Computer-aided design (CAD) software used to be solely the domain of professionals with an engineering background or a degree in product design. But today, with the growing accessibility of an affordable means of production, e.g. 3D printing, more people are interested in designing parts and products.

Does this mean Creo, a robust CAD software from PTC (Parametric Technology Corporation), is right for absolute beginners? No, not really — PTC’s Onshape is probably where you’d start— but, like a lot of CAD software, it has come a long way toward being easy to learn and incorporating automation to speed up the process of going from the earliest phases of product design all the way through to manufacturing.

Let’s take a look at Creo’s top features, how it compares to others in the same CAD category, and how you can take it for a spin for free.

What is Creo: The Nutshell

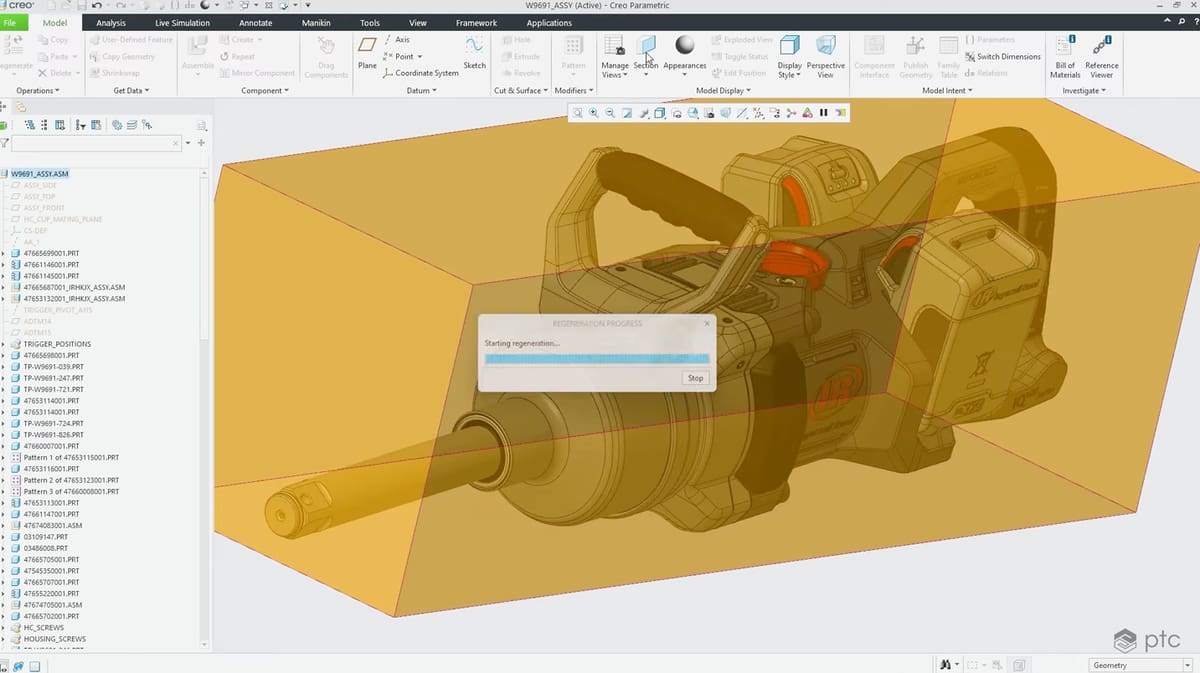

Creo is a comprehensive 3D CAD software widely used for designing complex mechanical products, such as car engines, machinery, and consumer products. It is part of the Creo suite of design tools that enables engineers to conceptualize, design, analyze, and validate products.

With Creo, once you design a product, you can also run it through simulations and optimize it for weight, performance, cost, and sustainability, plugging in a wide variety of material options and manufacturing processes from 3D printing to injection molding.

Creo is also available as a SaaS product (online CAD) offering, providing cloud-based tools for real-time collaboration with colleagues.

