If your 3D printed part needs to be flexible, bendy, elastic, or soft to the touch, there’s a growing range of filaments on the market that can deliver these characteristics while being easy to print.

The broad category of flexible filaments offers elasticity and durability, strength, and other attractive features, such as flame-retardancy, food safety, and even anti-bacterial properties. Many can eliminate electrostatic discharge, resist fading in UV light, and stand up to chemical solvents, which makes them suitable for automotive and industrial applications.

Although most flexible filament are fossil fuel-based materials, today you’ll find ones approved for long-term skin contact, so they’re ideal for prosthetics and wearable devices. There are also a few flexible filaments made from 100% recycled material or partially made from bio content like vegetable oils

There’s a lot to choose from so we’ve checked them out for you!

| Company | Filament | Material | Shore | Elongation at break | Price per .5 kg (approx.) | Where to Buy |

|---|---|---|---|---|---|---|

| NinjaTek | NinjaFlex, NinjaFlex Edge, Cheetah, Armadillo, Eel, Chinchilla | TPU, TPE | 83A - 90A | 295% - 900% | $45-$59 | |

| Fillamentum | Flexfill | TPU, TPE, PEBA | 90A - 98A | 250% - 1,000% | $55 | |

| Recreus Filaflex | Filaflex, Reciflex, Conductive | TPU | 60A, 70A, 82A, 95A, 98A, 92A | >100% - 950% | $41-$84 | |

| Bambu Lab | TPU for AMS, TPU 95A HF | TPU | 68D, 95A | > 650% | $20 | |

| Polymaker | PolyFlex TPU90, TPU95, TPU95-HF | TPU | 90A - 95A | 330% - 587% | $32 | |

| ColorFabb | nGen Flex, varioShore | TPU | 95A - 92A | 400% / 490% | $40-$50 | |

| Formfutura | FlexiFil, Python Flex, MD FLEX | TPC, TPU | 45D, 98A | 450% - 530% | $35-$73 | |

| MatterHackers | MatterHackers | TPU, TPE | 90A, 98A | 508% - 600% | $12.40-$25 | |

| 3DJake | 3D Jake TPU A95 | TPU | 95A | 400% | $30 | |

| Dynamism TPU95 | TPU HS | TPU | 95A | - | $25 | |

| SainSmart | Glow TPU, Temperature-sensitive TPU | TPU | 95A | - | $31-$40 | |

| Filoalfa | Alfa | TPU | 90A | 600% | $26 | |

| Forward AM | Ultrafuse Flexible Filaments | TPU, TPC, TPS | 85A, 45D, 64D, 95A, 90A | 600% - 661% | $31-$40 | |

| Sunlu | Sunlu TPU | TPU | 95A | 300% | $25 | |

| Kimya | PEBA-S, TPC-91A, TPC-ESD, TPU-92A, TPU-R | PEBA, TPC, TPU | 91A - 93A | 352% - 550% | $38-$86 | |

Which Filaments Are Flexible?

Flexible filament is made from various thermoplastic materials, such as:

- TPU (thermoplastic polyurethane),

- TPE (thermoplastic elastomer)

- TPC (thermoplastic copolyester)

- PEBA (polyether block amide)

There are also plus proprietary blends offering unique combinations of print characteristics. If you’re wondering about silicone, know that it can be 3D printed but not with FDM 3D printers. Unlike solid polymer filaments that are malleable when heated and solidify once again when cooled, Silicone, once solidified, can’t be made pliable again. There are silicone-type resins for vat polymerization and material jetting 3D printers.

Rubber might be another material you think of when you think of flexible materials, but you can’t 3D print with natural or synthetic rubber. However the next best thing is TPU, which exhibits properties, such as flexibility, elasticity, and resilience, resembling natural rubber. It is commonly used in 3D printing for applications where rubber-like characteristics are crucial.

TPE is a bit less rubber-like, yet offering flexibility and elastic behavior. It offers resistance to certain chemicals and bonds well to other materials, making it suitable for creating multi-material components. Also, only found in industrial 3D printing applications, TPC and PEBA have their own distinct characteristics, and are not as closely related to rubber as TPU or TPE. TPC is known for its chemical resistance and toughness, while PEBA is valued for its high flexibility and impact resistance.

