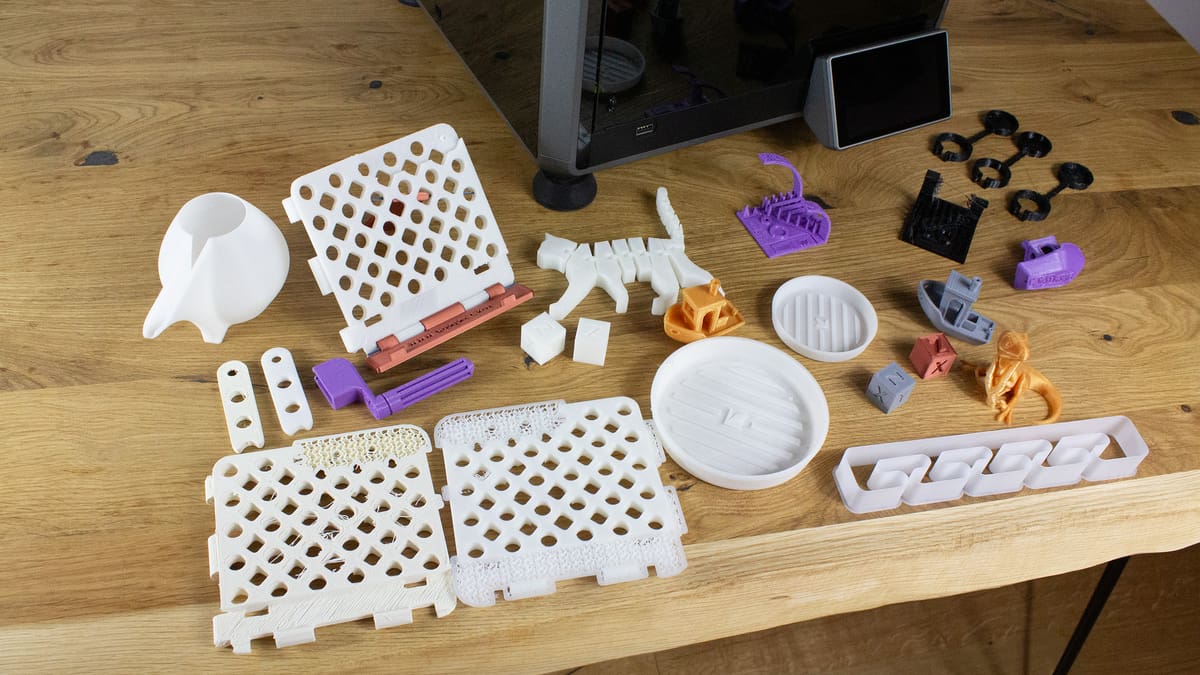

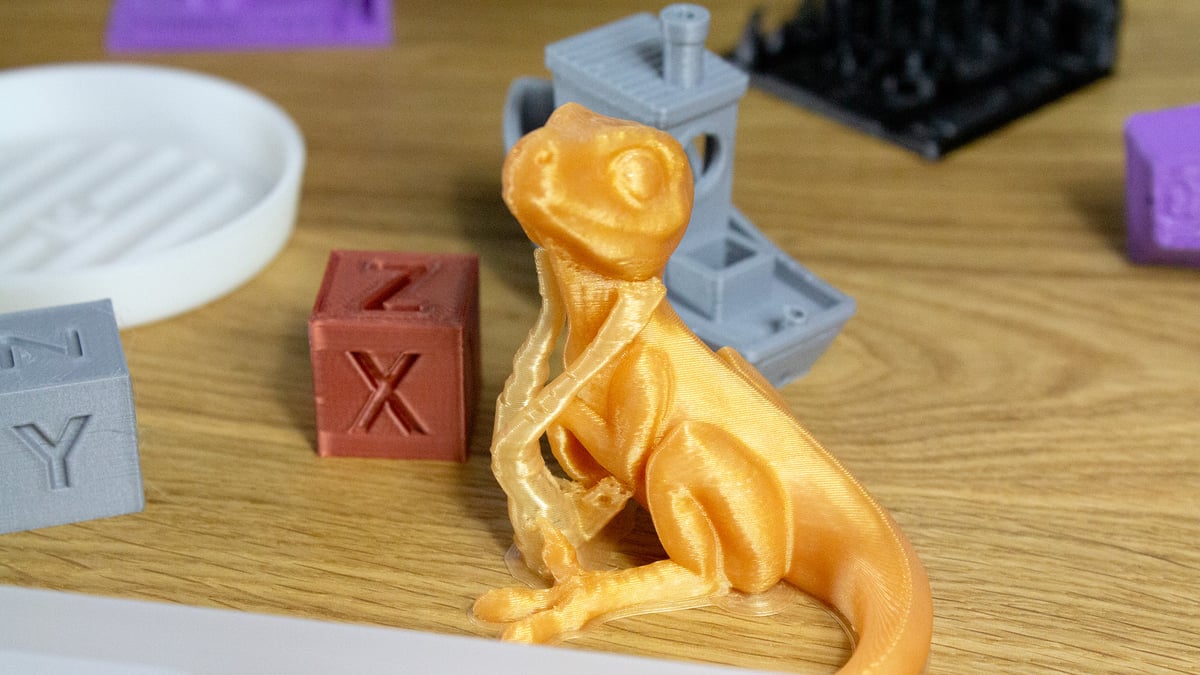

Printing

Out of the box, the Creality K1 produces impressive parts. The company made a point to highlight an “upgraded Z axis” that it claims reduces Z banding, and it seems to be right. On all our successful prints, the K1 produced parts with admirable layer uniformity. They look great and – with materials that play nice – print consistently.

This is further highlighted by Creality’s speed test print – a pre-loaded test print that produces a ribbon-like shell in vase mode at the machine’s top 600 mm/s speed. It wasn’t just vase mode that made the test print seamless; layers are practically non-existent on the part.

It’s interesting to note that the K1 shakes like crazy printing at these speeds, and it’s impressive that it still manages to produce high-quality results with the amount the machine moves. Clearly input shaping is doing some heavy lifting here, and it shows the value of integrated accelerometers to achieve high speeds.

