3D printing is firmly established in today’s dentistry industry. Whether in-office or at a major dental lab, 3D printers are revolutionizing many aspects of dental care and manufacturing ranging from the fast, accurate printing of dental models for education to more economical, customized full dental prosthetics and restorations.

The global dental 3D printing market size is worth around $3.94B in 2024 and could reach $41.09B by 2034, according to Precedence Research. In fact, 2024 was a big year for dental 3D printer launches with the marketplace significantly remade by new products from Asiga, Formlabs, SprintRay, Rapid Shape, Phrozen, Flashforge, and B9Creations.

With chair-side production of try-ins, custom trays, temporary crowns, and surgical guides, 3D printing accelerates service and puts local dentists in full control of patient-specific products. The ability to produce parts from 3D scans and digital files, means fewer appointments, faster turnaround times, and vastly lowered costs, resulting in an overall improvement in patient care.

But if you’re here, you may be already sold on the benefits on 3D printing. Let’s take a look at the growing selection of 3D printers that can bring your practice or lab into the era of digital dentistry. This article focuses mainly on the entry-level machines from top manufacturers, yet many have larger volume and more feature-rich offerings.

Which Type of Dental 3D Printer Fits Your Needs?

As a dental practitioner or a specialist in a dental laboratory, you know that there’s a world of difference between dental models for patient education and dental parts for patient use.

If your goal is to print reasonably accurate models of a patient’s mouth taken from an oral 3D scan or impression in order to, for example, explain a procedure to a patient, then there’s no need for a specialized dental printer. In fact, you have a much wider range of printers to choose from for model making than you do for printing parts that will come in contact with a patient.

However, if you’re looking to print biocompatible dental parts – anything that will come in contact with a patient’s mouth or skin, such as clear aligners, veneers, temporary or permanent replacement teeth, or dentures – you’ll need to use biocompatible materials certified by the regulatory authorities in your area, such as FDA in the US, CE in the EU, KFDA in South Korea, etc., plus approved software and 3D printers. This is our focus in this article.

Specialty Dental 3D Printers Companies

Because there are numerous regulations related to medical devices, it pays to work with a 3D printer manufacturer that specializes in the dental market (either entirely or as a large focus of their business). These companies offer practical expertise and support, along with an ecosystem of dental-focused products and services, plus a continuous supply of necessary consumables. Many have dental and orthodontic practitioners on staff.

Fortunately, there’s a growing number of 3D printing companies specializing in the dental market, and also dental equipment companies that have developed their own 3D printers and materials, such as Kulzer and DMG America

The 3D Printing Technology Learning Curve

Adding 3D printing to your dental practice or lab requires that you learn new techniques, technologies, materials, and processes, so naturally, without sufficient training and support, you’re unlikely to get the most out of your printer investment. Choose your vendor carefully. All of the companies we feature below offer full ecosystem support for dental professionals.

Many 3D printer manufacturers offer dental solutions that include service plans, such as personalized onboarding, proactive check-ins, and phone and email support, along with resource libraries of guides, videos, and tutorials. Several 3D printer manufacturers, such as SprintRay and Kulzer, focus exclusively on digital dentistry, offering a comprehensive approach and promising a smooth integration between dental printing software, printers, accessories, materials, and support.

How Are Dental Parts 3D Printed?

To illustrate how the components in digital dentistry work together, here’s a quick overview of the workflow to make a patient-specific dental night guard in-office.

It starts with the digital scan of the patient’s mouth with a hand-held intraoral scanner, external scanner, or the scan of a traditional plaster dental cast or model.

From there, your digital images are uploaded to computer aided design (CAD) software specific to the dental industry, such as Exocad or the software that comes with your 3D printer. There’s a wide range of dental CAD programs that will integrate with most major 3D printer brands. Choose the software that best matches your (and your staff’s) skill level.

Next, if your dental software doesn’t do this automatically (and most do), you’ll upload your design files to “slicer” software that either comes with your printer or is compatible with it. The slicer transforms your digital model into 3D printing instructions for the printer.

