How do you follow up a Super Racer? With a V400, apparently. A name that isn’t representing cylinders on some gargantuan engine. The V400 is FLSun’s latest delta 3D printer and “400” stands for speed. The company claims it can produce quality parts at 400 mm/s – a full 200 mm/s faster than its former much-lauded Super Racer 3D printer.

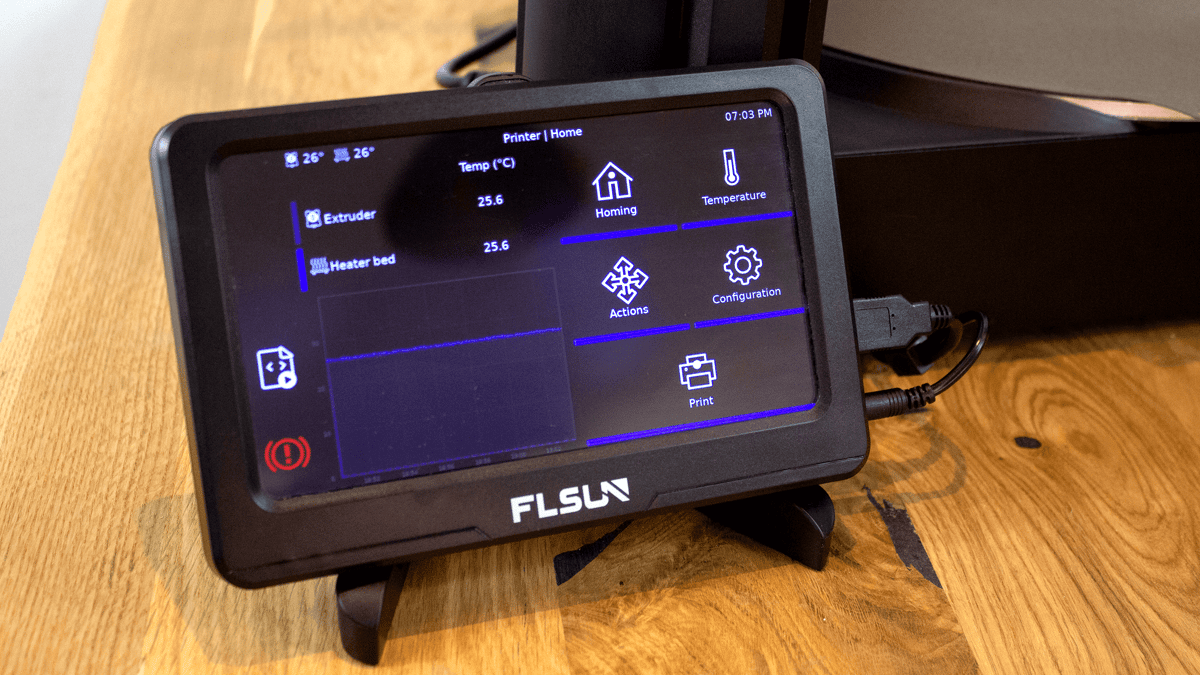

This latest delta printer can hit these impressive speeds thanks, in part, to the Speeder – FLSun’s new 7-inch touchscreen interface that hosts the main processing component of the V400’s Klipper firmware.

For a more typical Cartesian 3D printer, these speeds would be impossible to reach with anything resembling quality results. It’s a bold claim even for a delta and should make even the most hardcore delta fans attentive.

So, we’re here to give you the full picture of how this printer holds up to FLSun’s claims, and how the pre-installed Klipper firmware makes for the machine’s overall experience. Strap in; we’re riding with a speed demon this time.

Verdict

Pros

- High-speed 3D printing

- Klipper and Mainsail are great user experiences

- Easily achieves exceptional levels of detail for FDM

Cons

- Disappointing adhesion with high-temperature materials

- Heat bed’s magnetic soft tile layer prone to damage within rated temperatures

- No power loss recovery

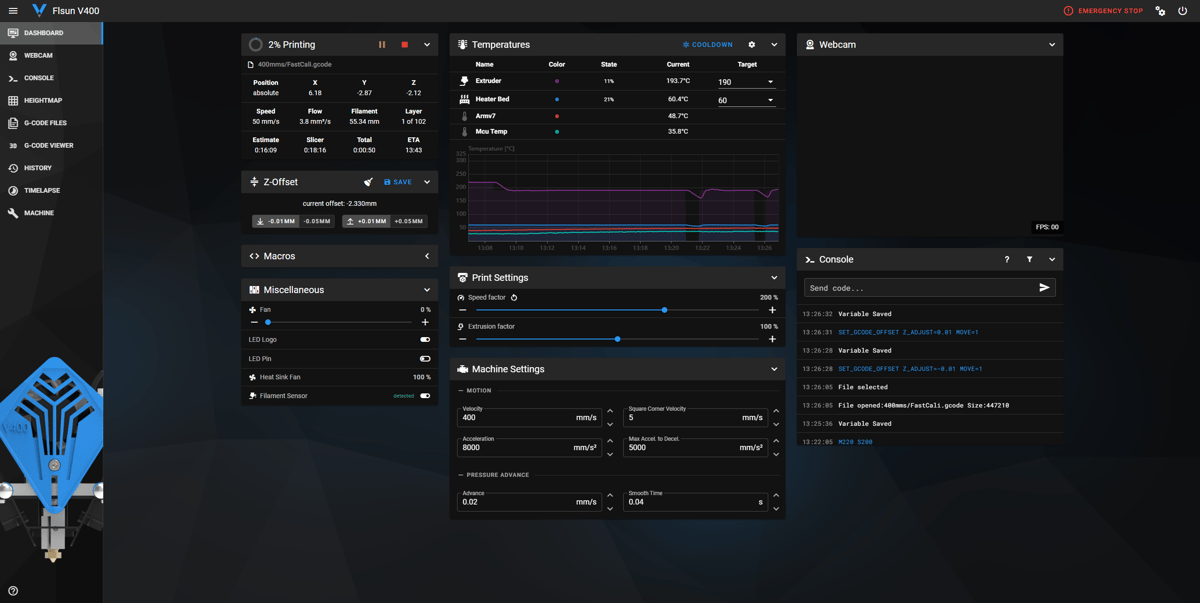

The FLSun V400 is priced near the high end of what we consider a consumer 3D printer at ~$850. For that money, you get a machine with some pretty attractive hardware, a generous Ø300 x 410 mm build volume and at least one core feature that is unique on the market right now. That feature is, of course, the pre-installed Klipper firmware, which delivers all the popular firmware’s benefits without any installation fuss. That includes attractive and user-friendly interfaces on both the “Speeder” 7-inch touchscreen and Mainsail web interface. The system is a joy to use and feels premium all the way through.

We were skeptical about FLSun’s claims of reliable printing at 400 mm/s, but in pushing the machine to its limits, it impressed us. In fact, it often surpassed FLSun’s claimed max 400 mm/s speed to impressive results – at least on Klipper’s speed output.

Of course, not everything was perfect. The printer failed to meet relatively low expectations while printing high-temperature materials, seemingly due to its lackluster PEI-coated magnetic spring steel print bed. It was even damaged while printing in-spec. Still, the 300 °C its hot end provides is good for the occasional nylon or polycarbonate part. If a bit frustrating to get right.

For everything else, the V400 surpassed our expectations and delivered very attractive parts with little adjustment or even initial calibration and felt like a joyfully seamless experience.