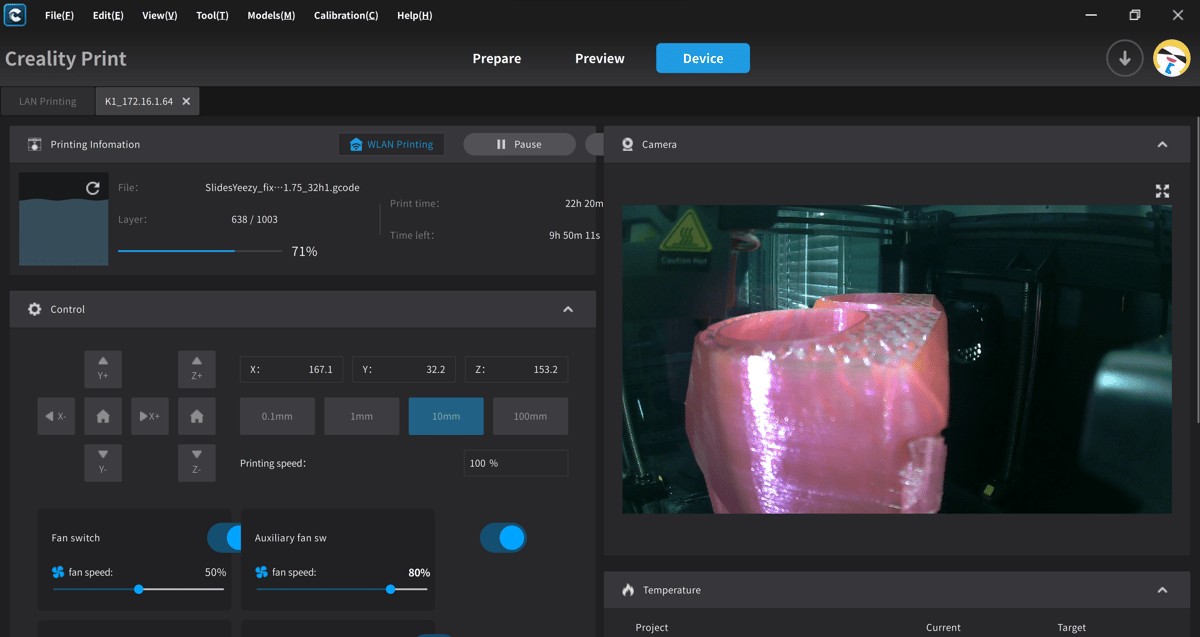

Prints do seem to rely heavily on the K1’s auxiliary fan to achieve good results even at its default 300 mm/s printing speed, and that makes sense – 3D printers touting fast speeds are increasingly implementing these side-mounted fans. Unfortunately, prints that block the airflow from the auxiliary fan can struggle. You’ll need to slow it down if you notice the far side of your prints suffering.

Some Like It Hot

One major attraction of the Creality K1 is the printer’s all-enclosed design. Keeping the print chamber toasty is crucial to prevent warping during printing with higher-temp materials such as ABS, ASA, PA, and PC – if they cool too quickly and unevenly, they can warp and crack. Closing the sides and roof of the printer traps heat from the bed and hot end, creating a more stable environment for the print to form.

It’s a passive system that compliments the printer’s capabilities nicely. And, while you do get a readout of the temperature inside the chamber, you cannot control it. Printing in the mid-200s with a 100-degree print bed seemed to give us a consistent 40-50 ℃ in the zone above the print bed.

The benefit is clear, with the result being, generally, warp-free prints.

One minor flip side to this largely beneficial feature is that the printer itself gets quite hot to the touch. The body, gorgeous as it is (the K1 has to be the best-looking printer Creality has ever made), heats up quite some. The extruder lock – the tiny metal switch to actuate the gears onto the filament – by nature of being small and requiring force, even feels too hot to operate in such conditions, which might be an issue for longer prints that require filament changes.

