Serial production of parts has been a mainstay of manufacturing since the advent of the factory system in the first Industrial Revolution but now, with what’s being called Industry 4.0, tech-enabled alternatives are emerging.

Chief among them is 3D printing or additive manufacturing. The industry is steadily transitioning from a prototyping mainstay to small batch production on its way to being a full manufacturing option, someday.

Yet, many companies are already using 3D printing for their volume manufacturing. Just look at the popular 4DFWD 4 running shoe from Adidas, the Virto M-Titanium hearing aid from Phonak, the wide range of spinal implants from Stryker, and the millions of mascara brushes 3D printed for Channel. 3D printing is the manufacturing method of choice for these volume products because it is faster or cheaper or the only way the product could be made.

For example, when it comes to price, 3D printing quantity of less than 5,000 or 10,000 units is often much faster and cheaper when you consider that you don’t have to create tooling or molds before producing any end-use products. Plus, every production run can be different, with a slightly improved design, without having to worry about creating a new mold.

The cost associated with an injection mold for a simple small part that you could hold in the palm of your hand can easily reach into the $10,000 range.

Companies often turn to 3D printing services before they invest in 3D printers themselves to prove the method. We did the same with some test parts that we wanted 3D printed in volume.

Take a look at what we found at several of the top services and how they cater to today’s manufacturers.

Tips for 3D Printing Volume Parts

Many companies expand to volume production with 3D printing after using it for prototyping and understanding the process and results. In fact, it’s not unusual for companies to order a batch of 3D printed prototypes and realize that the parts are exactly the quality they want in an end-use part. Depending on the volumes required, 3D printing can win over processes like injection molding.

If you’re not familiar with additive manufacturing, ordering large volumes of parts in a new technology can feel risky. You’ll want to thoroughly experiment with materials and techniques before jumping into bulk.

To reduce the risks and ensure that you get the best value and quality without any surprises (such as cost overruns, quality issues, or delivery delays), we offer the following pieces of advice:

- Select a 3D printing service with experience in production

- Order smaller batches before placing a large serial order

- Reduce shipping costs with distributed manufacturing (e.g. using several services in various locations)

If you are working to a deadline or to a budget, finding a company offering good communications, and transparency of costs will certainly help you avoid the wrong ones.

Specialized Volume Services

As more companies turn to 3D printing for volume production, more printing services are upping their volume game with special services, which may include split shipping, white label production, print-on-demand part catalog services, and a broader scope of part quality inspections and even certifications.

If you need to distribute your product, many 3D printing services, like Craftcloud, have partners across the globe. You can ensure that every part, no matter where it is 3D printing, will have the same properties and quality if you 3D print it on the same brand of printer using the same perimeters.

Serial Production: Sample Volume Part Comparison

Meet The Five Printing Services

To assess the cost, lead times, shipping costs, and process capabilities, we sent three parts to five varied companies for comparison: Craftcloud, WeNext, Xometry, Protolabs, and Quickparts. We selected these companies because they are some of the larger and more robust options but they are by no means the only companies that can offer volume 3D printing. If you’re shopping around you’d also want to look into Protiq, Addman, Materialise, and Forecast 3D.

In some cases, we were able to get an instant quote, whereas in other cases, we had to wait for a manual quote because of the large volume of parts. When dealing with volumes, it is beneficial to have a human in the loop to look over things, so a manual quote can be desirable in these instances.

