Flux got its big break in 2015 with a successful Kickstarter campaign, raising $1.6 million for the Flux Delta, a 3-in-1 3D printer that could also laser engrave and create 3D scans of objects.

The Delta is long gone, but Flux has endured, focusing its product lineup instead on the lucrative world of desktop laser engravers.

For the Flux Beamo, the company returned to Kickstarter, raised close to half a million, and subsequently released a laser cutter/engraver that promises pro-quality work, cutting-edge technology, and powerful features in exchange for ~$1,500.

To find out if the Beamo lives up to its promises, we fired up the laser and went to work, singeing our way to a verdict. Read on to find out how it fared.

Verdict

Pros

- Desktop-sized, compact machine

- User-friendly and powerful UI

- Versatile 30W laser

Cons

- Limited work area

- BeamoGo App does not function (yet)

- Must be operated in well ventilated space (or with a pricey air filtration unit)

The Flux Beamo is a value-packed desktop laser cutter and engraver that combines affordability with ease-of-use. Strapping a 30W CO2 laser diode, the Beamo can take on many materials and opens up a world of possibilities for your making, be it home improvements or items to flog as a small business.

Laser Focus

Among laser cutters, CO2 is the go-to tech. Combining low power usage with relatively low price and high efficiency, it’s a common laser type that’s ideal for consumers and maker spaces.