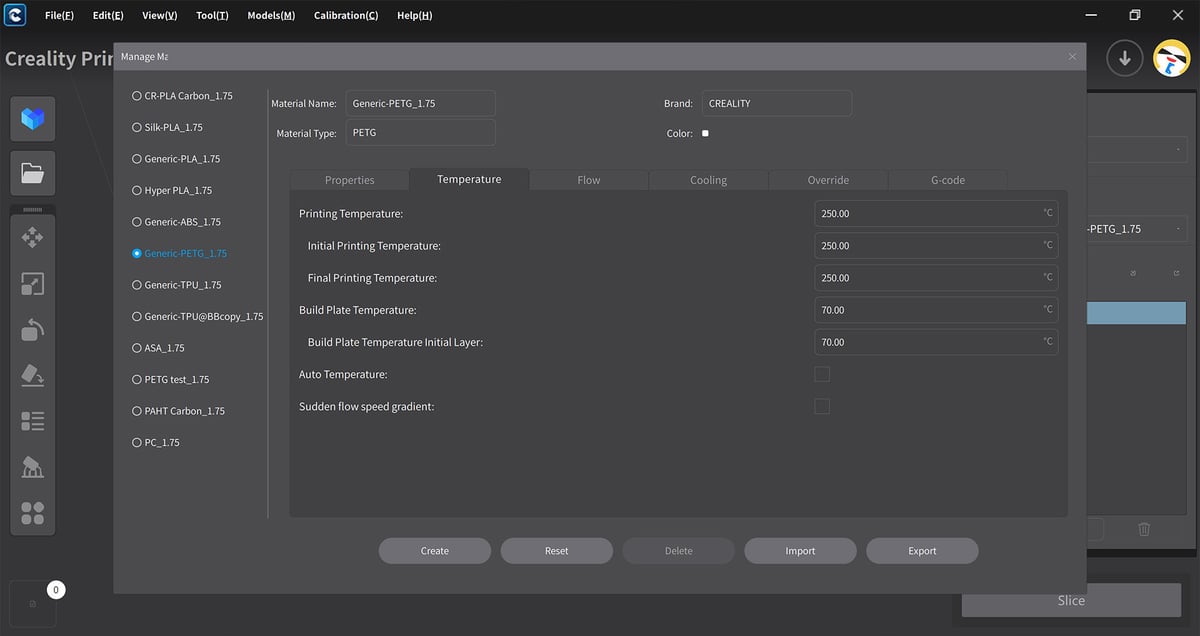

Configuring Things Out

Facilitating your flighty flaunts on fancy filaments that are not PLA, PETG, ABS, or TPU means customizing material profiles in Creality Slicer. While the slicer offers you all the options to set these up, the process is a little convoluted, particularly considering the simple UI the rest of the printer’s experience presents.

There are two areas to focus on for this; material profiles and parameter configs. The former lets you create the baseline print settings for a material, including the flow and temperatures. Parameter configs are the quality settings, so to speak, letting you specify layer heights, wall thicknesses, temperatures again… ah yes. Parameter configs trump material profiles, of which new ones have to be copied from existing profiles, meaning the likelihood of a setting mismatch and wasted time diagnosing why the print isn’t behaving as you expect is elevated. It gets a bit frustrating. There are simpler slicers and printers for this.

