It just takes one good idea.

There’s that moment when you 3D print something that turns out great, and you think to yourself, “I could sell this!” For most 3D printing hobbyists, this is a fleeting fantasy, but for many others, it has turned into a successful business.

Below, we look at 10 very different successful businesses selling their 3D printed product ideas. These are not Etsy shops selling articulated dragons or keychains, but rather original product ideas that address a niche or fill a need that these entrepreneurs identified earlier than anyone else, or their business approach is stronger and more sophisticated. There are even some ideas that are just so unique, or the item is just so beautiful, that customers simply have to have one.

If you’re looking for what to sell, how to sell, and where to sell, along with how to avoid copyright and legal issues, we cover all of this in two of our most popular guides here on All3DP: “Things to 3D Print & Sell: 3D Printed Items That Sell” and “Selling 3D Printed Items – A Legal Guide.”

Here, though, we take a look at 10 specific businesses to see what their key to success is and what they all have in common.

MagCAD Designs

- Products: Bicycle Accessories

- Printing Technology: Selective Laser Sintering (SLS)

- No. of products for sale: 250+

- Customization Available: Yes

- Years in Business: 7

Blending a personal passion with expertise in engineering is the secret to success for countless small businesses, including MagCAD Designs. This small company founded by former professional cyclist Andrew Magnier, who also studied engineering when he wasn’t racing, started out as hobby and very rapidly grew into far more.

Still a side gig to his full-time job at machinery manufacturing JCB in the UK, MagCAD Designs sells hundreds of unique 3D printed cycle accessories, such as custom mounting brackets and holders for essential electronic gadgets from Garmin, Wahoo, and GoPro.

As a maker and a designer, Magnier says he takes design briefs from customers and turns them into durable and practical products that address specific needs. “We do not charge huge amounts for our design time,” he says, “instead we make these custom products available for others worldwide to buy.”

And, it turns out, that thousands of cyclists have similar equipment needs. MagCAD sells thousands of variations, mostly printed in nylon, some in metal, and also 3D printed waxes for molding.

More 3D printed cycling accessory businesses:

