3D printing is a solution comfortably at home in the modern dental industry. The fast, personalized, and affordable applications suit dentists and consumers alike, while future trends, such as a growing senior population, an ever-strengthening demand for cosmetic dentistry, and common diseases, such as edentulism, suggest the potential for its utility is only set to increase.

It is already big business, but according to a report this year from MarketsandMarkets, over the next five years, the value of the dental 3D printing market will grow by more than double to a gigantic $6.7 billion. One 3D printer maker, Carbon, told All3DP that its customers printed more than 6 millions dental parts in 2023 using nearly 50,000 liters of dental resin.

The heightening demand has spurred technological advancements in the industry, which, in turn, has quickened product development and helped to create better quality and more complex and customizable items while reducing cost and waste.

Polymers comprise the largest share of materials used in the dental 3D printing market. This includes photopolymer resins, most of which are FDA-certified biocompatible and ideal for high-performance products with high durability and impact strength rivaling traditional dentistry materials.

Resins are particularly worthy of attention due to a range of recent developments that have expanded their ability.

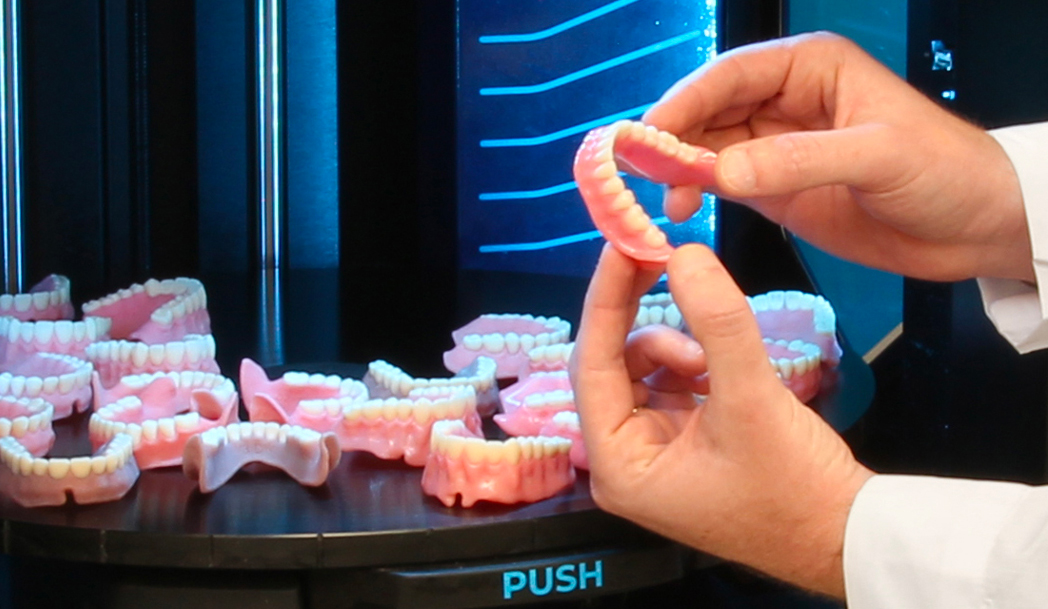

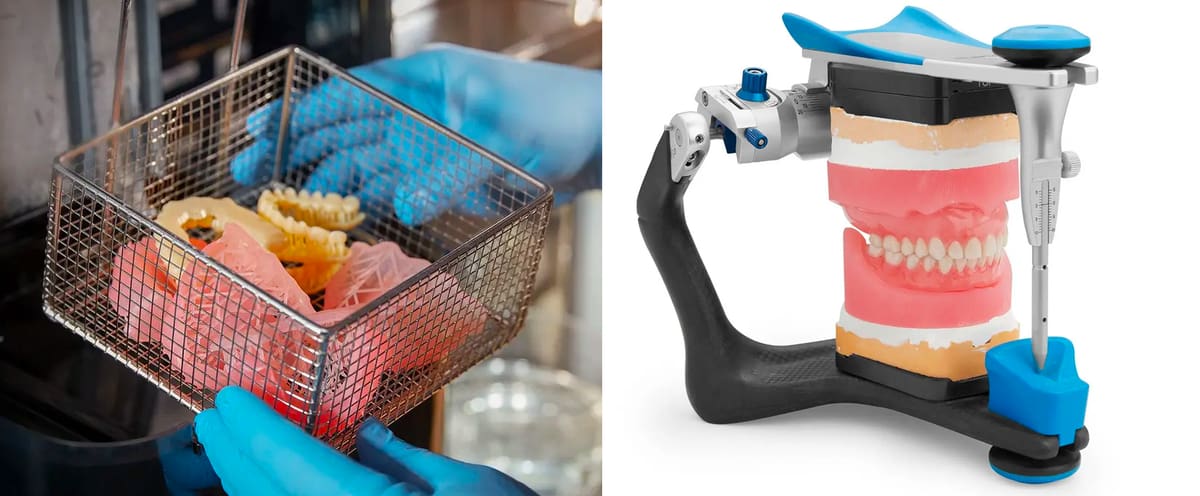

In 2023, 3D printer and material maker Stratasys launched a new biocompatible resin material that produces full-color, natural-looking dentures in a single piece ready for patients to wear. The advantage of the new resin with the Stratasys 3D printer and software, the company says, is its ability to print volume batches of dentures where each one is patient-specific based on individual dental scans.

