So you thought that glow-in the-dark, conductive or magnetic filaments are exotic? In that case, you have no idea how exotic things are getting. Prepare to be pleasantly surprised as we present the most fantastic (and useful) 3D printing materials that have emerged out of R & D labs in 2017.

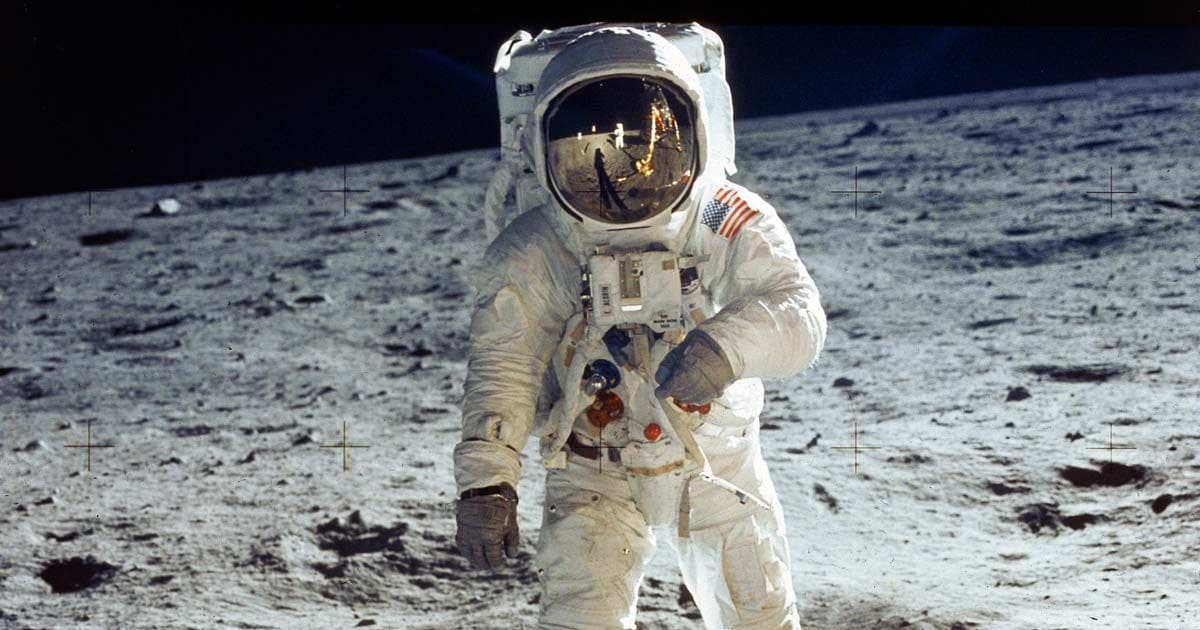

Moon dust and Mars dirt

In Cory Doctorow’s sci-fi novella “The Man Who Sold The Moon”, a small team takes on the daunting mission of launching a machine that collects lunar dust (regolith) and uses it to 3D print structural housing panels for future settlement.

Believe it or not, this science fiction idea has finally become reality this year. A team led by Ramille Shah at the Northwestern University has managed to 3D print structures made out of Martian and lunar dust simulants!

If that’s not fantastic, we don’t know what is. The unique 3D paint used for this project was created using NASA-approved lunar and Martian dust simulants.The 3D printed structures are over 90 percent dust by weight—but you wouldn’t know it. Despite being made of rigid micro-rocks, the 3D printed material is flexible, elastic, and tough, and shares a lot of characteristics with rubber. After being printed, it can be cut, rolled, folded, and more.

“For places like other planets and moons, where resources are limited, people would need to use what is available on that planet in order to live,” said Dr. Shah. “Our 3D paints really open up the ability to print different functional or structural objects to make habitats beyond Earth.”

“We even 3D printed interlocking bricks, similar to LEGOs, that can be used as building blocks,” said the innovative assistant professor.

That’s moon dust and Mars dirt we are are talking of folks! And you thought glow-in-the-dark filaments were exotic??

Astronaut Urine

If you have seen the movie “The Martian”, then you probably already know the many creative uses of human waste. If you haven’t, then go watch it. It’s a darn good movie.

But even the author of the The Martian (the book that inspired the movie) did not imagine that you could actually 3D print with urine.

Sometimes, reality is indeed stranger than science fiction. Recently, researchers at Clemson University announced that they have been developing a technique for turning human waste into 3D printing filaments!