Tech Terms to Know About Flexibles

If you need your final parts to have a degree of flexibility – anything from super rubbery to just a touch of give – you’ll want to pay attention to a few key measurements that are detailed in your filaments’ technical data sheet. Some filament called “flexible” may not disclose exactly what it’s made of, so to know how parts made from it will perform, you’ll need to understand the following terms.

What Is Shore Hardness?

Shore hardness is a common term you’ll hear when it comes to polymers, but it’s more general than the more technical measurements like “Young’s modulus” or “elongation at break”. For example, most flexible filament would be Shore A, and within the A category they would have individual values, such as Shore hardness 95A. You may also see Shore values in the C or D category, which more often denote hard rubbers and semi-rigid plastics. The most common Shore value for flexible filaments is 95A.

What Is Elongation at Break?

Elongation at break is how much a part can stretch before breaking. This measurement is shown as a percentage and the higher the number the better the material will resist reforming when stretched. Flexible filaments average around 600% elongation at break. By comparison, regular PLA averages around 8%.

TPU Doesn't Print on all Printers

There are far cheaper flexible filaments available than our picks here but, buyer beware. Unless your filament comes from a brand or reseller you trust and is accompanied by a full technical specification sheet, you’re risking hours of frustration with failed prints. Plus, check if your 3D printer can even print with flexible materials, many can’t.

For example, Bambu Lab says most of its printers are not compatible with TPUs that have a short hardness level of 95A, 85A, 83A, 80A, 75A or below, while other types of TPU work just fine.

Skip down to the end to read more essential tips for printing with this sometimes tricky material.

Consumer vs. Pro Flexibles

Because of the difficulty of printing some flexible filaments and, unfortunately, some of the poor quality filaments on the market, several pro and “pro-sumer” printer manufacturers, including UltiMaker, Markforged, BigRep, Stratasys, and others, work directly with chemical makers to formulate their own flexible filaments tuned specifically to their printers. This helps ensure that you get exactly the right print speed and temperature to use, plus a host of other perimeters that have already been uncovered through hundreds of hours of print tests.

These printer branded filaments can save a lot of time and fine-tuning, which can easily justify the usually higher price tag.

NinjaTek

NinjaTek offers four kinds of TPU filament (NinjaFlex, Cheetah, Armadillo, Chinchilla, and Eel) and one TPE (Edge), all with varying properties in a wide range of colors.

NinjaFlex has a shore hardness of 85A, making it extremely flexible and squishy. The company says its proprietary technology enables a low-tack, easy-to-feed texture ideal for direct-drive extruders. The material has abrasion and chemical resistance and results in consistent printed parts.

Cheetah TPU is designed to be able to print at higher speeds, hence the name, while the NinjaTek Armadillo is a non-flexible TPU that features the extremely tough and abrasion-resistant qualities of TPU in an extremely strong, rigid material that can be used as an alternative to PLA, ABS, and even nylon filaments. This TPU is meant for printing high-wear parts, such as gears, fasteners, and protective cases.

Lastly, the Chinchilla filament is the softest of the bunch, created through a proprietary blend of TPE resins. With Chinchilla, you can create soft, long-lasting printed parts for fashion, healthcare, and grips. Chinchilla has been tested to be skin-safe using EpiDerm Skin Model.

Available sizes & diameters: 0.5 kg, 1 kg: 1.75 mm, 3 mm

Colors: Midnight, snow, sapphire, fire, almond, and six others

Fillamentum

Fillamentum is a well-known filament manufacturer, and its Flexfill TPU is definitely worth a try. Flexfill TPU has two available shore hardnesses: 92A and 98A. The 92A line is very soft, while the 98A line is a bit stiffer than some of the other TPU filaments on this list, plus it’s easier to print.