As a monolithic solution, there is no assembly, something that’s uncommon compared to other 3D printed denture solutions. Often, the denture gums are 3D printed in one material, while the teeth are printed in another and then hand assembled. Stratasys’ J5 DentaJet 3D printers can print with multiple materials and multiple colors at once.

Recently, the dental division of 3D printer and material maker Formlabs introduced its Premium Teeth Resin, a new material for printing natural-looking teeth for dentures and temporary full-arch implant-supported restorations. The new tooth-colored resin is a nano-ceramic filled Class II biocompatible material. In October, Formlabs launched three other healthcare-focused resins: BioMed Elastic 50A Resin, BioMed Flex 80A Resin, and IBT Flex Resin.

New from printer-maker Carbon, is the approval for use on its platform for materials from dental industry partners, Pac-Dent, Keystone, and Desktop Health.

It’s an exciting time for the dental industry as these functional-material advancements combine with state-of-the-art printers to make cost-effective, quick, and precise products for customers.

In this guide, we’ll look at different types of resins, what can be done with them, and the particular attributes a dental professional might want to look for in each material.

Which Materials Work With Your 3D Printer

If you’re new to the 3D printing landscape, an important aspect to note about dental resin materials is the difference between open and closed 3D printing ecosystems. In other words, whether you have a choice of resin brands or no choice at all.

A closed system means your 3D printer brand will only work that that brand’s materials. An open system simply means you can chose which brand of material you want to use, typically with some limitations.

Naturally, over the few decades of the history of 3D printing, closed systems were the forerunners, tested in tight commercial markets with a single proprietary system, enabling the technology to prove itself and gradually develop within a small feedback loop.

Over time, improved performance and efficiency, along with outstanding material options from third-party companies and customer demand for flexibility, moved most 3D printer makers to validate or certify the use of “outside” materials, or simply become “open material” platforms.

A material that’s validated for a particular 3D printer brand means extensive testing has been done to establish the ideal printer settings to achieve optimized results. This doesn’t mean that you can’t use non-validated materials in your 3D printer, but it will take time and experimentation to come up with the ideal printer settings for your applications. Your printer will come with a list of tested and validated brands. If you use a material outside of this list you may not achieve the print quality or speed that’s typical of your printer.

Makers of dental resin, such as Asiga, say their materials are suited for their own Asiga 3D printers and any resin 3D printer that uses a light source with a 385nm or 405nm wavelength.

Nevertheless, both open and closed systems still have their merits: Purpose-built closed systems can reliably produce time and time again with virtually no need for experimentation, while open systems can allow for various suitable materials from any supplier, each with specific beneficial attributes.

Another criterion for selecting dental resin is whether it is suitable for LCD (also known as MSLA), SLA, DLP or all three types of resin 3D printers. These three technologies all work a little differently so ensure your resin type matches your resin printer technology.

