There are a lot of ways to compare fused deposition modeling (FDM) and Multi Jet Fusion (MJF) 3D printing methods. If you look at them from the perspective of a hobbyist, one is accessible and affordable and the other is definitely not. However, if you’re a company considering buying an industrial FDM machine or a MJF machine to fabricate fixtures and tools, these two technologies can produce parts that seem very similar. And when you’re ordering 3D printed parts from a printing service and have the choice between FDM or MJF, you’ll notice a wide range of prices, materials, and delivery times and may wonder what’s behind these differences.

Let’s take a closer look at all the ways that the choice between these two 3D printing methods is a close call, and the ways one or the other is the clear winner.

FDM & MJF Simply Explained

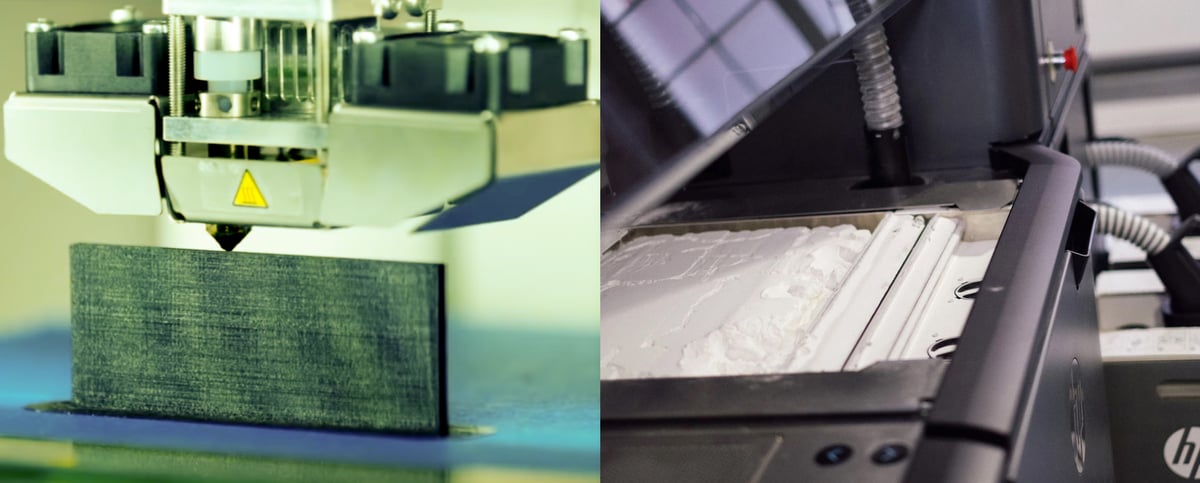

We have a lot of articles here on All3DP diving deep into both of these technologies, but here, let’s sum it up this way: FDM uses either polymer-based filament or polymer pellets heated and extruded through a nozzle, layer-by-layer to form a part; MJF, in a nutshell, involves using two types of liquid agents to fuse powdered polymer material when exposed to heat, layer by layer.

- Materials: FDM can use dozens if not hundreds of materials, MJF prints with about eight.

- Brands: FDM 3D printers are available from hundreds of manufacturers, MJF from one.

- Price: FDM 3D printers range from $150 to $500,000+, MJF printers start at $200,000.

FDM vs MJF: Buying a 3D Printer

If you’re looking to purchase a 3D printer, the choice of FDM or MJF has everything to do with what you’ll be fabricating and how many.

First off, MJF 3D printers are industrial machines, so there’s no point comparing them to an FDM that is not also industrial. Sure, you can get a very nice nylon manufacturing jig from a non-industrial 3D printer like a Bambu Lab or a Prusa. However, industrial 3D printers arguably offer a level of reliability, predictability, and repeatability that consumer 3D printers lack. They have ease-of-use and process management that companies look for when assessing whether or not a machine will boost manufacturing efficiencies.

Let’s say you’re considering an industrial FDM or MJF for your company that makes end-use auto parts. You’ve taken a close look at your part catalog and identified 200 parts that could potentially be 3D printed in nylon PA12 instead of injection molded. You’ve identified 50 more that could be redesigned for 3D printing to perform better, weigh less, and take up less space, potentially giving you a competitive edge.

Instead of injection molding these parts and keeping them in stock, you want to manufacturer on-demand.