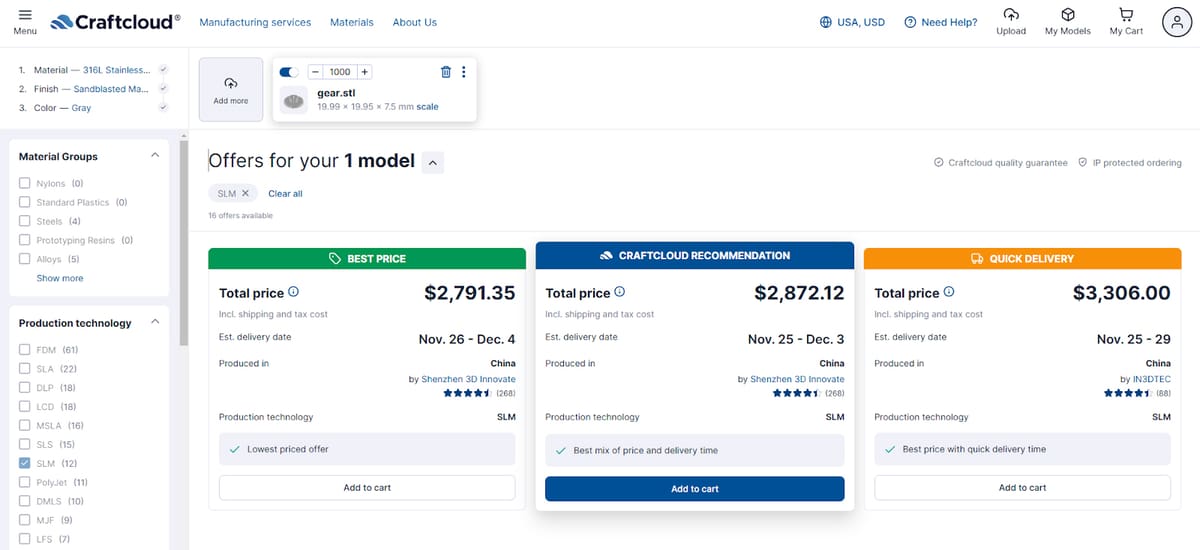

Craftcloud

Craftcloud is a website offering manufacturing services from a range of providers all over the world. All you have to do is upload your model, and select which 3D printing process and material you need, and the website automatically finds a list of vendors along with the price for your parts.

From the companies we approached for quotes, we found that Craftcloud offered the best options in terms of price, and provided instant quotes for all items, regardless of process or quantity. The instant quote tool will give you a good idea of how much you will pay for your parts, based on geographic location.

We also noted that for the same part, Craftcloud was as much as 5 times more budget friendly. Craftcloud presents you with a recommended vendor which has the best mix of value and delivery time. Alongside the recommended vendor, it will present the option for the company with the fastest delivery, and the company with the cheapest price.

The interface is easy to use, and quotes are generated instantly, even for large quantities, while most of the other sites we used required a manual quotation for large orders, often taking several days to receive an accurate quote.

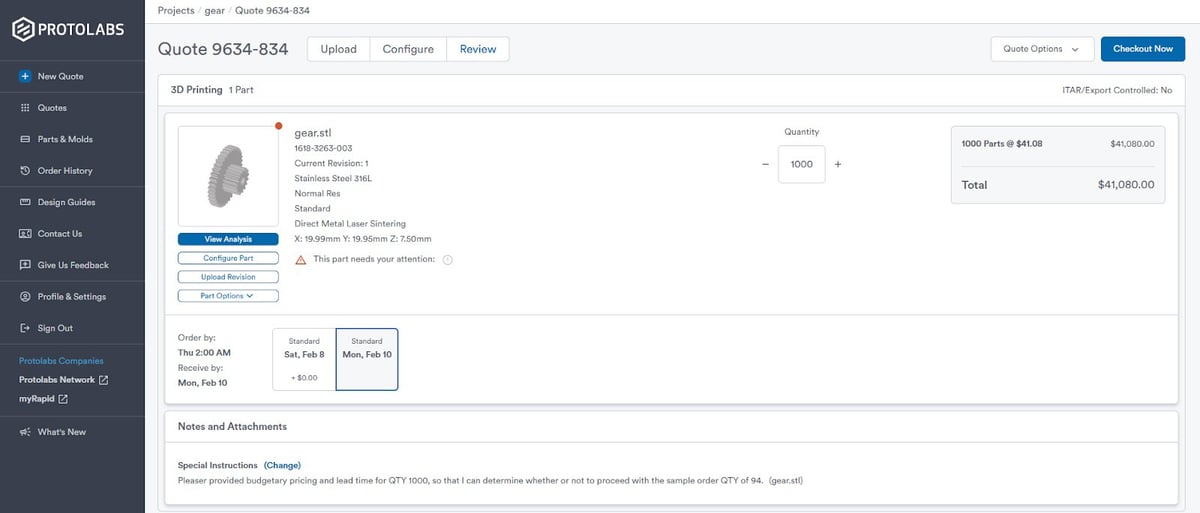

Protolabs

US-based Protolabs is a huge CNC machining and injection molding contract manufacturer but is equally known for its 3D printing. It has a digital quoting platform, which provides not only instant quotes but also features a design analysis tool to ensure your parts are manufacturable.

