Formlabs, the Massachusetts-based company and segment-leading manufacturer of desktop SLA 3D printers, has lifted the lid on two new additions to its lineup.

Dubbed the Form 3 and Form 3L, these new professional machines build upon Formlabs’ work with the Form 2, a desktop 3D printer that has cemented itself as one of the first names in print quality and usability since launching in 2015 (was it that long ago!?). Where the Form 2 uses what you could consider a traditional stereolithography apparatus (SLA) setup of a laser directed by a galvanometer to cure resin, the Form 3 and Form 3L use what Formlabs is calling Low Force Stereolithography (LFS).

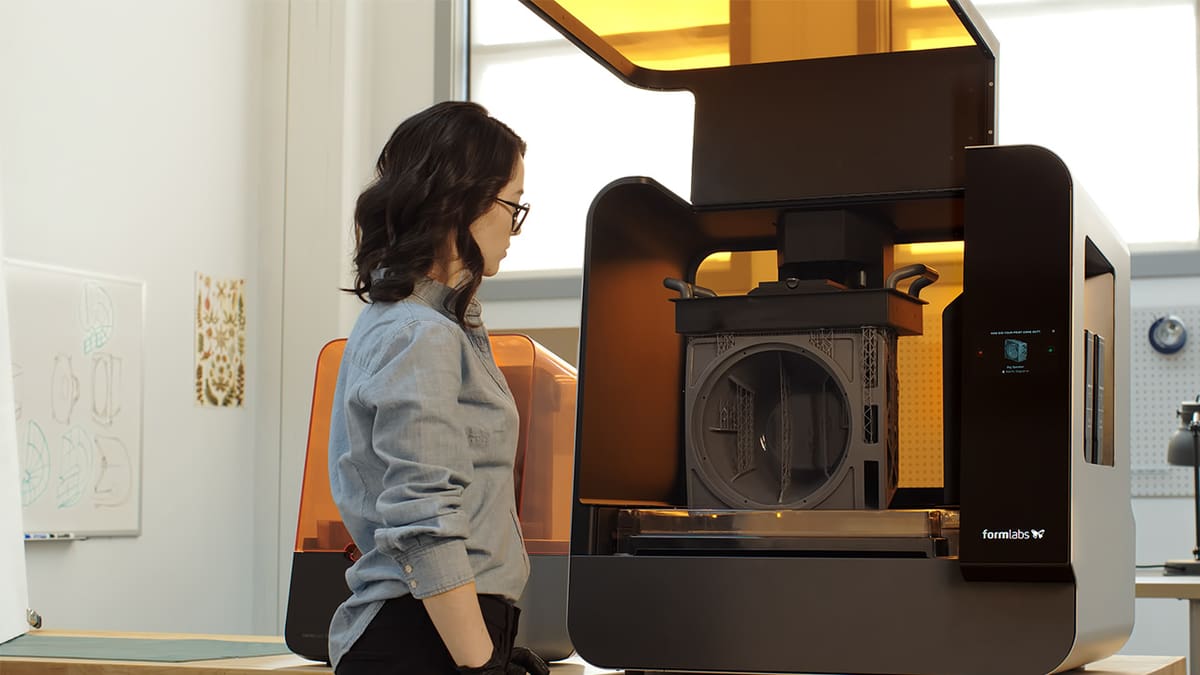

Marking a new direction for the company, the Form 3L is a near-industrial scale machine that touts a huge build volume in a desktop form. A step change in technology over its predecessor, the Form 2, while maintaining its signature ease of use and a vast library of professional materials, it should prove an affordable alternative to other large SLA machines in the industrial space.

Join us as we explore all we know about the Formlabs Form 3L.

Features

For those unfamiliar with the stereolithography apparatus (SLA) technology Formlabs employs in its 3D printers, SLA makes use of a directed laser to set photosensitive resin within a tank. An accurate and quick way to render resin into solid material; this process comes with challenges that can affect the model as it prints.

For one, the position of the print must change to allow subsequent layers to build on top of it, which introduces the problem of ‘peel’ force within the resin; the shifting and pressure therein exerted on the delicate printed part. Formlabs’ Form 2 printer uses a sliding wiper to peel the model from the tank gently. While effective, the company has deemed it worthy of an upgrade.

To address this challenge, and allow the technology to supersize for the Form 3L, Formlabs has developed a new spin on the process called Low Force Stereolithography.

The low force aspect of this process is attributable to the new flexible tank and LPU — more on that shortly) that the Form 3L uses, LFS is said to reduce peel force and allow for linear illumination. The LPU gently protrudes into the flexible and transparent base of the resin vat, pushing the film onto the build plate in perpendicular sweeps, curing the resin in a single pass.

Said to improve the surface quality, LFS was primarily developed to minimize the impact the stresses of SLA typically have on a print. By building to a print with at this gentle, flexible interface, prints on the Form 3L can benefit from delicate support structures that should, in theory, brush away in hand.

In addition to the benefits of LFS mentioned above, the Form 3L also features a uniform high-density laser spot — an advancement possible thanks to Formlabs’ new Light Processing Unit (LPU). Developed from the ground up, the LPU makes use of a system of lenses and mirrors, alongside the galvanometer typically found in SLA systems, to consistently direct the laser perpendicular to the build plate.

Connectivity to the Form 3L comes via WiFi, Ethernet or USB. Notable here is the bump to include 5Ghz frequency WiFi networks. Formlabs is paying close care to the operability of the new machines, with enhanced monitoring through a suite of sensors set to alert the user when attention is required.

The defining feature of the Form 3L is its large build volume. Measuring out at 200 x 335 x 300 mm, it will be one of, if not the largest desktop SLA 3D printer going. Where the print volumes of the Form 2 and Form 3 will continue to appeal to professionals favoring tightly packed detail and small batch runs, at five times the possible print size the Form 3L unlocks the door to broader prototyping and production needs.

As with Formlabs machines of the past, the Form 3L officially supports Formlabs-produced resins only, which is not necessarily a bad thing. Packaged in no-mess cartridges that plug into the printer, the company boasts of an expansive library of professional materials catering to a variety of industries. The Form 3L aims for continuous printing with little to no downtime, something helped by the ability to load two of the company’s resin cartridges at once.

The Formlabs Form 3L is expected to begin shipping in Q4 2019. Priced at $9,999, it’s quite the step up from the Form 3’s $3,499 but competitively undercuts the competition by some margin.

Tech Specs

GENERAL

Printing Technology: Low Force Stereolithography (LFS)

Laser: Light Processing Unit (LPU) X2, 250 mW405 nm

Build Volume: 335 x 200 x 300 mm

Z-Layer Resolution: *25 – 300 microns

XY Resolution: 25 microns

UI: 5.5-inch touchscreen

Connectivity: WiFi, Ethernet, USB

Build Platform Leveling: Automatic

Materials: Formlabs resin cartridges

SOFTWARE

Software bundle: PreForm, Dashboard Printer Management

File types: STL, OBJ

WEIGHT AND DIMENSIONS

Weight: *48 kg

Dimensions: 775 x 520 x 735 mm

*subject to change

Where to Buy

Available for preorder now, the Formlabs Form 3L is expected to start shipping in Q4 2019.

License: The text of "Formlabs Form 3L: Review the Specs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.