Types of Dental Resins

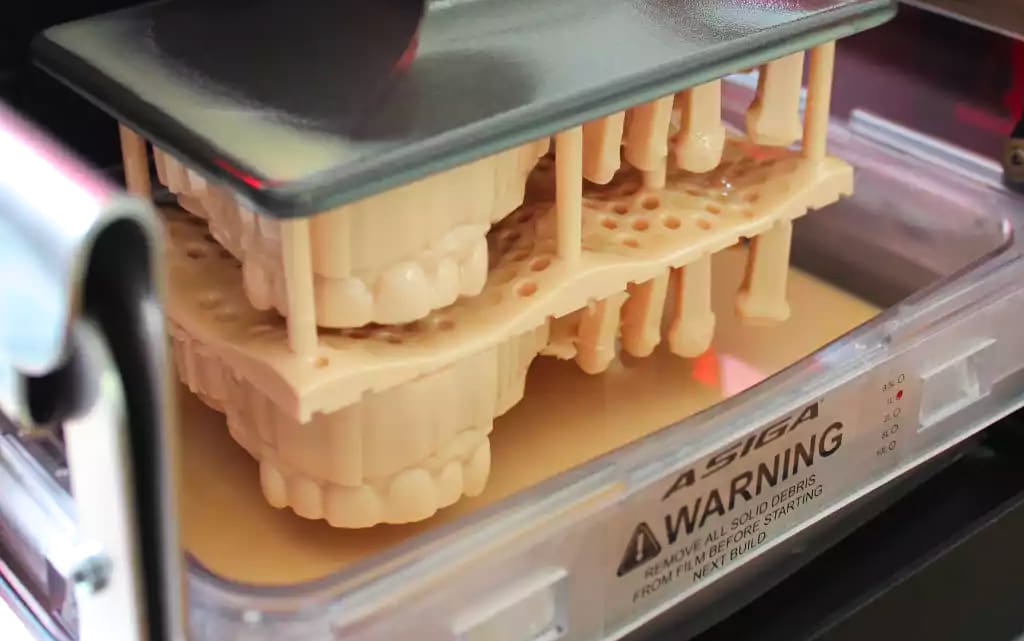

Dental Models

Industry practitioners must rely on precise and accurate models for dentures, gums, implants, crowns, or bridges. The resins available deliver this by focusing on crisp finishes, allowing for very fine detail. Dental models have quick printing times, minimal shrinkage, and are resistant to temperatures for further work with aligners. Strong, hard models suit orthodontic work, study practice, or working models.

Gingiva Masks

Combined with dental models for the adjustments of implants, crowns, and bridges, gingiva masks are used to resemble soft gum-like oral tissue accurately. The resins on the market exhibit stability alongside high elasticity and flexibility. Although tear-resistant, the gingiva masks can be cut and trimmed easily into precision fits to supplement the models. Natural colors mimic organic tissue and are often odorless and tasteless.

Because these parts typically do not interact with the patient, you’re not limited to special gingiva-specific resins and can substitute with other manufacturing-grade flexible resins, yet they are not typically found it pink.

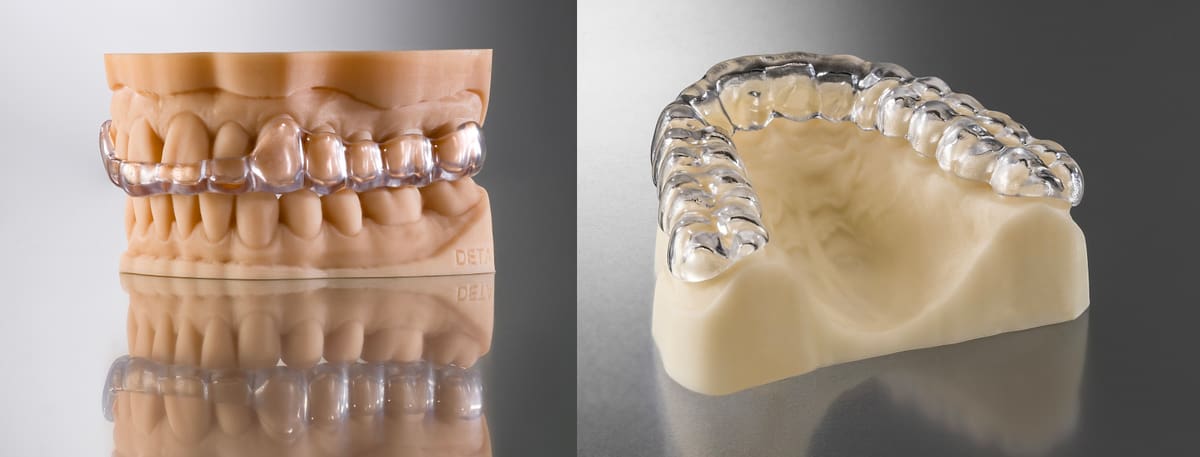

Aligners, Nightguards, Splints

To deliver the required protection to prevent stress-related dental conditions like bruxism, the durability to retain the shape necessary for the treatment plan, and a comfortable fit for use long enough to see a clinical impact, these products must be supremely strong and flexible. Transparent biocompatible resins are favored, as are those that are easy to use and easy to clean.

Impression Trays

Stability over time is of paramount importance with impression trays as the long-term retention of the precise dental record is necessary for further treatment. Therefore, accuracy, low shrinkage, and high printing speeds are vital. Using biocompatible materials without taste, odor, or allergy issues is also key for approval.

Surgical Guides

These accurate, pressure-resistant prosthetic components come in several low-cost biocompatible resins, safe to be placed in the mouth, allowing space for implants and drill sleeves. Often transparent, these resins’ mechanical properties and high flexural and tensile strengths minimize the breakage or brittleness concerns when drilling. The most popular resins are odorless, tasteless, and can be sterilized with standard processes.