The company’s Flexible TPE is safe for food-contact applications and for applications in contact with skin. It’s also available in two different hardnesses 90A & 96A Shore. Filamentum’s Flexfill PEBA 90A is flexible with unique thermal, mechanical, and chemical behavior from other TPEs. It especially retains its flexibility at subzero temperatures, if that’s a quality your part needs.

Available sizes & diameters: 0.5 kg, 0.7 5kg; 1.75 mm, 2.85 mm

Colors: Natural, traffic black, signal red, signal yellow, luminous green, and seven others

Recreus Filaflex

Filaflex was first created in 2013 as one of the first elastic filaments for 3D printers, and since that time the company has introduced several versions, including a TPU 100% from recycled origin and a new electrically conductive TPU called Conductive Filaflex.

The filaments of the Filaflex range have great print bed adhesion, so they don’t need a heated bed, blue tape, or any adhesive. They’re also odorless and resistant to solvents, acetone, and fuel.

Reciflex is a flexible TPU filament 100% of recycled origin, both from footwear industry leftovers and from Recreus’ internal production. Its hardness ranges between 96A and 98A Shore due to the variations attributable to its origin as a recycled material, practically imperceptible in the printed parts.

In 2024, Recreus in partnership material science company Balena launched a decomposable flexible material called BioCirFlex3D 3D printable filament. Although, biodegradable like PLA, this new material has to go through an industrial composting process to decompose properly.

Available sizes & diameters: 0.25 kg, 0.5 kg, 3 kg; 1.75 mm, 2.85 mm

Colors: 10+ depending on the product

Bambu Lab

Bambu Lab is known for high-speed printing and makes its own TPU. Although the printing recommendations simply says less than 200 mm/s, you’re actual printing speed will likely be somewhere around 50-30 mm/s — faster depending on the model.

The company offers a TPU 95A HF (high speed) and a new TPU for AMS (automatic material systems) launched in November.

Like most material changers, Bambu Lab’s AMS is generally considered incompatible with flexible filament like TPU, given that flexibles can easily jam in the long filament pathing. This noew TPU for AMS solves that problem.

Bambu TPU for AMS has a Shore hardness of 68D and a good toughness, the company says, while minimizing stringing, delivering the “ease of PLA printing alongside TPU’s signature flexibility and durability.”

Both products have embedded chips in the spool which can be read through the AMS to set the print parameters.