Once your night guard is printed in certified biocompatible resin, it requires some cleaning to remove any residue, removing the supports, and curing in light to harden fully. The last step is typically some polishing and it’s ready for the patient to try on. Depending on your printer, the entire process could take a few hours.

| Printer | Technology | Price Range | Print Volume | Min. Layer Height | Accuracy | Max Print Speed |

|---|---|---|---|---|---|---|

| Formlabs Form 4B | LCD | $6,430 | 200 × 125 × 210 mm | 25 micron | ± 50 microns | 100 mm/h |

| SprintRay Pro 2 | LCD | $10,000 | 188 x 105 x 75 mm | 50 microns | n.a. | 100 mm/h |

| Shining 3D AccuFab-Cel | DLP | $7,000 | 192 x 120 x 180 mm | 50 microns | ± 35 microns | 100 mm/h |

| B9Creations B9 Dent Lab | DLP | $30,000 | 192 x 108 x 320 mm | 50 microns | ± 50 microns | 25 mm/h |

| Phrozen Lumii DLP | DLP | $3,100 | 130 x 73 x 160 mm | 10 microns | ± 50 microns | 90 mm/h |

| Ackuretta Sol Plus | LCD | $10,950 | 440 x 370 x 500.5 mm | 30 microns | n.a. | n.a. |

| Flashforge Focus Ultra | LCD | $4,500 | 197 x 122 x 180 mm | 25 microns | n.a. | 50 mm/h |

| Rapid Shape Pro 20 | DLP | $10,000 | 133 x 75 x 115 mm | 25 microns | ± 34 microns | n.a. |

| Asiga Max 2 | DLP | $10,000 | 119 × 67 × 75 mm | n.a. | n.a. | n.a |

| 3D Systems NextDent LCD1 | LCD | $6,000 | 128 x 80 x 140 mm | 30 microns | n.a. | 45 mm/h |

| Desktop Health Einstein DLP | DLP | $13,000 | 190 x 107 x 102 mm | 25 microns | n.a. | n.a. |

What to Look for in a Dental 3D Printer

Your choice of printer for dental models or biocompatible dental parts depends on a variety of factors including what you intend to print, how much you intend to print per day or week, how fast you need your parts, your budget, and how automated or easy-to-use you want the process to be. Are you just getting started or are you expanding or upgrading your operations?

You’ll also want to consider the level of service and support from your manufacturer and which dental software the printers are compatible with. Software is a big consideration. You’ll want a print preparation program that integrates with the dental software you already use and enables you to configure prints with as little programming as possible. You’ll want to be aware of any licenses, annual fees, or installation limits.

Most manufacturers will send you a sample print, so be sure to request one to evaluate whether it meets your expectations for details, surface finish, and strength.

When asked to rank key purchase criteria for selecting the 3D printer brand their lab uses most, dental pros responding to a survey by printer manufacturer Carbon, said: accuracy, reliability and maintenance, return on investment, total cost of ownership, quality of materials, and lowest price topped the list.

Let’s take a detailed look at the top digital dentistry solutions in the industry. Scroll to the bottom for a look at materials and post-processing equipment.

Formlabs Form 4B

In 2024, Formlabs launched the Form 4B which offers a huge (5X) boost in speed over the popular Form 3B+ and is the company’s new flagship resin 3D printer for dental applications.

The company says the new Form 4B can complete most prints in under two hours and small parts in minutes of cycle time. She speed comes from a major shift in technology. The Form 4 is a DLP resin 3D printer, where as the Form 3 was an SLS resin 3D printer. The lasers used in SLS are slower than the light source in DLP.

Couple the faster Form 4 with the Form Auto, the hardware extension that automatically removes finished parts from the build platform and deposits them in a holding bin, and dental practices can substantially boost productivity, Formlabs says.

Formlabs also introduced a new post-processing curing unit that cures dental indications 90% faster than the standard Form Cure. There’s also a new feature in the Formlabs dental print preparation software that lets you automate more workflows and create pre-set orientation and support settings for each dental indication.

Also in 2024, Formlabs announced that its nano-ceramic filled biocompatible Premium Teeth Resin has received FDA 510(k) Medical Device Clearance for 3D printing temporary single units of crowns, inlays, onlays, and veneers, and up to seven-unit temporary bridges. These applications has been previously cleared in the EU.

In addition to the Form 4B there’s a larger version, the Form 4BL with a print volume of 353 x 196 x 350 mm.

SprintRay Pro 2

SprintRay only makes dental 3D printers and was busy in 2024 launching two new machines. The new Pro 2 is is an LCD resin 3D printer is a machine that the company is calling “the most advanced 3D printer we’ve ever built.”