“If astronauts are going to make journeys that span several years, we’ll need to find a way to reuse and recycle everything they bring with them,” explains Mark A. Blenner, Ph.D. “Atom economy will become really important.”

That’s why Blenner and his team developed a biological system using strains of the yeast Yarrowia lipolytica. The yeast requires nitrogen and carbon dioxide to grow, and can be fed with astronaut urine.

Over time, polymers with different mechanical properties can be extracted from this biological system, giving astronauts the necessary materials for 3D printing spare parts, new tools, and whatever else they need on a long-distance mission.

At the moment, Blenner and the other researchers can only produce small amounts of 3D printable polymers or nutrients with the mix of waste and yeast, but with more research they believe they can make a system with a high output. In fact, if their biological system turns out particularly well, it could even be used on Earth as well as in space.

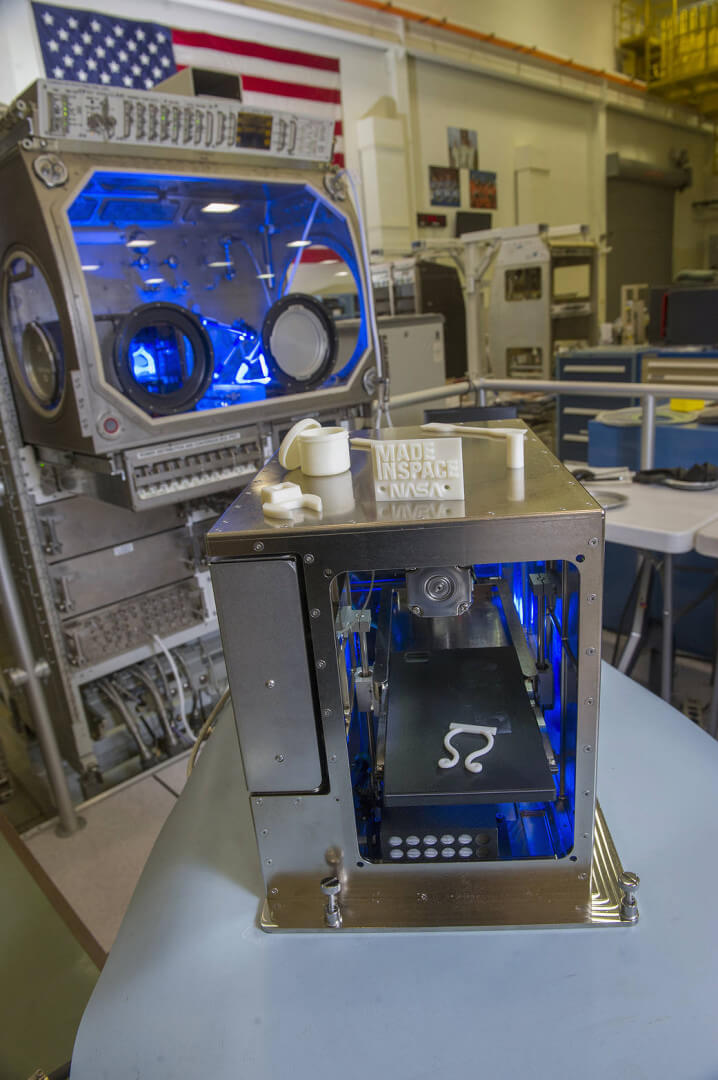

Space Plastic

Since we are on the topic of space exploration, here’s a material that was invented recently and is currently being used and tested at the International Space Station (ISS). It’s a plastic made of Polyetherimide/Polycarbonate (PEI/PC) that is several times stronger than the plastic that the 3D printer on board the ISS earlier employed.

Yes, that’s right. ISS has a 3D printer on board since a few years now. Keeping the ISS functional requires lots of specialized tools and it is often hard to anticipate which tools the crew will need for an unforeseen malfunction or an upgrade. Since it’s impractical to launch a rocket each time a necessary tool is missing, they decided to have a 3D printer which prints tools on demand.

But the tools that the 3D printer could create wasn’t without limitations. Due to the harsh conditions in the vacuum of space, the tools were limited to repairs within the station. You couldn’t repair something on the outer walls, for example.

This new plastic is changing the status quo. “In a vacuum, PEI/PC is not going to emit particles, it’s resistant to the UV environment, it’s resistant to atomic oxygen, so it can perform actual uses in space,” explained the vice president of Made In Space, the manufacturer of the new space plastic material.

The company is currently testing a 3D printer, Archinaut, that has the ability to operate entirely outside of the station. This system will be launched to the ISS in 2018, and could be used to make the first 3D printed satellite ever created in orbit.