This gripe, of course, only exists for printing with materials outside of Creality’s default list. Stick within the guard rails of generic profiles, and you can certainly accomplish quick and generally intervention-free printing.

Software Woes

As we mentioned before, the Creality K1 runs on a modified version of Klipper that Creality calls Creality OS. Unfortunately for the K1, it doesn’t work like other Creality implementations of Klipper that we’ve seen.

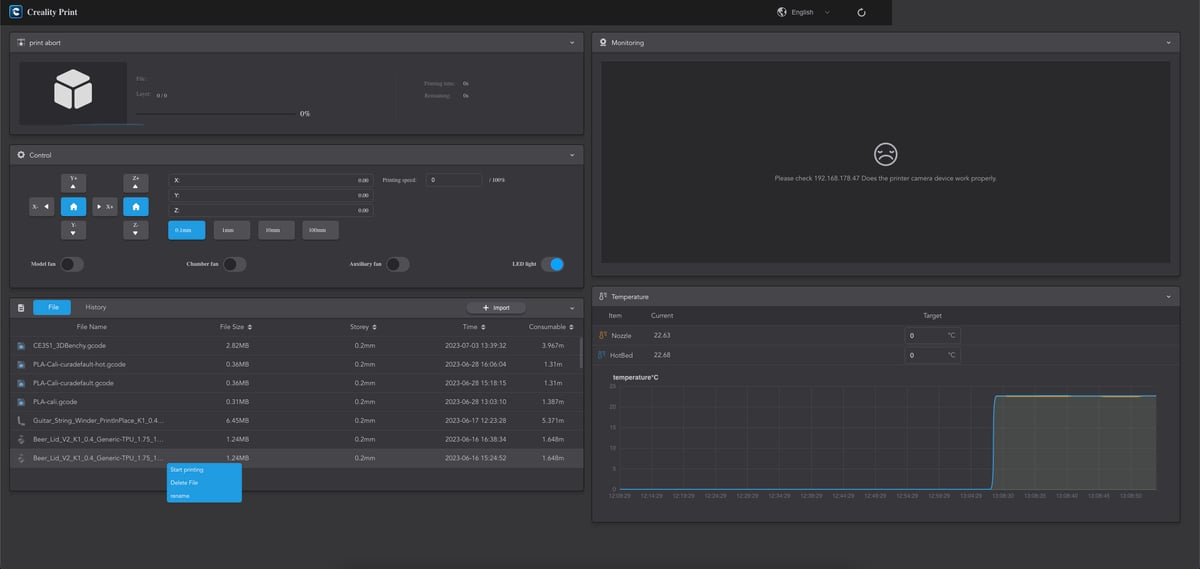

In the K1’s Creality OS, a web interface that appears to be based on Fluidd (we can’t say for sure) is accessible – but its functionality in comparison to a full Klipper UI is haphazard. For one, the customizability features are gone, leaving only the interface home screen. No profiles, no custom macros – nothing. To put such an omission into perspective, there are two official build plates available for the K1. With stock Klipper, you would be able to map out the bed mesh for each, save them to the printer’s memory, and switch between the two on the fly as you print. Heck this even applies to multiples of the same plate type, or third-party compatible plates – anything. This is absent from the K1.

