“No, I don’t want high-speed 3D printing; give me the slow stuff,” said no one ever. Of course, you want to 3D print high-quality parts as fast as possible, but with so many filament makers slapping a “high-speed” label on their materials today, it makes one wonder: Is this a gimmick, or is there some science behind it?

Let’s take a look behind some of the hype and hyperbole when it comes to high-speed 3D printing and the role your material choice plays in print speed.

What print speed is considered high-speed, you may be wondering? The answer varies, but generally, 300 mm/s and faster is considered high speed. More FDM 3D printers today can operate at these speeds. For example, Bambu Lab printers can print up to 500 mm/s, the fastest Anycubic is around 300 mm/s, the K1 Max from Creality says it will max out at 600 mm/s, while some Original Prusa and Elegoo machines can reach 500 mm/s. On the professional desktop side, a Raise3D Pro3 – using proprietary materials – can reach 350 mm/s.

With these new speeds comes the need for new materials. Let’s take a look at why.

What is High Speed PLA?

The speed of the nozzle movement during extrusion affects various properties of 3D printed parts. High print speeds place new demands on controlling other printing parameters (heat, layer height, flow rate, fan speed, etc.) and may result in over-extrusion on edges while under-extrusion elsewhere, stringing, oozing, layer shift, infill gaps, warping, and surface defects – there’s a reason a common troubleshooting tip is to lower print speed. Plus, adding new layers before the previous layers have completely solidified can lead to deformation, lower dimensional accuracy, and lower mechanical properties, studies show.

So while you can print with just about any material at 300 mm/s, the resulting quality is the issue. The goal of high-speed PLA is to enable you to print quality parts faster. Layer adhesion, surface quality, and overall mechanical properties of your part are the variables that will change between regular PLA and high-speed PLA, material makers say.

High-speed PLA is a re-formulation of PLA (polylactic acid) to make it behave differently. One main goal of these high-speed versions is to extrude more consistently within a higher speed range, providing a consistent surface finish and mechanical properties. As you may know, the higher the maximum print speed, the wider the range of different speeds your printer will produce in making your part.

Another attribute of high-speed PLA is to melt faster and cool faster.

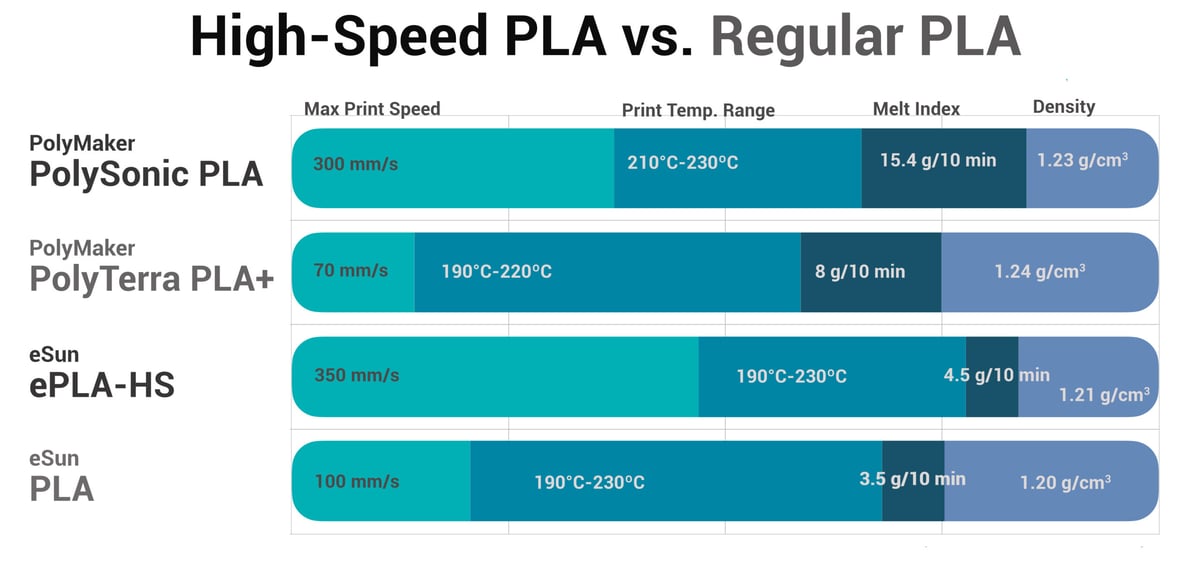

Faster printing reduces the amount of time the PLA filament spends inside the hot end, so it needs to be formulated to melt faster. This brings up a polymer measurement called “melt flow index”.

Melt flow index (MFI) – also known as melt mass flow rate (MFR) or melt index – is a measure of the flowability of a polymer when it is subjected to a specific set of temperature and pressure conditions during extrusion. There are set conditions for MFI testing, which are usually defined by international standards, such as ASTM or ISO.