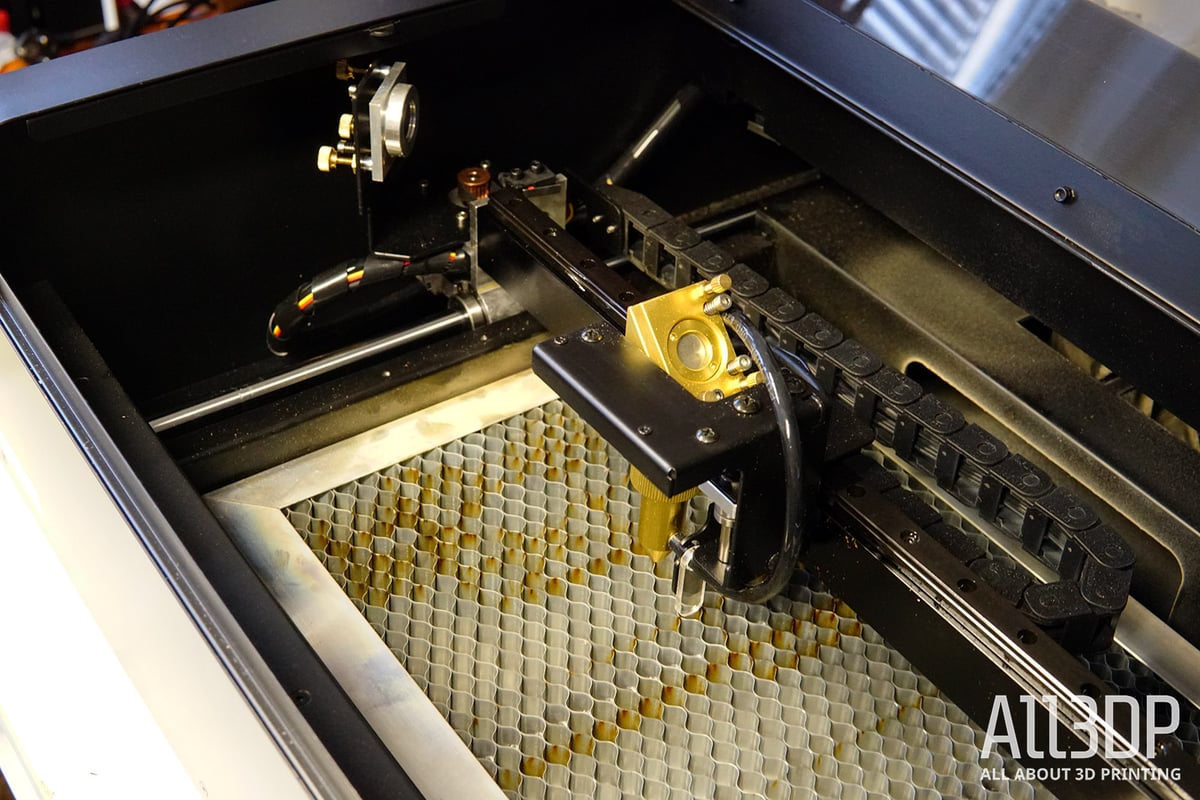

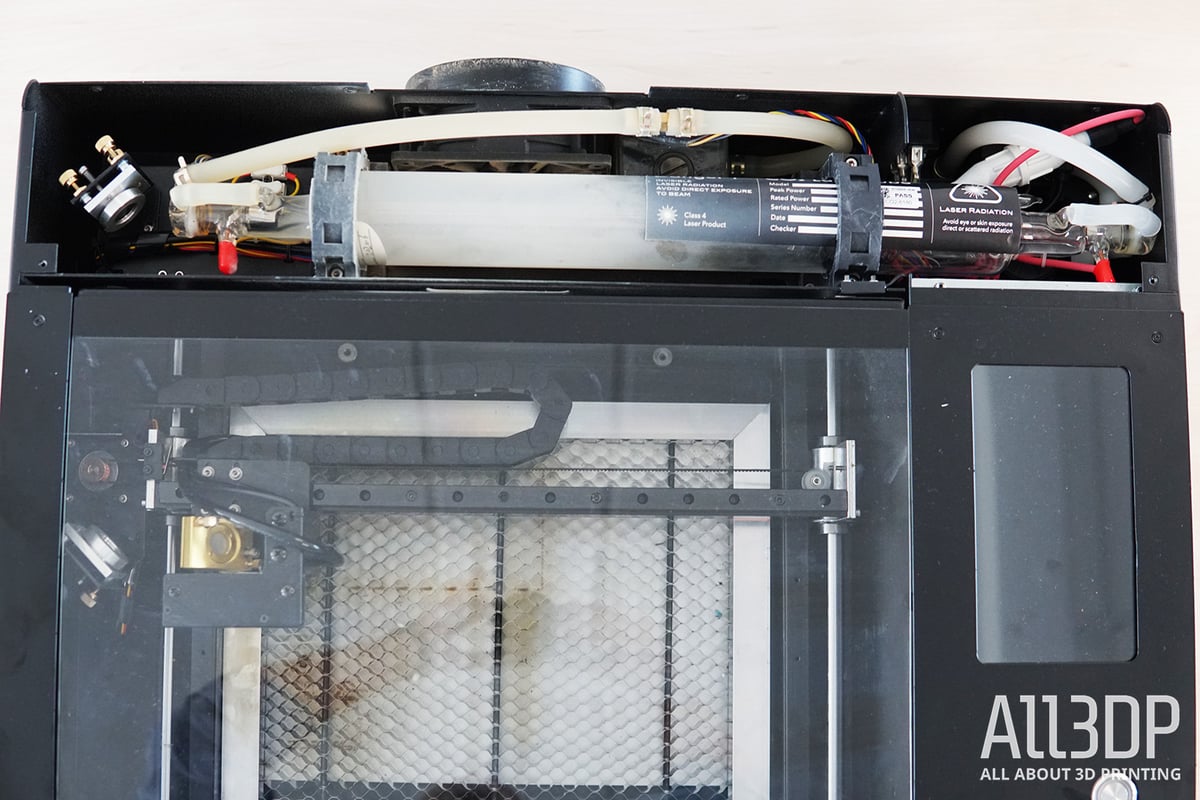

The laser source emits from a glass tube filled with gas – primarily carbon dioxide, hence the name – when electricity passes through, producing infrared light. Both ends of the tube are mirrors: one fully reflective, the other semi-reflective and allowing a beam to escape. The generated beam leaves the laser tube – situated out of sight in the Beamo’s enclosed rear block – and directed via a three-mirror setup towards the laser head, where a lens focuses it down to a spot size of approximately 0.05 mm. Because of this, the Beamo can achieve a resolution of about 1000 dpi.

At 30 watt, the laser in the Beamo is capable of engraving a variety of different materials, including wood, cardboard, fabric, glass, acrylic, leather, metal, stone, tile, and others. Cutting is limited to cardboard, paper, wood, acrylic, and other similar lightweight materials. The maximum cutting depth is between 3mm and 5mm, depending on the material.

For most of the default programs, available in the Beamo software, the laser power stays below 50%, a measure to prolong the lifespan of the diode (according to Flux, it is recommended not to exceed 70% for long periods). This gives you some headroom to fine-tune and experiment with laser power. It doesn’t feel like the Beamo is at full throttle in its default state.