You can still upload G-code through the web interface, thankfully, but despite there being buttons that seemingly let you start the print from here, it doesn’t work. This issue seems to carry into Creality Print slicer, too, with listed files from the print history visible, selectable, but “Start printing” option inoperable.

The lack of features present in the K1’s firmware doesn’t stop at Klipper. Basic controls that we’ve come to expect any 3D printer to have are missing, making the K1 a severely limiting device to work with. There are no extruder controls beyond those pre-packaged for material changes and no opportunity to change the printer’s Z-offset. While auto-bed leveling performed consistently well for us, we would have liked to adjust the offset at times. As it is, if you’d like to change your Z offset, you’re going to have to do it through your slicer.

Even standard features that do exist don’t function as expected. Adjusting print speed – something you might consider important on a 3D printer touting how it pushes speeds – simply doesn’t work. Any time we tried to change the print speed from its default 100%, it jumps back. This, of course, made some aspects of the testing more tedious than it needed to be. “Does this filament just need to print a little slower? Guess I’ll reslice it to find out.”

Should You Buy One?

For printing performance, the Creality K1 is a quick and capable tool that can chew through everyday filaments as easily as it does trickier, heat-happy materials. The enclosure is key, and gives it a marginal edge over the similarly-priced Bambu Lab P1P.

The software experience is good enough for regular, low-intervention printing, particularly if you’re content to sit in the slicer, slice models using only a small handful of materials, and throw them directly to the printer via local network. This is, in our opinion, the K1 at its best. Elsewhere, it feels clear using it that the K1 feels rushed, from sloppy UI elements to non-functional features. It was worse, but it’s getting better.

The overwhelming roughness of the printer at launch has smoothed out a great deal, and while a post-launch hardware redesign now makes it a functionally excellent printer, it’s still the poorer modern printing experience compared to others on the market today.