Creo’s Claim to Fame: Parametric Modeling

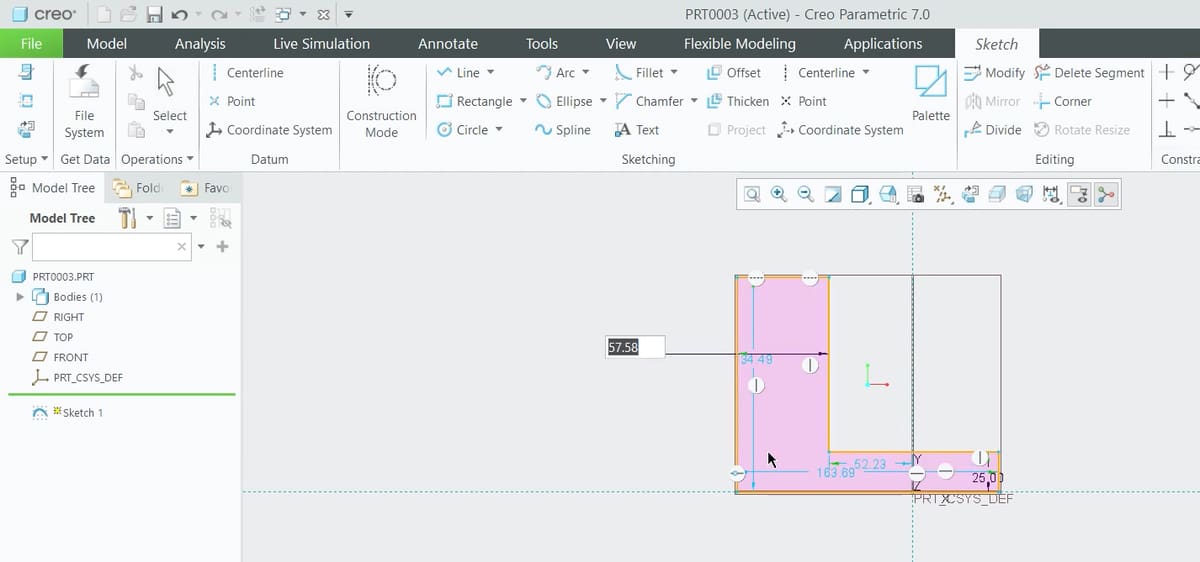

At its core, Creo is a parametric modeling tool. This means it enables you to define and control geometry using parameters, such as dimensions, constraints, and relationships. For example, in Creo, you wouldn’t draw a box with a pen tool, you’d plug in measurements for height, width, and length to define your box.

This approach ensures that part measurement and their relationships to other parts remain consistent as the part is developed. Changes to one aspect of the model will automatically update related features, ensuring consistency and adaptability throughout the design process.

PTC was one of the early developers and pioneers of parametric modeling. The company introduced Pro/Engineer (later renamed Creo) in 1988, which was the first commercially successful CAD software to use parametric, feature-based solid modeling.

This doesn’t mean you can’t draw with Creo. You can do that, too, but it’s not why you’d choose Creo. The freeform design tools let you create organic shapes and aesthetic details. This makes it suitable for industries like automotive and consumer products that want a mix of aesthetic originality and mechanical performance.