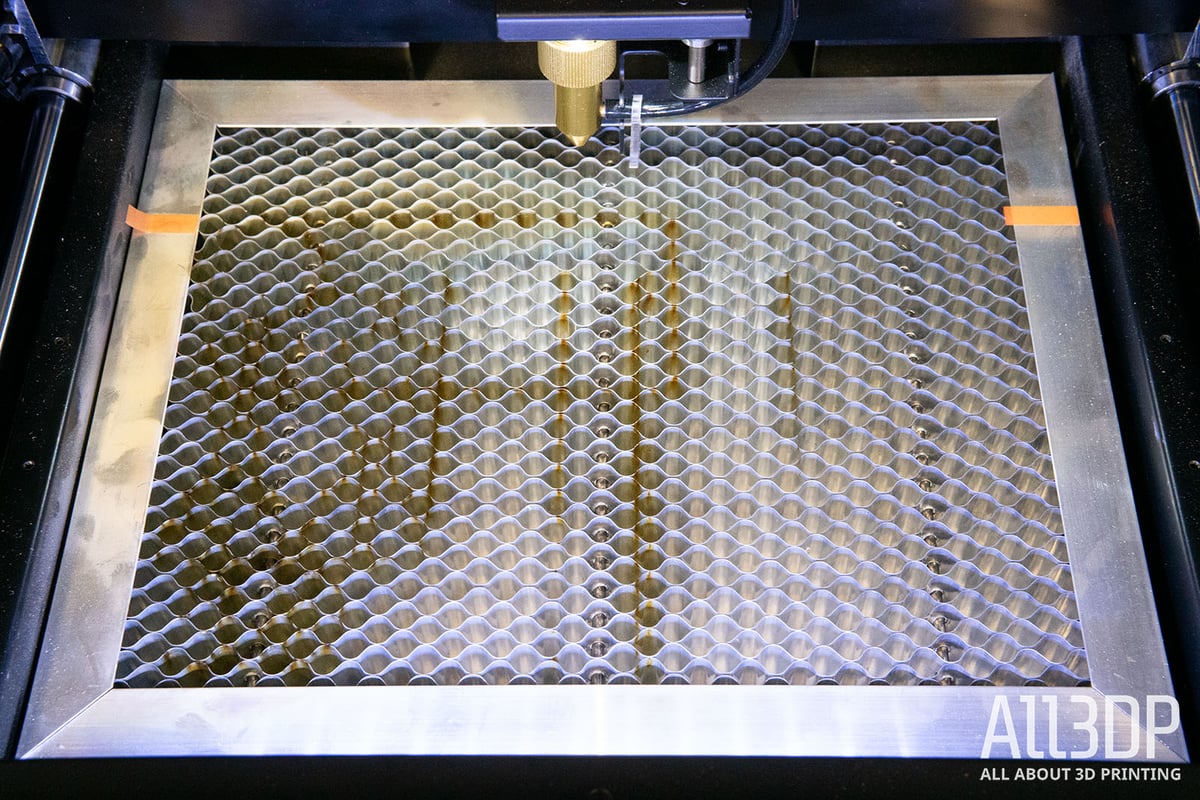

Fleshing out the Beamo’s interior further is the 300 x 210 mm sized aluminum honeycomb bed, which provides structural support, absorbs collateral energy, diffuses the light emitted during lasering, and allows airflow for material cooling. The bed is removable, allowing you to increase the height of materials inside the chamber from 25 mm to 45 mm.

The working area is surrounded by a metal case that gives the Beamo a svelte look typical of desktop laser cutters (think K40 or Glowforge, and the impression is similar.) At 615 x 445 x 165 mm, the Beamo puts out a professional vibe without being cumbersomely large. A large acrylic door provides ample visibility and easy access. For safety reasons, the Beamo automatically pauses when opened mid-job.

Complementing its small size, and intended spot on your desktop is a ventilation outlet with a powerful fan. Obviously, you’re burning material when laser cutting and engraving, which results in smoke and other nasty emissions. Some materials are worse than others, even to the extent that they emit toxic fumes. If you plan to run the Beamo as is, its exhaust pipe, provided, can be fed through a window for adequate ventilation.