The Tech

Dandy Delta

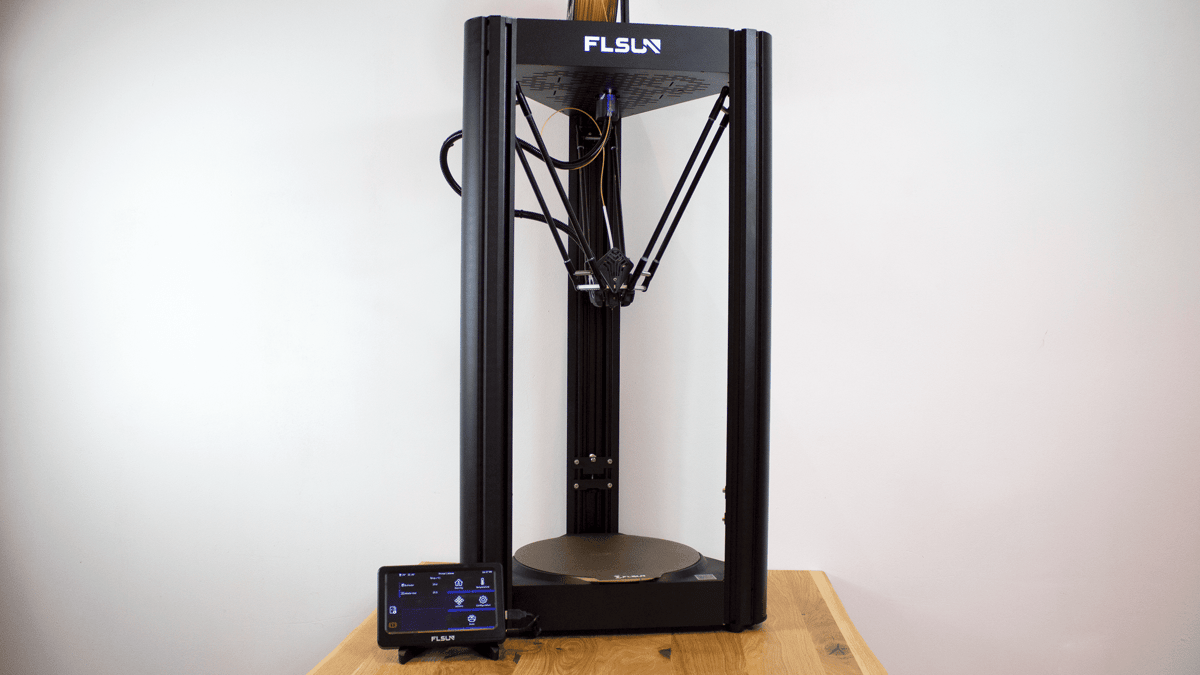

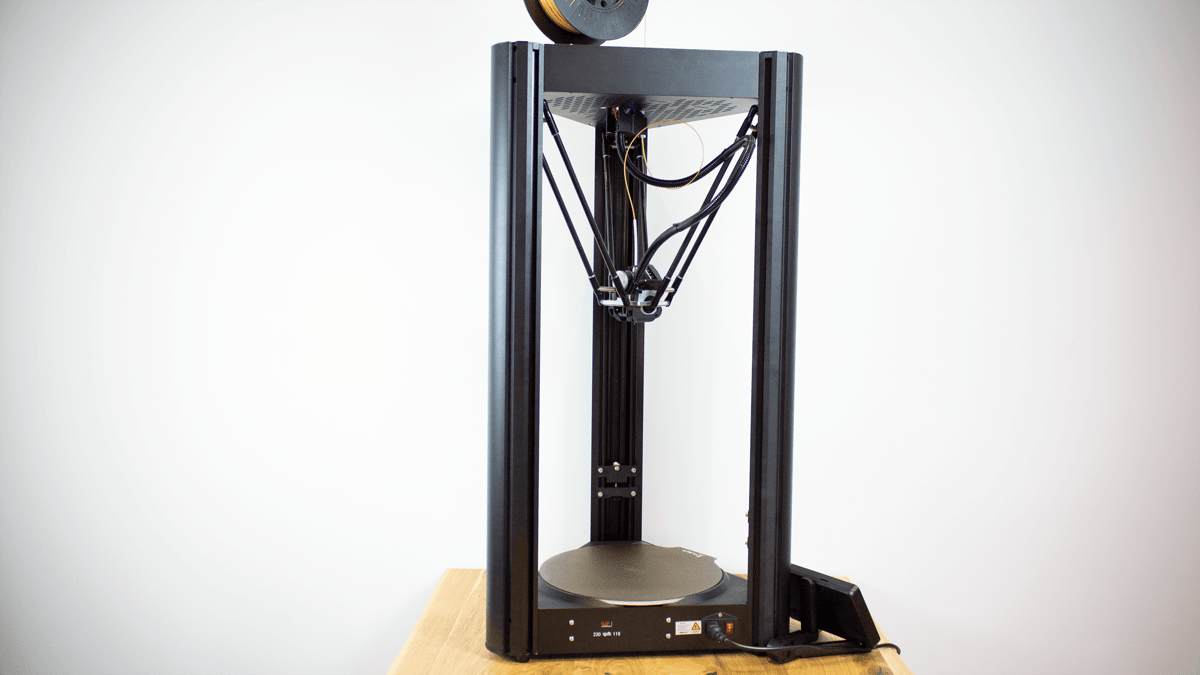

As expected from FLSun, the V400 is a delta 3D printer, and quite a large one at that. The printer towers, even for a delta, at a full meter tall. That size made accommodating the printer a small challenge, especially given the extra height added by the spool holder on top, so home users should be wary.

Of that height, the printer has 410 mm in Z-axis build volume accompanied by a 300 mm elliptic diameter. To ensure you’re not running out of filament halfway through that large volume, the system is fitted with filament detection.