Available sizes & diameters: 1 kg; 1.75 mm

Colors: TPU 95A HF, 6; TPU for AMS, 7

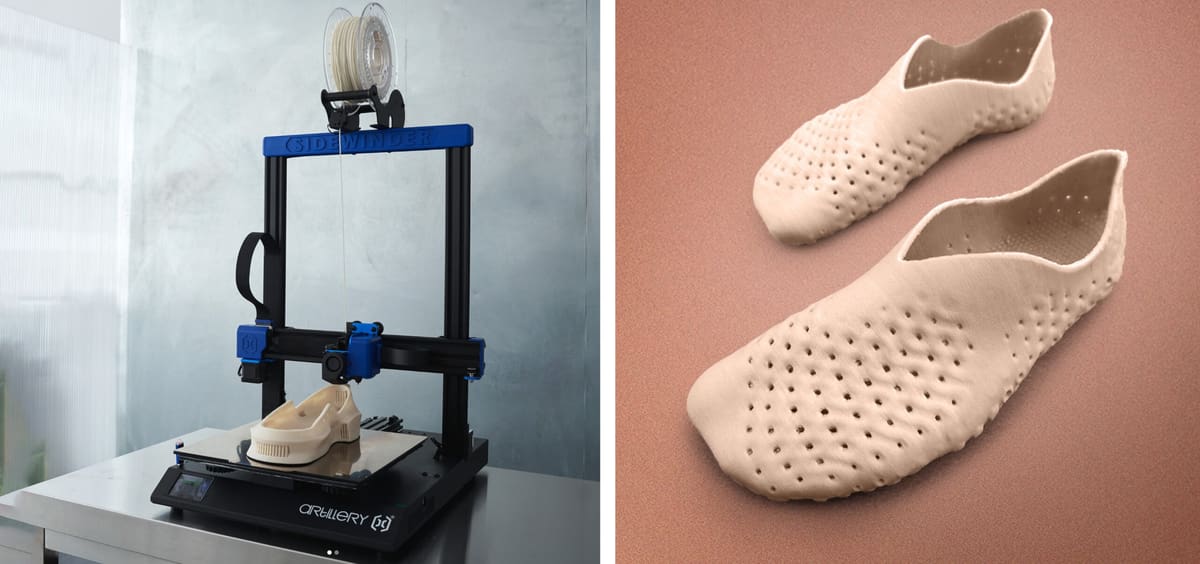

Polymaker

Polymaker has three TPUs in its PolyFlex line, which are all based on chemistry from industrial polymer maker Covestro.

PolyFlex TPU90 is designed to provide great flexibility without compromising on printing speed, Polymaker says. It also has the ability to resist damage from ultra-violet (UV) light. PolyFlex TPU95 is engineered to work on most desktop 3D printers, the company says, while PolyFlex TPU95-HF is ideal for high-speed printing.

Available sizes & diameters: 750 g; 1.75 mm, 2.85 mm

Colors: Black, white, red, blue, yellow, orange

ColorFabb

ColorFabb offers two lines of flexible filament, nGen Flex and varioShore TPU.

nGen Flex is described as a semi-flexible 3D printing filament engineered to allow most users to print at regular print speeds, cutting down build times compared to other very flexible filaments. The material’s high-temperature resistance enables steam sterilization so applicable for prosthetics and orthotics, along with automotive parts, apparel, tooling, or a variety of consumer products. nGen Flex is available in black, clear, and dark grey.

The ColorFabb varioShore TPU (in 9 colors) features variable shore hardness, reduced weight and density, and soft touch. The variable softness is achieved by altering the print temperature. Extruder temperatures between 200ºC and 250ºC will produce very soft prints, whereas lower temperatures produce more rigid prints. Theoretically, you could print one product with various shore harnesses in different areas by adjusting the temperature.

Available sizes & diameters: 0.65 kg, 2 kg; 1.75 mm, 2.85 mm

Colors: Flex: clear, black, dark grey; varioShore: skin tones, black, red, blue, white