Indirect Bonding Trays

The most effective indirect bonding trays increase patient comfort and reduce the amount of time in the dentist’s chair. A fast treatment is achieved due to the flexible printed resins allowing all orthodontic brackets to be placed precisely and quickly in a single session. These 3D liquid resins are typically biocompatible, transparent, light-curing, with high-tensile strength, and come in odorless and tasteless ranges. Although strong and stable in place for installation and bonding, these resins will tear under added force rather than impact the bracket’s placement.

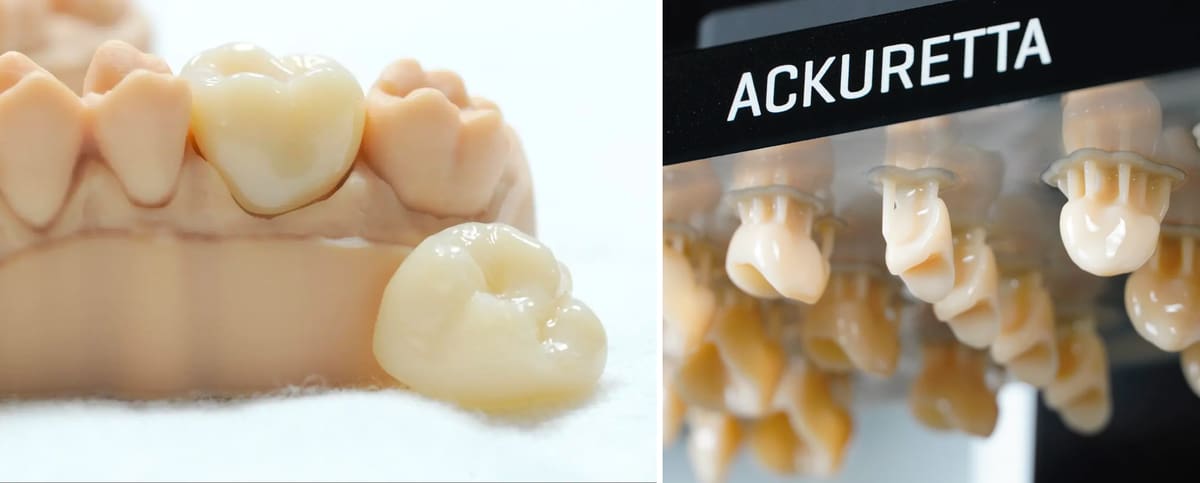

Crowns and Bridges

Suitable for either short-term, long-term, or permanent use, these biocompatible resins offer the durability of traditional dental fixtures. Commonly self-curing, some are intended to restore function before final restoration and so need to fit natural dental aesthetics while being easy to process, accurate, and resistant to the daily wear and tear of usage. Others are designed for manufacturing permanent restorations (crowns, inlays, onlays, veneers, artificial teeth) with perfectly matched opacity. Resins typically have low viscosity and are easy to clean, with colors consistent with light and medium palettes. Note the price differences between temp and permanent resin materials.

Denture Try-Ins

Denture try-ins can take the uncertainty out of the denture fitting process. These short-term trial dentures are designed for precision and efficiency and intended for evaluation of fit, occlusion, esthetics, and phonetics during try-in appointments. For edentulous patients who don’t already have a denture, they can start with a full try-in to get the fit right before moving on to the definitive, 3D printed high impact denture.

Denture Base

At a fraction of the cost of traditional methods, 3D printed denture bases are now easy, quick, and high-quality. Stable, clear human tissue colors come in odorless and tasteless biocompatible resins designed to be highly personalized, long-lasting, and resilient to wear with accurate fits and reliable flexural properties.

Denture Teeth

With both chipping and fractures key concerns of artificial teeth, the robust mechanical properties of those produced with 3D printed resins offer added strength and durability. Patients and dental professionals benefit from reduced costs and waiting times that can often provide dentures on the same day. The innovative biocompatible materials imitate teeth accurately with natural margins and a range of colors available to satisfy desires for aesthetic appearance. Stain-resistant resins can further limit the aging of denture teeth, making them a positive long-term investment for patients.

Castable Resins for Metal Dental Casts

With a focus on precision, details, and a smooth finish, these liquid resins suit the needs of many types of metallic prostheses. Fast printing, fast curing, and commonly 100% ash-free in content with a rapid burnout, these castable resins cause no irritation, are safe to handle and are often odorless. Their high casting quality is stable over time, limiting any damage to the investment through cracks or expansion, and exhibits low shrinkage percentages to match the original 3D model.

When using a castable resin for your 3D printing, you’re not limited to specific dental resins since casting resins are also widely used for jewelry making and do not need to be biocompatible.

License: The text of "Best Resins for Dental 3D Printing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.