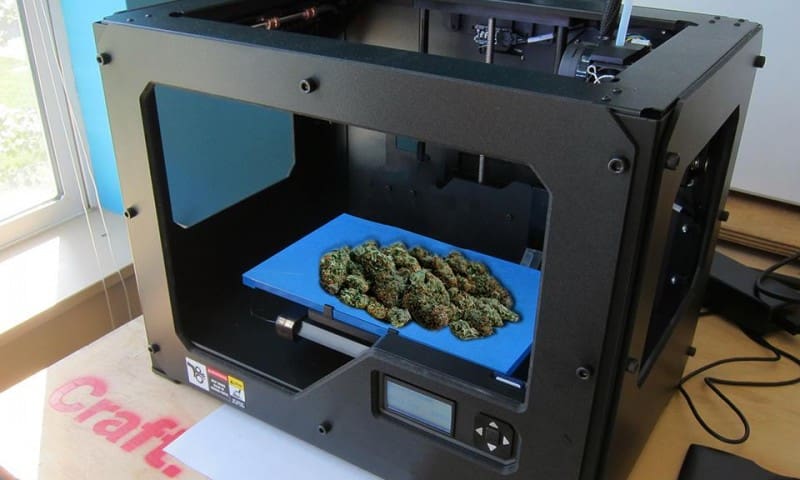

Edible Cannabis

If you take medical marijuana, you are going to love Potent Rope : a new edible 3D printing material made out of Cannabis. Talk about 3D printing reaching new highs!

The project is a brainchild of legal Cannabis industry experts Ashley Herr and Paige Colen who are convinced that this idea is useful.

“Rather than taking a 10 mg liquid gel capsule full of cannabis oil or a tablet, how about 3D printing a 7.5 mg poodle, or Eiffel Tower, or a tiny rocket ship?” Colen asks. “This filament will allow for us to tailor make specialized cannabinoid profiles that will specifically address any individual’s requirements.”

So it’s not only about creating funny shapes for your edible cannabis, it’s also a highly effective dosing tool. This could be a big draw for cannabis users who prefer edibles to other forms of consumption, since the dosages of typical edible products can be varied and uneven.

Ashley and Paige have been working on this idea for almost three years now. They have come up with a suitable formulation – a water-soluble thermoplastic polymer that can be mixed with different cannabinoids and terpenes – and have received a publication notification from the US Patent and trademark Office. The formulation is considered safe to eat. The thermoplastic polymer is FDA approved.

The creators (who are also sisters) are now looking to produce their “green” filament on large scale. Their timing seems to be perfect, with legalization occurring across the U.S. and elsewhere. The sisters have already formed agreements with cannabis companies in Nevada, Maryland, California, and Colorado.

There are apparently other advantages to using Potent Rope too. According to Herr and Colen, being able to 3D print cannabis edibles will allow users to try out different combinations of ingredients. This goes a step further than just tinkering with dosages: users will be able to create a strain of their own, choosing from Sativa, Indica, CBD, or THC oils.

Only time will tell if this turns out to be a million dollar filament, but the creators are convinced of its value. “Combining cannabis with 3D printing technology is a logical next step for both industries,” they say. “Cannabis supporters are looking for new ways to make use of the plant, and 3D-focused inventors are modifying, creating, and exploring new designs and materials.”

Excited? Learn more about Potent Rope in our article New Marijuana Filament Will Let You 3D Print Medicinal Edibles

Ash

Burning coal is not the most environment friendly power generation method, but huge parts of the world, including China and India, are heavily reliant on this source of power. Under the Donald Trump administration, the USA also seems interested in exploiting its coal reserves to the max. So while we are at it, why not take full advantage of burning coal and everything that comes with it?

This is why researchers at the NTU, Singapore have come up with a 3D printable geopolymer mortar (concrete) which is composed (mainly) of fly ash, a residue from burnt coal. The mixture also contains steel slag and various secret chemicals. It can be used for construction 3D printing, that is, for building houses. How would you like to love in a house made of ash?

Fly ash, which is left over after burning coal, has long been dumped in landfills as it serves no practical purpose. The researchers at Singapore saw this as a futile waste of material. After conducting research over the course of two years, a team led by Ming Jen Tan (of the School of Mechanical and Aerospace Engineering) published their findings on this potential new use of fly ash in the journal Cleaner Production and Materials Letters.

Of course, getting everything perfect—from flow rate to setting times—has been a massive challenge, but the NTU team thinks it has come up with a more-or-less viable product, which is incredible given that it comes from waste.