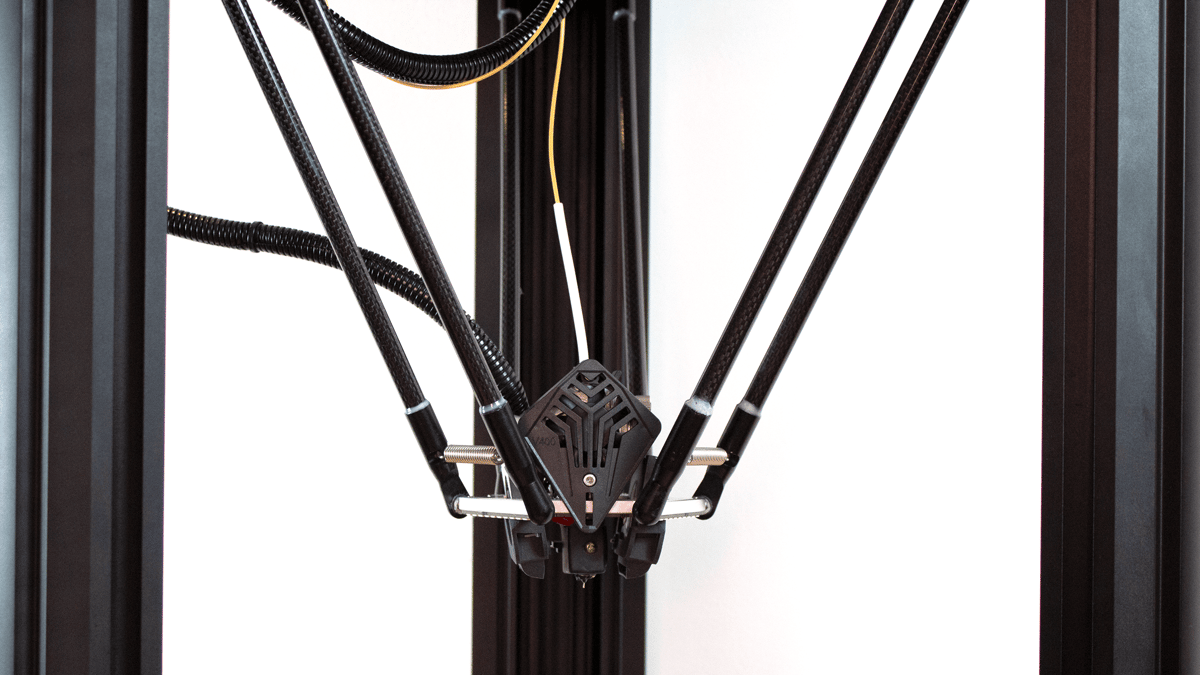

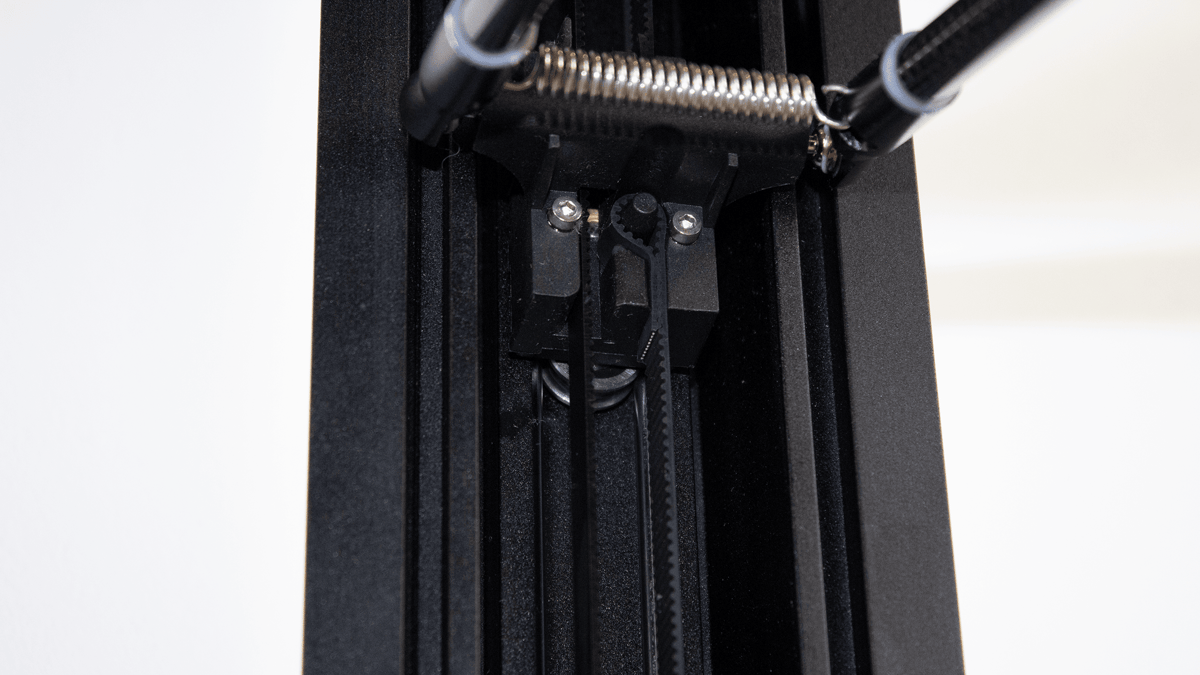

The V400’s arms navigate along a slightly different guide this time: three grooved bearings ride on two linear guides per axis to carry their respective arms. We were somewhat surprised to see a move away from the Super Racer’s bearing block linear rail, but the linear guides quickly proved effective. According to a FLSun blog article comparing the two movement systems, it seems the company decided the heavier linear rails would negatively impact printing speed.

Those linear guides, secured in sturdy enclosed axes, proved plenty rigid, too. You’d expect a machine of this height to have some difficulty with stability, but it was exceptionally stable.

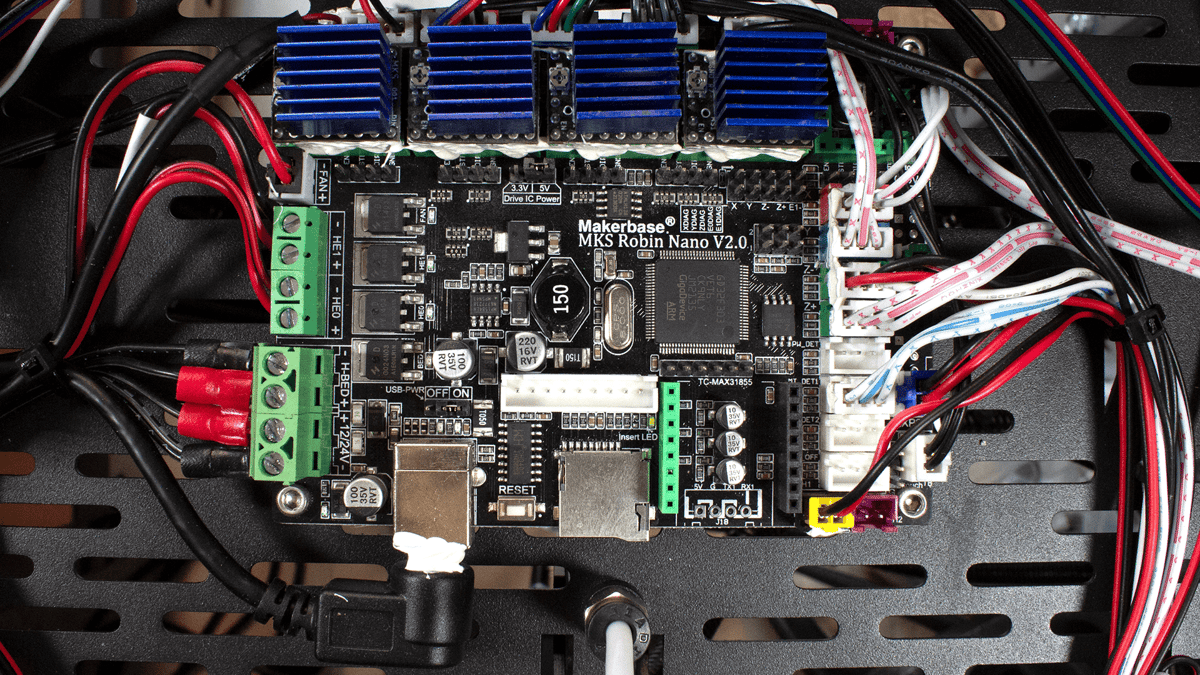

The printer control board, the one running the less intensive MCU component of the Klipper firmware (more on that below), is a 32-bit Makerbase MKS Robin Nano V2.0 running an ARM-based GigaDevice GD32F303VET6. As you’d expect from a more premium printer, screw terminal power wires are cleanly crimped and other connections are secured for shipping with conservative amounts of adhesive.

Speeder & Speedy Speeds

The primary selling feature of the V400 is twofold: it comes with Klipper preinstalled and can, according to FLSun, reach print speeds of up to 400 mm/s with quality results. Those two features aren’t removed from each other, but there are more reasons to want Klipper firmware than just faster printing.

For those not in the know, Klipper is a 3D printer firmware that bypasses some of the limitations of firmware like Marlin by adding a second computer to remove heavy processing tasks from the 3D printer’s direct control board. Among the many other benefits of this system, this helps 3D printers process and execute commands faster — usually resulting in faster printing times.

The tradeoff is, of course, the second computer. It requires something a bit beefier than a regular 8-to-32-bit control board, typically a single-board computer like a Raspberry Pi. Whatever system is used must be powerful enough to run a Linux-based OS that Klipper runs on top of. The 3D printer’s control board is then relegated to executing Klipper’s commands with its simpler MCU component.

For its Klipper installation, FLSun has included its new “Speeder” with the V400: a 7-inch touchscreen interface with 1 GB of DDR4 memory and 16 GB eMMC (storage), complete with Wi-Fi for remote operation. FLSun has told All3DP the Speeder will also be available as an independent purchase soon, but no sign of that yet.

The Speeder’s Wi-Fi interface uses Klipper’s Mainsail UI, which was a great experience during our time with the machine. It loaded exceptionally fast upon switching the printer on compared to other web interfaces we’ve used. It made it easy to remotely upload our files to the printer, start printing, and generally have total control from a PC workstation. Once loaded, it presented us with a wealth of information and possible adjustments. Pretty well anything you could want when managing a printer remotely. The touchscreen interface, running KlipperScreen, is similarly excellent; we never hesitated to use the responsive direct controls while interacting with the printer or inspecting a print.

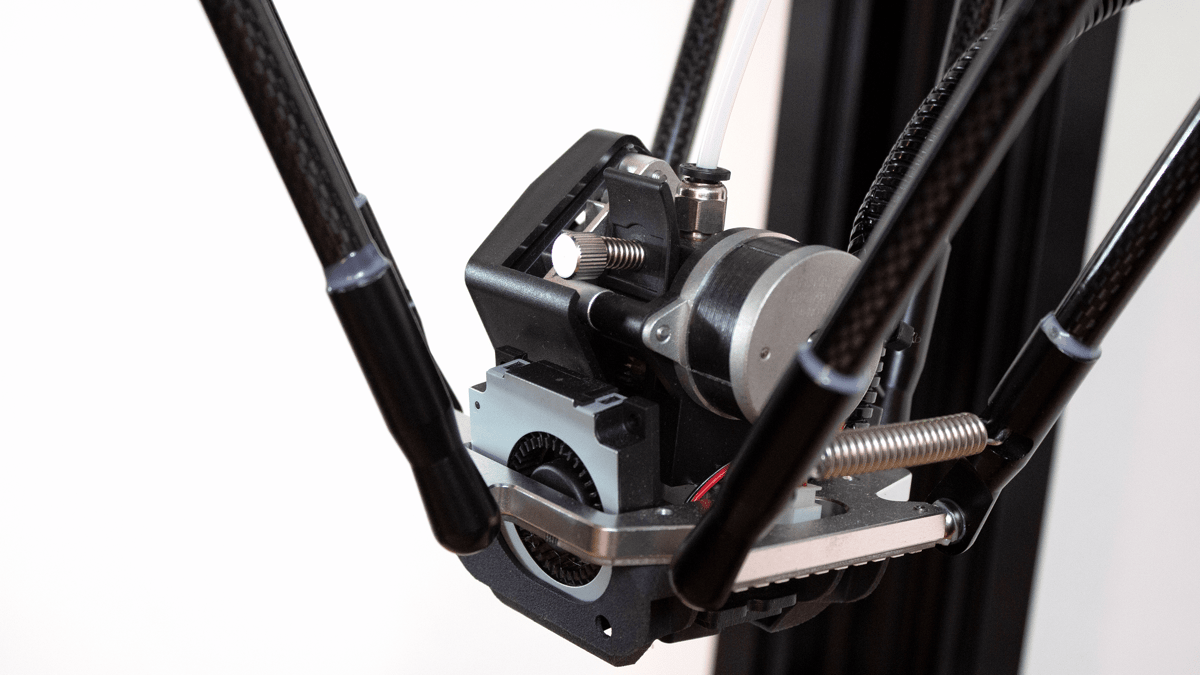

The lightweight dual-drive direct extruder helps keep things sharp at high speeds, too, especially while printing with flexible materials. Even more than a standard direct extruder, the dual-drive gears further ensure fine control and extrusion stability while printing, which is ever more important when trying to push out filament consistently at higher speeds.