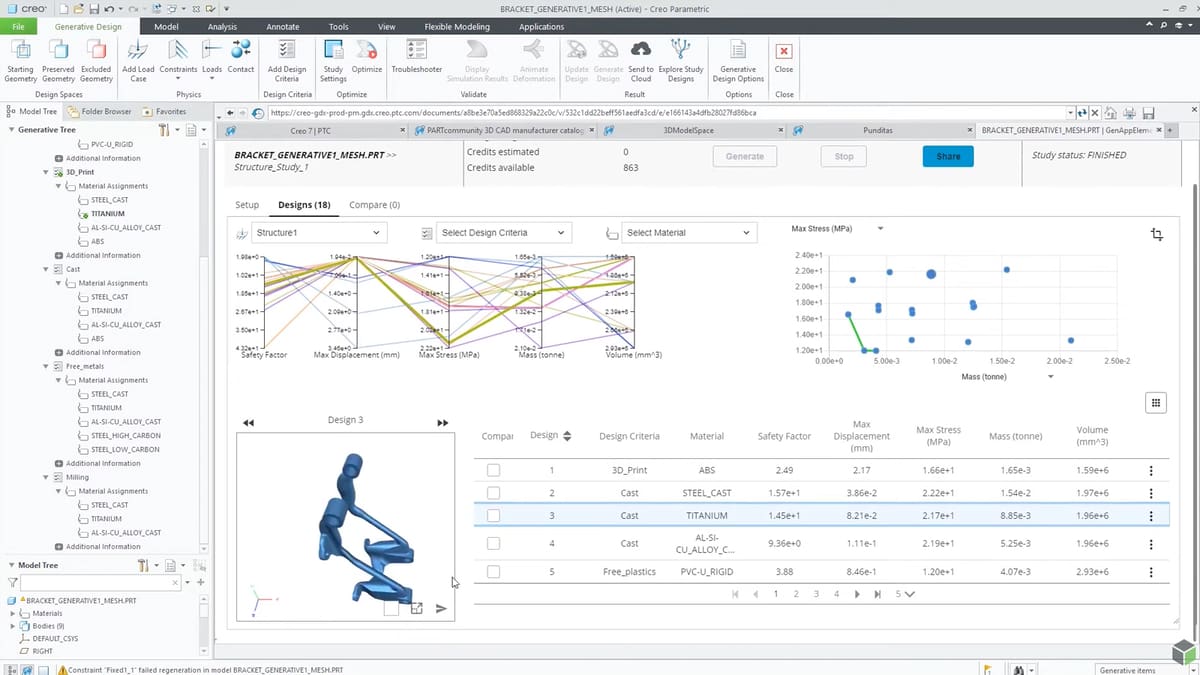

Parametric or freeform are not your only part development options. There’s also generative design, which is a type of parametric design. This tool use algorithms to generate optimized design solutions based on specified needs, parameters, and constraints. For example, say you’ve created a rectangular box for a bowling ball. By imputing the weight and shape of the ball and what the box is intended to be made of, the algorithm will provide options for design that balance the shape, strength, and material usage of the box.

Test Drive Your Design with Creo Simulations

Another strength of Creo is its simulation capabilities, both those baked in and as optional plug-ins. Creo lets you simulate how your project will perform under real-world conditions. This way you can validate your design choices early in the design cycle to avoid a lot of redesign and rework.

There are simulation tools to test designs for structural integrity, thermal performance, and other physical properties, helping to ensure that products meet performance requirements before manufacturing.

PTC offers various solutions for performing analysis and simulation on your parts, assemblies, and products.

There’s Creo Simulate, which supports numerous structural, modal, thermal, dynamics, and fatigue analyses. It uses a variation of finite element analysis called Geometric Element Analysis (GEA), which is said to be more forgiving to less experienced analysts, but still produces accurate results.

Creo Simulation Live is a more robust analysis tool within the Creo design environment that enables you to perform structural, thermal, modal, and other studies with simulation results in real time.

Creo Ansys Simulation (and Creo Ansys Simulation Advanced) have more features and tools while Creo Flow Analysis is specific to turbulence, radiation, cavitation, and fluids and Mechanism Dynamics Option is a simulation module for moving components.

PTC offers a useful PDF that details and compares the simulation tools in each of the offerings.

Creo for 3D Printing

Although the vast majority of Creo users are designing parts destined for traditional manufacturing, a growing segment is using Creo for additive manufacturing.