Although famed for their rapid lead times and low costs, Protolabs was actually the slowest in terms of delivery and the most costly overall. Both Protolabs and WeNext were extremely responsive in terms of providing the manual quotes, and we received the quotes within 24 hours of placing the RFQs.

The company has recently opened a new 120,000-square-foot facility in North Carolina primarily dedicated to metal 3D printing. For our parts, we had to wait for manual quotations as the volumes were so large. Out of all of the companies who quoted us, Protolabs was the most costly for the metal gear and MJF parts, and had the longest lead times.

One thing that the company does offer, is a range of certification options including material traceability, which is crucial when designing parts subject to ITAR and other regulations in highly controlled industries.

WeNext

Wenext is a leading manufacturing service bureau in China that provides on-demand manufacturing services, including 3D printing, CNC machining, sheet metal fabrication, and injection molding. The site features an instant quoting engine, and the company has its own massive in-house production capabilities to meet any manufacturing needs. Their range of 3D Printing services includes LPBF, SLA, SLS, and MJF, and they can quote for prototypes, small batches, and serial production.

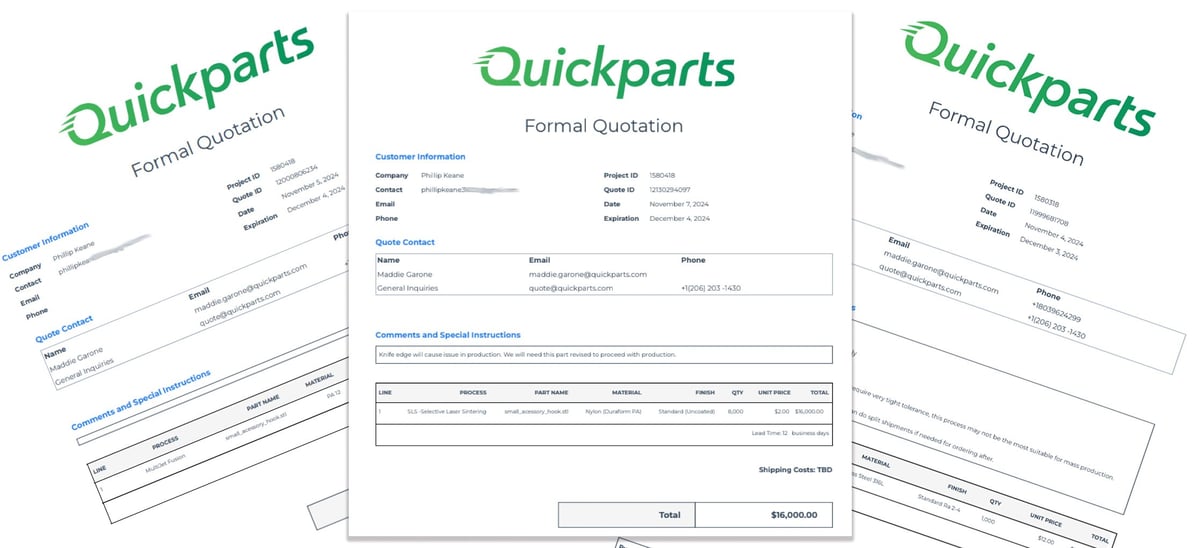

Quickparts

Because this company offers 3D printing and traditional manufacturing they offered good advice in terms of manufacturability and whether or not additive manufacturing was the best option, although we did have some issues with the quote engine – it didn’t save the correct details, and the errors were discovered when they contacted us to clarify the details.

Based in South Carolina, with a global presence, Quickparts is an additive manufacturing service provider that spun off from 3D Systems. Due to the connection with 3D Systems, Quickparts exclusively uses 3D Systems’ metal 3D printers.

The company has experienced staff on hand to guide you with your requests and indeed advised us that additive manufacturing was not the best route for our metal gear production. They recommended we use casting instead, but they were kind enough to provide us with a quote for the work anyway.