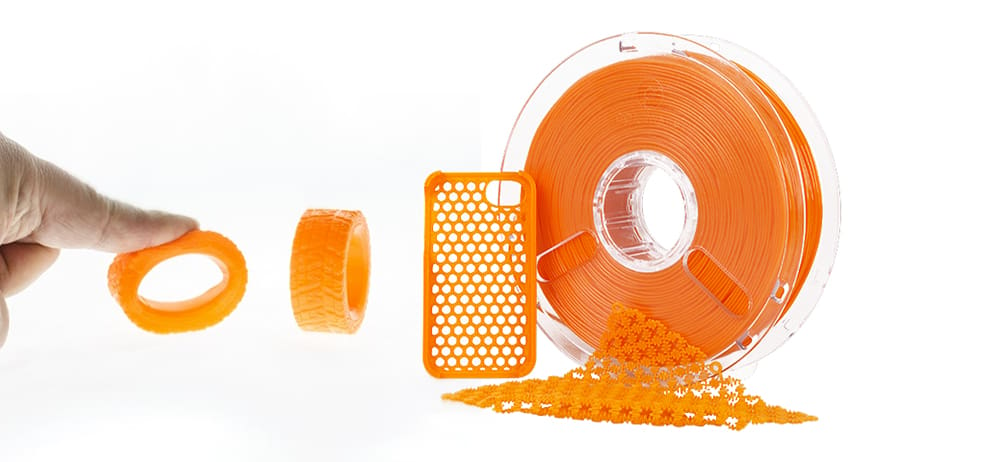

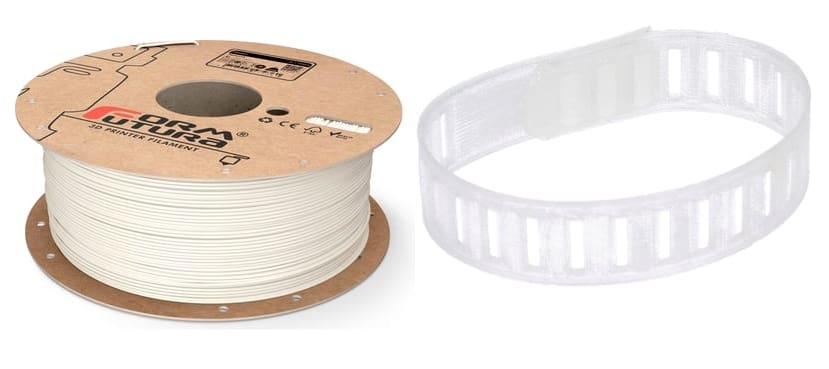

Formfutura

Formfutura offers three types of felxible filaments. FlexiFil is a rubber-like high-performance TPC (thermoplastic co-polyester) with a type of “flexural memory” that enables objects to return to their original position after being bent. Formfuture says FlexiFil is unique in its combination of flexibility, mechanical strength, durability, good chemical resistance, excellent UV resistance and ability to withstand extreme temperatures.

Formfutura’s Python Flex is a TPU filament for flexible and elastic parts that are designed for high-speed printing on both direct drive and Bowden style extruders, the company says. Python Flex can be printed directly on a glass plate without having to use a heated bed. The filament is extremely transparent in its natural form.

Formfutura says its MD Flex is a flexible TPU type of 3D printer filament enhanced with a patented nano-copper composite that eliminates more than 99.99% of fungi, viruses, bacteria and microorganisms, and has been scientifically proven effective against SARS-CoV-2 / Covid-19 with high antiviral efficacy.

Available sizes & diameters: 0.65 kg, 2 kg; 1.75 mm, 2.85 mm

Colors: clear, black, dark grey

MatterHackers

MatterHackers, the 3D printer and materials reseller also makes it own filament. A lot like the Amazon Basics brand — good quality products for less — MatterHackers materials are very affordable but fit the bill whether you’re looking for prototypes or professional quality parts. The company offers TPU is two series and a wide range of colors.

The more affordable MH Build Series TPU, which comes in grey, clear, black, and a rainbow of translucent colors, and has tensile strength, elongation at break, and other properties ideal for prototypes.

The Pro Series TPU is definitely on the more flexible side of the spectrum. The Pro Series TPU is a highly malleable elastomer that is used to create prints with high toughness while retaining superb flexibility. It also has a high resistance to abrasion. This TPU will adhere to most bed types without any adhesives and a cooling fan is highly recommended.

If you want something even bendier, they also sell a Pro Series Flex TPE that’s similarly impressive.

- Available sizes & diameters: 1 lb (~450 g); 1.75 mm, 2.85 mm

- Colors: Pro: Black, white, red, blue, clear, grey, green; Build: translucent, clear, black

3DJake

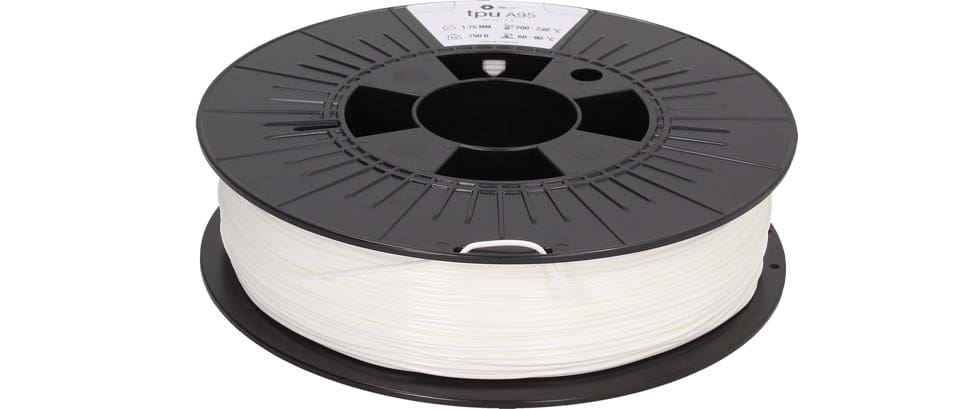

European 3D printer and materials reseller 3D Jake ventured into manufacturing its own branded filament years ago and it has gained a following for quality.