Sprintray says the Pro 2 can print up to six full-arch dental models in 15 minutes with more “than 99% dimensional stability.”

The 12-inch touchscreen is an easy-of-use feature you won’t find on may other models. The Pro 2 boasts a 35 micron XY resolution.

Rather than a traditional build volume (X,Y, and Z), SprintRay provides print volume in terms of two type of kits available for the machine. The “Standard Kit” has a 188 x 105 mm build platform and, we assume, and Z or height that would accommodate any typical dental model. The same with the “Arch Kit”, sold seperately, with its slightly smaller build plate.

Shining 3D AccuFab-Cel

Shining 3D – probably best known for its 3D scanners – is another company offering a fully integrated 3D digital dental solution from obtaining 3D data with its own brand of dental 3D scanners, then designing with professional dental CAD software, to printing dental products, including working models, orthodontics models, implant models, surgical guides, wax-ups, and partial frameworks.

The company’s DLP 3D printer offers users “an intuitive and user-friendly workflow,” the company says, “with fast print speeds and high accuracy.” With a open material system users can choose from virtually any resin for model, restorative, implant, and orthodontic applications. Like many printer makers, Shining 3D partners with industry- brands in dental materials, providing more possibilities and flexibility in material selection.

The AccuFab-Cel, featuring a layer thickness of 100 microns can print orthodontic models in 14 minutes and surgical guides in 20 minutes the company says.

Shining 3D is the first company to design a ceramic build platform, which it says not only provides longer durability but also improves the user experience.

Another uniqueness is its AI Mode that enables you to give feedback on the printing issue so it will automatically adjust the printing parameter to solve the problem.

B9Creations B9 Dent Lab

Popular resin 3D printer maker B9Creations entered the dental market in 2024 with its B9 Dent Series: the B9 Dent Lab and the B9 Dent XL. The company created a comprehensive solution with dental-specific CAM software and materials designed for a wide range of indications, along with automated post-processing units.

Although these two printers are B9Creations’ first line of dental printers under its own name, the company has (and still does) manufacturer the Cara Print 4.0 3D printers for Kulzer, one of world’s leading dental companies.

The B9 Dent Lab is large-format (192 x 108 x 320 mm) DLP 3D printer with an “effective resolution of 50 microns” . Dent XL, which is also under $10K and a smaller print volume but greater accuracy.

B9Creations 3D printers are out of the box and printing in 15 minutes, the company says, and never requires calibration.

Phrozen Lumii DLP

Phrozen has been making resin 3D printers for decades and entered the dental industry in 2020 with the Sonic XL 4K. In 2024, it launched the Lumii DLP 2K.

Lumii boasts a 51 micron resolution and is equipped with a built-in air purifier to create an odor-free printing environment and a safe workplace, the company says. There’s also a resin heater built in and USB and WiFi connectivity.

Pre-calibrated resin settings enable quick printing of the desired dental part with little calibration. Like many printers on this list, the Limii offers pre-validated resin parameters that enable you to simple tell the printer which resin you’ve loaded and it essentially does the rest.

You can print on the standard plate (130 x 73 x 160 mm) or the mini plate (105 x 73 x 160 mm) for smaller jobs done faster. The Lumii can print two occlusal splints in less than half an hour or two full denture bases in about 55 minutes.

Ackuretta Sol Plus

The Sol Plus is a large format LCD resin 3D printer focused on throughput. It can tackle full-arch dental models, biocompatible permanent crowns, bridges, splints, dentures, and more.

Engineered to efficiently print up to eight dental models at a time horizontally, or 28 vertically in less than four hours.

Sol Plus has an open material system, which makes it applicable for dental crowns, splints, guards, dentures, surgical guides, models and more. Although we can’t verify this claim, the machine boasts the “fastest resin heater” at 2 °C per minute. Bringing the resin up to printing temperature quickly is a sought-after efficiency feature.

Ackuretta reports an XY resolution of 45 microns on the Sol Plus.

Flashforge Focus Ultra

In 2024, Flashforge launched an upgraded Focus Ultra LCD resin 3D printer with, what it says is enhanced software, firmware, and hardware for a “better user experience.” The Focus Ultra can print orthodontic models, restoration models, surgical guides, gingiva masks, temporary teeth, veneers, and castable wax patterns.