The V400’s direct extruder is also capable of reaching up to 300 °C, making it capable of printing high-temperature materials like nylon and polycarbonate. Still, we don’t recommend the printer for the purpose of printing with these materials. The printer’s frame is untenable to an effective enclosure in more ways than one, and its PEI-coated spring steel print bed, though effective for most standard materials, proved unreliable with more temperature-sensitive filament in our experience. More on this later.

Printing & Usability

Setting Up

The V400 comes partially assembled and is extremely simple to put together. Any of the machine’s more complex or delicate parts, such as the linear guide motion systems, are factory-assembled and housed securely in such a way that makes the components difficult to harm during shipping or assembly.

The simplicity is somewhat limited by the difficulty of managing the hulking meter-tall 3D printer’s size, but not significantly. Its components snap and bolt together with ease and required little adjustment. Though belt tensioners are helpfully provided on each of the axes, we found tension well-tuned from the factory.

The written instructions were mostly fine, but those new to 3D printing may get tripped up by a lack of detail. However, FLSun has helpfully included video assembly instructions on the provided USB stick that should clear things up. They’re easily missed since the manual doesn’t point out the various tutorial files’ existences but are well worth watching if this is your first rodeo.

Once assembled, you can pop the magnetically attached bed leveling probe onto the print head and run the V400’s leveling routine. The probe is a style of switch that’s been popular on delta 3D printers for some time now. It hangs under the hot end to probe the bed before users manually input a large offset. It’s not the ideal system since the need to attach and remove it for calibration and printing prevents the printer from automatically generating a mesh before every print, but they do the job fine. Here’s one area the V400’s instructions failed: not instructing users to heat the bed before creating a mesh, and the hot end before finding your offset. Doing so ensures any physical difference caused by heat while printing will be accounted for.

In terms of couriering files from our slicer to the printer, whether chucking our G-code onto a USB stick or using Klipper’s attractive pre-installed Mainsail UI to transfer the files over our local network, the process was extremely easy. The tedium of SD cards of all sizes will not be missed.

The Prints

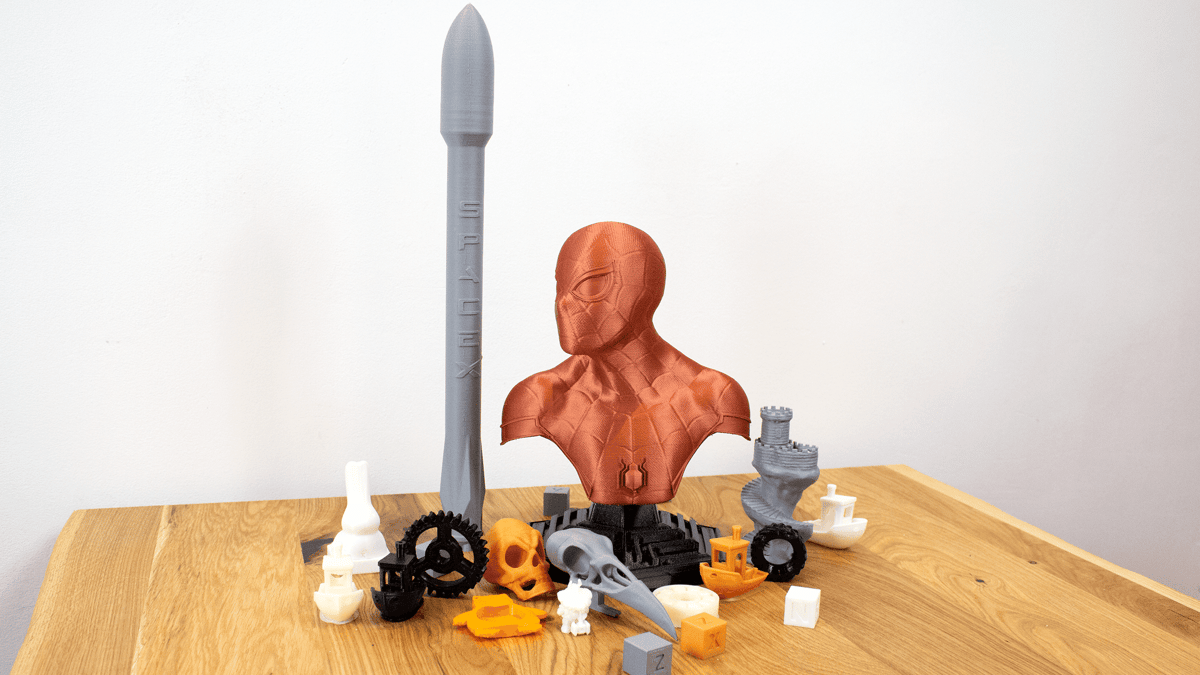

To start things off, we used FLSuns sample PLA to run through a few pre-sliced models and get a feel for things. Right off the cuff, we were impressed. FLSun’s test models aren’t particularly challenging — sample models are almost always sliced to show a best-case scenario — but all printed with exceptional detail and uniformity with no hardware calibration whatsoever. A quick overhang test (also pre-sliced as a sample) came out flawlessly, demonstrating the V400 can print perfectly stepped overhangs at even 70 degrees with the correct tuning; a real testament to the dual blower-style part fans.

We kept with the provided spool for a couple more prints, including this tiny dwarf miniature printed in exceptional detail for a 35 mm model on the massive machine. We had a hard time capturing the miniature model’s detail on camera, but we were impressed. The details are precise all around, but perhaps most on the dwarf’s pauldrons where a teeny deboss can be seen clearly.

From here, we moved on to materials we’re more familiar with. We noticed some minor issues with a rough top-layer finish, but this was easily handled by disabling combing and adjusting the flow slightly.