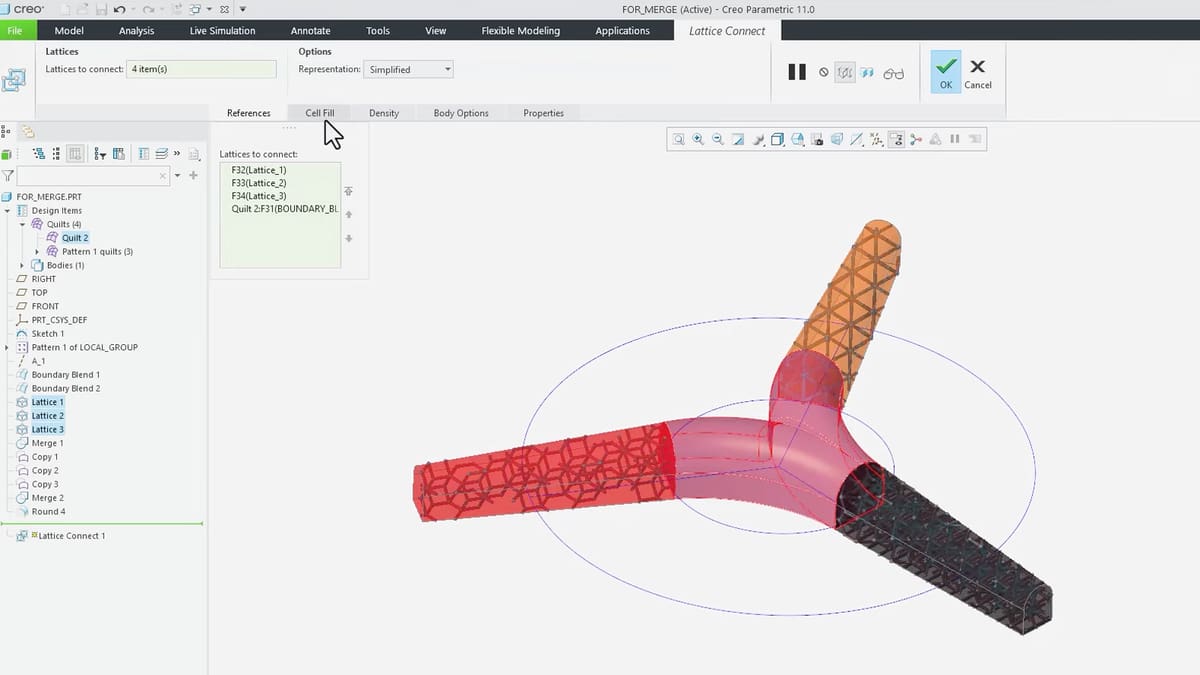

Creo 11 offers two extensions for 3D printing whether you’re looking at prototyping or final part production. These extensions — Creo additive manufacturing extension and Creo additive manufacturing advanced extension for Materialise — feature enhanced lattice capabilities with the addition of stochastic lattices based on the Delaunay algorithm (irregular, random 3D structures created through Delaunay triangulation of randomly distributed points), hard-edge definition, and the ability to create lattice structures using custom cells, which enables highly complex parts that cannot be produced using traditional manufacturing.

Creo for AM enables you to:

- Create parametrically controlled lattice structures and fully detailed parts with accurate mass properties.

- Identify printability issues in your design

- Scale, position, and show a clipped view of the model and probable support material on the tray

- Automatically optimize the position of the model in the tray for printing

- Define profiles for multiple supported printers

- Modify, manage, and save print tray assemblies

- Assign materials and colors, calculate build and material consumption, and print directly from Creo to supported 3D printers

Just Updated in Creo Version 11

If it’s been a while since you took a close look at Creo as your CAD option, there’s a lot new.

Creo 11 launched in April 2024 and includes some new tools and advancements in existing functionalities. It has enhancements for electrification, composites model-based definition, simulation-driven design, and manufacturing.