The 3D Jake TPU has a low tendency to warp so it can also be printed without a heated bed, but if you have a heated bed the recommended temperature is 60-90 ˚C. TPU A95 can be used on all common desktop FDM 3D printers. 3D Jake recommends increasing the flow by about 5-10 % for more consistent extrusion.

Available sizes & diameters: 1 kg; 1.75 mm, 2.85 mm

Colors: 11 including white, blue, red, orange, clear, and silver

Dynamism TPU95

Dynamism is another 3D printer and materials supplier that has branded its own TPU filament to sell to customers as the most economical of its TPU offerings. But this is no discount filament. Dynamism TPU HS is a workhorse, general-purpose flexible filament formulated for high flow to allow for printing at higher extrusion speeds. As a sustainability bonus, it comes on recycled cardboard spools and with external cardboard packaging also made from recycled cardboard.

Available sizes & diameters: 1 kg; 1.75 mm, 2.85 mm

Colors: black

SainSmart

SainSmart offers its own brand of TPU in an impressively large variety, including clear, translucent colors, glow-in-the-dark, and color-changing temperature-sensitive TPUs.

The glow effect is even stronger after exposure to UV light, gradually decreasing in brightness over time. But be careful – too much exposure can damage the filament.

Available sizes & diameters: 1,000 g; 1.75 mm

Colors: Black, white, red, blue, yellow, orange, +10

Filoalfa

Filoalfa’s Alfa, 100-year old Italian thermoplastics company, is a relative newcomer to the filament market, mostly sold in the EU, but available to ship worldwide.

Filoalfa’s offers a wide range of 3D printing filament and its flexible TPU-based filament is available in two hardnesses levels and seven colors. The company says it has excellent physical shock absorption characteristics and UV resistance, which helps it keeps its high degree of elasticity unchanged over time.

Alfa TPU is also resistant to a wide range of industrial oils, greases, alkalis, acids and many other industrial chemicals. The company also offers an antibacterial flexible filament called Bioflex with a 35 Shore D hardness.

- Available sizes & diameters: 700 g, 1 kg, 2.5 kg; 1.75 mm, 2.85 mm

- Colors: Black, white, red, blue, +

Forward AM

Forward AM, a spinoff of chemical giant BASF, offers its Ultrafuse line in several flexible variations. The Ultrafuse TPU 85A is based on BASF’s Elastollan chemical materials and the company says it features maximum reliability, consistent product quality, and cost-efficiency.

Ultrafuse recently discontinued its TPC 45D and its TPS 90A.

Available sizes & diameters: 1 kg; 1.75 mm, 2.85 mm

Colors: black, white, clear, red, orange

Sunlu

Sunlu began selling filaments in 2013, and since then, it has grown to 40 production lines, 41 inventions, and over 200 intellectual rights.

When it comes to TPU and flexibles, Sunlu enthusiasts note that its TPU Silk has a better-looking and shinier surface finish than other TPUs on the market. Most makers find success with small prints, which are readily squishable.

Sunlu also offers a more standard TPU we have put to the test. It it one of our go-to brands when it comes to consistency and a really nice feel, especially for projects, such as bicycle grips and stress balls.

- Available sizes & diameters: 1.1 lb (500 g); 1.75 mm

- Colors: Black, white, red, blue, pink, orange, +

Kimya

Kimya was a company that made three different types of flexible filament: PEBA, TPU, TPC, and even a rTPU from 100% recycled materials. It went out of business in November 2024, but resellers probably have material on the shelves.

The company’s PEBA is based on the PEBAX material by Arkema. It can be used to make shoe soles or other sports equipment and offers substantial energy returns. The Kimya TPC-91A 3D filament offers chemical and impact resistance and is used in industrial applications in sectors, such as electronics, textiles, and roofing, along with decorative and leisure 3D printing applications.