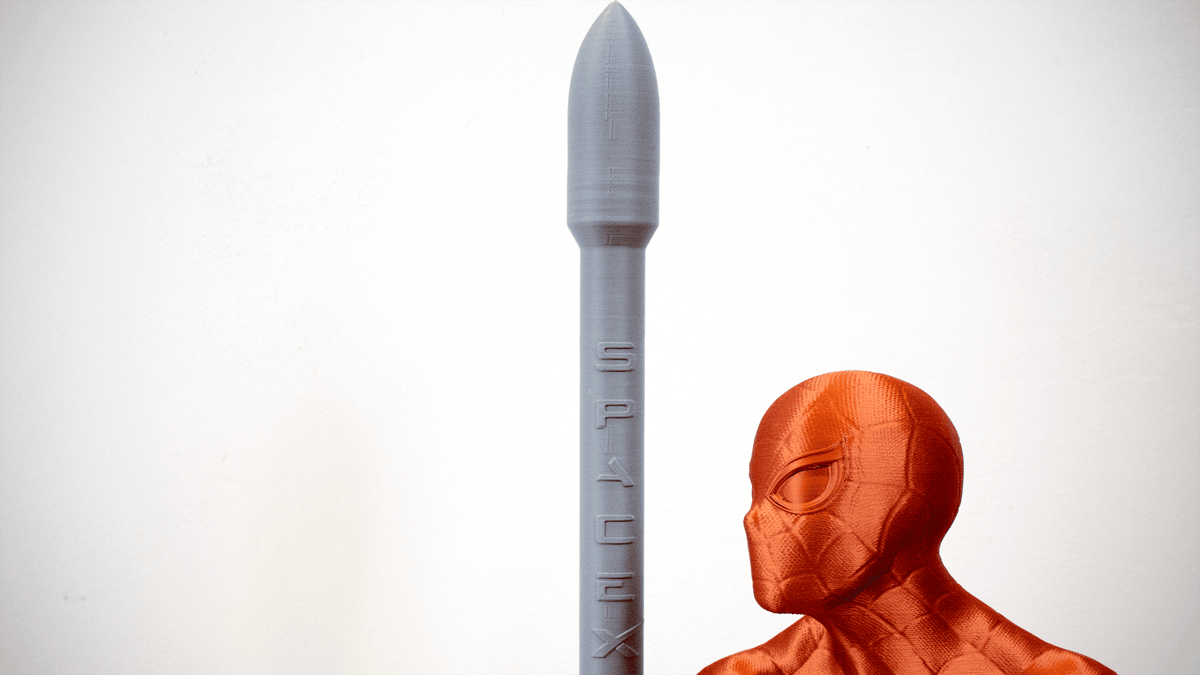

Looking for a challenge for the towering 3D printer’s 410 mm Z-volume, we filled it to the tip-top with a SpaceX Falcon 9 Rocket. Quality printing throughout the Z volume is one of the typical advantages of delta 3D printers, but the falcon model is thin, making it more prone to wobbling than wider-based models. Its larger top adds to that imbalance, too. This resulted in some resonance at the wide tip, but less than expected. Little enough, we debated whether it even merited a mention here, in fact. The V400 is certainly a stable machine.

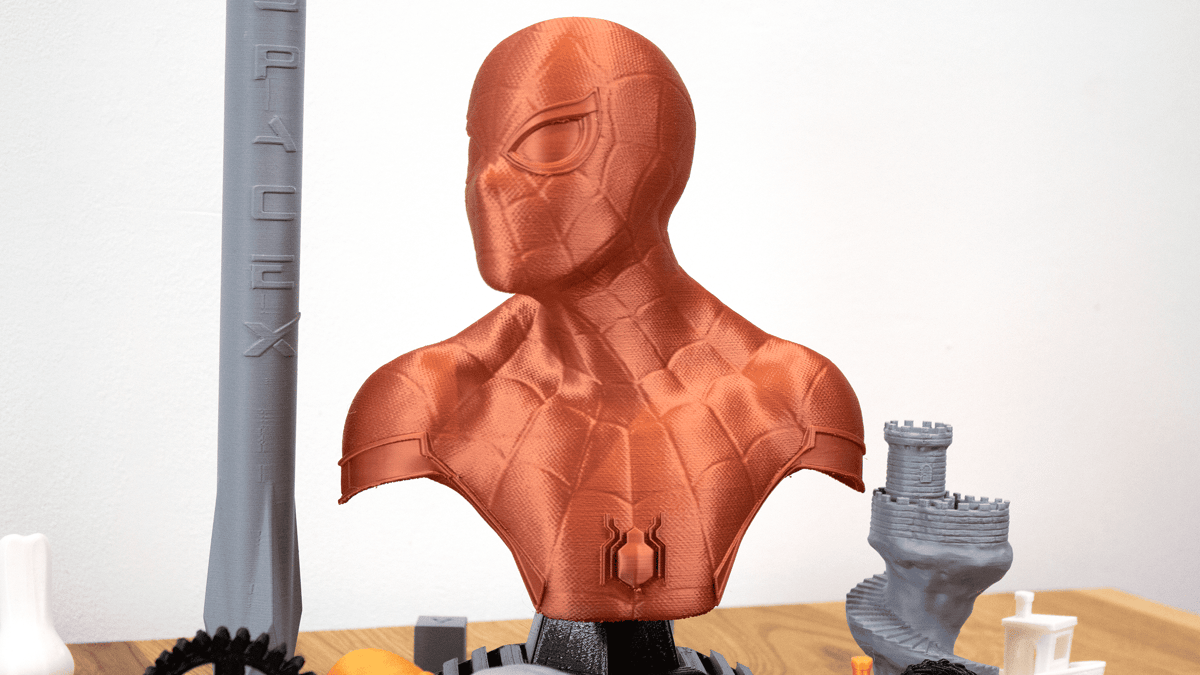

To push things further, we moved to a model that is both detailed and reasonably large: a bust of Spider-Man from the movie Home Coming. The spidey suit features subtle indents between the more prominent web-pattern pattern that is difficult for FDM printers, but the V400 did it justice, capturing all the small details.

Though our Spider-Man bust was printed in PLA, we printed the base in PETG. Stringing was relatively mild thanks to the direct extruder, and though some warping was present, it wasn’t severe. It could be corrected by adjusting bed temperatures or printing with a wider brim.

The Experience

Overall, our experience using the V400 was one of the best we’ve had in some time. It felt like the printer could handle whatever we threw at it with ease. That is, barring one problem: printing high-temperature materials.

While standard materials like PLA and PETG performed well across the board, and flexibles proved equally trivial, we found bed adhesion to be a weak point for the V400 regarding high-temperature materials like nylon and polycarbonate (PC). We had extreme difficulty finding a sweet spot where our high-temperature materials could put down the first layer reliably — bonding agents be damned. Once we did, we still suffered regular warping on bottom layers and many detached prints further along in the process.

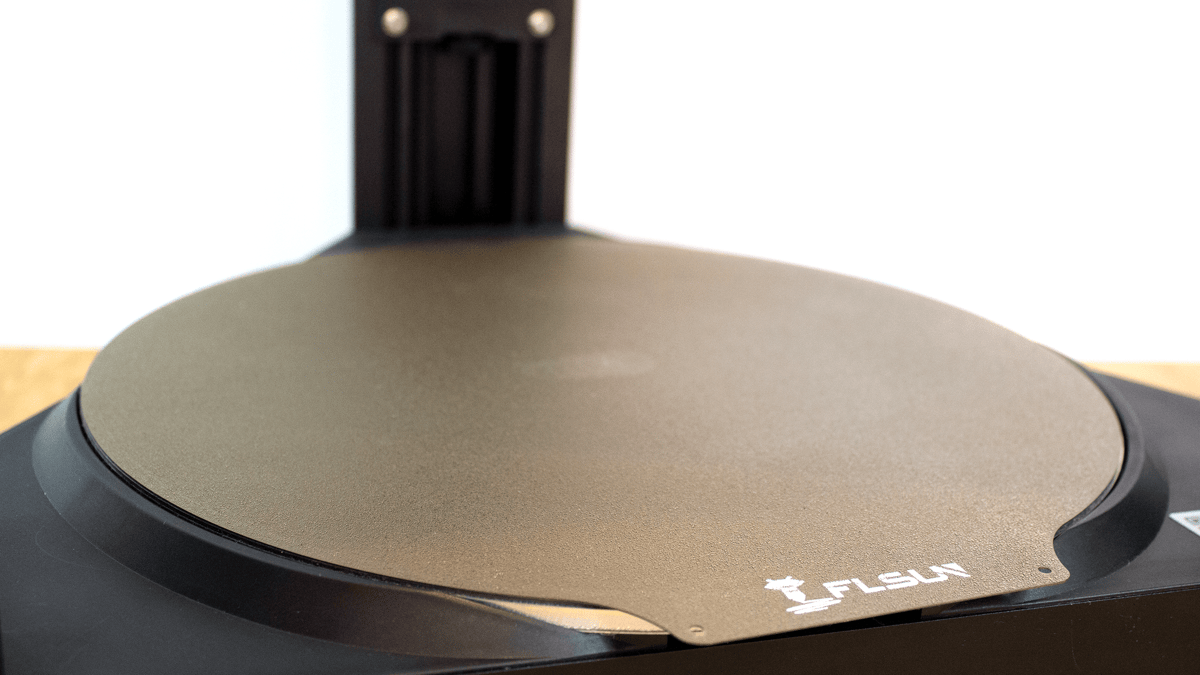

Poor adhesion is a problem shared between many printers trying to adopt PEI-coated spring steel print beds lately. In fact, the V400’s bed performed very well relatively, considering issues only arose with more challenging materials. You expect some trouble when printing with nylon in an open build volume, but we’ve still had better experiences on smaller Cartesian printers that can also be easily tented. Not so for the large-framed V400, especially considering how its heated bed hangs just slightly off the edges of its base – making any potential enclosure mod difficult.