Only a few PLA makers will disclose this measurement on their filament technical data sheets. Perhaps, no one really shops for filament based on the MFI numbers, but eSun and PolyMaker say they disclose these figures to help customers develop consistent processing conditions to achieve a level of quality control and predict the performance of a polymer in various applications, since it can influence final part properties, such as mechanical strength, surface finish, and dimensional stability.

How is PLA Made into High-Speed PLA?

Material scientist Brian Alexander at Solvay Specialty Polymers (and member of the All3DP Editorial Advisory Board), says there are ways to manipulate the melt strength, crystallization speed, and viscosity in polymer processing, but these are usually company secrets. “We are now starting to see specialized or optimized grades of PLA for additive manufacturing rather than just taking the standard injection molding grades,” he says.

Modified grades of PLA to improve processing speed could be the result of additives to standard PLA or adjustments made at the very beginning of the polymer’s creations, called the reactor phase, where chemical reactions occur to form polymer chains, Alexander says.

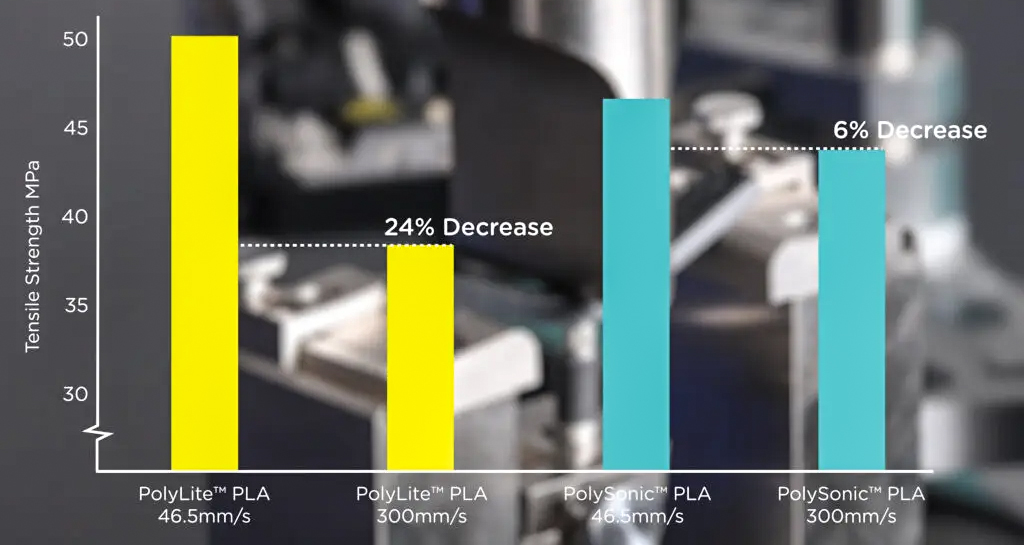

Yet, when polymers are optimized for speed, what happens to performance? Is anything being sacrificed to print quickly?

Material maker PolyMaker released its PolySonic PLA in September 2023. Along with the material, the company shared its research on the material’s mechanical performance. As the chart below from the company shows, a test print made with PolySonic PLA Pro at 300 mm/s had 12% less tensile strength than the same part made with PolyLite PLA at a 46.5 mm/s.

Granted, PLA is not a material sought after for its mechanical strength, rather it’s mainly used for parts with high surface quality and detail. PolyMaker’s testing of its own material shows no change in dimensional accuracy of tolerances comparing high-speed PLA to standard PLA. This is in part due to the material’s ability to transition from fluid to solid with near-zero shrinkage, the company says.

When comparing the data sheets of PLA vs. high-speed PLA, you can see hints of the polymer reformulation in measurements, such as the lower molecular density of the high-speed material. But, technical data sheets and research claims can all be misleading, especially if you’re using them to compare materials. We’ve noticed that mechanical properties listed for test parts printed with high-speed materials often list a print speed of just 40 mm/s.

“To truly check the polymer’s integrity, you would need to print parts at different speeds and processing parameters and do a quick impact (Charpy or Izod) test to see how the parts break,” notes Alexander. “An impact test highlights defects in the printed part, such as interlayer adhesion or porosity, which would be the first to be affected over tensile modulus or strength.”

Despite all of these measurements, your experience with high-speed PLA is likely to be unique. High-speed 3D printing is a marriage of materials, hardware, and software, plus the geometry of your part.

To test for print speed, download a print speed test model. These models generally come with instructions on how to set the correct settings. This model linked here will essentially print the same shape at gradually increasing speeds, allowing you to visually identify the optimal setting.

High-speed or high-volume extrusion PLA filaments can be up to twice the price of the same brand’s regular PLA, so experimentation on your systems with your typical parts is the best way to see if the high-speed PLA you select is a gimmick or not.

License: The text of "Is High-Speed PLA Just a Gimmick?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.