According to the researchers’ tests, the 3D printable mixture is just as strong, but only when the structures are oriented in a practical way. This is because the “mechanical properties of 3D printed geopolymer are mostly dependent of loading directions due to anisotropic nature of the printing process.”

Impressively, the researchers think they think they can make the material even stronger—as strong as reinforced concrete. While they don’t know exactly how they will achieve this, the researchers are continuing their study to see if they can perfect their product, while attempting to reduce its cost at the same time.

The best thing is that the 3D printable concrete would also help the construction industry to reduce its carbon footprint, since no materials need to be made from scratch. Concrete production currently accounts for around five per cent of the world’s carbon dioxide emissions.

Polluted Air

If you thought 3D printing with fly ash was earth-friendly and cool, wait will you hear this. Students at the Technical University of Madrid (UPM) in Spain have won a prize for UrbanBees, a 3D printing project which proposes using swarms of bee-like drones to capture contaminating particles in the atmosphere before converting them into filament for 3D printing.

The bee drones would, according to the Madrid students, collect pollution from the air like a bee collects nectar from a flower. They would fly through highly polluted areas of the sky, using information gleaned from radio waves to determine where the pollutants can be found in the highest concentration. Harnessing those pollutants and getting them out of the air is a good thing in itself—China has already deployed drones to do this—but the students have a further plan: they want to turn what the drones collect into usable 3D printer filament.

UrbanBees is still in the idea phase, and we don’t know if this audacious idea will ever turn into reality. The students say that they plan to target various metals (aluminum, calcium, potassium etc.) in ultrafine PM10 particles, which are known to cause lung cancer. We also know that the proposed drones would be mostly autonomous, organizing themselves into formation and returning to charging stations when necessary.

So what can you make out of pollutants? The researchers suggest glasses, bicycles, scissors, and cutlery could all be made from the pollutants, though the possibilities are endless.

Here is the presentation video that got the team from Madrid an innovation prize at the drone technology expo CivilDRON.

Food Waste

The BARBARA project, funded by the EU’s Horizon 2020 innovation program, is trying to create functional automotive and construction parts from food waste.

11 organizations across the EU have joined forces at BARBARA, a three year research project. According to the project’s website “Food waste and agricultural by-products will be used to purify pigments, fragrances, reinforcing agents or biocide compounds, which will be incorporated into engineered bioplastics derived from corn processing industries. These new materials will be transformed into prototypes with customized properties (mechanical and thermal resistance, surface or colour appearance, fragrance release or self-sanitizing surfaces) to be validated for their use in two highly demanding sectors such as the construction and automotive industry.”

The new materials will be based on food waste (from vegetables, fruits and nuts such as carrots, almonds or pomegranates) or agricultural by-products (from corn) and must possess specific mechanical, thermal, aesthetical, optical and antimicrobial properties to make them suitable for their industrial use.

As part of the project, Acciona Construction, one of the 11 BARBARA participants, is planning to test biopolymer-based prototype molds for beams in its construction laboratories. Such molds are often used for constructing bridges, towers, roofs, and ceilings—load-bearing structures that must be capable of absorbing vibrations, good and bad.

Similarly, Centro Ricerche FIAT will validate demonstrator prototypes such as car door handles, dashboard fascia for the automotive sector.

Wouldn’t it be nice if the three-year project resulted in an effective method for turning organic waste into 3D printing materials? We wish the project a lot of success.

Crack cocaine

In May 2015, American artist KATSU took the idea of material design to a whole new level. The prominent–and prolific–artist, activist and hacker is known for his graffiti art and encouraging the audience to sometimes vandalize in his pieces. Certainly, he’s not known for shying away from controversy.

For an exhibition at San Francisco’s Gray Area Foundation for the Arts, KATSU bought $250 worth of crack cocaine in San Francisco’s Tenderloin District. He then started 3D printing the material.

The project was intended as a message about the gentrification of urban areas, Katsu told Business Insider UK.

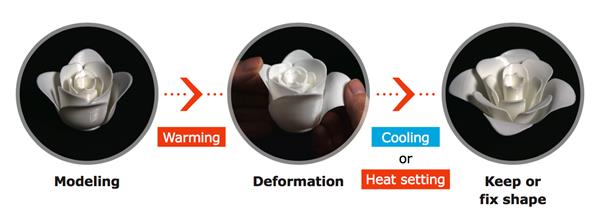

A sculptable material

Unitika, a Japanese advanced materials company, is trying to make 3D printing scluptable and malleable. We have heard that they are making thermo sensitive material which softens at body temperatures and can be deformed by hand.