This is the type of scenario where MJF shines. This technology can 3D print batches of end-use-quality parts fast. The powder bed acts as a support for parts with complex designs so there’s no support printing or support removal, like with FDM. The technology enables more complex designs and intricate features than are possible with FDM since the unsintered powder can be removed from internal cavities, allowing for more sophisticated designs.

MJF can offer higher precision due to the controlled nature of the fusing process, which results in parts with tighter tolerances and more accurate dimensions.

MJF is for when you need hundreds or thousands of parts a month, it’s also a better choice if your parts need to look — to your internal or external customers — like very professionally made parts on par with the injection molded parts they’re used to.

Therefore, for our auto parts company scenario, MJF would deliver the fast batch printing of end-use parts with excellent surface finish and a complexity of design.

Let’s say you’re looking to purchase a 3D printer for your manufacturing facility to fabricate specialized parts for your machinery, like spars, jigs & fixtures, and unique solutions to optimize your production efficiency.

Here, you’re looking to be able to make very unique parts in-house and replace the current method of sending them out to be machined from metal or nylon. You’re looking to modernize your production by redesigning some parts of your machinery to function better with new parts that consolidate older parts or incorporate features that are very difficult or impossible to machine, such as intersecting tubes or internal channels.

In this case, an industrial FDM may be the better fit than MJF because volume and speed are not the priority, rather you have the opportunity to 3D print in more than nylon, TPU, or polypropylene. Material choices in FDM are wider and include food-grade polymers, high heat resistant materials, and chemical- and solvent-resistant materials, among others. You can use the same FDM printer for your part prototypes in an economical materials, then print the final part in a more engineering-grade material.

The heated chambers of industrial FDM machines produce parts with excellent mechanical properties. Printing with soluble support materials shortens post-processing time so you’ll have your specialty parts in days instead of weeks or months when using traditional machining.

In-house fabrication of parts reduces time and cost, and enables you to pursue part innovations that may have been shelved because of the cost of fabricating the parts.

But What About Price?

Overall competition in the industrial FDM space is driving down the price of these printers even more in the past five years. MJF machines have some competition from similar technologies, such as selective laser sintering, binder jetting, HSS, and SAF, but are still more expensive that most industrial FDMs.

As a side note: If you’re wondering how the two polymer-powder based 3D printing technologies MJF and SLS compare, we’ve done that in “MJF vs SLS 3D Printing: The Differences Short and Sweet.”

But What About Mechanical Properties?

It’s not true, as a blanket statement, that MJF is stronger than FDM. Comparing mechanical properties of FDM-made parts and MJF-made parts is more complex mainly because MJF is one technology from one brand and FDM has a lot of subtle and not-so-subtle differences between brands and machine types.

For example, some FDM 3D printers have super heated chambers to enhance interlayer fusion. There’s also the argument that for a super strong part, you could simply choose an FDM material, such as PEEK, that’s much stronger than any material you can print with on MJF.

That said, 3D printing service providers will often recommend MJF as the stronger option for the reasons we detail below.

FDM vs MJF: Ordering 3D Printed Parts

When using a 3D printing service, like Craftcloud, you’ll be faced with a choice of technologies for your part. FDM will almost always be cheaper.

First, as we mentioned above, you can’t really compare consumer-level FDM printers to MJF. This is important when using a print service because you may not know what type of FDM printer your printing service is using? Of course, you always know what type of MJF machine your service provider has because they are all made by HP.

Some of the most popular FDMs at print services are from companies, such as Prusa, UltiMaker, and Bambu Lab. These are ideal for rapid prototyping and can, with the right attention and care, create excellent end-use parts. However, when you upload a design to a 3D printing service you usually can’t specify the strength requirements of the part. When you can provide notes indicating that your part needs to withstand a certain amount of pressure or force, the service will likely recommend MJF (or SLS) because the mechanical properties of parts produced with these technology are more predictable.

FDM part quality can be affected by the speed of the printing, the humidity in the filament materials, the temperature in the chamber or print farm, and other differences between individual FDM machines.

Industrial FDM 3D printers are more commonly used as the in-house printers at companies, and are not as popular at service providers because they are slower than MJF and have a lower part capacity, so not the top choice if your business model is volume. 3D printing services want to combine as many customer orders into one print run as possible, which is one reason why MJF is so popular at these services.