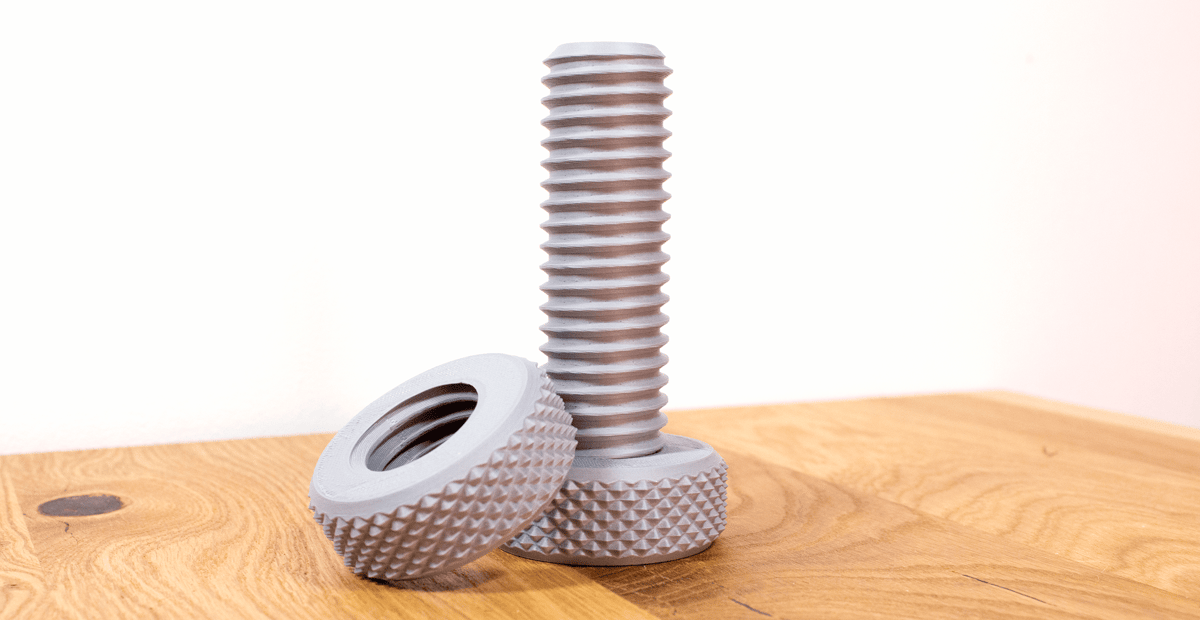

Though high-temperature materials prove to be a weak point, we always appreciate a quality bi-metal heat break separating the hot end and Teflon. Besides, the ability to print with these materials at all is a nice luxury, if nothing else. And we did manage to produce some good models, such as this polycarbonate bearing, which printed with minimal warping and sufficient clearance after some trial and error with the material.

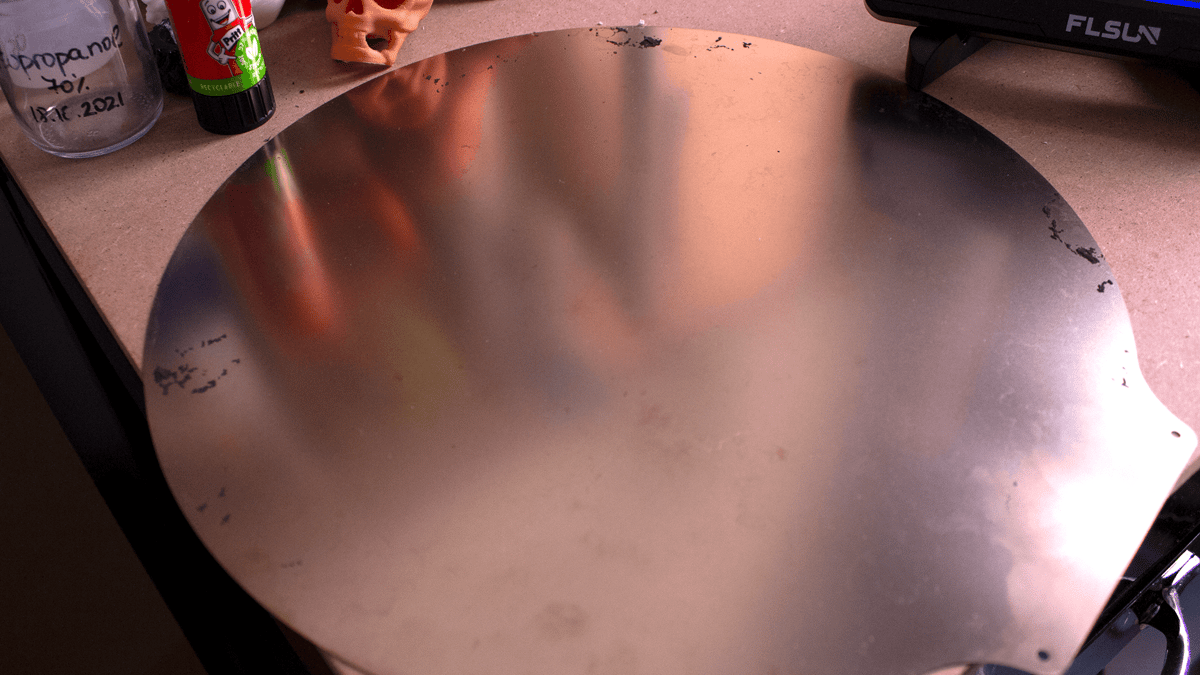

Still, the print bed did disappoint us further. While printing at temperatures required for nylon and PC – up to the V400’s rated 110 °C – the bed was prone to bond with the magnetic soft tile underneath, tearing it when the magnetic bed was removed. It was more prone to this while the bed was still hot but also stuck and tore after having plenty of time to cool. What’s the point of a removable spring steel bed if you have to wait for it to cool down anyways? That’s certainly not cool.

One downside of using Klipper during our testing was the absence of print recovery. This means something as simple as a brownout could be print ruining without an uninterruptable power supply (UPS). We experienced the worst outcome of this when a jostled Speeder loosened the interface’s power cable. The processing board briefly lost power during several prints, forcing the screen to restart and stopping our print in its tracks despite the printer itself still receiving power. To be fair, this is mostly a non-issue. The absence of power-loss recovery is simply part of Klipper, and a UPS is a simple solution, but FLSun could seat the Speeder’s barrel connection a little better to prevent the issue.

But Is It Really Fast?

First, a small note about 3D printer speeds: advertised print speeds aren’t the speed of operation throughout a print’s entirety. You can’t simply compare “print speed” in the slicer and expect the percent difference to be shared by print time. Advertised speeds are better thought of as the maximum speed a printer can reliably print at. It will still need time to accelerate, slow down for corners, etc. (processing commands also come into play here, but Klipper alleviates the issue). Only in an ideal scenario – such as a long wall – will a 3D printer hit the top speed specified in the slicer.

The V400’s default print profile is, more or less, just the SuperRacer’s profile. It’s set to print at 150 mm/s, at which the V400 prints with exceptional quality. The majority of prints above were printed with these stock settings. So, while walls are slowed to a more reasonable 75 mm/s, it still prints with impressive speed.