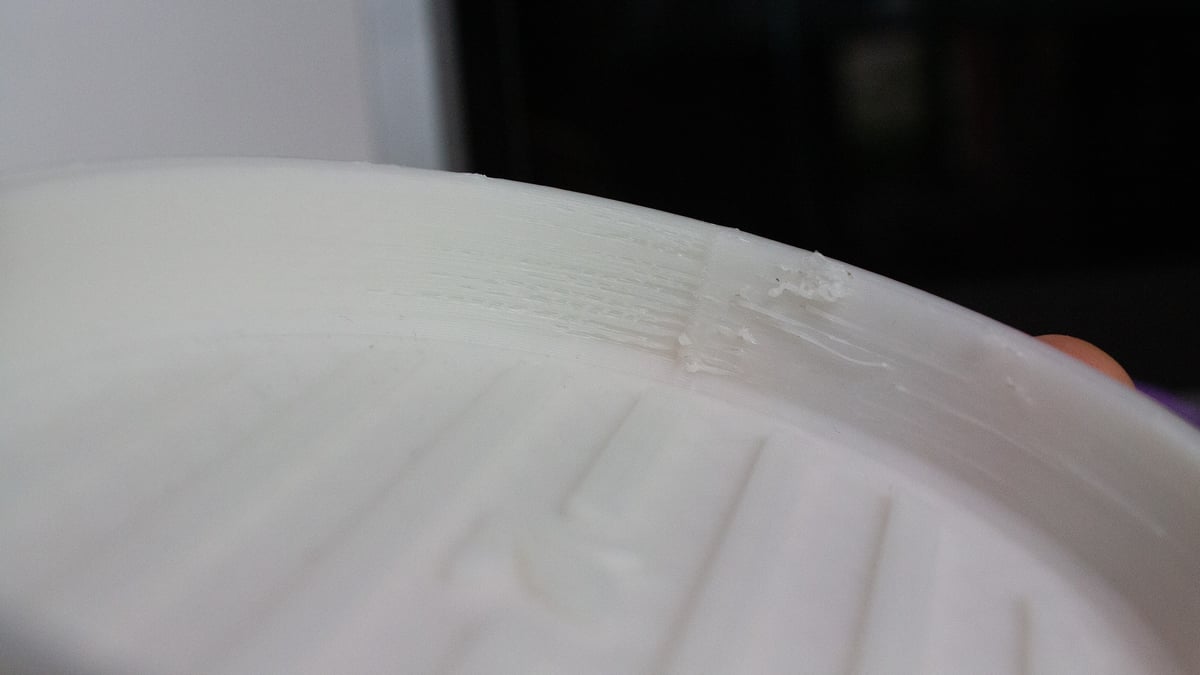

Update – Hot End, Hot Topic

September 13, 2023 – Matt Mensley | As anyone who read our initial review will be aware, we were quite disappointed with the K1. A small part of this disappointment lay in the system’s seeming inflexibility with materials. During initial testing, we got inconsistent results with flexibles and didn’t have the time to explore too deeply with tougher materials after difficulty with even basic stuff like PETG exposed problems with our unit. Prints regularly failed with the characteristics of heat creep – inconsistent extrusions, under-extrusion, messiness, and weakness in the prints.

Well, some time has passed, and with the K1 continuing to operate in our lab in the meantime, we have some more experience, plus a few firmware updates under our collective belt to comment on. But, crucially, there was a hardware change amid all this that has, like a magic wand, fixed out printing issues with the K1. Here’s the rub of things, as best we have heard or can tell.

Change is Good

The Creality K1 is an admirable PLA printing machine, spitting out high-speed hyperpolylactic prints like nobody’s business. That, we know, and Creality does a thorough job of reminding us all that its Hyper PLA is the way to go for fast prints. But the K1 is fully enclosed and boasts the heating chops and hardware to tackle tougher engineering-grade materials.

Except, for much of our time with the K1, it simply couldn’t do it. The above-mentioned heat creep-like issue prevented almost every attempt and eventually escalated with the printer losing its grasp on heating reliably; an ordinary extrude command using the printer’s menu (which is set to 240 °C by default) heated far beyond its target and struggled to cool itself back down.