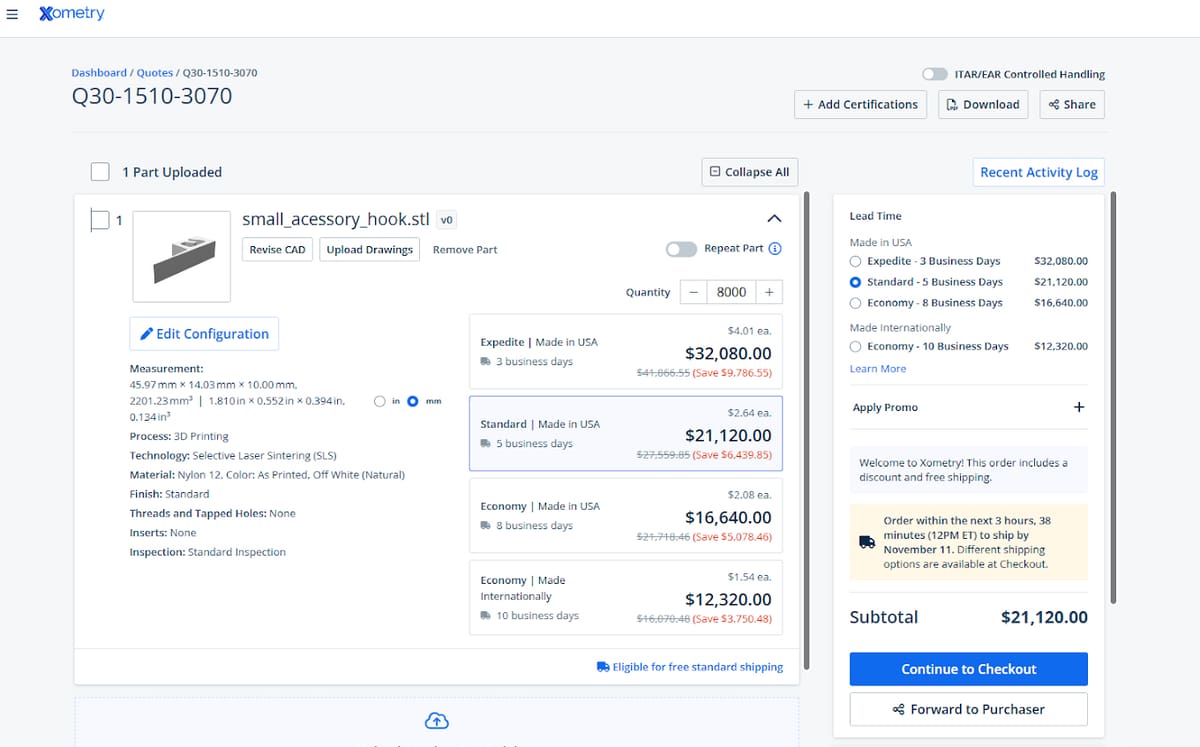

Xometry

Xometry is one of the world’s largest online contract manufacturing services boasting a range of technologies. It has factories and will provide you with a network of manufacturing partners. Their website gives instant quotes for prototypes and small batches, but you may have to wait for a manual quote for larger orders. We got the quotes for the plastic parts without issue but were unable to get a quote for the metal gear, as it was determined by their engineers that it was uneconomical to do so.

As you can see from our test results below, there is a wide range of prices and delivery times for the same items, so it pays to shop around, particularly when dealing with large batch orders, or serial production runs.