Alternatively, there is the standalone BeamAir filtration unit, which takes the exhaust from the Beamo and churns it through various filters. It’s loud and pricey (~$800), but it means you don’t need to be near a window to use the laser.

One of Beamo’s greatest strengths is its ease-of-use, which is apparent in the little things, such as focusing the lens. When processing materials of different heights, you have to focus the lens accordingly. Rather than manually twisting and turning the lens to eyeball the focus, the Beamo instead simplifies the task for you.

Focusing the laser for the loaded material is a cinch. Once you drop the Beamo’s retractable “focus bar,” you hand-turn the focus ring, lowering both until the bar rests on the material. That’s it. It’s not automatic, but it takes the guessing and busywork out of focusing, which is a great thing. The more significant implication of this is that you have a much better chance of repeatable results. An auto-focusing module is available separately, but it costs $250.

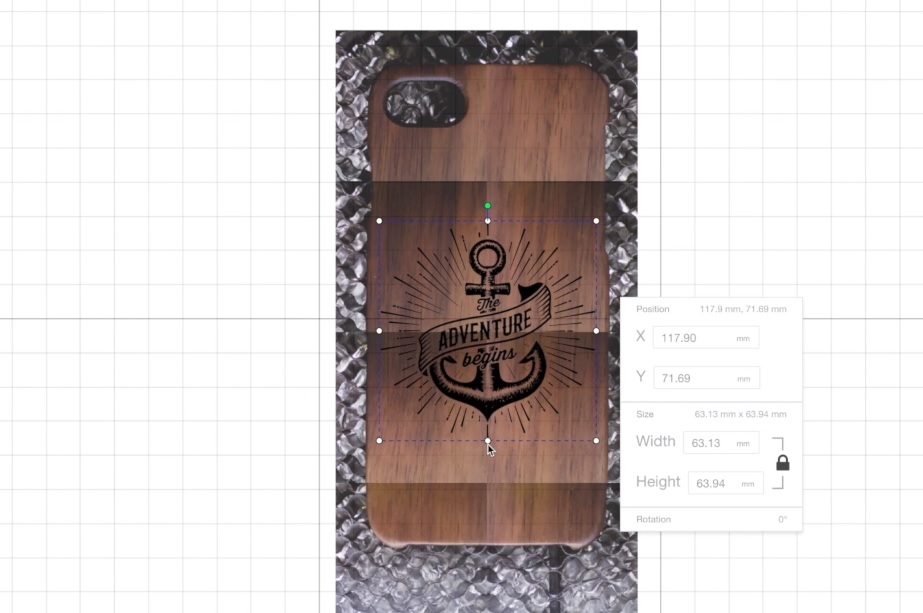

Also practical is the included HD camera mounted onto the laser head. Once connected via WiFi, you can preview your workbench within the software, allowing you to place your design onto the material precisely. Taking the guesswork and imprecision out of lasering is not to be underestimated, and spending more time away from the machine knowing that when you hit “Start,” you will get exactly what you want is oddly comforting. On the downside, the camera can only preview 300 x 195 mm of the work area, losing almost 20 mm in the Y-axis. Not much, but also not ideal.

The Beamo has an excellent large color touchscreen offset from the work area. Running off a Raspberry Pi and responsive, you may not see this display much since it’s so easy to operate the machine remotely via WiFi.

The Beamo’s rear features two USB slots – one is permanently occupied by the WiFi antenna – in addition to an Ethernet port, power input, and exhaust fan vent.