For quick prototypes, on the other hand, service bureaus choose non-industrial FDMs because they are very fast when using economical non-industrial materials, like PLA.

If your looking to 3D print a large volume of parts, the calculations my tip toward MJF being the more economical choice over FDM. A print bureau could print, depending on the size, hundreds of parts in one print run and deliver thousands of parts a week. FDM machines have a lower capacity. However, in our experiment below uploading a part to the service provider Craftcloud, FDM was cheaper at large volumes, too, even if it took a bit longer to deliver.

MJF vs. FDM Part Price Chart

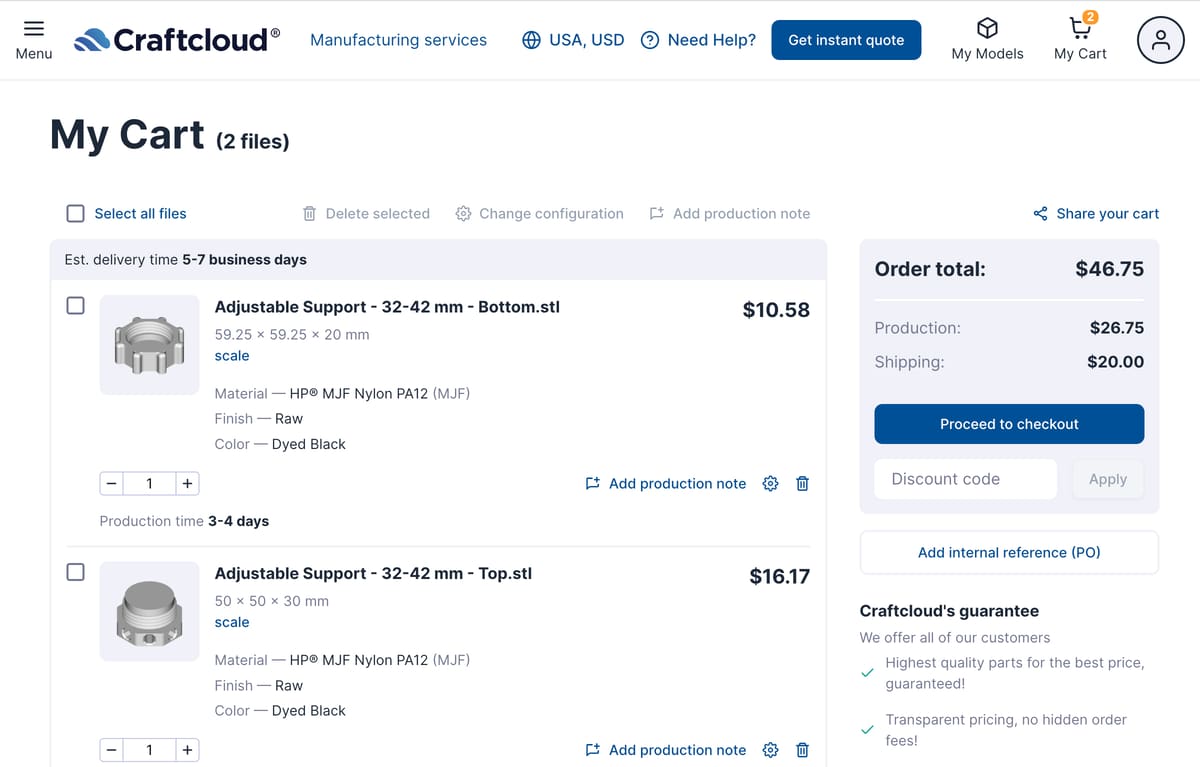

Here we took a look at MJF vs FDM at the 3D printing service provider Craftcloud. We uploaded a two-part support model (shown above) and requested quotes for various printing methods, materials and volumes.

For one part in nylon, MJF was 25% more and for 5,000 parts in nylon MJF was more that double, but as we mentioned already, the type of FDM machine (consumer or industrial) or the type of nylon was not available on the online quoting systems so the mechanical properties of the FDM parts could not be predicted.

Have experience in both technologies or think we missed something? Let us know in the comments below.

License: The text of "FDM vs MJF 3D Printing: Decision Maker’s Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.