City Frames

- Products: Miniature City Models

- Printing Technology: FDM

- No. of products for sale: 100+

- Customization Available: Yes

- Years in Business: 6

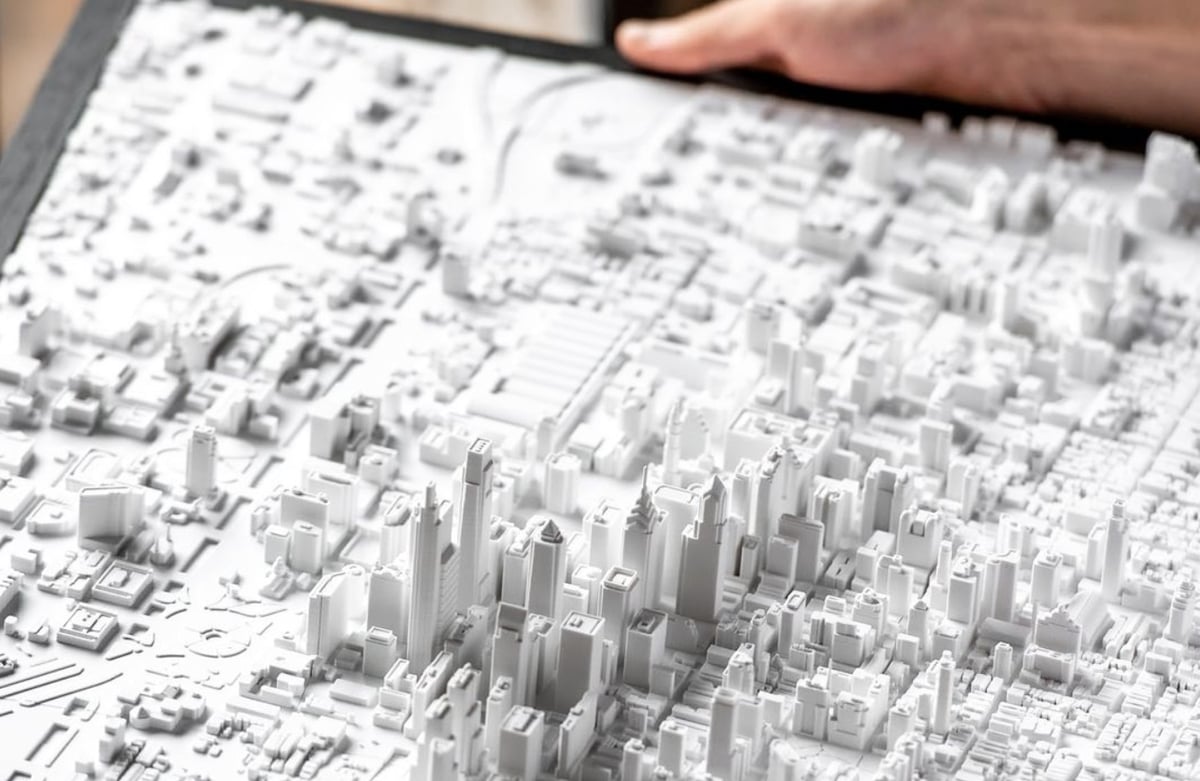

In 2018, Alexander Mueller traveled from his native Germany to New York City and, like most first-time visitors, was astounded by the skyscrapers. Photos just couldn’t represent the scale of what he experienced, which led to an idea.

He spent a year diving deep into the world of 3D modeling, architecture modeling, and 3D printing miniatures before launching his business, City Frames, on Kickstarter. In a nutshell, Mueller takes satellite data of major cities (and any location for custom orders), adds in a bit of manual processing, and generates a unique 3D digital terrain model of the location that’s then 3D printed on UltiMaker machines and nicely framed.

The idea took off, orders flowed in, and by 2021, the company moved to a larger manufacturing space near Frankfurt. City Frames has fulfilled orders from 89 countries, has nearly 100 cities in its digital repository, and says it has gone though more than 1,400 kilometers of filament.

Honey & Ivy

- Products: Lamps

- Printing Technology: FDM

- No. of products for sale: 45+

- Customization Available: No

- Years in Business: 5

- Also sold at: Etsy

Honey & Ivy started in a suburban Portland garage and now sells a wide range of 3D printed table lamps and home accessories at its online shop. Industrial designer and 3D printing hobbyist, Danny Han launched the company in 2019 as a side gig to his day job at HP, where he worked for more than a decade until Honey & Ivy took off and now requires his full-time attention.

In addition to the whimsical designs, Han says the company is dedicated to collaborating with local artists and designers and committed to the environment. Honey & Ivy uses only plant-based polymers and has planted over 2,500 trees in an effort to combat deforestation through a partnership with filament maker Polymaker.

The company appears to use Prusa 3D printers and its lamps retail for about $60 to $80 each. Unlike many 3D printed product online ships, Honey & Ivy’s online presence and product photography is on par with Ikea and similar larger retailers. Their ecommerce environment is slick and modern and the company is continuously innovating, delivering new designs, frequently.

More 3D printed lamp businesses:

pwnCNC

- Products: CNC Machining Accessories

- Printing Technology: FDM

- No. of products for sale: 50

- Customization Available: Yes

- Years in Business: 5

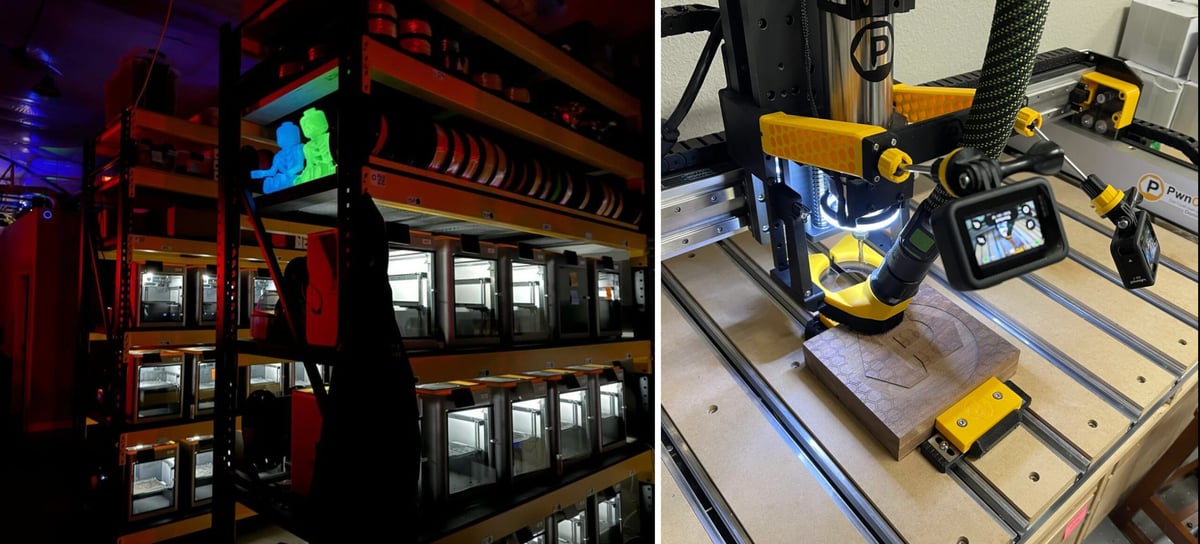

While working as a software architect full time and pursuing his CNC hobby on the side, Daniel Moran identified gaps in hobby-level CNC equipment. For the non-pro, there were a lot of ways to make CNCing more convenient and less of a mess, he thought. Having engineering skills, Moran set about designing various vacuum attachments, extenders, adaptors, and all manner of bits and bobs he could 3D print. They worked so well, he thought he’d offer a few online.