The Good Kind of Simple

Software

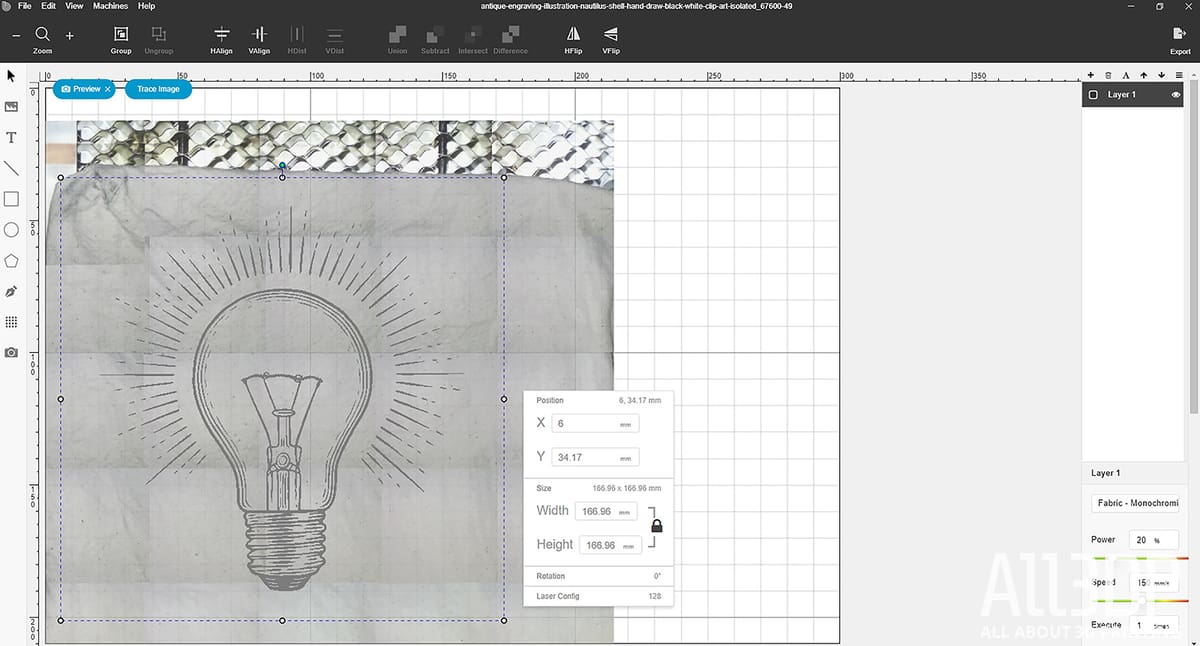

The included software, Beam Studio, can be downloaded from the Flux website and connects to the Beamo via WiFi or Ethernet. Beam Studio is our favorite aspect of working with the Beamo. It’s incredibly straightforward and makes you want to play around just for the fun of it, let alone quickly set up your lasering jobs.

