A 3D printing technology first patented back in 1984, stereolithography (SLA) offers several advantages over Fused Deposition Modeling (FDM), despite the latter being more accessible and affordable. With SLA 3D printers, users gain access to parts with a higher quality print resolution and more intricate details, not to mention biocompatibility and castability.

While these professional resin-based 3D printing systems traditionally come at a higher cost than FDM, the Massachusetts-based 3D printer manufacturer Formlabs has made it a mission to bring SLA technology to the masses.

In Spring 2019, Formlabs announced its new Form 3, yet another evolution of its widely regarded desktop SLA 3D printing product line. Focusing on speed, reliability, and versatility, the Form 3 is by far the most advanced and intelligent system released by Formlabs to date (we certainly became enamored during our hands-on review). A few months later, in November 2019, the SLA 3D printing pioneer decided to double down on its success with the dental industry, releasing a variation of the Form 3 specifically designed for orthodontic applications.

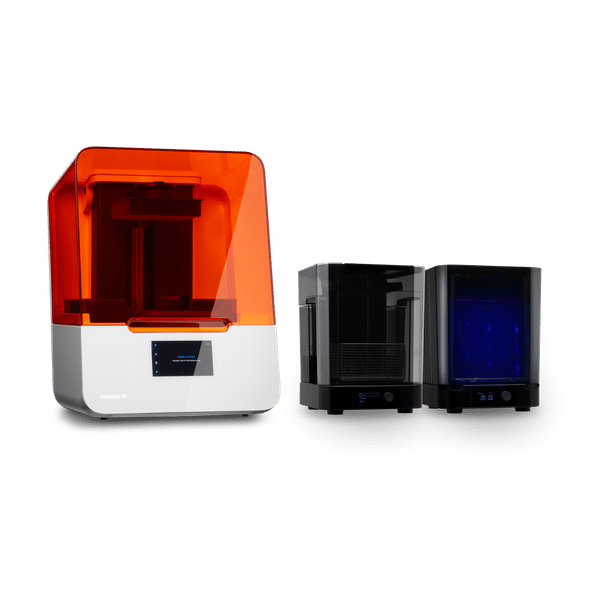

Cue the Formlabs Form 3B, a new iteration of the Form 3 that sports a clinical white color scheme and is reported to deliver “crisp and consistent dental parts.” Alongside the release of the Form 3B, the company’s commitment to the dental sector was further solidified with the launch of Formlabs Dental, a new business division that caters exclusively to dental industry professionals.

What, exactly, does the Formlabs Form 3B offer dental professionals? How does it differ from the original Form 3? Let’s review the specs to find out.

Features

The Formlabs Form 3B was created in order to provide dental professionals with a reliable production ecosystem to make dental fabrication faster and more cost-effective. Optimized for use with biocompatible materials, Formlabs has leveraged years of experience, along with its team of dental professionals, to design a machine that is tried and tested for orthodontic applications.

When it comes to basic technical specifications, such as build volume and print resolution, there’s not much distinguishing the Form 3B from the Form 3. Like the Form 3, this new iteration offers a 145 × 145 × 185 mm print area, an XY resolution of 25 microns, and shares other similar attributes and components with its predecessor.

The Form3B utilizes the proprietary Advanced Low Force Stereolithography (LFS) technology and is equipped with a flexible resin tank and a custom-designed Light Processing Unit (LPU). By employing this advanced technology, these 3D printed dental models have an impeccable surface finish and part quality right out of the printer.

According to Formlabs, the Form 3B allows dental professionals to produce two to three times more parts in single operation compared to smaller DLP 3D printers, reducing overall labor time and costs. Furthermore, this dentally-designed 3D printer is part of a fully modular ecosystem, making it easy for users to scale up depending on their production needs.

On the surface, one notable difference that sets the Form 3B apart from the Form 3 is its clinically styled white base, making the Form 3B fit for the medical environment. What the Form 3B offers, however, is more than a new color scheme, it also presents an entire ecosystem for dental professionals to create orthodontic products, from 3D scanning the patient to part preparation.

This workflow starts with 3D scanning, where dental professionals can digitally capture an individual patient’s anatomy with an intraoral scanner. From there, the 3D scan can be sent to a lab or design station and transformed into a virtual 3D CAD design.

Once the CAD file is imported into Formlabs’ PreForm print preparation software, the models can be sent directly to the Formlabs Form 3B 3D printer. Finally, using the company’s post-processing equipment, which comprises of the Form Wash and Form Cure, the parts can be prepared for intraoral use or employed for a variety of indications.

Formlabs is currently offering the Form 3B 3D printer in two different packages.

Starting at $4,999, the Form 3B Core Package includes all of the basic tools needed to start producing dental parts and models, as well as a liter of Model Resin and a one-year membership with the company’s Dental Service Plan (DSP), which will discuss in further detail below.