In addition to speed and accuracy, the Focus Ultra offers some of those little extra features that remove the small pain points of dental 3D printing, such as a drip-proof build plate and a resin tank pin that take just a second to remove for quick material changes. On the more substantial side, there’s a new picture-rich user interface on a comfortable 7-inch touch screen.

The Focus Ultra boasts a 33 micron resolution.

Rapid Shape Pro 20

Rapid Shape is another 3D printer maker that is primarily focused on dental applications, although it also serves jewelry and industrial sectors. In 2024, the company launched the Pro 20 is a DLP resin 3D printer with more than 20 presets for particular resins and dental parts.

Rapid Shape introduced a new RS Turbo feature in the Pro 20 that will print a batch of aligner models (150μm layers) in just 7 minutes and crowns or bridges models (50μm layers) in 15 minutes. Other than these examples, Rapid Shape does not offer a maximum print speed.

Paired with the Pro wash and Pro cure, this is an integrated system for an efficient workflow.

In addition to its proprietary materials, Rapid Shape partners with known material manufacturers, such as Dreve, Kulzer, BEGO, and Keystone Industries to offer a range of biocompatible resins.

Rapid Shape also offers a wide array of larger production printers for dental labs.

Asiga Max 2

In 2024, Asiga launched two new 3D printers, the Max 2 and the Ultra.

The Max 2 is what Asiga is calling a “significantly update” of its popular Max printer with not only a new look but also a new user interface.

The Aisga’s software can connect with a range of computer operating systems and 3D model file formats, including Exoprint from Exocad and 3Shape Implant Studio. The integrated PC can manage multiple builds at the same time, and offers a range of user-friendly features, as well as a lifetime of free software updates.

3D Systems NextDent LCD1

3D Systems, one of the world’s largest 3D printing companies with a vast portfolio of machines and materials, reentered the desktop size dental 3D printer market in 2023 with its smallest 3D printer, the NextDent LCD1. 3D Systems is squarely addressing the accessibility hurdle in dental 3D printing with this entry-level machine, which it hopes will create life-long 3D Systems customers who move up to the company’s other, larger dental machines as their practices expand.

The NextDent LCD1, as you might guess, features LCD (liquid crystal display) technology, also called masked stereolithography (MSLA), which is uncommon among dental 3D printers. It’s faster than other types of resin 3D printing. The LCD1 has a print speed of 4.5 cm per hour, an XY resolution of 49 μm, and a small layer height (30 – 150 μm).

All resin 3D printing requires post-process washing and curing parts. The NextDent LCD1 has companion machines to handle these tasks.

The company’s large NextDent 5100 printer is for high-speed 3D printing for production of dental appliances and castings, and delivers precise results with minimal human intervention, the company says. Combine the printer with other 3D Systems dental solution components to create a comprehensive workflow. This includes the NextDent LC-3DMixer for optimal stirring of materials and the NextDent LC-3DPrint Box for UV post-curing.

Desktop Health Einstein DLP

3D printer maker Desktop Metal has two 3D printers aimed at the dental market through its Desktop Health wing. The audaciously named Einstein series launched in 2022 is “fit for a genius”, the company says, and comes in a desktop and a laboratory size. Both are DLP printers compatible with a wide range of dental resins.

The desktop version has a generous 190 x 107 x 102-mm build volume and a 25-micron minimum layer height. Unlike most companies on this list offering a suite of printer, washing machine, and curing machine, Desktop Health doesn’t make its own post-processing machines but partners with other companies.