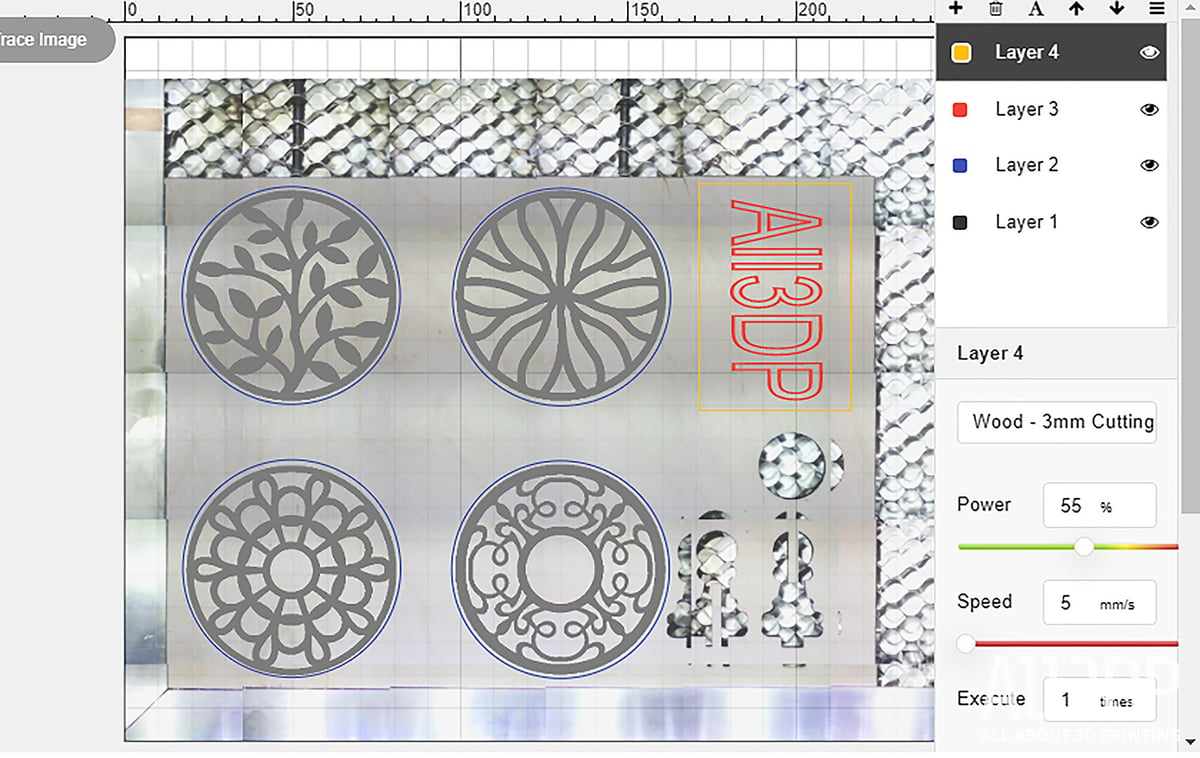

You have a few ways to set up a job. Firstly, you can draw simple designs in-app using a few simple tools, including primitive shapes, a free-form drawing, and a text generator. You can also import files from a variety of popular image creation programs (think Inkscape, Adobe Illustrator, AutoCAD, and you get the idea.) The software is compatible with JPG and PNG file types for bitmap engraving, and SVG or DXF files for vector engraving. Bitmap files consist of pixels and are best suited for monochrome engraving and etching (they do not scale well), whereas vector files are composed of paths defined by various points and are well suited for cutting jobs.

Beam Lab also uses a Photoshop-like layer system, that allows you to program multiple tasks with different settings for the same job. You can set the laser to cut out the model’s edges and then engrave the surface and vice versa, each layer allowing for individual laser power and speed settings. Plus, the software offers presets for engraving and cutting different materials.

The camera allows you to place and preview your desired engraving or cut precisely on the material. This method of job alignment can be approached in a couple of ways. Unlike a fish-eye lens single-image that a system such as the Glowforge uses, the Beamo instead takes a grid of images and merges them into one picture. As we stated above, unfortunately, the camera doesn’t capture the whole engraving area but narrows it down to 300 x 195 mm. We marked the honeycomb workbench accordingly to spare us from repeatedly placing objects out of bounds – something Flux should have done in the first place.