For $5,999, the Form 3B Complete Package comes with the same package deal plus the Form Wash and Form Cure. At the moment, these two offerings are available for customers in North America and Europe, and currently has an average lead time of one month.

A Wide Array of Resin Materials for Dental Applications

The Formlabs Form 3B is designed for compatibility with a large swath of dental resin materials. The company currently has around 50 materials scientists developing new materials and profiles that will be verified by its unit of dental professionals before hitting the market. At the time the printer was released, Formlabs announced that four new hues of denture resin were added to the material portfolio.

While more dental materials are expected to be released in the near future, Formlabs already has a wide range of resins available for orthodontic applications. Here’s a quick glance at what’s currently available:

- Model Resin: This resin was developed for high precision, accuracy, and throughput, all of which are critical requirements for dental models. According to Formlabs, Model Resin is ideal for dental modelmaking and clear aligner production.

- Surgical Guide Resin: This is an autoclavable, biocompatible resin developed specifically for Formlabs 3D printers. Surgical Guide Resin can be utilized to 3D print dental surgical guides for implant placement. It was rigorously tested with autoclaves, solvents, and implant systems, ensuring part quality, accuracy, and performance.

- Dental LT Clear Resin: Dental LT Clear Resin is a clear, biocompatible material made for the production of splints and occlusal guards. It’s a Class IIa long-term biocompatible resin that is highly resistance to fracturing, while also offering high optical transparency.

- Castable Wax Resin: A highly tested material made for casting and pressing crowns, bridges, and RPDs, Castable Wax Resin provides sealed margins and contains 20% wax for reliable casting with clean burnout. There’s no post-curing process required as the printed patterns offer high strength, which in turn increases the speed of production workflow.

- Grey Resin: A precise general-purpose model making material that has a matte surface finish, opaque appearance, and precise details. According to Formlabs, Grey Resin can be used by dental professionals to create strong models and prototypes with a high degree of accuracy.

- Digital Dentures: Multiple resins have also been developed to digitize the denture production process, making it more cost-effective and efficient. Denture Base Resin is designed for denture bases and try-ins, while Denture Teeth Resin can be used to produce denture teeth.

Formlabs Dental Offers Full Support to Customers

Another aspect that bolsters this dental fabrication ecosystem is the Dental Service Plan (DSP) offered by the Formlabs Dental business unit. This program includes personalized onboarding training, proactive check-ins from staff, equipment diagnostics every six months, as well as phone and email support.

With dental experts stationed in Boston, Massachusetts, and Berlin, Germany, onboarding is made easy for customers from both continents. This training is intended to help customers optimize their specific use of the Form 3B. For those who are new to dental 3D printing, Formlabs also has a treasure trove of online resources, including guides, videos, and tutorials.

Tech Specs

Here are the technical specifications for the Formlabs Form 3B:

Printing Properties

- Technology: Low Force Stereolithography (LFS)

- Resin Fill System: Automated

- Build Volume: 145 × 145 × 185 mm (5.7 × 5.7 × 7.3 in)

- Layer Thickness (Axis Resolution): 25 – 300 microns (.001 – .012 in)

- XY Resolution: 25 microns (0.001 in)

- Laser Spot Size: 85 microns (0.0033 in)

- Resin Cartridges: 1

- Biocompatible Materials: Yes

- Supports: Auto-Generated, Light-Touch Removal

Hardware

- Minimum Access Dimensions: 405 × 530 × 780 mm (15.9 × 20.9 × 30.7 in)

- Printer Dimensions: 405 × 375 × 530 mm (15.9 × 14.8 × 20.9 in)

- Weight: 17.5 kg (38.5 lbs)

- Operating Temperature: Auto-heats to 35 °C/Auto-heats to 95 °F

- Temperature Control: Air-heated print chamber

- Power Requirements:

- 100–240 VAC

- 2.5 A

- 50/60 Hz

- 220 W

- Laser Specifications:

- 1 Light Processing Unit

- EN 60825-1:2007 certified

- Class 1 Laser Product

- 405 nm wavelength

- 250 mW power

- 85 micron (0.0033 in) laser spot

- Connectivity: Wi-Fi (2.4, 5 GHz), Ethernet (1000 Mbit), USB 2.0

- Printer Control: 5.5″ interactive touchscreen, 1280 × 720 resolution

- Alerts:

- Touchscreen alerts

- SMS/email via Dashboard

- Two LED status indicators

- Speaker for audio alerts

Software

- System Requirements:

- Windows 7 (64-bit) and up

- Mac OS X 10.10 and up

- OpenGL 2.1

- 4 GB RAM

- File Types: STL and OBJ file input, FORM file output

Where to Buy

You can order the Formlabs Form 3B, along with all the essential tools to start producing dental parts, directly from the manufacturer. Click on the link below to learn more:

License: The text of "Formlabs Form 3B Dental 3D Printer: Review the Specs" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.