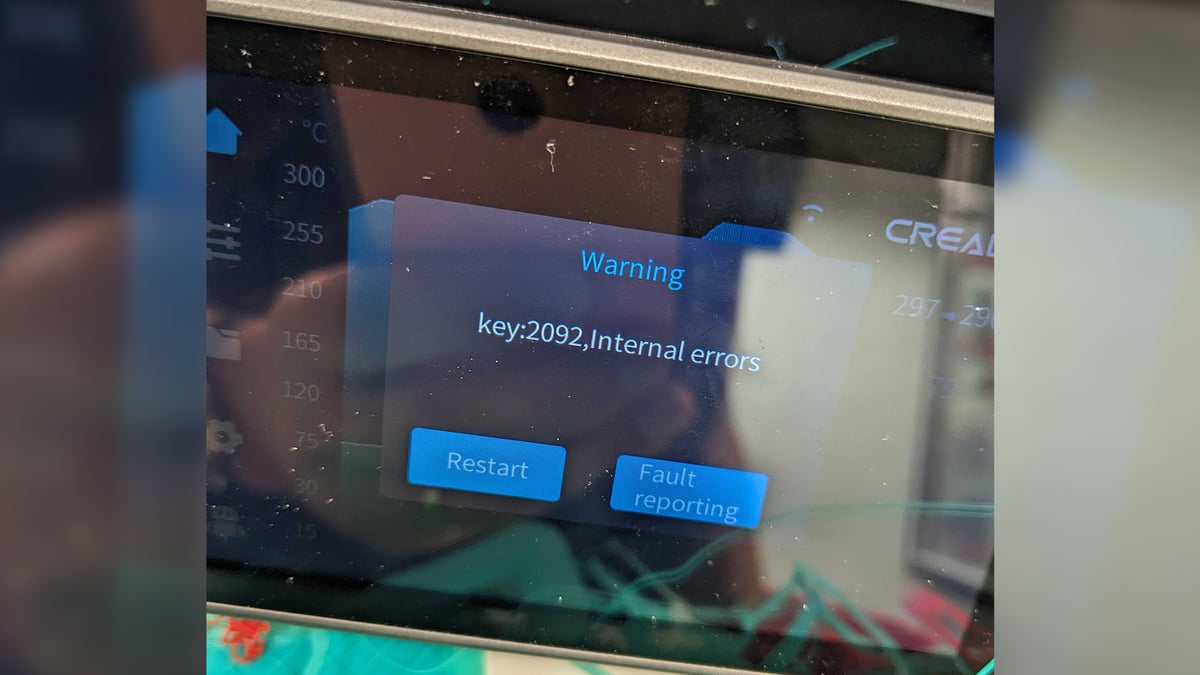

Shortly after, all prints resulted in an error code 2092 message within their first few layers, calling time on our experience of the Creality K1 with its original stock extruder and hot end. The heating issues point to a problem with the thermistor, which might’ve been fixable had the original hot end not used one that is integrated into its ceramic heating block.

By some happy coincidence, around the time of our initial publication, Creality announced an enhancing gift accessory bundle as thanks to all happy (ahem) Creality K1 owners, including an AI camera accessory, a spool of Hyper PLA filament, and, curiously, a replacement hot end and extruder, all for a token ~$2 price with proof of purchase for the printer.

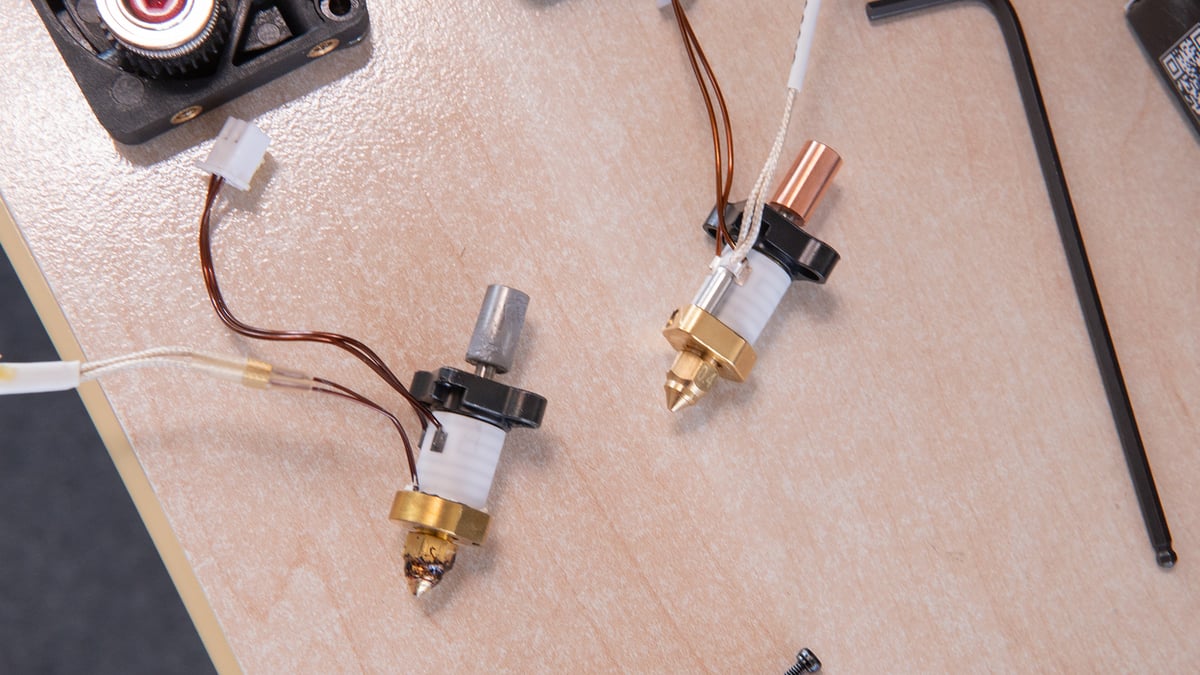

The hot end and extruder, we have been told, improve stability and, therefore, print performance. No other details were given at the time, even in the blog post announcing the parts. Certainly nothing to suggest there was a wider issue at play. We’ve since learned from Creality that the single-metal heatbreak and glass thermistor of the original K1 hot end basically left it susceptible to issues like heat creep and eventual failure. How many printers have been affected, we’ll never know.