Creo now features an enhanced enclosure volume feature to optimize and calculate

the minimum bounding box of your part or assembly for packaging optimization. A handy tool. There’s also improvement to the generative design tools within Creo. It now has minimum feature size constraints, bearing load support, and painter’s symmetry constraints.

Simulation has also taken a step forward, including the tools leveraging Ansys technology, with new simulation-driven design capabilities for better design ideation, guidance, and validation. Creo simulation live now includes conjugate heat transfer to simulate heat transfer between solid geometry and fluid bodies.

Free Download, 14-day Trial of Creo & Prices

It’s not possible to get the full version Creo for keeps without paying some cash. However, you can get a free trial, a free limited-feature student version, or save a lot of money with a student license. Let’s look at your options.

Free 14-day Trial

To take advantage of a 14-day trial of the fully functional version of Creo, you just fill out a form on their website.

Free Limited Functionality for Students & Educators

To get engineering and design students hooked on Creo’s features early, PTC offers it to them for free, but it’s not the full version and it comes with some limitations. There are different free student versions for University students, K12 students, and one for FIRST (For Inspiration and Recognition of Science and Technology) teams, which is an organization that aims to inspire young people to pursue careers in science, technology, engineering, and mathematics through various robotics competitions.

Creo licenses expire after one year, but students who are still in school can renew by reapplying.

Although it’s pretty easy to download the Student Edition of Creo (just a simple form), note that files created with this edition typically have a watermark or a tag indicating that they were created with the educational version. These files may not be compatible with the full version of Creo, or they may carry the watermark when opened in the full version.

Certain high-end extensions or modules, like some simulation tools, advanced manufacturing capabilities, or specialized design tools may be restricted or not available in the educational version.

University Student Edition Premium License for $257

If you want a fuller version of Creo and you’re a student there is the University Student Edition Premium License. Purchase of this edition requires valid academic identification.

Full Creo Subscription

- Creo Design Essentials: ~$3,040 / year

- Creo Design Advanced: ~ $8,880 / year

- Creo Design Advanced Professional: ~ $15,400 / year

- Creo Design Engineering: ~ $21,300

- Creo Design Engineering Professional: ~ $29,400

PTC does sell Creo licenses directly through its website and through its sales team, but this is most common for large enterprises or organizations that want to deal directly with the software vendor. It’s more typical to buy a Creo license through third-party resellers and partners. These companies typcially bundling additional services like training, support, and consulting.

Creo System Requirements

The Creo trial requires a 64-bit operating system to run

- Operating systems: Windows 10 or 11

- Minimum RAM: 512 MB

- Video display: 3D-capable graphics card

- CPU: Single- or dual-quad processors

- Internet connection: Required to activate

Free Creo Alternatives

If the free versions of Creo aren’t available to you and the paid versions are too expensive, there are a number of free alternatives to Creo. These options are far more limited in features, but they’re excellent for more modest needs.

- Autodesk Fusion Personal Use License: Autodesk offers a limited-feature version of its CAD software, Fusion, for personal projects (non-commercial use). Free Fusion for personal use has limited functions and import/export file types, but is pretty robust compared to other free options.

- FreeCAD: Designed around parametric modeling, FreeCAD is a solid choice for free CAD software. It’s made to design real-life objects of any size, not limited to either products or architecture.

- Onshape Free Hobbyist License: Creo-maker PTC also makes another widely used CAD program called Onshape, which is a fully featured CAD platform perfect for open-source projects, makers, hobbyists and those learning to use modern CAD. This no-cost plan is meant for creating non-commercial product designs that are open-source and publicly online.

- Solid Edge Community Edition: Solid Edge is a comprehensive software suite much like Autodesk Fusion. Parametric modeling, assemblies, simulations, and technical documentation are all in its wheelhouse. The Community Edition of the software is free for makers and CAD enthusiasts, and the version is not as limited as Fusion for personal use.

License: The text of "Creo Parametric Software: Big Picture & Free Download" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.