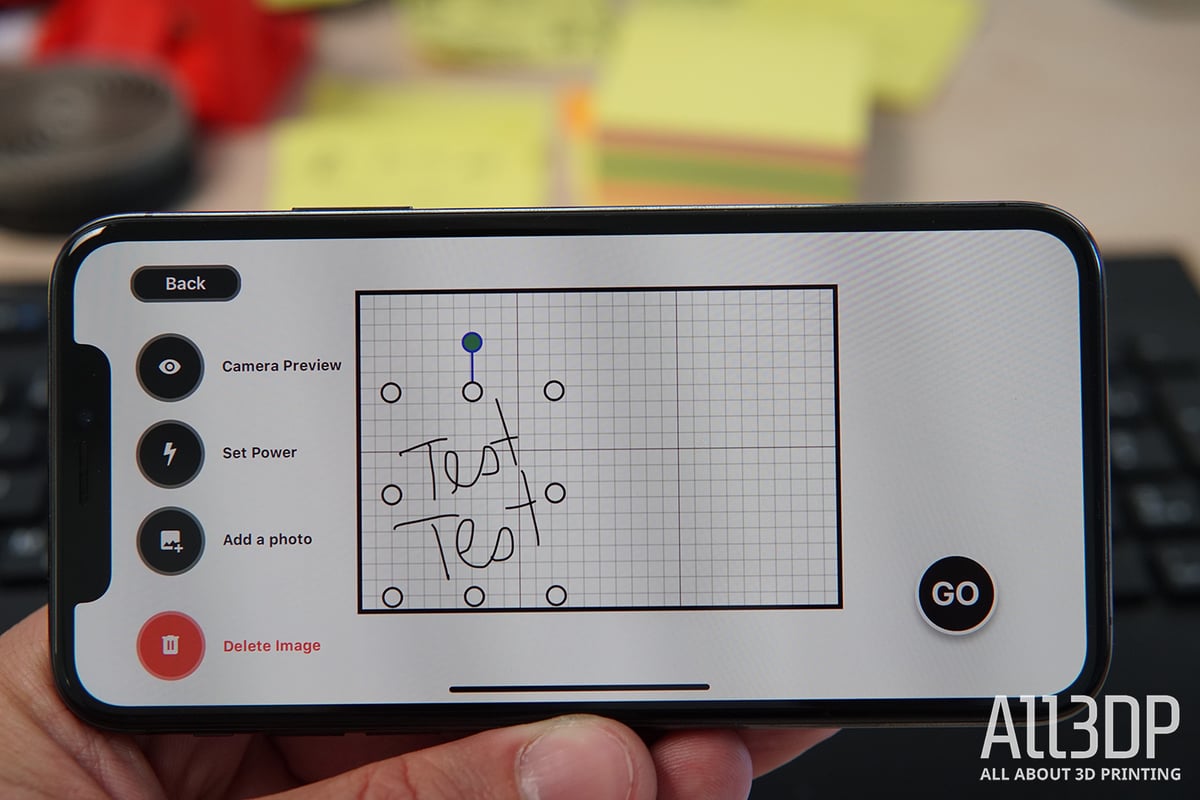

If you want to bring your hand drawings to life, you can use the trace image function by placing the sketch (or any other picture for that matter) onto the workbench and letting the camera scan and convert it. A neat little feature, especially if you have kids that love to scribble away all day long.

From a few test runs, we can say it functions best with strong colors. For the best results, take a photo using your smartphone and import that. Gimmicky, but cool.

The free mobile app, BeamGo, comprises the drawing feature, plus other essential control and job setup features from Beam Studio. Unfortunately, it crashes whenever we try to send a job to the laser. It looks good and could be useful, but not until Flux gets a grip on it.

One feature we found lacking in Beam Studio is the ability to add blockers to your jobs – setting specific parts of your material completely off-limits from the laser. If you want to risk engraving valuable and personal items, this would give extra peace of mind.

Usability

A range of material presets make the Beamo pretty accessible for laser newbies. You will find yourself tinkering with the settings more as you acquaint yourself with the machine, and branch out with the materials you use.

Engraving comes in two types: shading and monochrome. For the former, you must flip the shading switch, which is buried in the picture settings, and crank up the power to get good results. We found shading leather and wood worked well with the power turned up to ~20%, up from the default of 15%. Monochrome engravings, on the other hand, fare better at the default settings, as does cutting. You can create and save your profiles for future use, too.

Even though Flux claims that the acrylic cover provides sufficient eye protection from the Beamo’s 30W laser, we would recommend picking up and wearing a pair of CO2 laser safety goggles. We’ll always advocate excessive safety around lasers, so generally try to avoid looking and around the area of the laser while the Beamo is in operation.

Secondly, the operating noise of the Beamo is about 65dB – about as loud as a running vacuum cleaner.

Consumables & Maintenance

Maintenance is inevitable when owning a laser cutter. Especially the parts involved in the creation and direction of the laser beam will degrade with use, namely the laser tube, mirrors, and lens. Flux estimates that the lifespan of these consumables is about a year under general, regular usage. Spare parts can be bought directly from Flux or a 3rd party, starting from $20 for the mirrors, to about $180 for a new laser tube. You’re looking at a possible investment of $230 a year in maintenance costs.

Apart from the consumable parts that need replacing from time to time, the Beamo also needs additional servicing, such as refilling the water cooling, cleaning the mirrors, and realigning the optical path. Thankfully, the Beamo team includes a comprehensive user manual that details all possible eventualities.

If you are thinking of buying the Beamo, or any CO2 laser engraver for that matter, you need to be aware of these recurring costs. Your machine will inevitably need open-heart surgery at some point in its lifecycle to stay in tip-top shape.

Is It Worth It?

The Beamo is Flux’s entry level laser engraving and cutting machine – a device that tries to hit the sweet spot between affordability, ease-of-use, and capability. It overwhelmingly nails it. Its appearance, and user-friendliness are unquestionably premium in execution.

Where the Beamo falls short, though, is in its etching and shading, of which the resulting engravings are a little lackluster. It could be argued that the 30 W laser is a little lightweight, taking steel engraving off the table. But, in the Beamo’s favor, it is cheaper than the machines that can etch steel. The engraving area could be larger, not least, when using the camera preview mode.

If you have the budget, you can enhance the Beamo with add-ons such as a rotary tool or a hybrid laser that can broaden the machine’s capabilities.

Testing the Beamo has been a lot of fun. Its ease of use gets the creative juices flowing, which flow all the more with no showstopping barriers or real frustrations in the workflow. We’ll be sad to see it leave our lab.

