Printer manufacturer MakerBot’s recent announcement that its Method printers can now print real stainless steel parts is a game-changer to an entire market of professionals who thought metal 3D printing was out of reach.

MakerBot qualified the BASF Ultrafuse 316L Stainless Steel filament by Forward AM for use in Method and Method X printers outfitted with the Labs Gen 2 Experimental Extruder. This is a significant step forward toward making metal 3D printing more accessible to a wider range of users, especially small- and medium-size businesses that want to experiment with metal parts before investing in a dedicated metal 3D printer.

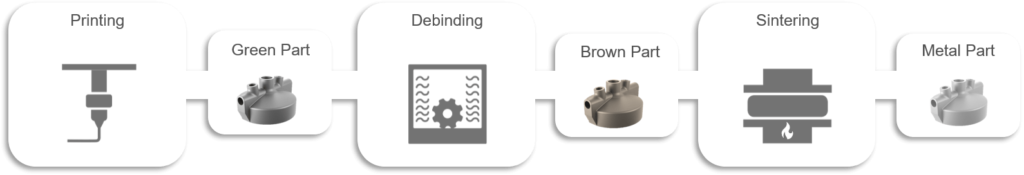

Even though you won’t get solid metal parts right off of your print bed – they have to be shipped to a third-party to be debound and sintered in high-end furnaces that are also used in metal injection molding industry – you now have the ability to experience for yourself the promise of 3D printed metal.

Let’s take a look at exactly how you can print real metal stainless steel parts on the MakerBot Method.

The Makerbot Method as a Metal Printer

The Method is one of the most popular professional desktop 3D printers on the market from Stratasys, the parent company of MakerBot. It’s a workhorse of a printer commonly found in machine shops, factory floors, and anywhere strong and reliable FDM prints are used.

With an open materials platform and a growing portfolio of advanced engineering-grade materials, such as carbon fiber and ABS Kevlar, the Method is now the only industrial desktop 3D printer in its price-class with a heated chamber that can print polymer, composite, and metal materials.

Both the Method and the Method X are approved to print metal, but it’s the extruder, specifically the Labs Gen 2 Experimental Extruder, that enables you to print with metal as well as a list of third-party materials. The Labs Gen 2 extruder enables printing with more abrasive composites and polymers for longer because of its hardened-steel components. Swap out different extruders on your Method for different base and model materials.

Another reason the Method printers are particularly adept at printing metal is their heated chambers – up to 60 °C for Method and 110 °C for MethodX – and ability to control the speed at which a part cools down during the printing process. This can help reduce the risk of de-lamination or having the part layers separate.

“By supporting a metal filament as part of the MakerBot Labs program, customers now have an easier and more affordable way to experiment with 3D printing metal before investing in a full printing, debinding, and sintering solution,” says Johan-Till Broer, vice president of product development at MakerBot.

What is Ultrafuse 316L Stainless Steel?

BASF Forward AM Ultrafuse 316L stainless steel filament is not the only stainless steel filament on the market, but it is the only one approved for use on the Method printers. BASF developed the technology nearly 30 years ago for metal injection molding and is still the standard today.

As with other filaments, the Ultrafuse 316L is a metal-polymer composite. It’s made out of more than 80% 316L stainless steel particles with a polymer base. After a part is printed, the polymer is removed from the part in the debinding process and the metal is further densified or compacted in the sintering step. In the sintering furnace, the part will shrink considerably but consistently. The result is a final part that can achieve up to 96% of the density of pure 316L metal material.

Because 3D printing metal parts with Ultrafuse is a three step process – printing, debinding, and sintering – once you print with Ultrafuse 316L, you pack up your part and send it to a third-part for de-binding and sintering.

Facilities that post-process your metal parts include DSH Technologies for the US and Canada. Debinding and Sintering (D&S) partner services are offered in kilogram-based tickets where each ticket is worth 1kg of printed part processing. D&S service tickets offered through distributors, such as MatterHackers, either bundled with the filaments or separately. Additional tickets and build plate adhesives can be ordered through BASF Forward AM distributors.

In Canada, Shop3D.ca also sells debinding and sintering tickets for services at DSH Technologies, while in Europe, printed objects are debound and sintered at the DSH Technologies sister company Elnik Systems in Germany. European material supplier IGo3D sells Ultrafuse 316L for €460 per/3-kg and tickets for post-processing at €69 each.

Total Cost of Metal Printing on Method

At about $4,000, the Method with the required extruder is far less expensive than a dedicated desktop-size metal 3D printer, such as the Desktop Metal Studio for about $60,000 – add a debinder unit and a furnace and your metal 3D printer investment tops $160,000.

If you’re adding up all the costs, however, there is more than the $4,000 for a Method. The Ultrafuse filament is about $456 for one 3-kg spool and typically comes with a “processing ticket” which covers the debinding and sintering of 1 kg or less of green parts. Still, it’s significantly less than buying a dedicated metal printer.

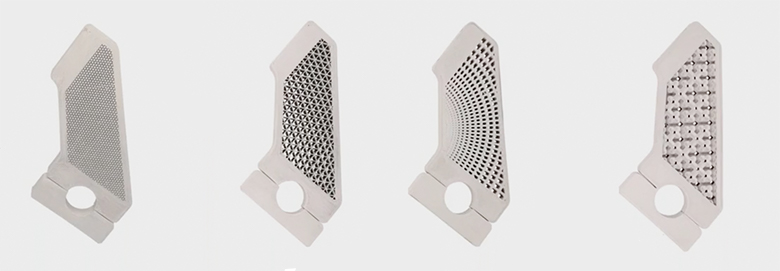

Metal 3D printing in general is less expensive than machined metal because you can create complex geometries that lead to increased performance with less material. The metal brackets pictured above are a great example of 3D printing metal parts for specialized machinery that are lighter and use less material than machined metal parts, so they’re less expensive to produce. The infill on these brackets would be difficult if not impossible to achieve with other methods.

Other Printers Also Print with Ultrafuse 316L

Although it’s the most recent, the Method is not the only desktop FDM printer that can print metal parts with the Ultrafuse 316L. The minimum requirements to print with Ultrafuse 316L are just a heated bed to 90 ºC and an industrial extruder that can reach 230 ºC, so a wide range of printers can handle the material.

Next to Makerbot, most popular metal FDM printing systems with Ultrafuse metal filaments are multiple models from Ultimaker, Raise3D, and BCN3D.

There are also other brands of 316L stainless steel filament, so it’s always best to check with your printer manufacturer before printing with a metal filament.

License: The text of "FDM Metal 3D Printing: Makerbot & Ultrafuse" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.