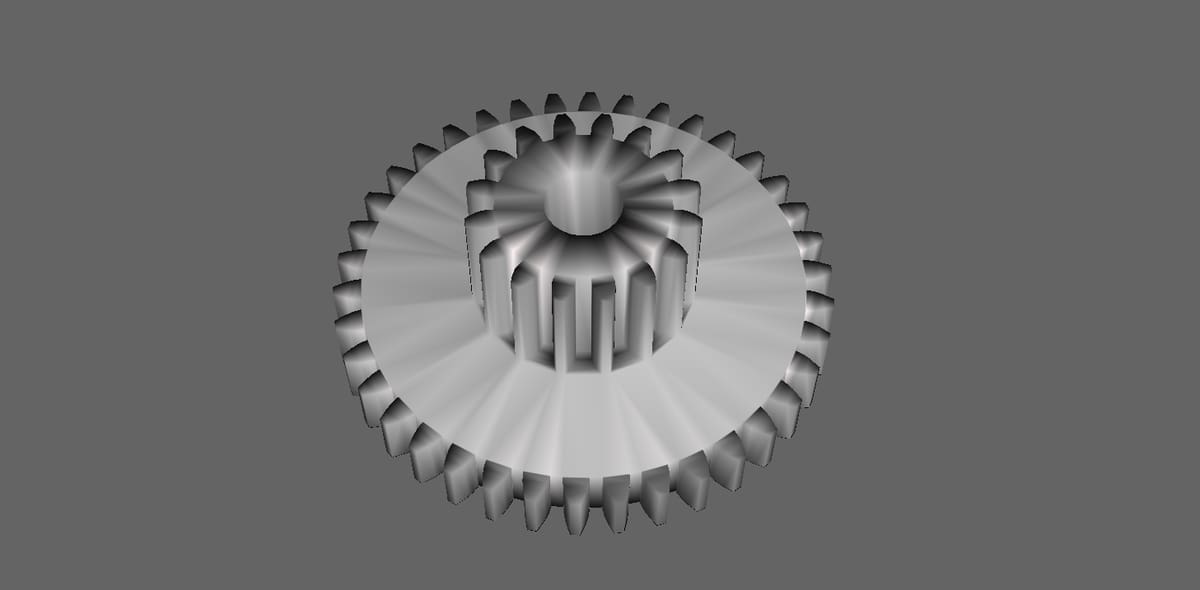

Order for 1,000 Stainless Steel Gears

Although our sample part isn’t very complex or something difficult to find in a part catalog, we used it to represent the type and size (19.99 × 19.95 × 7.5 mm) of a part suited to volume production with 3D printing.

A more realistic example of a metal part suited for 3D printing is typically very unique (not off-the-shelf) and features design elements, such as internal channels or lattice fill, that are difficult or impossible to mold or machine. Part consolidation is also a reason companies turn to metal 3D printing instead of traditional manufacturing. Metal 3D printed parts are often those that are produced in one solid piece, whereas the machined or molded version would be made in several parts that then require assembly.

We sent the exact same gear STL file to each of the five 3D printing services below. We requested the same material and the same 3D printing technology, metal laser powder bed fusion. We required 1,000 units, and we requested the quote to include shipping to New York, USA.

Part 1: 1,000 Metal Gears (Stainless Steel 316L)

Xometry was not able to provide a high-volume instant quote and, unfortunately, never responded to our request for a manual quote. We were able to get an instant quote for 1 gear and the price was $238.34. Interestingly, the price on Xometry for this same gear out of the same materials CNC machined was $1,685.41 for a quantity of one. QuickParts could CNC one gear for $352.78 out of stainless steel 316.

Xometry also offers metal binder jetting using a stainless steel and brass material that was $81.67 for one part.

There were various finish and delivery options, such as a mirror polish to the stainless steel and rush delivery, that would boost the price. Craftcloud and Protolabs also offered the option of choosing which company would print the parts for us, although we always selected the lowest-cost option.