There has been no public acknowledgment from Creality of the issue affecting some units. The company has told All3DP it will give the new-design parts to those that report such printing anomalies to it without having to buy the “enhancing gift.”

Creality kindly provided All3DP with the hot end, extruder (and AI camera accessory) following the publication of our review, and you can immediately see the clear material differences, including a different heatbreak (now bimetallic), an externally mounted probe style thermistor instead of a glass one that’s buried in the ceramic heater block, plus the inclusion of a fiberglass shim to sandwich between the extruder motor and print head frame (though in our experience this now changes the dimensions of the print head, and the cover no longer fits…).

The component combo now comes as standard on the Creality K1. Fortunately, the improved hot end has largely addressed our concerns with the K1’s printing performance and sees the machine handily dealing with the likes of ASA, Nylons, and Polycarbonate filaments.

Alternatives

If you’re planning to pass on the K1, your next port of call is probably the Bambu Lab P1S. It’s the closest analog to the K1, costing $100 more but offering more or less the same build volume, temperatures, full enclosure and connectivity, but has the additional possibility of multi-material printing using the company’s AMS four-filament addon.

Alternatively, for the same price as the Creality K1, there’s the Bambu Lab P1P. Expect similar capabilities, albeit without the enclosure but with Bambu Lab’s superior software and AMS compatibility.

Those set on a ready-to-run CoreXY system should check out Qidi Tech’s recent offerings. The X-Plus 3 is close to like-for-like but with the advantage of an actively-heated build chamber. Be sure you get the revised model – as with the K1, changes were made post-launch.

If you’re not necessarily keen on CoreXY 3D printers but find the K1’s feature set appealing, you can take a gander at Klipper systems touting similar hardware that came out last year. The Biqu Hurakan is much more affordable at ~$380, but you’ll sacrifice some speed. On the other hand, the FLsun V400 is a Delta 3D printer that’s more expensive than the K1 at ~$850, but we found it to produce quality parts at higher speeds. Both are capable of input shaping and use regular Klipper firmware, so you can add macros and print wirelessly to your heart’s content.

Featured Prints

Shout out to the talented folks who designed the models featured in this review’s photos:

- Cute Baby Velociraptor by Marcoglossum, via Printables

- Sheet Music Stand by Hobbyman, via Thingiverse

- Plant Pot Dish/Saucer by PRSPR, via Printables

- Print In Place Guitar String Winder by DavVvE, via Thingiverse

- Handleless Watering Can by Mav3r1ck, via Thingiverse

- Beer Guard, Beer Lid by Ambifox, via Thingiverse

- Streichmaß by Calliano, via Thingiverse

- Woodworking T-Square Hole Scribe Precision by Martin, via Printables

- ProosaXY by SnakeOilXY, via GitHub

- Voron Switchwire by Voron Design, via GitHub

- TriComb Vase by pavol.n, via Printables

- #3DBenchy by CreativeTools, via Thingiverse

Tech Specs

- Technology: Fused deposition modeling (FDM)

- Year: 2023

- Assembly: Fully-assembled, plug and play

- Mechanical arrangement: CoreXY

- Build volume: 220 x 220 x 250 mm

- Feeder system: Direct

- Nozzle: 0.4 mm copper alloy

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 100 °C

- Print bed material: Magnetic, Flexible

- Bed leveling: Build plate strain gauge array with auto-bed leveling

- Connectivity: Wi-Fi, USB

- Filament sensor: Yes

- Filament diameter: 1.75 mm

- Frame dimensions: 355 x 355 x 480 mm

License: The text of "Creality K1 Review Update: Redemption?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.