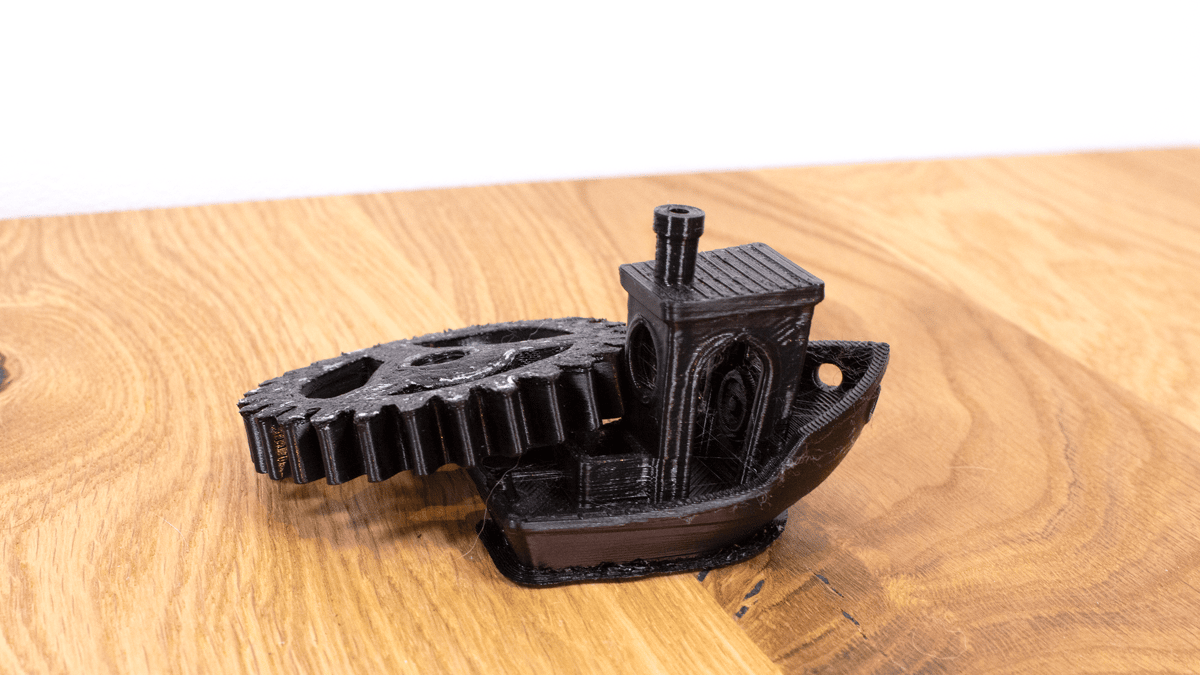

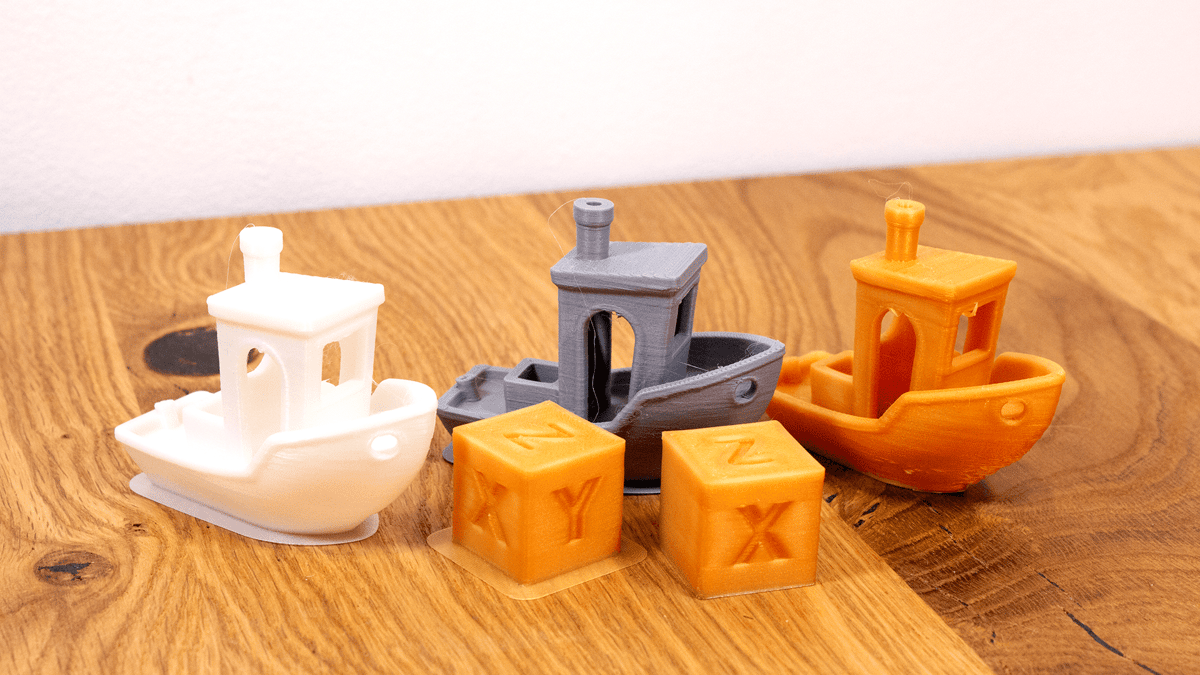

When we raced 3DBenchy prints between the V400 and a similarly priced Cartesian-XZ-head 3D printer, the V400 printed a quality part in 45 minutes with its default profile over the Cartesian’s 1 hour and 26 minutes. Printing at 400 mm/s barely improved the printing speed of our next Benchy, which took 42 minutes, demonstrating the limited impact print speed can have on smaller or more complex models. If you’re keen, speed could be increased further by tuning acceleration, but it remained at default during our testing.

To press things somewhat, we took one of FLSun’s sample parts, the nut and bolt, and cranked its speed percentage setting up to 300% in Klipper – expecting failure. Except it succeeded. This model was clearly sliced to print at the V400’s peak of 400 mm/s since Klipper reported up to 1200 mm/s at times. It’s important to note here that we didn’t conduct testing with an accelerometer, so we can’t attest to whether the machine’s limits were reached before that or what they were. But we can say the part came out flawlessly despite us mercilessly cranking its speed.

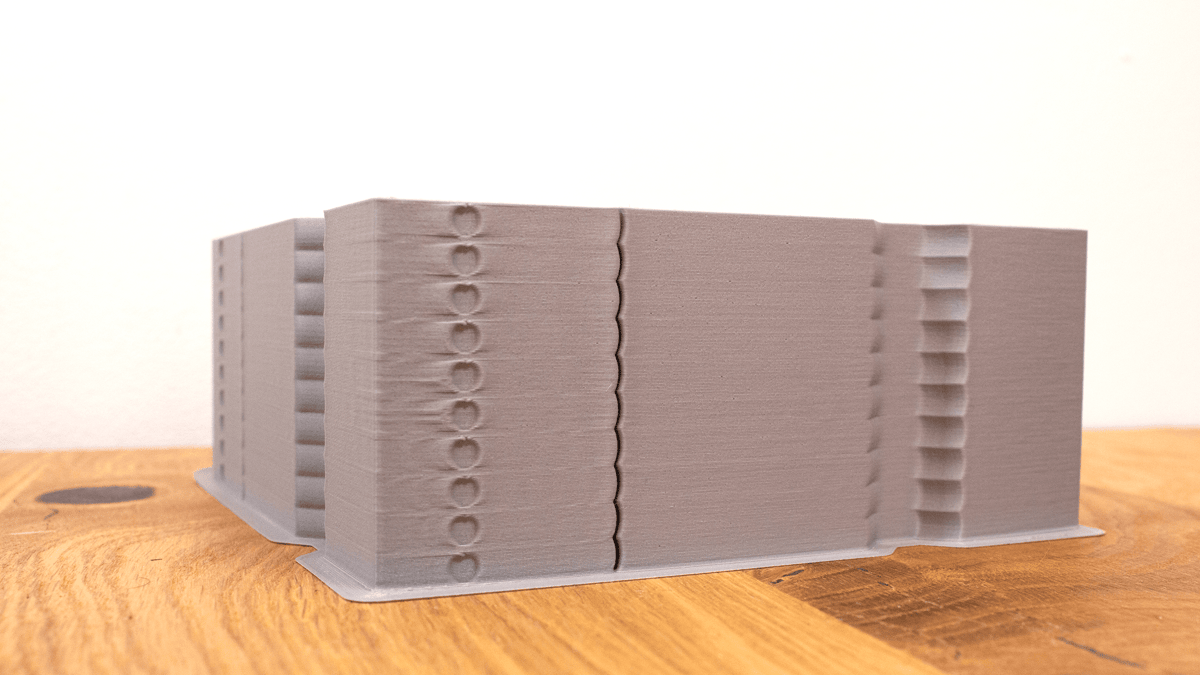

We conducted similar tests with models completely unsuitable for fast 3D printing to see what speeds Klipper would report. For example, a calibration cube set to print at 400 mm/s across the board (walls, infill, and all), which we similarly cranked up to 300% speed, printed just fine but only reported up to about 800 mm/s. Which makes perfect sense for the 20 mm³ model.

Anything more detailed than a cube would certainly have visible flaws here, but we found it impressive nonetheless.

For a more practical test, we ran the Acceleration Tower found in Cura’s plug-in Parts for Calibration with its custom G-code set to increase speed by 50 mm/s every 25 layers at 0.2 mm layer height. This prints a model going from 50 mm/s at its base to 500 mm/s at the top, surpassing FLSun’s marketed speed on a part that would be ideal for actually using these speeds: mostly long and straight to take advantage of the speed but with some fine details.

The test came out near perfectly, all the way up to 500 mm/s. When we pinch the top, we can feel a touch more give compared to the bottom, suggesting the infill is weaker here, but it’s minor. At 400 mm/s, no such give is noticeable.

So, can the V400 print at 400 mm/s without loss of quality? In our experience, yes.

This won’t likely apply to more detailed models, but most 3DBenchys printed at 400 mm/s came out with an appearance we’d typically expect. Some lesser materials did noticeably suffer in overhangs, but quality filament performed exceptionally at the V400’s highest-rated speeds.