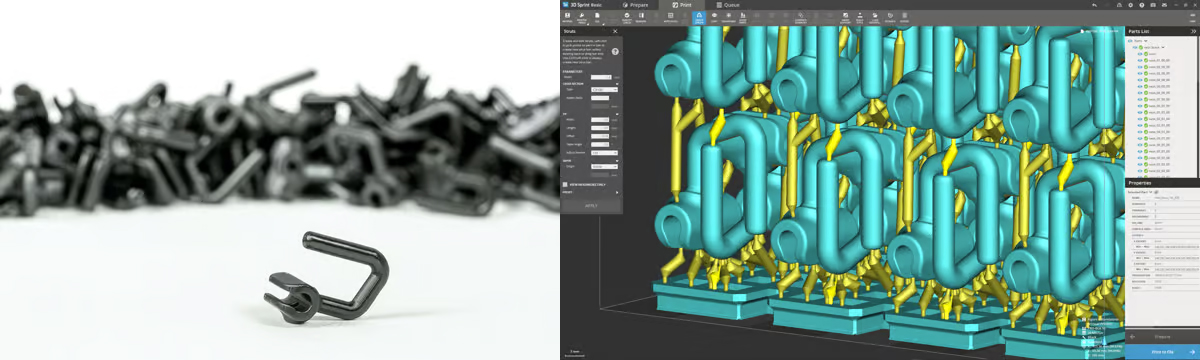

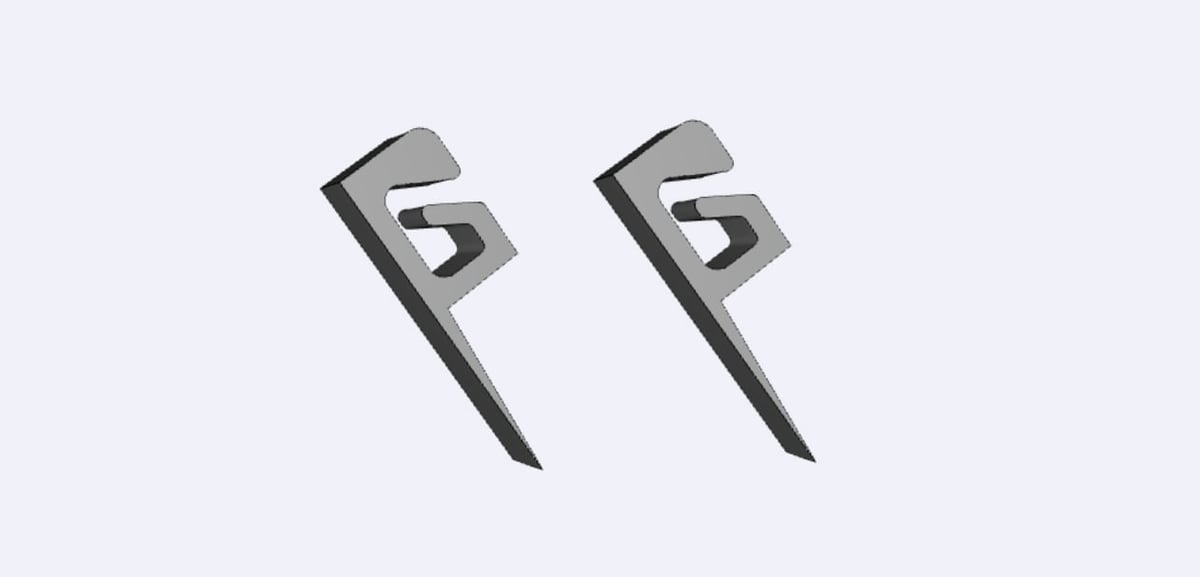

Order for 8,000 Nylon Hooks

For the second component, we chose to demonstrate high-volume plastic 3D printing with a small plastic hook. Again, the design of this part isn’t taking advantage of all that 3D printing can offer, but is a good representative size (46 x 14 x 10 mm) and shape to provide a general idea of the cost and speed of 3D printing.

We selected nylon (PA12) as our material because of its wide application in end-use parts. Our order was for 8,000 pieces.

As for technology, we opted to compare two: MJF (Multi Jet Fusion) and SLS (selective laser sintering). Both technologies used nylon and their mechanical qualities, detail level, and surface finish are comparable (with some differences we highlight in our in-depth article comparing the two).

Comparison of MJF & SLS

As you can see in the results in the charts below, some 3D printing services could deliver MJF parts cheaper than SLS parts while the reverse was true from other services. MJF is not inherently more or less expensive than SLS. The difference is a matter of the number and kind of machine capacity the service has.

MJF, however, is considered a volume-production technology since more parts can be printed at the same time than with SLS, and MJF prints faster. In reality, though, at these services, delivery times didn’t reflect the higher throughput of MJF technology.

If you know you want your nylon parts in MJF you can also seek out a 3D printing service that specializes in MJF and there, you “may” be able to see the benefits in terms of volume better. We have an article on MJF service providers below.

Part 2: 8,000 Nylon Hooks (Nylon, PA12) Multi Jet Fusion

The second component was a small plastic hook that was printed with MJF (Multi Jet Fusion) with PA12 material. For this order, we requested 8,000 units, to be shipped to New York.

Part 3: 8,000 Nylon Hooks (Nylon, PA12) Selective Laser Sintering

Post-processing options varied widely from vapor smoothing to coloring.

You May Also Like:

License: The text of "5 High-Volume 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.