Features

Laser cutters and engravers allow you to bring ideas to life. You can engrave detailed patterns, intricate text, and beautiful images for gifts, home decor, or just for fun.

30 Watt Laser

The Flux Beamo is equipped with a 30-watt CO2 laser that Flux claims can cut through cardboard, paper, wood, and leather, and engrave acrylic, stone, glass and many other materials.

Said to engrave at 0.05 mm layer spacing and with a resolution of 1,000 DPI, the Beamo’s laser benefits from water cooling, and can be upgraded to a hybrid laser via an add-on which combines diode laser and CO2 laser to, Flux claims, improve cutting speed and efficiency.

Compact Size

The Flux Beamo is fully enclosed and has a relatively compact footprint of 615 x 445 x 177 mm. Complementing this small size are a couple of safety features including automatic pause should the lid open during operation and a ventilation outlet with a powerful fan, that makes it an attractive prospect for design and educational environments.

At 22 kg (50 pounds), the Beamo has a degree of portability to it.

Inbuilt HD Camera

With the inbuilt HD camera on the Flux Beamo, you can preview the work area and the workpiece on your laptop or phone. This has the benefit of allowing you to align your work before hitting ‘run’ and should cut back on frustrating loops of trial and error.

Note that the 300 x 195 mm preview area is a bit smaller than the total engraving area of 300 x 210 mm.

Beam Studio

The Beamo comes with Flux’s in-house developed software Beam Studio that lets you edit texts and vector files, modify bitmap images, distribute objects, among other things. The Beamo is compatible with: JPG, PNG, SVG, and DXF filetype.

This broad file compatibility means you’re mostly free in creating images to engrave using the graphics editor of your choice – Adobe Illustrator, Autocad, Inkscape, CorelDraw… even Microsoft Word.

The iOS and Android BeamCam apps provide remote control and advanced functionality, such as its photo mode. You can take a photograph using your smartphone, upload it to BeamCam, align the design, and engrave it. Additionally, you can transform hand-drawn images into digital files using Flux’s SmartTrace software, which digitizes your doodles and lets you engrave them.

Further Features

Additional features on the Flux Beamo are:

- Internal water-cooling – the closed-loop water-cooling system circulates water throughout the machine

- WiFi connectivity – lets you control/monitor the device remotely

- Autofocus (add-on) – the focus will adjust according to the thickness of the material, enabling the Beamo to cut deeper in multiple passes

- Rotary (add-on) – allows you to engrave on curved objects like bottles or glassware

Tech Specs

Backing up the features mentioned above, here are the specs for the Flux Beamo:

General

- Dimensions: 615 x 445 x 177 mm

- Weight: 22 kg

- Touch panel: 1024 x 600 LCD

- Camera: Yes (preview area: 300 x 195 mm)

Work Area

- Work area: 300 x 210 mm

- Work area depth: 45 mm

- Borderless work area: 260 x 210

Laser

- Laser Type: 30watt CO2 Laser

- Cutting thickness: 0-5 mm (varies by material)

- Max. moving Speed: 300 mm/s

- Max. material height: 45 mm

MATERIALS

- Cutting and Engraving: Cardboard, paper, wood, leather, acrylic, etc.

- Engraving Only: Glass, stone, metal, stainless steel, fabric, etc.

SOFTWARE

- Operating system: Windows, macOSX, Linux, Chrome OS

- Engraving modes: Vector / Graphic (monochrome, grayscale)

- File compatibility: JPG, PNG, SVG, DXF

Similar Lasers

For more laser cutters/engravers and how they stack up, check out our Best Laser Cutter Guide or the Best Laser Engraver Guide.

Orion Motor Tech 40W Laser

The 40W laser cutter by Orion Motor Tech is one of the many budget K40’s out there. With 300 x 200 mm, it offers a similar-sized cutting area than the Beamo but lacks many and more of the Beamos ease-of-use features, such as a preview camera. With a mind-boggling low price of ~$450, it is the budget alternative out there.

Glowforge Basic

The Glowforge Basic is Glowforge’s entry model, a bit of a no brainer there. With a 40W laser, it has more horsepower under its hood plus a bigger working area with 279 x 495 mm. Priced around ~$2.500, it’s about a third more expensive than the Beamo.

License: The text of "Flux Beamo 30W Laser Cutter Review: Cutting Edge" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.