The Kimya TPU-92A 3D filament offers good resistance to heat and to the external environment and it’s food-safe.

Available sizes & diameters: .75 kg; 1.75 mm, 2.85 mm

Colors: black, translucent, red, white, dark blue

Tips for Printing with Flexible Filament

You can throw out everything you’ve heard about printing with flexible filament. Today, there is such a wide range of flexible filament types that it’s almost impossible to give general direction, but there are certainly some important points to keep in mind.

Dry Before You Print

Flexible filament is often, but not always, very hygroscopic, meaning that it sucks up moisture from the air. If you open your sealed filament and expose it to air, it will have a negative effect on the printing behavior and, of course, the quality of your final print. Even if you follow the printer settings exactly, you can still end up with failed or suboptimal prints because of moist filament.

If your filament’s been left out, you’ll need to dry it in an oven or a filament dryer. How long and what temperature? Well, that can be the tricky part because there’s often no way to know how much moisture the filament has soaked up. Your drying machine may let you know when the filament is dry, and the filament manufacturer may include drying instructions with the filament (such as drying in an oven at 70 ºC for five hours), but in the end, it’s often trial and error. Just remember: if you see steam rising from your hot end, your filament is wet.

Your best bet is to try to keep your filament sealed and stored properly in the first place (also protected from UV light and heat) and for as long as possible. If this isn’t possible, look for flexible filaments that don’t require any drying, including some made of TPS.

Heat & Prep Your Bed

Many flexible filament manufacturers say their products don’t require a heated bed, but most filaments do perform and adhere better with a bed temp around 40 ºC but usually not more than 60 ºC. Your filament will come with recommended bed temperatures. Flexible filaments almost never require a closed chamber, but again, keeping your heat consistent is always a help. Whether or not you need tape, glue, or adhesives on your bed depends on your filament type and brand.

Nozzle Temp

Your filament comes with recommended printing temperatures for a reason. Yes, a hotter nozzle can make for faster printing, but printing temperature can affect the flexibility of your final print. Ideally, your 3D printer will have a print profile for the exact brand of flexible filament you’re using; otherwise, prepare to experiment and achieve the ideal balance between heat and speed.

Be Patient, Go Slow

To get those almost-invisible layer lines and a consistent soft-to-the-touch finish, your flexible filament will need time. Thermoplastic elastomers like to go slow and typically print best at slower speeds and smaller layer heights. Filament makers have made great strides in fast-printing flexible materials with some churning out parts at 100 mm/s, but there’s always some sacrifice of print quality with speed.

If your flexible filament clogs your extruder, high speed is the likely culprit, although it could also be moisture in your filament.