It is a bit frustrating that the provided slicer profile is, more or less, just the Super Racer’s more conservative speed profile and doesn’t include speeds of 400 mm/s. Some of the V400’s sample models print at this high advertised speed, but FLSun doesn’t seem to trust end users with it – FLSun should be providing slicer profiles with the speed it’s advertising, even if they include more conservative profiles along with it.

Is It Worth It?

The V400 costs a hefty bag at ~$850, putting it just a touch over the price of a DIY Original Prusa i3 MK3S+.

For that price, you get a 3D printer with a generous Ø300 x 410 mm build volume that can be used dependably and at very impressive speeds – speeds we were surprised to find matched the manufacturer’s ambitious claim – and at a level of detail we were similarly impressed by.

The combination of FLSun’s delta kinematics and Klipper’s processing power allows the machine to tackle detailed models with subtle features quickly and effectively. It also makes for a very enjoyable user experience given its quality-of-life features like out-of-box Wi-Fi controls via Mainsail web UI that feel the realm of more expensive systems.

But some boxes the V400 seems to check at first glance aren’t so rosy. Namely, the 300 °C max hot end temperature. It’s nice to have when you need it, but we don’t believe the printer is suitable for regular printing of common high-temperature materials like nylon or polycarbonate. In fact, printing at these temperatures resulted in damage to our printer’s soft tile heatbed layer despite being rated for 110 °C temperatures.

All told, the V400 is a high-speed 3D printer capable of putting out high-quality, detailed parts. It’s stacked with features both practical and luxurious that make it a joy to use and is a machine we’re very comfortable recommending – if you have the room to accommodate its massive frame size.

The V400 isn’t being shipped out to the public just yet, but if you order now, FLSun says units will ship out after September 20, 2022.

Features

400 mm/s Printing Speed

Of course, speed is the main event here. Flsun’s biggest promise and the very reason for the printer’s name.

Delta printers typically steal the show from Cartesian printers when it comes to print speeds, but the V400 offers another level. For reference: print speed settings on your typical Cartesian 3D printer would typically be around the 60 mm/s mark. The Super Racer, however, Flsun’s previous crown jewel, was advertised to reach speeds of 200 mm/s — way faster than your “normal” 3D printer. Albeit, this was not always with exceptional results. Something we discovered during our review.

The gist of it: even on the V400, we’ve seen prints come out fine at maximum speed, but it is a generally good idea to dial back some of the speed to achieve cleaner prints. That said, if you’re looking for the most headroom possible for your SpeedBoatRace, the V400 delivers enviable results while printing at high speed.

Dual-Drive Direct Extruder

Achieving reliable high-speed 3D printing requires as much precision as you can muster throughout the process. The V400’s direct extruder helps with that, as do its dual drive gears feeding filament through the extruder evenly and securely.

Delta printers typically go for a Bowden setup to reduce the weight on moving parts, which allows for higher printing speeds. For the V400, however, FLSun created a lightweight direct extruder weighing about 400 grams.

The extruder’s hot side also includes a bi-metal heat break, so it can print at temperatures up to 300 °C. This puts high-temperature materials like nylon and polycarbonate on the menu, but we found the materials frustrating to work with on the V400. Still, it’s always good to have the option around, and something as simple as a new print bed may remedy this issue.

Build Volume

At a meter tall, the V400 is a gargantuan 3D printer. Delta printers don’t typically house the largest build surface but shine when it comes to Z volume. But with Ø300 x 410 mm, the V400 offers quite the print space to work with, given its mechanical arrangement and price. For comparison, the Super Racer offers Ø260 x 330 mm, which was already pretty sizable for a Delta.

Carbon Fiber & Linear Rails

To further decrease moving weight, the V400 uses carbon fiber for its arms holding the print head. Carbon Fiber is a high-strength, ultra-lightweight material that helps eliminate even more weight than the already lightweight print head does. With less mass to move around, printing at high speeds becomes less prone to printing artifacts.

The printer also features dual linear guides for the needed rigidity when operating at these high speeds. We were a bit surprised to find the company move away from the linear rails implemented on the Super Racer, but, according to FLSun’s blog, it found linear guides to offer better performance.

PEI-Coated Spring Steel Print Bed

Following the trends of the times, FLSun opted for a PEI-coated flexible spring steel print bed on the V400. This bed was one of the weaker points of the V400, but, that said, during our time with the Super Racer and its tempered glass bed, we found its level of adhesion to vary wildly, with some materials not consistently sticking to the bed. For the V400, our difficulties were limited to high-temperature materials, with more standard filaments sticking reliably.

“Speeder” 7-inch User Interface

A gargantuan 3D printer needs a big UI to match. 7-inches is more than we usually get on a 3D printer but, after all, in this day and age, no one wants to tap away at a tiny screen. What is this, 2015? The V400’s IPS screen has an excellent 1024 x 600 resolution and is extremely responsive with a well-organized menu. It feels quite premium, really.

And the UI comes pre-installed with Klipper firmware. The interface is Wi-Fi capable, using the extremely appealing Mainsail UI to control your printer via web browser.

Further Features

The FLSun V400 is also equipped with:

- Silent stepper drivers: The V400 works pleasantly quietly. We found it to operate at about 50 – 60 Db, with the fans louder than its stepper drivers.

- Filament sensor: A handy filament sensor ensures you can take advantage of all the V400’s generous build volume without worrying about running out. But the channel isn’t especially tight. We struggled to feed our materials through it at times.

Featured Prints

We use many models generously shared with the 3D printing community to conduct these reviews. If you like what you see, here’s a list of who designed them and where you can find them to 3D print yourself.

- Dwarf Miniature by Christian (@free-minis), via MyMiniFactory

- Boneheads: Raven Skull by 3DKitbash

- Spiral Tower by Jukka Seppänen, via Thingiverse

- SpaceX Falcon 9 Rocket by Cosine Additive, via Thingiverse

- Spiderman Home Coming by David Ruiz Olivares, via Thingiverse

- Murray the Demonic Skull by Fotis Mint, via MyMiniFactory

- Parametric Spur Gear by sergeevio, via Thingiverse

- Better 3D Printable Bearing by Nelson Botsford, via Thingiverse

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2022

- Assembly: Partially assembled

- Mechanical Arrangement: Delta

- Manufacturer: FLSun

3D Printer Properties

- Build Volume: Ø300 x 410 mm

- Feeder System: Direct

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 110 °C

- Print bed material: PEI-coated spring steel

- Frame: Aluminum

- Bed leveling: Automatic

- Connectivity: Wi-Fi, USB

- Print recovery: No

- Filament sensor: Yes

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: PLA, ABS, PETG, Wood, TPU, PC, nylon

Dimensions and weight

- Frame dimensions: Approx. 500 x 430 x 940 mm (without spool holder)

- Weight: N/A

Similar Printers

You may also be interested in the following printers:

For further information, feel free to check out our Best Delta 3D Printers Buyers Guide.

Flsun Super Racer

Before the V400, the Super Racer was the cheetah in Flsun’s stable. It has a default speed of 150mm/s and can reach up to 200mm/s. Although, during our review, we found it yields best results when toned down a bit.

With a build volume of Ø260 x 330 mm it offers a little less room than the V400 and comes with a tempered glass bed instead of the PEI-coated spring steel plate, but it can currently be snatched up for just $459. Half the speed, half the price? Seems fair.

Flsun QQ-S Pro

Flsun loves a delta 3D printer. Another one in the Flsun family is the QQ-S Pro, the older brother of the Super Racer if you will. With a Ø255 x 365 mm build volume, it offers more space than the Super Racer, although it can’t go quite as fast. However, with a 32-bit motherboard, auto bed leveling, and Wi-Fi compatibility, it isn’t exactly inferior.

Original Prusa i3 MK3S+

If you have the budget for a V400 but are looking for something that can handle high-temperature materials, you may want to step back from the deltas and take a look at the tried-and-true Original Prusa i3MK3S+.

It’s a bit older at this point, but was our Top Pick 3D printer under $1,000 since our review all the way back in 2018. And that’s for good reason. The Prusa uses custom Marlin firmware that is chock-full of smart, self-diagnostic features that make 3D printing and troubleshooting relatively easy. If you ever need them, that is. It’s also one of the most reliable 3D printers around.

But of course, it’s also small enough to easily tent, and so popular that you’re sure to find any mod that suits your needs or a large helpful community for troubleshooting should you need it.

Correction – October 19, 2023: A previous version of this article erroneously referred to Klipper’s MCU component by the host component’s name “Klippy.”

Lead image source: All3DP

License: The text of "FLSun V400 Review: Klipper Delta Magic" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.