Fast forward a few years, and pwnCNC is Moran’s full-time business. Online, the company sells nearly 200 CNC accessory items, about half of which are 3D printed. He has more than 30 Bambu Lab X1C 3D printers churning out parts day and night. Best sellers include the Speedsetter, which is a bit length calibration tool for when you want to use similar sized bits on a project and load them without having to rezero your Z (CNC hobbyists will know what this means).

Although there are a lot of knock-offs of pwnCNC products online, Moran’s are available in a distinctive yellow. His YouTube channel promotes his products as well as his own expertise in the field and customers review pwnCNC positively for the product quality and customer service.

Printed Reef

- Products: Aquatic Tank Accessories

- Printing Technology: FDM

- No. of products for sale: 55

- Customization Available: Yes

- Years in Business: 3

- Also sold at: Amazon

Printed Reef is an aquarium hobby accessory maker specializing in the delicate environment of contained corral reefs. As anyone familiar with this hobby, which can quickly grow into an obsession, already knows, there’s a lack of affordable and specialized tools for the precision work of growing reef coral, such as coral plug stands.

Printed Reef stepped up in 2021 to offer a range of 3D printed designs solving some of the most common hassles that reef hobbyists encounter in maintaining a healthy reef environment. Products include various holders and brackets for common brands of aquarium equipment as well as stand sifters and fish feeders. Materials include what the company calls “reef safe” PETG.

Customers have left glowing reviews of Printed Reef online, especially the customer service and product advice.

Motoism

- Products: Motorcycle Attachments

- Printing Technology: FDM, SLS

- No. of products for sale: 25

- Customization Available: Yes

- Years in Business: 4

- Also sold at: Various motorcycle accessory retailers

Motoism makes and sells a range of attachment parts, most of which are 3D printed, for a wide brand selection of motorcycles, including BMW, Ducati, and Harley-Davidson. Founded in Munich in 2017 by brothers Ben and Lion Ott, one an industrial designer and the other an engineer, the company combines their experience and passion for motorcycles.

If you’re looking for a set of aero wings for your Ducati Monster 937 or some fork covers for your Triumph Scrambler 900, Motoism is the place. Accessories and kits are 3D printed in carbon-fiber infused materials to be ultra-light weight and durable. Electronic components are assembled by hand and many of the parts from Motoism are “tailor-made”.

Motorcycle accessories for high-end and custom bikes are in demand from a loyal following of enthusiasts who know engineering and design; they’re willing to pay hundreds of dollars for the perfect part. Yet, Motoism says 3D printing enables it to offer all of its products at prices that would be impossible to match using conventional manufacturing methods.

Martinson Manufacturing

- Products: Air Conditioner Vents

- Printing Technology: FDM

- No. of products for sale: 6

- Customization Available: Yes

- Years in Business: 6

- Also sold at: Amazon

In 2019, Joe Martinson invented a hose adapter that helped laser engraving machines vent exhaust more efficiently. It was mostly 3D printed and sold well – more than 10,000 units – due partly to Martinson’s YouTube channel where he helped people with their exhaust venting issues.

A few years later, Martinson used his venting expertise to help a wider audience of people with a more common challenge: air conditioner window venting. By 2023 the demand for Martinson Manufacturing‘s window inserts for air conditioners became so great that it completely shifted the direction of the company, which now focuses mainly on custom AC window kits promising a “perfect fit.” The vents are also used for venting clothes dryers and basement venting.

Operating out of his basement workshop, Martinson Manufacturing 3D prints various venting hoods, covers, and accessories to accompany acrylic window inserts, all custom fit for a better look than a DIY solution yet at a lower cost than a lot of professional installation options.

Martinson 3D prints using a farm of 12 Bambu Lab P1Ps and one X1C.

Smoke 3Designs

- Products: Marijuana Accessories

- Printing Technology: FDM

- No. of products for sale: 25

- Customization Available: Yes

- Years in Business: 4

With the sale and consumption of Marijuana and related products legalized in 39 US states and a growing number of European countries, it hasn’t taken long for savvy entrepreneurs to recognize a market for 3D printed weed accessories.

US-based Smoke 3Designs launched in 2020 and focused on two astonishingly simple products, a joint-rolling tool called the “Roll-a-Cone” (pictured above), which retails for $11 each and the “Hold-a-Bowl” 3D printed bong bowl holder. Both are available in a wide range of colors (including convenient glow-in-the-dark) and include the company logo.