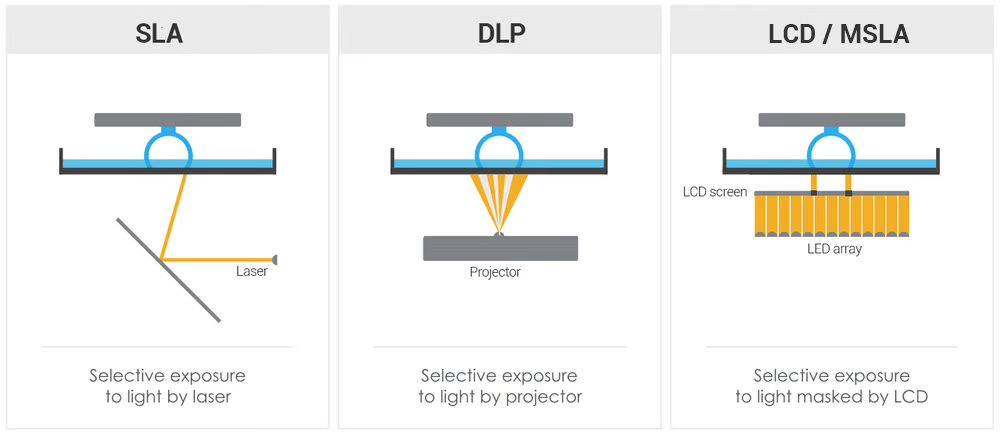

Dental 3D Printing Technology DLP vs LCD vs SLA

Although there are more than a dozen types of 3D printing technology, only a few are used in dentistry. Because the application requires highly precise and accurate parts, practitioners rely on resin 3D printing also known as vat polymerization. This technology, with subcategories including digital light processing (DLP), stereolithography (SLA) and liquid crystal display (LCD), uses a liquid resin cured by light to form a final part.

There’s also material jetting, which is another resin technology. It enables multicolor realistic looking parts. One example the PolyJet printer from Stratasys.

Practitioners are split between the three major resin 3D printing technologies, DLP, LCD, and SLA, which is slower than the other two. SLA machines once offered more resin variety, but that not the case anymore. In fact, the argument could be made that resin 3D printing is moving away from laser-based SLA, particularly in the desktop market, since they tend to be more expensive machines to buy and maintain.

However, in 2025, an interesting preliminary study indicated that SLA outperforms DLP and LCD when it comes to producing strong temporary dentures. Researchers say that the limited number of direct comparisons and reliance on indirect evidence suggest that further research is necessary to confirm these findings. It is inferred that this study should not be taken as a claim that SLA 3D printed parts are inherently stronger than DLP or LCD parts (although research in other industries points to this). Rather, among the 3D printed PFDPs research conducted to date where flexural strength was measured, SLS and SLA come out on top.

Rather thank the underlying technology, desktop users should focus on the features, available materials, and print quality of the machines.

Materials

Many printer manufacturers work in conjunction with these material manufactures above to brand their own resins with properties that match the demands of their specific printers. But not all resins are interchangeable. Your printer will come with a list of tested and validated brands. If you use a material outside of this list you may not achieve the print quality or speed that’s typical of your printer.

Of course, any material for use in a patents mouth must be certified biocompatible in your region (by the FDA, CE, etc.). In addition to this certification, look for materials that meet ISO (International Standards Organization) levels for impact, strength, fracture-resistance, and stain-resistance.

Post Processing Equipment

Although a dunk in a simple dish of isopropyl alcohol (IPA) may suffice for washing most prints and curing could be done with sunlight or an inexpensive UV lamp, for interoral parts, a closed, automated approach is cleaner and more efficient.

Several printer manufacturers offer the washing and curing equipment necessary for final parts. Buying your accessories from the same manufacturer as your printer ensures easy integration, but you’re not locked in. Many accessory brands are interchangeable. The more sophisticated your printer, the easier the wash and cure process is, and many industrial printers incorporate printing, washing, and curing into a single unit.

Part Washing Accessories

The liquid solution you wash your prints with, and for how long, depends on your materials. Each type of print you make may have slightly different washing requirements.

The SprintRay Pro Wash/Dry, for example, is a fully-automated two-stage wash and dry system that promises finished parts in 10 minutes. Thanks to a suite of automatic features, the only time you have to touch IPA is when you pour it into the reservoirs. The unit comes with pre-calibrated hydrometers that sink in clean IPA and float when it’s dirty. So you always know when it’s time to refresh your IPA.

Zortrax offers an Ultrasonic Cleaner ($375), that uses high frequency sounds propagated in liquid detergent to remove excessive resin from parts 3D printed on the Zortrax Inkspire.

Part Hardening Accessories

Most resin printed parts come out of the printer only partially cured and require more exposure to UV light to fully harden. Curing boxes of various sizes provide uniform 360-degrees of light in a controlled environment. One example, the Rapidshape RS Cure, for example, uses powerful LED lights in combination with heating and a vacuum. This curing box is equipped with a wireless data link to the 3D printer so the right curing program is pre-selected for the part that was just printed.

Although some curing boxes have extra bells and whistles for convenience, most of them are so similar that many printer brands don’t even make their own and will point customers to a range of suitable options.

You May Also Like:

Lead image source: Digital dentistry. Source: Waldmann Lighting

License: The text of "The Best Dental 3D Printers 2025" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.