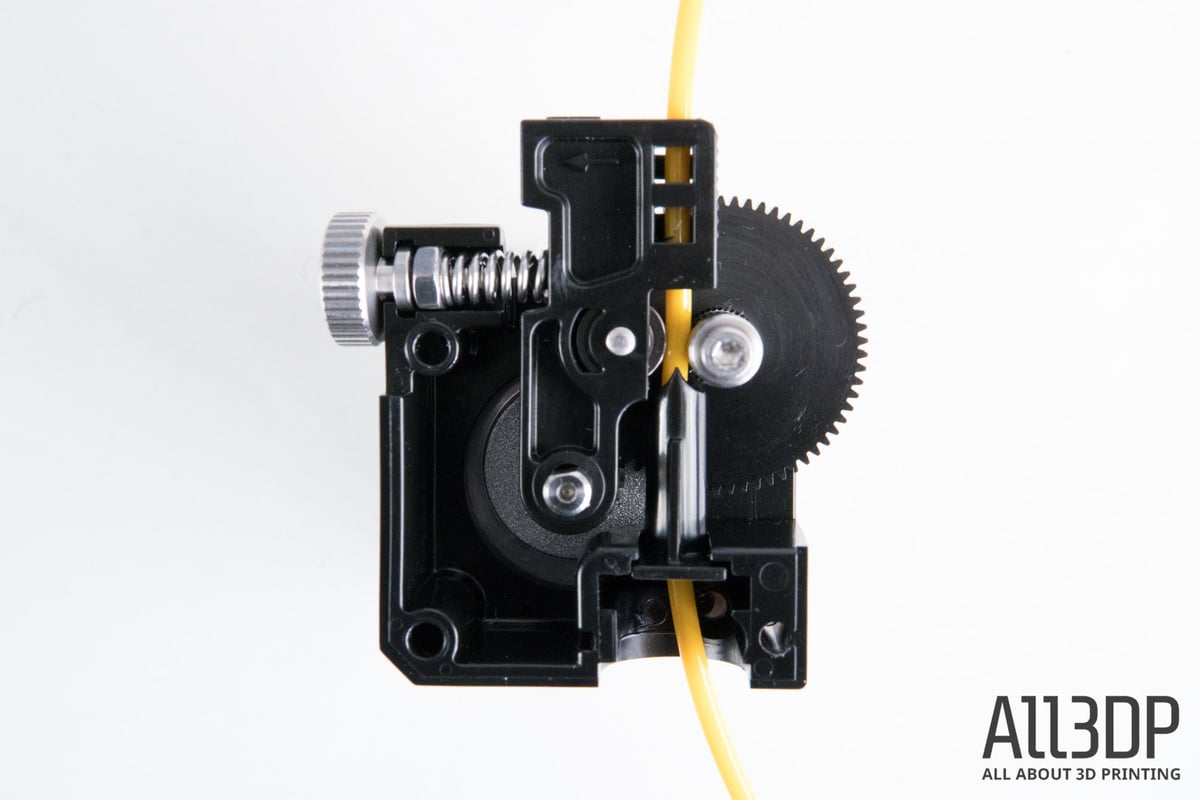

Extruder & Settings

Many flexible filaments work fine with Bowden extruders, but most will work best with a Direct Drive extruder. The reason is that the distance between the drive gear and the hot end should be as short as possible to efficiently feed the filament into the nozzle without stretching it.

As with any material, follow your print profiles, but if you don’t have any or want to experiment, there are some things to keep in mind regarding your extruder retraction rate. You may come across advice that says to disable retractions when printing with flexible filament, but that’s a bit outdated. It may apply if you have an older extruder, but newer extruders and professional FDM printers shouldn’t have any issues with retraction. With retractions off, you’ll see some stringing that can be removed in post-processing.

Even in the best FDM printers, you may still need to experiment with your retraction settings. Keeping them to 2 mm and 20 mm/s is a good place to start. If you notice the filament bunching up in the extruder, keep adjusting your retraction settings until you find the sweet spot.

Additional Tips:

- Avoid using rafts because the base layers have a higher extrusion rate, which could lead to problems.

- Where possible, mount the filament spool above the printer to reduce resistance from the extruder pulling the filament

- Part cooling fan is required

Get Your Flexible Parts 3D Printed

If TPU or flexible filament doesn’t sound like a material you’re ready to master, you can leave it to the pros at a 3D printing service. However, when you upload your design file to a 3D printing service, such as Craftcloud or Xometry, and select TPU or “flexible”, you’ll find that they usually will not be printing your part using filament.

3D Printing Technologies for Flexible Parts

There are three other types of 3D printing that will produce TPU and flexible parts besides FDM with filament. There’s stereolithography (SLA) and the most common methods for professional parts are selective laser sintering (SLS) and Multi Jet Fusion (MJF).

Be sure to inquire which 3D printing method your service provider uses. FDM, for example, is quick and cheap for prototypes, but it may not have the mechanical strength you would need for an end-use car part.

SLS technology can produce TPU parts with high mechanical properties and fine detail. The technology is most often used with nylon but is equally adept at TPU parts. MJF is similar but faster and used for higher volumes of parts.

The resin 3D printing technologies, such as SLA, digital light processing (DLP), and material jetting, do not offer TPU as a material, but instead offer a range of flexible resins commonly used to 3D print wearable technology, sports equipment, and soft hearing aid components.

Lead image source: Various TPU 3D printed productions including a translucent wheel using Eryone TPU.

License: The text of "The Best TPU & Flexible Filaments" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.