Smoke 3Designs prints with Prusa 3D printers, among others, using PLA.

Invent3D

- Products: Trophies

- Printing Technology: FDM, SLA

- No. of products for sale: 25

- Customization Available: Yes

- Years in Business: 6

Invent3D was established in Malta in 2018 with the goal of using its capital investment in 3D printing technology hardware and software to be the island nation’s premier 3D service provider. Although it planned on delivering a wide range of services to a broad audience (and it does), one product has surged to the top and become what the company is most know for: Trophies.

From schools and businesses to non-profit organizations and sports clubs, recognizing achievement with a trophy is universal. And, as it turns out, it’s an ideal product to 3D print because it always needs to be unique (or at least customized), can be iterated and altered quickly, is fabricated in low volumes, and typically made and delivered locally.

Invent3D works with each client to custom design a trophy, which is then made with sustainable recycled plastic. Its customers return, year after year, because the flexibility in design – well above and beyond the traditional “cup” or etched glass – enables them to have a truly unique product.

UAU Project

- Products: Vases & Home Accessories

- Printing Technology: FDM

- No. of products for sale: 25

- Customization Available: Yes

- Years in Business: 4

The humble 3D printed vase, when presented in the right light and marketed with sophistication, can led to a successful business. Warsaw, Poland-based design studio UAU Project founded by two local designers, Justyna Fałdzińska and Miłosz Dąbrowski, in 2011, started off selling 3D printed vases in appealing colors to “show that 3D printing is the best way to make good design sustainable and accessible,” the company says.

Single vases were popular, but once the designers started to stack them into pedestals, or “totem poles”, as they call them, the simple vase transformed into something more unique.

Combining an appealing color spectrum with a range of textures and shapes, these assemblies of 3D prints are now available as candle holders, table legs, and simply as art. In fact, two vases from the company’s Things of Rave collection were acquired by Stedelijk Museum Amsterdam in 2023 for its permanent collection.

UAU Project offers customers more than 100 colors to choose from and a “build your own” totem pole product along side a range of other objects.

More 3D printed vase businesses:

Winter Hill Jewelry

- Products: Jewelry

- Printing Technology: FDM

- No. of products for sale: 25

- Customization Available: Yes

- Years in Business: 8

- Also sold at: Etsy, local gift shops

Yes, this is number 11 if you’re counting, but it was just too hard to narrow down our list.

Winter Hill Jewelry is a one-woman show founded by Vanessa Templeman, who fell in love with drawing and designing 3D pieces for herself and her friends. In late 2015, she set up her first display at a local artisan’s event in Somerville, Mass. Since then, her business has thrived on its ability to rapidly respond to trends, global events, and customer demand.

Winter Hill Jewelry sells designs for holidays, seasons, and custom creations to match the aesthetic and theme of resellers’ shops.

She says on her site that her creations are known as conversation starters that help customers stand out in a crowd. Whether you’re wearing giant beet root dangles or Star of David studs, these accessories enable you to express yourself without saying a word.

Although the design are relatively simple, the key to success is timeliness and rapid delivery. Templeman prints in PLA and wood-infused PLA.

Common Keys to Success

These 10 businesses couldn’t be more different yet they all use 3D printing to offer a unique product. Although passion, innovation, and business savvy are a common theme, there are other key business approaches and practices that led these companies to profitability.

3D Printing is Secondary

It’s not very apparent that many of these products are 3D printed because it’s not the selling point. The product – the innovation of it – and typically the price are the draw for customers. The fact that it’s 3D printed is secondary. Although, when the manufacturing method is mentioned, the focus is on sustainable materials or the “advanced technology” aspect.

The Customer is King

As with selling anything online, your reputation is critical. One unhappy customer can post his or her dissatisfaction on countless outlets, which doesn’t seem fair, but that’s online retail. Bending over backwards with easy and prompt product returns, quick replies to questions, an online FAQ, and friendly service, is essential to grow your business. We noticed that most of these businesses had very favorable online customer feedback.

More Affordable than Traditional Manufacturing

Many of these businesses offer a product that’s much better than a DIY solution yet more affordable than a traditionally manufactured solution. 3D printing enables the fabrication of products without the minimum volume required to make injection molding or casting profitable, and without any additional tooling, like molds.

Go On Social

Although not all of the businesses above have a YouTube channel, most have Instagram and Facebook accounts to tell the unique story of their company. Those with YouTube videos use it to post their expertise in their field, whether its 3D printing or CNC machining, they offer their advice and guidance for free.

License: The text of "10 Entrepreneurs Who Made 3D Printing Pay Off" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.