The material’s unusual thermal property allows you to sculpt your 3D printing part further after the printing is complete. This would allow fine adjustments to made to 3D printed objects after they have been printed.

Of course, it would be a disaster for most use cases if your 3D printed part changed shape after you touched it. But for certain applications like medicine and art, this material could be a huge boon.

While Unitika doesn’t mention medical applications for its new material, it does emphasize the versatility of its polymer filament, as well as the fact that makers can apply “fine adjustment” and “precise and delicate finishing by hand” after printing.

This is an interesting feature. While you wouldn’t necessarily want to print mechanical parts with a filament like this, the reworkability does open up really cool possibilities for models and artworks.

For example, if your printer can’t handle super-fine resolutions (or if you just happen to be a master with a chisel), the ability to make small incisions, twists, and markings upon a 3D printed object really changes the way you can approach the whole process.

What’s even better, the material can be permanently fixed into shape by treating it with higher temperatures, e.g., with boiling water. So theoretically, you can even try making mechanical parts with it!

The forthcoming 3D printing material, which Unitika plans to launch next year,, will be available in 1.75 mm diameter, and should be printed at 190-220°C, on a print bed heated no higher than 45°C. (Unheated print beds are also fine.)

If you are an artist, you probably want to get your hands on this material.

Degrade-on-demand biomaterial

A big trend in 3D printing is the development of materials that can change after the printing process. Some people call it 4D printing to capture this additional dimension of change.

Sculptable 3D printing materials are examples of this trend, since you can morph the printed object afterwards. But you know what’s even more fascinating? A material that can degrade on demand!

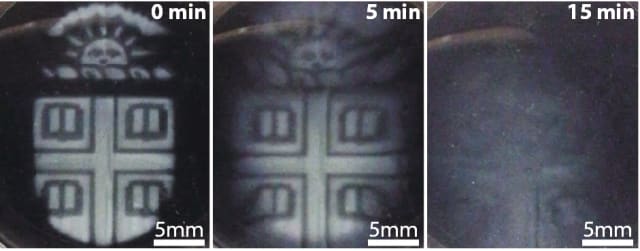

Researchers at Brown University are developing a biomaterial that degrades upon a special chemical trigger.

Ian Wong, co-author of the research, explains “It’s a bit like Legos. We can attach polymers together to build 3D structures, and then gently detach them again under biocompatible conditions.”

The attachment between the polymer comes apart when the ions are removed using a chelating agent that grabs all the ions. Therefore, you can make or pattern transient structures that dissolve away whenever you want them to.

The researchers are using stereolithography as their printing process. They say that nothing like this has ever been attempted on an SLA machine – and that they had to figure everything out from scratch. To carry out the novel procedure, the scientists made solutions with sodium alginate, a compound derived from seaweed that is capable of ionic crosslinking.

By using different combinations of ionic salts, including magnesium, barium, and calcium, the inventors were able to make 3D printed objects with varying stiffness levels, a factor which affected how quickly the structures dissolved.

Wondering how such a degrade-on-demand biomaterial could be useful? The researchers have some ideas.

They suggest that the alginate material could be used to fabricate lab-on-a-chip devices with microfluidic channels.

“We can print the shape of the channel using alginate, then print a permanent structure around it using a second biomaterial,” says Thomas M. Valentin, a Ph.D. student in Wong’s lab and the study’s lead author. “Then we simply dissolve away the alginate and we have a hollow channel. We don’t have to do any cutting or complex assembly.”

The researchers have also found that if you surround human mammary cells with an alginate barrier, the cells migrate in specific ways when the barrier is dissolved away. This could be extremely useful in cancer research or in making artificial tissues and organs. More generally, it can find a lot of use in making dynamic environments for experiments with live cells.

“We can start to think about using this in artificial tissues where you might want channels running through it that mimic blood vessels,” Wong says. “We could potentially template that vasculature using alginate and then dissolve it away like we did for the microfluidic channels.”

Currently, the researchers are trying to achieve better control over the stiffness, strength, and degradation speed of the printed structures.

It’s funny how quickly science fiction turn into reality these days. These futuristic materials are sure to make anyone’s head spin – some of them definitely blew our minds. And given the trend, we are pretty sure that we will see much more exotic materials in the near future. If you happen to know about any awe-inspiring material that we missed, we would love to hear about it in the comment section.

License: The text of "The Most Exotic 3D Printing Materials That We Know About" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.